Correct installation of PVC windows affects the comfort during operation of the room no less than the quality of the structure itself.

The tightness of the connection of the sash to the framing profile, as well as the ease of opening the moving parts of the opening filling element, depend on the installation and adjustment of the fittings.

If the structure fails, it is necessary to repair the PVC window fittings.

What does the concept include?

Repair of plastic window fittings is a set of works to adjust, restore or replace fastening elements, opening and locking mechanisms of the sash. As a result of these activities, the following results are achieved :

Normal movement of a swing or flap handle.- Ease of opening and closing the window, which prevents the metal parts of the sash from touching the fixed profile.

- Restoring the functionality of the locking element of the flap if it fails.

- Absence of extraneous noise and squeaks when the mechanism is set in motion.

- Elimination of sagging of the sash due to deformation of metal fittings.

Important. Repair of fittings should be carried out when any signs of failure occur. Operating a window after identifying defects can lead to complete destruction of the fittings with the need for its subsequent replacement.

Advantages

Materials for the production of frames are varied, but wood holds a leading position. This is due to the advantages

- environmental Safety;

- naturalness of the base material;

- possibility of use in different interiors and styles;

- hygroscopicity;

- thermal conductivity is low;

- aesthetics.

If the material is properly cared for, the service life is 15-20 years without additional repairs and restoration. That is why restoration of wooden windows is actively carried out when they are installed in a house.

Types of adjustment of the PVC window mechanism

In practice, there are 3 main types of repair of PVC windows, each of which is carried out according to a specific methodology:

- Preventive – periodic maintenance of PVC frame sash mechanisms. During service, the fittings are subject to diagnostics, lubrication, and removal of traces of dust, grease, and corrosion. This type of repair also allows you to identify the malfunction in time and eliminate it in advance.

- Adjustment of fittings - each element of the mechanism of the movable part of the window frame can be adjusted by rotating the screws, which ensure slight movement of the hinges, latches, and locking elements.

- Ordinary – emergency repair with restoration of damaged elements or their replacement, if defects are detected.

Below we describe in detail the methodology for carrying out basic repairs to fittings for filling window openings.

Prophylactic

Preventative repairs are carried out regularly in order to maintain the integrity of the window structure, without the need for major restoration work. This service package for PVC windows includes the following actions :

- Opening diagnostics, checking the functionality of each element of the mechanism.

- Adjustment of fittings for normal operation in operating mode.

- Treatment of metal parts with anti-corrosion compounds.

- Lubrication of moving structural elements subject to friction.

- Straightening out deformed elements.

- Replacement of consumables, screws and other fastening elements.

- Drawing up a list of defects, issuing recommendations for replacing worn parts during the next preventive maintenance.

Note. It is recommended to carry out such repairs at least once every 12 months for residential premises with average operating conditions of the window structure.

Ordinary

Standard repairs of PVC window fittings are carried out when problems are identified during the diagnostic process of the element. The range of work to restore moving mechanisms includes the following production operations :

Replacement of fittings if it cannot be repaired or if it is physically worn out.- Installation of new individual structural elements.

- Straightening out deformed parts to be restored.

- Replacement or reconstruction of a window handle.

- Installation of new fixing or locking elements.

- Installation of new hardware when old fasteners are broken or damaged.

Each urgent repair, as a rule, is accompanied by preventive maintenance of the remaining parts, as well as adjustment of the fittings to ensure normal opening without moving elements touching each other.

Replacing the seal

Any rubber product reacts to temperature influences and “dries out” over time.

As a result, cracks appear and the windows are sealed. How to repair? Algorithm of actions:

- dismantling the old seal;

- cleaning the grooves from residual material;

- treating them with an appropriate adhesive composition;

- installation of a new seal.

The operations are simple, but there is a peculiarity - the material is quite elastic. Therefore, when laying it in the grooves, it must be placed freely, without tension. Otherwise, during temperature deformation, it will shrink and the tightness will be broken. A similar material is used to insulate windows using Swedish technology.

When might it be required?

Repair of metal elements of PVC windows may be required if any of the following situations occur :

- Sagging of the sash.

- Locking of locking mechanisms with the impossibility of further opening.

- The sash is not tightly connected to the main profile, which causes freezing and drafts.

- Loose fasteners or broken lock handle.

- Broken bolt or lock rod.

- Deformation of the locking tabs.

- Loose fittings.

- Broken hinges.

- Physical wear or fatigue failure of the metal.

- Complete separation of the upper or lower loop.

- Deformation of fittings due to elevated temperature, direct exposure to sunlight or open fire in case of fire.

Note. Almost any repair of double-glazed window fittings can be done by yourself.

If the window was installed recently and the consumer still has a warranty card with a current date, the best solution would be to contact the installers with a request to fix the identified problem.

Replacing the handle

The fastening elements are located at its base and covered with a decorative plate. It is enough to turn it at a right angle, and access to the screws is open. Then just unscrew it, change the handle, lock it.

There are special “comb” limiters on sale that will not allow a child to open the doors on their own. They are installed at the base of the handles, which are then mounted in place. You can also purchase a ready-made kit - a handle-lock.

What tools are needed?

To repair the fittings of plastic window structures, the master will need a certain set of tools, which can be purchased at any hardware store :

Phillips and straight screwdriver for the ability to adjust mechanisms using screws.- A miniature hammer with a striker weight of up to 300 grams and a nail without a point to allow knocking out the hinge rod when dismantling the sash.

- A screwdriver with a set of bits for removing hardware and, if necessary, dismantling and replacing fittings.

- Pliers, if metal products are fixed in the profile with clips or with adhesive compounds.

- Rags, brushes with stiff bristles, detergents for cleaning the mechanism from old dirt.

- Penetrating lubricant or machine oil to provide a protective coating to the metal.

- Sandpaper for removing rust from parts.

- If it is necessary to apply markings, you will need a tape measure, a construction angle, as well as a marker or pencil.

- To make additional holes for self-tapping screws, you need to purchase a simple drill with a thin drill bit for plastic.

Important. Tools and consumables must be of high quality and free from signs of mechanical damage.

Sagging of the sash

Over time, some distortion of the window sash occurs, and this is natural, given the weight of the double-glazed window. The adjusting element is located on its lower loop. It is necessary to remove the trim from it, open the window slightly and use a hex key to level it in the horizontal plane. The principle is simple: to raise the edge of the sash, the key is screwed in, to lower it, it is unscrewed (rotation counterclockwise).

General rules and technology

Depending on the type of breakdown, the technician selects a specific technological map for carrying out repair work. Algorithms for repairing window structures for each type of failure are described in detail below.

Planned

Planned maintenance of window fittings is carried out according to the following algorithm :

Checking the functionality of a structural element by repeatedly opening and closing in all possible directions.

Inspection of handles, hinges, locking mechanisms and latches.- Clean each metal part with a brush.

- Tightening the screws on the handle, hinge joints, and locking tabs.

- Re-inspect the functionality of the window to determine the need for adjustment.

- Lubrication of each moving element followed by control of layer uniformity.

- If necessary, replace plastic linings with hardware, tighten fastening elements.

- If a defect is detected, a more in-depth repair of the fittings will be carried out.

Based on the results of preventive maintenance, the window should open normally and lock in all possible positions. If any additional problems are identified, the repair is considered incomplete.

Full

When performing a full repair of fittings, the technician must identify the causes of the malfunction, and then carry out the following manipulations to restore the mechanisms :

- To carry out effective repairs, each sash must be dismantled. Removal requires the hammer and steel rod described above.

- If the handle breaks, turn the plastic plug 90 degrees and unscrew the two screws holding it in a static position.

- All edging fittings for locking the window are dismantled by loosening the screws.

- Metal elements freed from fastenings are picked up with a screwdriver or carefully dismantled using pliers.

- The fittings are placed on the workspace for inspection and making a decision on restoration or replacement.

- All metal parts must be cleaned, washed and dried. If there are traces of corrosion, you can use abrasive paper to remove them.

- Defective and worn mechanisms must be replaced.

- All metal surfaces must be treated with machine oil or penetrating lubricant.

- The fittings are installed in place and secured with self-tapping screws.

Important. If there are cracks or traces of plastic deformation on any of the surfaces, experts do not recommend straightening or welding the parts, as the operation of the mechanism will be disrupted. If such situations occur, it is necessary to purchase a set of new fittings.

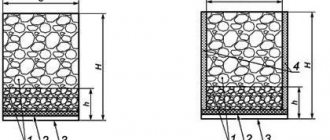

Replacement of glass unit

This is an extreme case, since you need to try very hard to break it. You only have to buy one thing - new “glass”. It can be ordered according to available sizes.

Repair algorithm:

CAREFUL dismantling of glazing beads. You will need a small hammer and a spatula;- removing the “glass”;

- installation of plates (adjusting) under the double-glazed window in the lower part of the frame. For opening sashes - no closer than 100 mm to the corners;

- installation of a double-glazed window and its alignment using the same plates;

- fixation with glazing beads.

Is it possible to manage on your own?

Turning to professionals always guarantees full functionality of the PVC window, as well as the opportunity to re-apply free of charge if the problem arises again. Carrying out independent repairs of fittings is technically possible in the following cases :

When performing maintenance on mechanisms that do not involve major repairs.- If the technician has minimal experience working with PVC windows.

- If the exact cause of the malfunction is known, and the technician has the necessary tools and consumables at hand.

In such cases, you should also familiarize yourself with the detailed technological map. - When the warranty for window installation has already expired, and the next call to a specialist is paid according to the price list of the service company.

Simple repairs usually do not cause problems for a DIYer. Before carrying out maintenance or restoration of mechanisms, you should also watch several popular master classes from professionals who talk about various nuances during repairs.

How to carry out the process?

To carry out preventive maintenance and repair of PVC window fittings with your own hands, you must follow a certain technological map :

- If the sash is skewed, you should adjust the screws at the interface between the hinge mechanism and the plastic profile.

There are two screws installed on the top and bottom sides of the window structure, which are responsible for the play “right-left” or “up-down”. To select the desired position, it is necessary to rotate the screws no more than one turn, and then test the sash in the operating position. - If a large gap forms when the window sash is closed, the technician needs to set the handle to a diagonal position and open it simultaneously in two directions. The adjustment screw will be hidden behind the locking bar. The position is adjusted by turning the hexagonal screw using the appropriate L-shaped key.

- When the sash does not close, two problems may arise.

One of them is skew, the correction of which is described above. Another reason is the accidental activation of the blocking element in the corner part of the structure. If an element breaks, it must be replaced. In case of a false alarm, the part is removed to its original position by pressing the hand. - If problems arise with turning the handle, you need to check the grip design itself and replace it. The defect may also be hidden in too tight abutment of the blocking elements when closing. They are subject to adjustment by turning a screw located directly on their end part.

Important. One of the main problems with PVC window malfunction is loose fittings, which occurs due to the loosening of several fasteners. In such cases, it is necessary to tighten each self-tapping screw or screw until it stops.

Loose pressing to the frame stand

The result is a slight draft. Since the sash “reclines” in 2 positions, it opens this way – for “ventilation” and “fully open”. To achieve this, you need to press on the lock (its “tongue” is located on the handle).

There is an adjustment screw at the top of the frame. It needs to be tightened up.

If it blows slightly only in the area of the seal, then this drawback can be eliminated in this way. The technique differs only in some features, which depend on the brand of fittings.

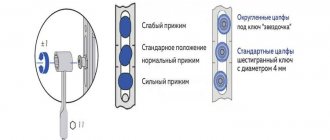

For "WINKHAUS"

Adjustment is made with an eccentric. It should be loosened a little (with pliers or fingers), and then moved in the desired direction.

For "ROTO"

Using a hexagon.

For "GU", "AUBI" and some others

Rotate the roller counterclockwise. There is a mark on it. The closer it is to the frame, the stronger the pressure will be.

WINKHAUS ROTO GU, AUBI

When blowing air in the hinge area, you need to use the adjustments and press the sash more tightly to the frame. Lining additional plates also helps.

Difficulties and errors

When performing repair work, beginners often make mistakes that can lead to serious damage and costly replacement of PVC window parts. To prevent this, every novice master must observe a number of nuances, which are mentioned by experts on online forums :

Before starting repair and restoration work, it is necessary to accurately determine the cause of the design defect.- Before adjusting the fittings, you should find out which screw is responsible for the specific direction of straightening the sash.

- If a rupture of a steel element is detected, it must be replaced, since welding will not be able to provide the original freedom of movement of the sash.

- Each repair must be accompanied by cleaning the metal from dust and lubricating the parts.

The main advice that experts give is that the design should be tested for normal performance. If a home mechanic is unable to repair the fittings with his own hands, you need to turn to professionals for help. Further intervention may completely damage the structure.

Aesthetic moment

An element of beauty and addition to the design is the plastic corner. A window corner is made from PVC by bending a hot sheet, which has a small thickness. The corner is used when installing slopes. It closes the gap between the plastic structure, the construction quarter and covers the mounting foam, protecting against various harmful influences.

The corner is not only strong, but also durable. It gives the same features to slopes. The corner also smooths out all the unevenness in the corners.

Average price per service

There are many companies on the market offering repair of PVC window fittings. All officially registered enterprises compete with each other both in terms of quality and the best price for customers. Average prices for professional service and repair of fittings for plastic windows are given below:

- Adjusting hinges and locking elements without removing the sash - from 250 to 550 rubles.

- Adjustment of elements with removal of the sash - from 900 to 1300 rubles.

- Lubricating fittings – from 200 rubles. per element.

- Replacement of a set of fittings with installation of imported parts - from 3,000 rubles, domestic mechanisms - from 2,000 rubles.

- Replacement of the handle – from 500 rubles.

All prices are reference information and are constantly changing, so they cannot be used to calculate the final cost of window maintenance.

Mosquito net

These components for PVC windows are considered optional for installation, but they protect the room in the summer from various insects, so consider their quantity and necessity when putting together the kit. The mesh has a small thickness. They can be easily dismantled for autumn and winter.

Some varieties, in addition to their protective functions, also prevent pets from falling out of the room.

There are the following types of meshes: