Glazing of balconies and loggias is carried out primarily in order to reliably protect their internal space from negative natural factors.

The ideal solution for these purposes, which is increasingly gaining popularity, is the installation of aluminum windows.

This is explained by the many advantages of such glazing: they are high-strength, and therefore more durable and at the same time easy to use.

They are used in cases where the owner of the premises wants to achieve a little more from the interior than just a dusty balcony.

For this purpose, the latest developments in aluminum window structures in the field of interior design are used today. They look great both on balconies and loggias in office buildings and in residential buildings.

Aluminum balconies: the right choice of design

Cold glazing of balcony rooms of any size is best made from aluminum profiles. These days, the market offers an abundance of high-quality aluminum alloy profiles. The main advantage of such structures is that the product is quite light in weight when compared with other profiles. The service life of aluminum structures is 50 years or more. This is very important and should be taken into account when drawing up an estimate of financial investments when planning to glaze a balcony/loggia. The second advantage is that the structure is much cheaper than a PVC profile.

To what has been said above we can add:

- Aesthetics;

- Fire resistance;

- Strength;

- Environmentally friendly.

The negative aspects of aluminum glazing include the high thermal conductivity of the material. When arranging a loggia/balcony, this nuance is important. There is an opinion among professionals that aluminum structures are used when cold glazing is planned.

To compensate for the high thermal conductivity, profile manufacturers began to produce structures with an air gap from the inside.

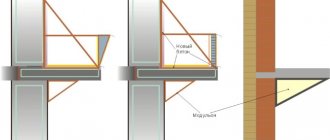

In order to better conserve heat, this cavity is filled with a special material. Additionally, instead of ordinary glass, reliable double-glazed windows are installed. Thanks to a simple calculation, it became clear that this approach to creating a profile brings aluminum structures to a leading position in the market. The appearance of aluminum profiles on the market makes it possible to glaze a balcony with an extension.

The mounting technology makes it possible to install aluminum structures with offset and not add serious weight to the load on the balcony/loggia fencing, since their weight is minimal. If the balcony room is small, then it is better to install a sliding window opening system, this will save space. It is possible to assemble and install such a system using aluminum guides yourself.

Have you thought about expanding your balcony? The remote design is one of the backup options for expanding the living space. Process technologies, calculations, as well as installation options can be found in the material: https://homeli.ru/komnaty/balkon/balkon-s-vynosom.

Results

Aluminum balconies are an excellent choice for those who value the comfort and decoration of their home. Modern designs have many advantages. They are practical, have a presentable appearance and provide reliable protection from weather conditions. With proper care, their service life increases significantly.

To do all the work correctly, you need to follow simple instructions. Also during the installation process, the features of the aluminum profile are taken into account. If you install it yourself, all work, including external and internal finishing, will take no more than two days. To save money, you can perform cold glazing. For more comfortable operation of the balcony, you will need to install a warm profile.

Glazing of balconies with aluminum profiles: installation sequence

Before glazing a loggia or balcony room with aluminum, it is necessary to complete a competent set of building materials and fasteners. If a home craftsman decides to do all the work on constructing the structure himself, then it is necessary to perform a preliminary calculation of the glazing area. This indicator affects the type of profile that will be selected.

According to their functionality, aluminum frames can be divided into 3 main types:

The hinged profile will be the ideal solution for a wide, voluminous balcony room. If the balcony is medium-sized or the loggia is narrow, then it is better to give preference to a sliding mechanism. In order to ensure highly efficient ventilation of the apartment, it is necessary to install 2 opening structures on 4 blind frames.

Precautionary measures

All work on balcony glazing must be carried out with a safety belt. It is better to use a sports one - it is lighter and cheaper than an industrial one. The industrial type is more reliable and durable, but you don’t systematically engage in steeplejack work.

The belt halyard should be approximately 2.5 m long. A halyard that is too short will complicate the work, and if it is too long, if you suddenly fall, the jerk can cause dangerous injury. The halyard carbine, and the entire belt as a whole, must withstand a load of 400 kg. If the load value is not indicated in the certificate for the belt, or there is no certificate at all, such a belt should not be taken.

The safety cord must be securely fastened. To do this, you need to drive an anchor pin with a metal collet into the main wall for the duration of the work, at least 150 mm. The head of the stud is in the form of a ring with a generatrix at least 8 mm thick; pin body diameter – from 16 mm.

You need to screw the pin into the collet until it stops and tightly, inserting a powerful screwdriver or pry bar into the ring. At the end of the work, the head of the stud, so as not to interfere, is cut off flush with the wall with a grinder.

Cold glazing of a balcony with aluminum profile

If there are already wooden frames on the loggia, then they need to be carefully removed using a special tool. In this case, the area of the balcony room must be cleared of any things and objects. It is imperative to check the strength and reliability of the balcony slab.

In older homes, concrete or brick foundations may lose their original strength over the years.

The old vertical surface must be reinforced with metal strapping. The constructed metal frame must take on the entire load from the glazed frames. Perhaps we can go the other way. Make a cement-sand base by pouring. A small formwork is installed at the top of the parapet. After pouring the solution, the surface must be made strictly horizontal. It is imperative to wait until the solution has completely dried. Only then is it possible to continue the glazing repairs.

In some cases, the parapet may be leveled by strengthening timber beams on top. This option is well suited for glazing loggias. The canopy is placed on top immediately after cleaning. This must be done before installing the frames. The canopy must be installed regardless of what kind of glazing - cold or warm - is done on a particular balcony room. This will ensure the drainage of rainwater from the glass unit. Before installation, you must remove the glazing from the frame. This is done so that the glass does not break during the fastening process.

Since the canopy has already been made, the next step is to strengthen the ebb from below. The void that has formed between the parapet and the ebb must be filled with sealant. The next step is to attach the mounting plates to the aluminum profile. It must be fastened with construction screws. The distance between the mounting plates should be about 7 cm. After this, the frame must be placed in the opening.

Have you thought about tinting your balcony? We offer you detailed material on this topic: https://homeli.ru/komnaty/balkon/tonirovka-balkona.

The design is necessary:

- Put;

- Secure with wood wedges;

- Align.

Leveling is a very important step and must be done carefully and carefully. The frame must be leveled horizontally, vertically and in the plane of the balcony/loggia. This is done in order to mark the places in vertical surfaces and the ceiling where holes will be drilled for fasteners. Having strengthened the frame, it is necessary to once again check its orientation in space. Vertical and horizontal deviations cannot be more than 3 mm.

Once the rigid structure is in place, it is necessary to install solid and movable frames.

Sliding doors should simply be removed and put back. When moving, the doors should open easily. If these conditions are not met, it means that the metal structure is skewed. We need to inspect it and do it all over again.

Frameless glazing

With frameless glazing, there are no vertical elements in the design. Such frames allow the sun's rays to freely enter the balcony, which is important for the shady side. Features of frameless glazing:

- special tempered glass (5-10 mm thick) is used;

- profiles are made of aluminum;

- the glass moves thanks to bearings with wheels;

- there are overlays;

- it is necessary to install the casing and ebb;

- it is necessary to install clamps;

- there must be locks on the handles;

- it is necessary to use acrylic or rubber seals;

- the sashes are fixed with tape.

Installation of the frameless structure is carried out in strict sequence:

- firmly fix the upper ebb;

- an aluminum profile with bearings is attached to it;

- install the upper silicone seal;

- glass is installed, they are connected in parallel using a seal;

- fix the lower part of the ebb;

- The gaps formed during the work (between the glass and the wall) are sealed with sealant.

During work, materials such as nails and screws are not used. A special glue is used as a connector for glass sheets.

The final stage of installation of aluminum profiles for balconies and loggias

At the final stage, it is necessary to seal all cracks and empty spaces with polyurethane foam. All foaming areas, both outside and inside, must be covered with plastic covers. After the finishing is completed, fittings must be installed on the frames.

Related article: How to properly line a balcony with clapboard

This is also an important stage; everything must be done extremely carefully. All levers and handles need to be checked and adjusted. The doors should move well along the guides. To do this, the elements need to be well lubricated with machine oil.

Glaze the balcony with wood

It’s good if the home handyman has carpentry skills. Then the option with glazing with wooden frames becomes cheaper. After all, using wooden beams, glazing beads and ordinary glass 4 mm thick, he can assemble the sashes, providing them with the simplest fittings from the nearest store. How to glaze a balcony yourself: video and photos. However, even in the absence of such talent, you can order an inexpensive finished product from a workshop. After which you can begin installation.

It is important to consider that a large structure can “sail”. Therefore, despite the visual appeal of large and wide openings, this unpleasant effect is worth remembering.

- Preparation has already been written above, so we skip this stage.

- There are no special tricks in installing such a structure; moreover, the process itself differs little from, say, installing a PVC profile. Using metal fastening plates and screws, we install a wooden frame without frames.

- The ebb, canopy and window sill are installed similarly to the glazing methods described earlier.

- The seams are foamed and subsequently hidden under the finishing.

- The sashes are fixed in place, the fittings are adjusted.

For a long time, this was the only way to glaze a balcony in a Khrushchev building. Of course, such glazing will never become the object of envy of neighbors. But if done carefully and securely fastened, it can protect against dust, falling leaves and change the microclimate on the balcony by a couple of degrees.

Glazing of balconies and loggias with aluminum profiles

All owners of their homes, when they decide to glaze their balcony, try to choose the most optimal and suitable option for them. This is not surprising, because with the help of a glazed balcony you can increase the space, add a place for children, or simply create an area for your pastime. We offer aluminum glazing for balconies.

Residents of houses and apartments think that aluminum profiles only have advantages in price compared to other materials. But this is not true at all. Let's look at all the features of this material for glazing balconies.

Do I need to get a permit?

Before you start glazing a balcony with your own hands, you need to take care of obtaining permission for this work. Installing windows on a balcony is not considered a redevelopment, but is equivalent to it. Therefore, complications after changes made to the loggia design are inevitable. At a minimum, in the absence of the necessary approvals and permits, it will not be possible to sell the apartment. Unauthorized glazing may result in a fine, after which you will have to legalize the changes made or dismantle them.

In addition, an increase in the total weight of the loggia can provoke its complete or partial collapse, which will lead to much more dire consequences. So it’s better to take care of permission and approval, as well as instructions for upgrading your balcony, in advance. This is quite long and tedious, but necessary.

Peculiarities

Any design has a frame and glass (or double-glazed window). Designs for aluminum structures are made from a complex alloy and other elements are added to allow the finished product to be stronger . Typically these substances are magnesium and silicon.

Typically these frames only have one air chamber. The wall thickness of the profile is approximately 1.5 mm, for a “warm” product from 1.7 to 2.0 mm.

Designs of sliding aluminum balconies

In their form, sliding aluminum systems are rectangular structures on loggias and balconies, where, with the help of rollers, the doors can smoothly move horizontally. To prevent precipitation from getting inside, the manufacturer places a seal around the entire perimeter of the sashes.

Stoppers are specially installed to protect the doors from falling out in strong winds. To lock the sash, the developers installed a latch. The sash can be dismantled if necessary.

Photo:

Water that accumulates due to precipitation flows out through the drainage, which is installed at the bottom of the frame. To ensure better daylight penetration, the design uses double-glazed glass. It’s even possible to install sandwich panels. This system can also be used in conjunction with glass, which reflects the sun's rays, and the rooms do not heat up so much.

Step-by-step instruction

A balcony differs from loggias in that it extends beyond the outer wall, has handrails and a balcony slab, and accordingly its top is limited by the balcony structure above.

Aluminum glazing is especially preferred in this option, since such structures are lightweight and will not unduly load the balcony slab .

If there is an old wooden frame installed on the balcony, it will need to be dismantled. The work must be carried out by at least 2 people so as not to drop the dismantled structures over the balcony. First, remove the glass and sashes, then dismantle the wooden box; if necessary, you can cut it into pieces with a hacksaw.

Important! After dismantling the wooden frame, carefully remove debris, clean the walls from foam and sagging concrete mortar, and prime the future junctions of the aluminum frame in order to increase the adhesion of the wall to the mounting foam in the future.

To obtain a high-quality result and durable aluminum balcony glazing, you need to fulfill a number of requirements :

- Before installation work, check the fastenings to the load-bearing wall for strength. If a crack is found in the concrete slab, it must be strengthened or even replaced completely.

- For minor damage, a simple cement screed can be used.

- If during the inspection the reinforcement frame is found to be damaged due to corrosion, the balcony is strengthened with iron beams, concrete is placed in the wall and a reinforcement mesh is welded to the structure.

- During the installation process, do not allow the frame structure to bend.

- Installation on balcony handrails is allowed only if the metal parts of the balcony structure are strong, otherwise it is reinforced with an additional metal structure.

- If the balcony is glazed with the frame extended, it is first sheathed, then aluminum glass blocks are installed on a strong base.

- Pipe stands are placed in the structure of a hanging balcony that does not have an upper ceiling.

- If the length of the balcony exceeds 4 m, an additional pipe stand is installed in the middle.

- The supporting frames are made of iron corners, which are painted after thoroughly cleaning the surface and degreasing it.

- It is required to make horizontal butt joints of the upper and lower parts of the frames.

- The maximum width for a balcony box that is taken outside is 1.5 m.

- Aluminum window structures are fixed to the walls only with the use of mounting strips.

Technology of glazing balconies with aluminum glass blocks:

The protective canopy is installed along the top line after dismantling the old structure and removing debris from the balcony room.- A metal profile is usually installed at the level of the base under the frame.

- The mounting plate is attached to the outside of the aluminum frame using self-tapping screws.

- The second side of the plate is secured to the external wall with anchors. The number of plates depends on the size and weight of the glazed frame, but, as a rule, manufacturers advise making them at least 70 cm.

- Install a window sill.

- Remove the sashes from the frame.

- Align the frame vertically and horizontally with wooden wedges, and then attach the mounting plates to the base.

- Fill all cracks with construction foam.

- They put on the sashes and begin to set up the operation of the moving parts of the structure.

- After 24 hours, remove any remaining hardened foam.

- Protect seams from UV rays and natural precipitation by painting or using special protective plates.

- Internal finishing work and thermal protection are carried out after installation of the window unit.

Types of profiles

The main advantage of aluminum balcony glazing is the availability of materials, as well as greater reliability in the design. Another thing is the compactness of the aluminum profile. This is an important part for small balconies.

There are different types of aluminum construction with the following parameters:

- opening designs;

- price;

- profile appearance

- internal profile view.

- number of thermal chambers;

- possibility of installing double-glazed windows of various modifications.

If you have a small balcony, you can really save space by installing sliding sashes.

Cold glazing of balconies using aluminum profiles is done using a design at the lowest price. They don't have insulation.

For simple glazing this is the best choice. In order to install warm glazing you will need:

- buy a complex profile that is equipped with thermal inserts;

- purchase a three-chamber double-glazed window;

- special glass that allows you to retain heat.

Video:

According to people, after they made warm glazing of the balconies, this room turned into an additional area. With this maneuver you can really increase your living space.

There are also remote glazings. then the balconies can actually be enlarged by moving the frames to the street.

This adds even more space and also makes the window sill wide.

Operating principle and advantages of sliding windows

Such systems are sometimes called sliding windows. Their opening is carried out by moving the shutters on rollers along guides. Several guides can be placed on one profile at once, which makes it possible to install up to 5 sashes.

When choosing such a window, close attention should be paid to the roller mechanism: the most durable are equipped with a shell made of polymer materials.

The sliding window system has a number of advantages:

- Due to the use of aluminum from which the frames are made, the structure weighs little.

- The strength of the material allows the window sashes to be narrow, so they let in more light.

- Double-glazed windows and hollow profiles improve the thermal and sound insulation of windows.

- Aluminum's resistance to the external environment makes the window durable.

- The roller system does not require any free space in the room for the window to fully function. At the same time, it becomes possible to combine blind and opening window openings.

- A special coating makes the appearance of the window aesthetic and attractive.

- The simple design is convenient to use and easy to repair.

- When using shut-off valves, such as latches, latches or even locks, such windows will ensure the safety of your home.

Advantages and disadvantages

Glazing a balcony using an aluminum profile is the right solution, in contrast to installing a PVC structure.

The positive side of this type of product is unique and the wooden and plastic glazing options cannot be proud of such factors:

- Very high strength, which is not comparable with other materials;

- Due to the low weight of the structure, you can mount it even on weak slabs and carry out removal up to 300 mm ;

- Using the small size of the frame profile, you can increase the light opening;

- Due to the rigidity of the material, one-piece structures of large size can be made;

- Aluminum construction does not burn;

- The material is highly resistant to weathering, retains the appearance of the profile, and does not change due to sunlight, moisture and different temperatures;

- The material is easy to clean, dust and dirt are not absorbed into the paint, you can simply wipe it with a damp cloth;

- Environmentally friendly.

The manufacturer guarantees excellent appearance and functionality of aluminum structures for up to 60 - 80 years . Using a special powder paint technique, you can give any color to the profile, and the coating will look like “new” for a very long time.

In addition to all the positive aspects, there are also disadvantages of this material:

- High thermal conductivity;

- It is possible for snow and ice to accumulate in winter in the cavity between the frame and the sash, and therefore the functionality deteriorates;

- Low sound insulation;

- When installing a conventional “cold” structure, the temperature outside the window and on the balcony is no different, and “warm” aluminum glazing with double-glazed windows is much more expensive than PVC.

Installation and adjustment of sashes

We proceed to installing guides and sashes with glass.

- Prepare the guides: measure the frame horizontally and saw off profiles of the required length. The cut areas are cleaned of roughness using sandpaper or a file.

- The guides are fixed with self-tapping screws on the upper and lower edges of the frame. The fastening step is 30 cm.

- The sashes are being assembled: double-glazed windows are inserted into them.

The easiest way is to assemble the three parts of the sash in the form of the letter “P” lying on its side. The glass is pre-glued with a rubber seal, which is cut at the corners. After inserting the double-glazed window, the second side post is carefully screwed on.

- The rollers are fixed in its lower part, at a distance of at least 5 cm from the edge of the sash. It is better to use a screwdriver for this operation rather than a screwdriver, so as not to crush them.

- Along the entire perimeter of the sash, a special brush seal - Schlegel - is attached to the grooves, the bristles of which should be turned towards each other. The schlegel itself should protrude 2–3 mm beyond the boundaries of the sash.

Frame installation

If we don’t have the opportunity to call specialists to your home, it’s quite possible to glaze your balcony with an aluminum profile yourself.

You just need to know and follow the instructions, with the help of which you can do everything efficiently and spend minimal costs.

Here are the instructions we offer you:

- Before installing an aluminum profile, you must take the necessary measurements, and then use them to order the design you need.

- Assess the condition of the frame. If necessary, minor defects will need to be corrected. Remember that if you have a weak frame, then mounting it using an aluminum profile is stupid.

- Before starting work, you need to dismantle the old glazing. The glass is removed first, then the frames. The old visor also needs to be removed.

- We remove all debris after dismantling. We level the entire surface of the frame.

- It is necessary to make special holes for fasteners in the profile.

- We remove glazing from the profile, then install it in the balcony opening using anchors.

- At the end, we need to install the sashes, install the glazing, and install the fittings.

Related article: Balcony in a frame house with your own hands

| Ukraine | Price, UAH. | Russia | price, rub. |

| Kyiv | 2400 | Moscow | 19717 |

| Kharkiv | 2000 | Saint Petersburg | 17656 |

| Odessa | 2350 | Kaliningrad | 12081 |

Installation of wooden window structures

First you need to install a box made of wood. After fixing the lower beam (railing) and the upper part of the structure (ceiling), the side elements are fastened with brackets to the walls.

Step-by-step instructions for glazing a balcony with your own hands:

- installation and fastening of support posts made of wooden beams - corner, end, intermediate;

- insert the frames after first removing the glass, install the front glazing first, then the side glazing;

- if distortions or other defects are found, they are removed by leveling with wedges;

- Having fixed the frames with self-tapping screws and anchors, seal the seams using polyurethane foam;

- return double-glazed windows and removed sashes to their place, making sure that the glazing beads fit snugly to the frames.

Advice. Before installing the wooden frame, treat the mounting surface of the main beams with sealant and antiseptic. This will help protect the structure, which can be pre-painted, from the accumulation of moisture penetrating from the outside, and will make the balcony room much warmer.

Reviews

Lyudmila, 29 years old.

Last year we installed an aluminum profile on our balcony. Very durable and comfortable design.

Svetlana, 37 years old.

Aluminum glazing is really cool. They glazed it 15 years ago, everything is still like new.

Valentina, 45 years old.

A couple of years ago, my godfather installed an aluminum structure on her balcony. He praises her very much.

Raw materials and production technology

Aluminum profiles and fittings (handles, rubber bands, screws) are used as raw materials for the production of aluminum windows. The technology for producing windows from profiles is considered more simplified, since ready-made cast aluminum is used. The profile is purchased wholesale from foundries at a price of 150 rubles. per kg.

The price also depends on what profile is purchased: cold or warm. Hence, two technologies are distinguished: cold glazing and warm glazing. A cold profile is 2-3 times cheaper than a warm one. The low price is due to simpler technology and lower performance characteristics (it’s not for nothing that it’s called “cold”). The cold profile is obtained through a simple extrusion process. The molding of the product is carried out by squeezing heated aluminum through a matrix with a hole. To create a warm profile, three components are used at once: the outer part of the profile, the inner part of the profile and a thermal break. The thermal break is located between the inner and outer parts of the profile and is carefully connected to them. Therefore, the product is more dense and insulated. The production of a warm profile takes more time, money and labor resources. The price for cold profile windows starts from $30 per sq. m. m., and from warm - from $150 per sq. m.

You can familiarize yourself with the regulatory documentation for the production of aluminum windows in the following documents:

- GOST 22233-93. Extruded aluminum profiles

- GOST 21519-2003. Window blocks made of aluminum alloys

- GOST 21519-84 (1992) Windows and doors for balconies, shop windows and stained-glass windows made of aluminum alloys. General technical conditions

The manufacturing technology of window structures involves the following sequential steps: cutting aluminum profiles into blanks, processing the ends of the impost, punching technological holes, drilling holes for the lock and cylinder, drawing sealing rubber, assembling frames and sashes, installing fittings, assembling the structure and installing fillings in products .

Ready-made windows can be sold to construction companies, wholesale resellers and small private firms engaged in installing windows in apartments and houses. The most profitable clients are large construction companies that have large volumes of work on the construction of residential complexes. It is not easy to conclude a contract with such a company due to high competition among window suppliers. To speed up sales volumes, you should hire a manager who will call companies daily and offer them cooperation.

Aluminum windows to the balcony

Glazing a balcony is one of the most important activities in the process of renovating an apartment. Firstly, this is necessary for insulating the home, because a significant part of the heat comes out through the balcony. Secondly, after installing windows there, you get additional space that can be used for certain residential or business needs. But, before starting work, you need to decide what material the glazing should be made of. And one of the popular options is aluminum windows to the balcony.

Aluminum windows to the balcony

Balcony glazing with aluminum profile with extension

Installation of ebb tides

The work of installing the frames can be considered completed only after the installation of the ebbs is completed. The window must certainly have an external sheen - this will protect the balcony from moisture. For its manufacture, materials such as aluminum, plastic, polyester, and galvanized sheet are used. The profile part of the ebb is always equipped with a special bend, adjusted to the frame. When installing the ebb, make a slight slope - this will improve the drainage of water from the window. If the work is done correctly, the balcony will be reliably protected from dampness. Also, properly installed ebbs are highly resistant to strong winds and muffle the noise of rain. The ebb is secured to the window with rivets, but more often with self-tapping screws. The space formed between the ebb and frame is filled with polyurethane foam. This allows you to better retain heat on the balcony. Until the foam dries completely, the ebb must be fixed in a certain position.

The ebb tide should come not only under the bottom of the slopes, but also from above and from the sides. This will protect the walls from moisture. Aluminum is considered the best material for creating ebbs, because plastic loses its shape and appearance over time. You can make an aluminum casting yourself. For this you will need an aluminum sheet. Markings of the future low tide are applied to it in accordance with the size of the window. Then the ebb is cut out and bent. Before installation, it must be powder coated. The ebb can be made of galvanized steel. They just cover it with a polyester compound, which lasts a long time and retains its original color. This option is cheaper than aluminum.

Glazing a balcony with your own hands is not as difficult as it might seem at first glance.

Pros and cons of aluminum balcony windows

Installing aluminum windows on balconies is becoming increasingly popular today. And for those who are just thinking about this, we will present the pros and cons of such glazing. Let's start with what advantages aluminum windows on the balcony have.

- Availability . Often people give their preference to aluminum windows precisely because of their low cost. On average, the price for them is 1.5-2 times cheaper than for similar glazing with PVC windows.

Glazing of balconies with aluminum profiles

Aluminum sliding windows for balcony

Balcony with aluminum profile windows

Photos of aluminum balcony windows

French balcony made of aluminum profile

Important! For owners of small apartments, it makes sense to consider the option of glazing the balcony with aluminum windows with a perimeter larger than that of the parapet. As a result, the useful area of the balcony increases and it can be used for arranging indoor plants in the warm season or as an additional refrigerator in winter.

Option for glazing a balcony with aluminum windows with a perimeter larger than that of the parapet

Aluminum window with sliding sash. Most often, similar structures are used for glazing balconies.

Section of “warm” and “cold” aluminum window profiles. The first differs from the second by the presence of two glasses with an air gap and a heat-insulating gasket between the outer and inner sides

Also, when thinking about purchasing aluminum windows for a balcony, you should be aware of their disadvantages. The main disadvantage of such structures is the insufficient degree of thermal insulation. A balcony with aluminum windows, as a rule, will be “cold” - in winter the temperature in it will exceed that outside by no more than 5-6°C.

Sliding cold aluminum structure Framex S22

Balcony in Provence style

The design of a balcony or loggia in the Provence style is becoming fashionable among our compatriots. They are attracted by discreet elegance, French simplicity, natural finishing materials and the presence of vintage elements. For a more detailed understanding of the issue, we recommend reading this article.

Another disadvantage is that aluminum frames and sashes are installed only on perfectly flat and pre-prepared surfaces. Therefore, before the installation process begins, the parapet will either have to be leveled using a cement mixture, or a wooden board will be placed under the structure and all glazing elements will be installed on it.

Video - Installation of aluminum balcony frame

We carry out installation work ourselves

Glazing a loggia with an aluminum profile can be done without the help of specialists who will require you to pay properly for their work. There is no particular difficulty in installation, you should adhere to the basic rules and the work will be done with five points.

Let's look at what stages the entire installation process can be roughly divided into:

- Preparing for installation

- Do-it-yourself installation of double-glazed windows

Preparatory stage

Like any other window frame, aluminum profiles require careful preparation. The final result will depend on the quality of the prepared surface. It seems that this is not at all related to glazing and one could treat such work obscenely, but no.

You should approach the work very seriously and carry out the necessary actions with due attention and perseverance.

The first step is to dismantle the old frame, but do not put too much force on it. Otherwise, you may damage the base, which is obviously bad.

Apply pressure specifically to the plane of the window, then the risk of damage is minimal. The nails securing the old frame to the concrete should come out quite easily and not destroy the base.

If there are parts from the old frame, pieces of chipping concrete or old fasteners left on the railing, be sure to remove them. If the surface of the base is too damaged, it should be restored; in this case, glazing with an aluminum profile is postponed for several days until the concrete has completely dried.

To improve the quality of installation, a wooden beam measuring fifty by fifty millimeters can be attached to the top of the railing. Our aluminum window frame will be attached to it. After the preparation has been completed, you can proceed to the next stage, installing double-glazed windows on your balcony or loggia.

Installation of aluminum structure

First you need to remove all opening parts, this will lighten the frame and make it easier to install. If there are blind areas of the window, the double-glazed windows should be removed from them so as not to damage them and to further facilitate the structure.

Mounting plates or brackets are then attached to the frame. The optimal step between them is fifty to seventy centimeters, depending on the total weight of the window and the thickness of the plates. They are fixed directly into the profile using metal screws.

The frame is installed in its place and secured with wedges. They also need to adjust the level we need, measuring it with a special device. The wedges must fit very tightly in order to calmly hold the entire frame together with the double-glazed windows.

Finally, all cracks are sealed with polyurethane foam and left closed for a day so that the foam dries completely. After drying, you can trim off the excess using a stationery knife and begin further finishing of the room.

Tips for working with glazing

The foam on the outside must be sealed, as under the influence of sunlight it will dry out and crumble. It is best to cover the seam with any mortar and then cover it with the material you like.

Remember to constantly check the level of the frame during installation. Especially after returning all the glass units and moving elements to their place. Under weight, the level may shift and it will need to be corrected. After foaming, such a procedure will be very problematic.

Why is such balcony glazing attractive?

This option is not able to fully protect against frost in winter, but in spring and summer the balcony turns into a comfortable veranda. Cold glazing with aluminum profiles has advantages and disadvantages, let's talk about them in more detail. Positive properties include:

- price

- light weight

- possibility to save space due to sliding doors

- long-term operation without repair

- minimal care

The full cost of such structures allows you to glaze the balcony compartment without extra costs, which primarily affected their popularity. The price of cold-type aluminum profiles is significantly lower than wooden or metal-plastic ones. Therefore, if warm glazing is not planned, then this choice is more preferable.

Photo of cold type aluminum profile

Aluminum itself is a light metal. Thanks to this, the frames are also lightweight; some types do not weigh more than 20 kilograms. They are convenient to transport, bring into the house and install on site without the need to install additional partitions in the frame of the window structure.

Cold glazing of balconies made of aluminum profiles in most cases involves the installation of sliding sashes, the operation of which is more convenient. In addition, this type of opening is safer. After all, swing frames, if not secured, can be damaged by strong winds, while sliding structures are used without additional fasteners.

In the photo - cold glazing of a balcony made of aluminum profile

The simple design of aluminum frames and immunity to corrosion makes them extremely resistant to various loads. There is nothing to break in them, and the double-glazed windows used can withstand any wind fluctuations. They do not require careful care. It is enough to wipe them with a soft cloth and soapy water. You don’t have to worry about safety and repairs for at least 10–15 years.

Variety of frames and their properties

There are several types of balcony frames, each with its own pros and cons:

Tree. Wooden frames are considered universal because they are environmentally friendly, have high sound and heat insulation properties, have an attractive appearance and a relatively low price. In addition, wooden frames can be made of any configuration. For a long service life, they must be treated with special impregnations that have moisture resistance and antiseptic properties. If cold-type glazing is planned, then preference should be given to larch frames. Every two years the frame must be coated with paint or varnish.

PVC. Frames made of polyvinyl chloride are highly durable and have a long service life. In terms of their heat and sound insulation properties, they are not inferior to wooden frames; moreover, they do not need to be processed or painted. Thanks to double-glazed windows, heat loss in the room is reduced to a minimum.

Aluminum. Aluminum window frames are very light, they are indispensable in situations where it is undesirable to load the balcony with heavy structures. In addition, aluminum frames are durable and provide high levels of thermal and sound insulation. The material is moisture resistant, does not deform over time and does not require complex maintenance.

Galvanized frames. They are used only in cases where the balcony simply needs to be closed from wind, dust, rain and snow. As a rule, the glass in such frames is single-layer, making this design particularly lightweight. This is an ideal option for balconies, the insulation of which is strictly contraindicated.

Disadvantages of aluminum frames for balconies

What's wrong with aluminum frames? Their main drawback is their high thermal conductivity. This is where the definition comes from - cold glazing. The aluminum profile does not have additional thermal insulation (except for what is manufactured using thermal break technology). Therefore, the temperature on the balcony or loggia in winter will be almost the same as outside.

Photos of aluminum frames

Also, aluminum frames have low noise insulation. The low tightness of the structure allows all more or less loud sounds to penetrate into the room. Only the overall background noise is reduced.

What disadvantages are there?

Although they have advantages, such frames, of course, also have disadvantages, which should also be mentioned. Let's look at the most significant of them.

The main thing that decides whether to buy a window or not is the very low rate of heat savings in the room. In winter, they maintain the temperature by only a few degrees. In very severe frosts, sliding mechanisms and fittings may become covered with a layer of ice.

Cold and warm glazing

Then it is possible to open them only after removing the ice, which brings certain inconveniences in use. They have a critically low level of tightness. Almost all noise from the street will pass through them; in strong winds, it is possible to blow through the cracks.

It is better to glaze a balcony with an aluminum profile if the main balcony door has good sound insulation; in this case, the leakage will be compensated.

If you compensate for the shortcomings by other means, then installing an aluminum window will be a very good solution. So, you can save an impressive amount and make your balcony or loggia glazed and protected from wind, rain and snow.

Aluminum frames – structural design

Today there are many design options for window and balcony structures. When ordering an individual option, you can make a request to spray paint of any shade - for example, the facade of your house. You can choose either regular or tinted glass; the price will differ slightly from the standard design.

A simple assembly process allows you to make glazing with aluminum profiles of various shapes and sizes, up to panoramic. But when using plastic structures, this will be extremely difficult and expensive.

In the photo - panoramic glazing with aluminum profile

What to do if you have a small balcony or loggia, but there are a lot of plans for using this room? The low weight of aluminum makes it possible to produce structures with “removal” for them. In this option, the frame protrudes slightly beyond the level of the parapet, thereby increasing the usable area and allowing you to organize a large window sill on one or three sides.

Attractive market

Modern aluminum glazing systems provide not only warmth and aesthetic appearance. By glazing the balcony using only two materials: glass and aluminum, you can increase the usable area in the apartment. And the owners of a small apartment will receive not only an additional mini-room on the balcony, but also brighter housing (due to an increase in luminous flux).

Aluminum windows have superior characteristics not only to their wooden counterparts, but also to windows made of plastic profiles (PVC). Aluminum, unlike plastic, does not burn, which means it is fireproof. Plastic not only burns well, but during the combustion process it also releases substances that are very toxic to humans: chlorine and hydrocyanic acid.

Aluminum is resistant to dirt and temperature fluctuations. The permissible temperature difference is from -50 to + 60 degrees. This is the best material for glazing street pavilions and kiosks.

Obviously, a properly organized business in the production of aluminum windows cannot be unprofitable. If there is active demand for the product, then you can enter the market!

To organize a business you will need to take the following steps:

- Register your business activity with the local tax service (IP or LLC).

- Rent a heated industrial premises with an area of 100 sq.m. m. and a warehouse for storing raw materials and finished products with an area of 50 sq. m. m.

- Find suppliers of raw materials for window production (aluminum profiles and fittings)

- Purchase the necessary equipment

- Hire staff

- Conduct an advertising campaign

- Start production

How to glaze a balcony with your own hands using a frameless method

- A very impressive type of glazing, but it also requires some effort and courage. The first thing many homeowners fear when they are offered this option is safety. If we are talking about installing “full-height” glass, then it may be worthwhile to provide some kind of removable structure, reaching a meter in height, and attached to the walls or floor at a time when, for example, children are playing on the balcony. It is quite simple to weld from metal pipes of small diameter.

- The second not entirely desirable effect of a magnificent view of the surrounding area is an equally wonderful view of the privacy in the apartment. Especially in the evening with the lights on. Those who do not want to provide neighbors and random passers-by with the opportunity to watch the reality show “live” can choose the following “rescue” options.

- Consider a system of curtains or blinds. The second option will be expensive, given the non-standard dimensions of the opening, and you will have to suffer with a fabric solution.

- At the planning stage, you can choose the type of glass with one-sided transparency. They look good, they are very good on sunny days, but in the fall and in cloudy winter weather such glazing brings melancholy due to the low light transmission. Alternatively, the presence of such glasses can be combined with regular ones.

- If we are talking about frameless glazing of a balcony only in the part where most people are accustomed to seeing the window opening, then the difficulties described above do not arise.

Important: glazing into the floor requires dismantling the parapet. Before carrying out work, you must make sure that the demolition is legal and will not cause negative consequences for the entire house.

- For all its attractiveness, the panoramic method requires additional costs for insulation, and you shouldn’t choose it if the balcony offers a “wonderful view” of the factory complex or the dull neighboring multi-story buildings.

- An aluminum panoramic profile will be cheaper, but its ability to retain heat, let’s say, tends to zero and you should think carefully before installing it.

There are many options, but each of them can be implemented on your own. How to insulate a balcony with your own hands - step by step. Therefore, balcony glazing can be considered a type of work on which you can save money.

Installation of a plastic balcony door threshold on separate supports

Another option for installing a threshold is separate supports. This option is as common as just landing on foam.

Stages of work:

- Plastic thresholds are usually sold in standard sizes. When you adjust it to your parameters, there will be a scrap left over, which needs to be placed under the door frame from the edge. Then place supports so that the threshold is pressed tightly against the door frame.

- Using a level, the threshold is leveled. Then the second layer of supports is laid, on average there should be 6 layers.

- Once you are sure that the threshold is level and good, remove it. Foam is applied to the point supports; first, the supports should be slightly moistened with a spray bottle.

- The threshold is placed on the foam supports and pressed tightly with a load.

The procedure is also simple, however, as with the foam version.

Why you should do the glazing yourself

Today, a large number of companies are engaged in the production and installation of glazing, but it is worth noting that the cost of specialist work is quite high.

Of course, the installation of a regular window may be included in the cost of the structure, but for full glazing of a balcony and loggia you will have to pay quite a bit extra. That is why a large number of people think about doing all the work themselves.

And further, we will consider the nuances that should be taken into account when carrying out work and preparing for it.