When purchasing window fittings, the key criterion is ease and convenience when opening and closing the window. In addition, when choosing handles for wooden windows, you should not forget about the decorative side of the issue. Tastefully selected fittings will highlight the beauty of wooden frames and become an excellent interior decoration.

Wooden window with tilt and turn mechanism

European brand Hoppe

HOPPE develops its own solutions to provide higher levels of protection and comfort in the area of high-quality handles. Protection against unauthorized opening from the outside and inside. Lockable window handle. Burglary resistance. HOPPE also meets the requirements of various standards. Offers you a wide range of fittings for doors and windows made of aluminum, stainless steel, plastic and brass.

Colors:

- silver aluminum

- brushed stainless steel

- aluminum steel

- aluminum in bronze color

- transport white

Material:

- aluminum

- stainless steel

- solid brass

Varieties of handles and locking mechanisms

Wooden windows come in two types: regular and euro. In the first case, the fittings can be quite simple: handles and latches or latches as a locking mechanism. This option is inconvenient and is most often used for summer cottages or rural outbuildings due to its low cost and ease of installation.

Wooden window with handle and latch

The best option for ordinary wooden windows is rotary handles with a locking mechanism. The principle of their operation is simple: when you turn the handle, the tongue either goes into the groove or comes out of it. If you have some carpentry skills, it will not be difficult to insert such a mechanism with your own hands.

Classification of handles and locking mechanisms for Euro-windows

When installing double-glazed windows, window fittings are purchased as a set, that is, the handle is an integral element of the entire opening mechanism.

The mechanisms are of the following types:

- Turning. The window opens horizontally, like a door.

- Folding. This option is suitable for rooms where frequent ventilation is necessary.

- Tilt-and-turn. Both options are possible here.

- Swivel and slide. The window can open not only into the room, but also as a wardrobe.

If the window is blind, there is no need for a handle at all.

The handles themselves, depending on the functions performed, are divided into:

- Standard. The design allows you to open and close the window from the inside.

- Handle locks. The built-in lock allows you to fix the handle in one position by turning the key so that children cannot open the window.

Window handle with built-in lock

- Removable handles. Useful for saving space.

- Double-sided. This type is indispensable for balcony or terrace doors.

- With push-button lock. After pressing the button, the handle is fixed in one position.

- Anti-burglary. If they try to open the window from the outside by pressing on it, blocking occurs.

- Curved handles. Convenient for windows that open towards the street.

Classification of handles by material of manufacture

For plastic windows, handles from the same material are traditionally chosen, but for wooden double-glazed windows there are more suitable options:

- Brass. This material is the most popular, as it harmonizes perfectly with wood and has anti-corrosion properties.

- Aluminum, steel and other metals and alloys.

- Tree. Wooden window handles are less common than metal products, but they are not inferior in decorative qualities, and varnish coating makes them durable and wear-resistant.

Wooden window handle

German line of handles Roto Line

Roto Line aluminum window handles are made from high quality, corrosion-resistant alloy. The handles securely fix the window in the required position; no additional holes in the window or frame are required. Thanks to special coatings, the handles do not require special care, and any dirt on them can be easily removed with a damp cloth. Possibility of installation on any type of structure - both classic windows and non-standard configurations (round, arched, exclusive shapes). Roto Line – classic models with aluminum elements, as well as handles with hidden Secustik safety mechanisms, button or rosette.

Colors:

- natural silver, anodized

- light silver, anodized

- titanium matte, anodized

- matt brass, anodized

- dark bronze, anodized

- bronze, anodized

- RAL 8019 grey-brown

- RAL 8022 black-brown

- RAL 9016 white

Roto Line window handle options:

- standard

- lockable 40 Nm

- lockable 100 Nm

- secustik

- with button

- TiltFirst

- curved

- removable handle with rosette

Window handles

Reguitti window handles: history, features, model range

history of the company

The Italian company Reguitti was founded in 1975. And over the forty years of its existence, the factory has managed to achieve not only major successes in the production of high-quality door and window fittings, but also wide recognition and popularity in most countries of the world.

For several decades now, the Italian company has been able to successfully combine the centuries-old traditions of its business with innovative technical solutions. Thanks to this, it annually produces the latest collections of fittings, maintaining the highest standard of quality for its products.

Today, Reguitti window handles are considered one of the best in the world and are widely used both at home and in public and commercial establishments.

Production Features

The most important feature of Reguitti is its dedication to the highest quality of its products. All accessories of the factory undergo multi-level quality control at each stage of production, which allows it to guarantee the highest quality and reliability of its products.

Reguitti window handles are made exclusively from high quality materials. They are manufactured using either brass or a patented ZAMAK alloy consisting of zinc, aluminum and copper. The metal surface of window handles is treated with specialized compounds that ensure their durability, wear resistance and resistance to external influences.

Recently, the company has introduced another revolutionary innovation into its production. Now all Reguitti window handles are treated with a special antibacterial composition Antigerm, which contains silver ions, providing reliable protection of the fittings from germs and viruses. No chemicals are used in the production of the unique composition, which makes it completely hygienic, hypoallergenic and environmentally friendly. This innovation made the fittings of the Italian company even more in demand and made it possible to use it even in rooms with increased requirements for cleanliness.

Reguitti range

Over the many years of its work, Reguitti has managed to develop a wide range of window handles with unique technical and, of course, aesthetic characteristics.

Based on functionality and technical specifics, all Reguitti window handles can be divided into three main types:

• Dreh Kipp (classic window fittings)

• Securblock (window fittings with a security mechanism)

• With Key (window fittings with a built-in key lock)

At the same time, Reguitti offers the widest aesthetic variety of window handles - from vintage fittings inspired by Italian classics, to bold modern designs and even luxurious handles decorated with Swarovski crystals. Thanks to this, among the range of products of the Italian company you can find fittings that will fit perfectly into any interior.

Installing a handle with a locking mechanism on a simple wooden window

There are times when you need to independently equip a wooden window frame with a handle with a lock. Having basic carpentry skills, this will not be difficult to do. For work you will need the following materials:

- pencil;

- roulette;

- hammer;

- chisels – narrow and wide;

- drill with drills;

- screwdrivers;

- fasteners (usually included with the locking mechanism).

Next you need to perform the work in the following sequence:

- In the place chosen for installing the mechanism, mark the outline of the lock's front plate with a pencil; to do this, you can simply circle it. After this, the lock is turned to the opposite side and the body itself is outlined.

- Several holes are drilled inside the body contour almost close to each other.

Preparing a hole for the lock body on a wooden window

- Next, using a chisel and hammer, you need to cut through the outline and deepen the recess to such a depth that the locking mechanism fits completely into it.

- Now you need to slightly recess the front strip so that it is flush with the surface. For this, the outline should be hollowed out very carefully.

- Using a drill, drill a hole for the handle. It should be slightly larger than her shaft. The handle needs to be adjusted.

- Next, use a screwdriver and screws to attach the lock.

- The next step is to install the handle.

- Finally, it is necessary to make a receiving hole - a groove into which the lock tongue will go. It is also decorated with a plank.

In the following video you can see in detail the process of inserting a handle with a lock into the window of a wooden window.

Manufacturing technology of handles for PVC plastic windows

Considering the fact that we live in an age of technological progress, the process of making handles for PVC plastic windows can be called quite simple. The basis of the structure is a metal rod, which is coated with a protective varnish before pouring.

PVC granules are heated to a liquid state in a special chamber. Then the rod is filled with flowing plastic under pressure. The PVC shell protects the metal from oxidation and also gives the handle a decorative appearance. To change the standard white color, color is added to the plastic.

Since the manufacturing technology of handles for plastic windows involves pouring molds under high pressure, no voids are formed in the structure of the material. The result is a durable and very reliable product, resistant to physical influences, ultraviolet radiation and moisture. The service life of the plastic handle reaches 10 years.

Manufacturers are ready to offer metal handles. They are more durable, but also more expensive than plastic ones.

What is a window handle made of?

The handle for a plastic window has a more complex design than its counterpart twenty years ago. It allows you to implement the micro-ventilation function, as well as activate the locking mechanism.

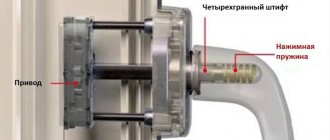

- The bracket

is in most cases L-shaped. Its size depends on the dimensions of the window, and the larger it is, the longer the handle lever will be. This is done to ensure ease of rotation of the mechanism, no matter how much force is applied when opening/closing the sash. - The core

is attached with two self-tapping screws to the plastic frame and is masked with a decorative overlay. Self-tapping screws are galvanized, with M5 threads and countersunk heads. - The pin

is a metal rod in the form of a tetrahedron (side width 7 mm, average length 40 mm) connecting the handle itself to the core. The durability of the entire plastic window largely depends on the strength of the pin.

This is the main set of components that make up handles for PVC windows. Differences may be in design, color, as well as the presence or absence of a lock (button).

To prevent the handle from opening by drilling, there is an option to install special plates made of durable steel opposite it. The plates protect the pin from any physical impact from the outside.

For additional security against thieves, windows use anti-burglary mechanisms that “tightly” block the pin if they press on the sash from the outside or try to turn the handle in an unnatural way.