The point of glazing a balcony is to retain heat - on the balcony and in the room adjacent to it. A high-quality glazed balcony often becomes a place for work (an office), a bedroom (especially in the warm season) or a place for leisure. But not everyone can afford to hire professional finishers, so many decide to do the work themselves. And it's possible! The main issues that you have to decide are the choice of building materials and their correct use.

Preparatory work

Preparing a wall opening for installation of a balcony block begins with dismantling the old structure.

Note! Before removing the old block, it is necessary to clear the window sill and remove the curtain rod and curtains. Furniture located close to the window should be moved away or covered with film to protect it from dust.

Dismantling the old block

Dismantling of a wooden window and door unit is carried out as follows:

- Remove the opening doors and balcony doors from their hinges. The glass is removed from the blind sashes, after removing the glazing beads.

- The window sill is dismantled. The concrete is broken with a hammer, cutting the reinforcing elements with a grinder. A wooden, aluminum or plastic window sill is simply removed from the opening.

- Remove the tides.

- Remove the old frames from the opening. To do this, they can be cut, starting from the bottom, or pryed with a construction cutter.

- The slopes are dismantled and the insulation is removed.

Dismantling an old wooden structure

If you are dismantling old PVC windows and doors, first remove all fasteners and then remove the frames.

Try to perform the work as carefully as possible to maintain the integrity of the opening.

Preparation of window and door openings

According to the current GOST, which regulates the connection of PVC windows to openings, the latter must have a flat surface. The presence of chips, potholes, and other irregularities, the depth of which exceeds 10 mm, is not allowed.

If the walls crumble, they are strengthened with binders. Oily surfaces are degreased. Irregularities are eliminated with the help of plaster, and cracks in brick and block masonry are eliminated with the help of high-rigidity foam insulation or the same plaster.

You can clean the opening from dust and debris using a stiff brush or vacuum cleaner. If installation work is carried out in winter, then snow, frost, and ice are also removed from the working surface.

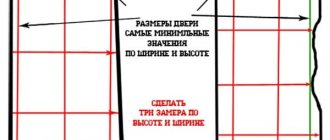

The walls of the opening must be aligned horizontally and vertically. Their deviation from the axes is acceptable, but not more than 4 mm per 1 m. Accurate measurements can be made with a building level or a laser plane builder. You can also control the equality of the diagonals in the opening.

The process of installing the frame in a clean and leveled opening

Connection of door and window frame

To connect the window and door parts, you must first remove the movable sashes from their hinges.

To do this you should:

- knock out the top hinge rod;

- open the locking mechanism by turning the handle;

- remove the sash from the bottom hinge.

Metal rod under the decorative hinge plug

Then prepare a connecting strip, self-tapping screws and an electric drill with a set of drills.

- Place the tie strip between the door and window frame.

- Place the entire structure “upside down” on a flat surface, making sure that there are no distortions in it.

- From the door side, drill tunnels in the end part of the frame in increments of 30-40 cm.

- Insert the fasteners and tighten them.

- Cover the visible parts of the fasteners with decorative caps.

- Apply sealing tape around the perimeter of the structure.

Profile for connecting balcony door and window

Fixing the sealing tape

If you want to make fastening units from the side of the window, you will have to remove the blind part of the window. To do this, you need to pry the glazing beads with a spatula, remove them, and then expose the glass.

Note! Choose self-tapping screws with a length of 80-90 mm so that when screwed to the end they do not violate the tightness of the window in the balcony block.

Connection diagram of individual parts of the block

Selecting fasteners for a balcony block

Before installing the balcony block, you need to make markings for the fasteners that will hold it in place. For these purposes, anchor plates or spacer frame dowels are used. What is the difference, what are the advantages of each option?

Anchor metal plates are attached at one end to the outer end of the window and door frame, and at the other to the wall of the opening.

Plate bent to the wall

Some of them (“with ears”) are first inserted into special grooves on the frame and only then screwed with self-tapping screws. Others (without “ears”) are fixed immediately, simply by attaching them to the box.

Fastening anchor plates “with ears”

The main advantage of anchor plates is that to install them you do not need to remove double-glazed windows from the blind parts of the window. This reduces the risk of damage to the PVC structure significantly, which is especially important for inexperienced craftsmen.

But anchor plates cannot always be used. They are unreliable fasteners for large (more than 4 m2) and structures with actively used sashes. They are also not suitable for installing a balcony door. However, many experienced craftsmen skillfully combine plates with spacer dowels, using the former in the upper part of the window-door unit, and the latter in the bottom and sides.

Fastening the balcony block to anchor dowels is the most reliable option. These elements are a set of a bushing and a durable metal bolt. When the bolt is screwed into the bushing, it expands, due to which the frame structure is reliably attracted to the walls of the opening.

However, the use of dowels requires the preliminary removal of even blind sashes, which may lead to a violation of the integrity of the double-glazed windows. If you are not a professional, then you cannot do without an assistant, or even two.

Removing the bead using a spatula

Note! To install the box using dowels, you will need a powerful hammer drill.

Installation of double-glazed windows

Gaskets must be placed in the lower and side internal parts of the frame installed in the opening. It is necessary to lay it so that the weight of the glass unit is evenly distributed over the frame. One of the edges of the gasket should extend slightly beyond the boundaries of the frame, so that after hammering in the bead, cracks do not form on the glass. After this, take two suction cups, press them to the surface of the glass and carefully place it in the window frame. At the end, the glazing beads are hammered in with a wooden mallet, and at this point, do-it-yourself glazing can be considered complete.

To fix the glass unit in the frame, you need to hammer in the glazing beads using a mallet

Installing frames and glass is a rather complex process that requires experience and certain skills, so if you are not completely confident in your abilities, it is better to immediately call specialists.

Installation of a balcony block

After you have chosen the method of attaching the PVC structure and made the appropriate markings, you can install the block in the opening. The complexity of this stage lies in aligning the frame box vertically and horizontally, securing it securely, and making an assembly seam.

Aligning and fixing the window-door unit in the opening

The window-door unit is not installed with direct support on the walls of the opening. To form an installation gap and transfer the weight of the PVC structure to the base, it is necessary to use support blocks (wedges). They can be plastic or wooden. The latter are easy to do with your own hands, but they require mandatory impregnation with antiseptics. The optimal length of the block is 110-120 mm.

Wooden mounting wedges

Two plastic mounting wedges form a rectangle, which allows you to securely install the balcony block in the existing opening. If necessary, the elements are shifted relative to each other. Due to the existing projections, they will not move apart. This allows you to orient the frame box in space.

Placing mounting wedges under the frame

Note! Mounting blocks must be placed under each vertical element of the balcony block, including under the impost.

Fastening the frame structure to the wall

According to the current GOST, after fixing the balcony block with temporary wedges, you can begin fastening it using anchor plates or dowels.

Fastening the block using plates

Installation of the frame box on the plates is carried out as follows:

- Mark the places where the plates are attached to the frame. They should deviate from its internal corners by 150-180 mm. The installation step is 600-700 mm. The distance from the impost to the nearest fastener should not be more than 180 mm.

- Mark the places for fixing the plates on the walls of the opening.

- Using a chisel, make recesses in the wall for fasteners. This “recessing” will help subsequently hide the plates under the final finishing of the slopes.

- Fix the fasteners on the frame so that they look towards the room. First, screw the plates in the lower left and right corners, then on the sides of the box, and lastly, in its upper part.

- Place the box in the opening, bend the plates slightly and secure them to the wall with dowels.

Screwing the plate to the PVC frame

Note! While working, check the evenness of the balcony block. During the process of tightening the fasteners, a noticeable distortion may occur.

Dowels are used as follows:

- Marking the balcony block. It is similar to the arrangement of anchor plates.

- The frames are drilled through from the ends at the designated points.

- Install the PVC structure in the opening, align it horizontally and vertically, and mark the walls along the holes already made.

- Fix the balcony block box with dowels.

Fastener seating depth

Diagram of fastening units

Note! After attaching the window and door unit to the wall, the side mounting wedges are usually removed. But the lower ones must be left as a support for the entire structure.

The difference between fastening with dowels and plates

Making an assembly seam

After installing the balcony block in the existing opening, you can proceed to making installation seams. The current GOST 30971-2012 assumes the presence of three main layers:

- central - responsible for heat and sound insulation of windows and balcony doors;

- internal - preventing the penetration of steam to the insulation;

- external - removing steam from the central layer, preventing moisture from penetrating into it from the street.

The general requirements for the installation seam are high quality insulation and the use of environmentally friendly and safe materials. Moreover, all of them must withstand operating temperatures in the range of -10..+40°C.

Central layer of assembly seam:

- Material – polyurethane foam or well-known polyurethane foam. An alternative is polyethylene foam tapes, thermolen, which are not so convenient to use and are used quite rarely.

- Laying - continuous filling of all seams and joints. The presence of delaminations and cracks is acceptable, but within 6 mm. The width of the foam layer is from 15 to 60 mm, the depth is not less than the thickness of the PVC box.

- Do not use polyurethane foam at air temperatures below -10°C.

Foaming the assembly seam

Use a special gun to apply polyurethane foam

Note! While the polyurethane foam is drying (at least 24 hours), the pre-hung window sashes and the balcony door must be closed.

Outer layer of assembly seam:

- Material – sealing tape, sealants.

- The water resistance limit is at least 300 Pa.

- Must be resistant to temperatures ranging from +70°C to -30°C and lower if we are talking about a frost-resistant seam.

Additionally, the outer layer of the assembly seam is protected with special overlays and strips.

The inner layer is an elastic sealant that is laid continuously. It should have greater resistance to vapor permeation than the central layer of the seam.

Nuances of balcony design

The main element of the balcony is the balcony slab. It is best to equip it during the process of building a house. But if this site was not planned at first, and after the completion of construction work the need for a balcony arose, do not be upset.

The balcony slab can be manufactured and reliably installed even after the work has been completed.

How correctly and reliably the balcony slab is installed depends on the strength of the entire balcony structure.

The extension box is made of brick or metal-plastic.

Certain calculations must first be made. The slab must withstand a certain load, so its certain safety factor should be calculated. If you do not have specific experience in construction work, then it is better to turn to professionals.

The construction of a balcony slab consists of creating a complete reinforced concrete product of certain dimensions or installing a metal structure by welding, installing supports, and then pouring the future slab with concrete.

After resolving the issue with the slab, they move on to arranging the balcony box. They are mainly divided into two types:

- the classic option, during the construction of which a metal or brick fence is installed;

- construction of a completely metal-plastic box.

Construction of a classic balcony

Such a balcony, as a rule, consists of fencing, glazing and roofing. Very often, when this design only enlivens the interior of the façade of a house, they only get by with a beautiful fence. It can be made of metal, wood or brick.

If, in addition to its appearance, you plan to use the balcony at any time of the year, then the roof and glazing must be installed. In such cases, the fence is sewn up with a special material, for example, siding. The insulation process is carried out inside.

Metal-plastic

For a balcony on the first floor it is necessary to obtain permits.

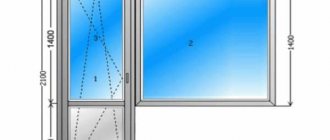

The metal-plastic balcony structure is arranged as follows. Balcony blocks are installed directly on the slab. Next, the plastic profiles are decorated with double-glazed windows completely or only halfway.

Such rooms resemble the arrangement of French balconies.

Please note that if you want to arrange a balcony on the ground floor of an apartment building, you must first obtain special permits.

Window sill installation rules

After installing the main part of the balcony block, you can begin installing additional elements. One of them is the window sill. It protects the assembly seam from external influences and increases the thermal insulation of the room.

Preparing the window sill and opening

You can install a plastic window sill or cover the ledge with ceramic tiles. However, the first option looks more organic in combination with a PVC balcony block.

Installing a plastic window sill will not take much time, but requires some preparatory work. You need:

- Remove all debris remaining after installing the window and door.

- Dust the work surface.

- Level it with cement mortar, if necessary.

- Make a drawing of the future window sill, taking into account the size of the opening and the angle of the slopes.

- Prepare the window sill itself. It needs to be cut according to the drawing. To do this, you can use a jigsaw, wood saw and other cutting tools.

Basic values for cutting a window sill

After completing the preparatory work, you can proceed directly to installation work.

Fastening the window sill in the opening

The window sill must fit tightly to the frame and be aligned along the main axes. To do this, he needs support points. Typically, their function is performed by plastic or dry, antiseptic-treated wooden blocks (blocks).

The supports are laid in increments of 50-60 cm in two rows: the first along the frame, the second along the inner wall.

Plastic supports for window sill

As soon as the first row of supports is installed, you need to take a piece of window sill and attach it to the frame. It should be aligned similarly to a full-fledged product.

Install the second row of supports and again use the building level. The angle between the window sill and the frame can be strictly 90° or be 2-3° greater (to remove moisture).

The final stage of work is foaming the space between the opening wall and the window sill. The first layer of foam is applied along the frame, the PVC product is installed, and the remaining space is filled with polyurethane foam. After a day, it will be possible to cut off the protruding excess.

Installation diagram of a plastic window sill

Price policy

When choosing a material for a balcony frame, give preference to the “golden mean”; do not trust suspiciously low prices, as they may mask poor quality.

The table shows the price per 1 sq. m products, approximate data are presented, prices may vary depending on the quality of the product and its manufacturer.

In large, urbanized cities, price lists are formed based on the income level of the population, so it is advisable for residents of the provinces to familiarize themselves with the cost of balcony glazing services in their cities.

Don't forget also about promotions and discounts that competing companies offer quite often.

The Internet is a useful and convenient thing when ordering balcony structures online. Always check the cost with the store manager.

| Types of balcony structures | Novosibirsk | Moscow | Saint Petersburg | Kyiv | Kharkiv |

| Aluminum | 3000 | 4500 | 4300 | 800 | 750 |

| Plastic | 5000 | 7000 | 6800 | 1200 | 1100 |

| Wooden | 6000 (euro frame) | From 3000 to 7000 | From 3500 to 7000 | From 700 and above | From 650 |

| Rub. | Rub. | Rub. | UAH | UAH |

Return to content

How to make a threshold for a balcony block

When installing a balcony block, you need to take care of adding a threshold. It is needed for a smooth transition between the living room and the balcony.

You can make a threshold with your own hands from plastic or tiles. However, before starting work, it is important to pay attention to the installation height of the door frame. If it is small, then you can install the plastic threshold according to the following scheme:

- Cleaning and leveling the concrete base.

- Installation of support bars (their thickness is chosen based on the desired threshold height).

- Aligning supports horizontally.

- Laying the threshold.

- Foaming the space underneath.

- Waterproof all joints using sealant.

Flat base for the threshold

Installing a plastic threshold on wooden supports

Plastic threshold for the balcony

To cover a concrete base with tiles, you only need to complete the first step. Then you can begin priming the working surface and applying the adhesive.

If the height from the floor to the edge of the door frame is significant, then you can raise the threshold using clinker bricks. In this case you will have to:

- Cleaning, leveling and priming the concrete base.

- Dilution of cement mortar.

- Laying bricks on mortar. Please note: they should not reach the angle of slope with the internal wall of the room 3-4 cm.

- Installation of wooden formwork around the perimeter of the threshold.

- Final filling with mortar.

- Removing formwork.

Laying clinker bricks

The ledge can be tiled or decorated with plastic.

Glazing types

If you want to arrange a living room on the balcony, then choose warm glazing.

To ensure the correct choice of plastic windows, we will take a closer look at the features of glazing and its types.

- Cold glazing. Direct purpose – protection from external weather influences. This type of protection is not able to keep the room warm in winter or protect from heat in summer. It is not suitable for arranging a full-fledged room on the loggia.

- To create a warm and cozy room, a warm type of glazing is suitable. Plastic windows with double-glazed windows are used. It reliably protects against moisture entering the room and provides thermal insulation. With warm glazing, full use of the loggia in winter is possible.

- Also, types of glazing are divided according to the type of opening of the window structure. It can be hinged or sliding. The swing system is already familiar to everyone, the essence of which is to open the sashes attached to the profiles using hinges. The sliding system is equipped with the help of a special roller system - window sashes move along guides.

We remember that the type of glazing depends on the future functional purpose of the room.

Finishing window and door slopes

Window and door slopes can be finished with plasterboard, plaster and plastic (sheet material, sandwich panels). Work technologies also vary.

Decorating slopes with plaster

Plastering is one of the most affordable and simplest options for finishing slopes. The plaster has a low price, is easy to apply, forming a smooth coating ready for final painting. However, this material has a low heat saving rate, can crack under the influence of external factors and is susceptible to mold formation. In addition, the process of working with plaster itself is quite dirty.

But if you decide to save your budget, then plaster the slopes as follows:

- Prepare your work surface thoroughly. Eliminate unevenness, degrease and remove dust.

- Check the evenness of the slopes using a building level. The permissible deviation along the axes is 2 mm per 1 m of the finished surface.

- Apply a layer of deep penetration primer.

- Attach a reinforcing corner along the edges of the slopes to “stumps” made of mortar or along the edge of the inner wall - a wooden rule (slat).

- Using a spatula, apply the solution to the work surface. This should be done as if throwing it.

- Distribute the solution along the slopes, making movements from bottom to top.

- Make a temperature gap between the frame and the slope in the form of a furrow 3-5 mm wide. Fill it with silicone sealant.

- After the plaster has dried, finish it with grout. To do this, use fine-grained sandpaper.

Distributing the mortar along the wall

When plastering, it is important not only to obtain a smooth surface of the walls, but also to evenly distribute the solution and maintain the slopes. It is for this purpose that a special tool is used - a malka. You can make it yourself from plywood, boards, timber or even leftover PVC panels.

The optimal width of the fry is 130-150 mm, and the length is 80-100 mm greater than the width of the slope. On one side of the tool you need to make a notch that should correspond to the thickness of the window frame. The mortar is pressed against the wall, one end resting it against the frame, and the mortar is leveled. It must be laid 5-6 mm thick.

Notch at the end of the fry

Perforated corner and window frame - beacons for distributing putty using a hammer

Installation of plastic slopes

Plastic slopes are resistant to moisture and mold, easy to maintain, aesthetically pleasing, and affordable. Their main disadvantage is fragility under directed mechanical influence.

The material for covering the opening can be a sandwich panel with insulation or a simple PVC panel. You can install them in two different ways - with or without a starting profile.

In the first case, the work is performed as follows:

- The starting U-profile is screwed along the entire length of the frame with self-tapping screws.

- A wooden batten is installed along the edges of the slopes. At the junction of the top and side elements, a gap of 10 mm should be left. The protruding parts (“spikes”) of the panels will go into it.

- A plastic slope pre-cut to the required size is installed with the end into the starting profile.

- Insulate the slope with mineral wool or polyurethane foam.

- The second end is fixed to the sheathing using “bug” self-tapping screws.

- An F-profile is installed along the edge of the inner wall, fixing it with glue or liquid nails. It is overlapped in the corners and then cut off.

- The junction of the slope and the window structure is insulated with liquid plastic or silicone sealant.

Fastening the starting profile around the perimeter of the frame

The space between the panel and the wall is filled with polyurethane foam

The second option - installing a plastic slope without a starting profile - involves performing similar actions, but with one exception. The PVC panel is inserted with a “spike” directly into the mounting foam, which was used to install the balcony block. To do this, it is cut to a depth of 10 mm. The width of the cut should not exceed 1 mm.

Note! If you use a sandwich panel, you can make the “spike” yourself. To do this, the product is first cut along the edge to ½ thickness. Then an incision is made across. The result is an L-shaped edge of the panel.

Features of working with drywall

The opening for a balcony block is rarely lined with plasterboard.

- Firstly, this is a labor-intensive process that involves working not only with this material, but also with plaster, primer, and glue.

- Secondly, you need to use only moisture-resistant drywall. But even with this, the entire skin will need additional protection from moisture.

- Thirdly, under the influence of external factors, drywall can swell and delaminate.

It is convenient to use gypsum board when you are sheathing internal walls. In this case, working with slopes will look like this:

- A metal UD profile is fastened along the window frame with self-tapping screws.

- A plasterboard blank is inserted into it, starting from the top of the opening.

- The formed cavity is filled with insulation, leaving 10 cm free from the edge.

- An adhesive composition is applied to the edge of the slope and the drywall is pressed against it.

- All joints are additionally coated with glue.

- After it dries, the slopes are puttied.

Adhesive method of fastening plasterboard slopes

Note! To obtain a smooth and durable base for subsequent finishing, you need to apply at least two layers of plaster to the drywall.

Remote balconies

Let us now turn to the types of balconies and loggias that can be installed in apartment buildings. In cases where the area of balcony premises requires the best, it can be increased due to remote structures.

Here are a few examples of arranging such balconies:

- Expanding the balcony space forward and to the sides. This type of extension of the structure allows you to expand the space up to 0.4 m. The additional frame of the fence extends beyond the boundaries of the fence. In this way you can expand the loggia. Arranging an increase in space by installing the fence at an angle relative to the base entails insulating the structure and finishing the outside with siding.

- Increasing space by increasing floor area. In this case, the dimensions can be expanded to 0.3 m, and the height of the railing can be set at your discretion. When moving a balcony along the floor, it is necessary to first dismantle all elements except the balcony slab. Next, a metal structure is mounted, which is attached to the slab and walls. The finished frame is subsequently arranged according to the chosen design. For more information on how to expand the balcony area using external glazing, watch this video:

When arranging structures with extension, the main thing is not to overdo it with the expansion dimensions. This could lead to a collapse.

Video master classes on the topic

Detailed videos that will help even a beginner install a balcony block with a window sill and slopes on their own:

Tuning the opening and installing the BB:

Independent installation of a window and door unit on a balcony is a labor-intensive process that requires a lot of time and financial costs. Directly installation is preceded by a large amount of preparatory work. Both are based on certain theoretical knowledge and practical experience. If you are not willing to risk a PVC structure by installing it yourself, consider hiring a professional.