Choosing wooden windows is not as simple a process as it might seem at first. It is not enough to just select the wood. It is, of course, important, but not as much as is commonly believed. There are other criteria that primarily determine how reliable a wooden window will be and how long it will last.

The very first thing is to correctly evaluate the functionality of windows. Do you need French blind wooden windows? Ordinary wooden windows with double glazing? Double framed? Attic? Despite its apparent simplicity, this is an important question, because you are installing windows not for one year, but for several decades, so try to take into account all possible nuances.

Secondly, you must definitely take into account the climate zone in which you live. This factor affects not only what wood to choose for windows, but also what kind of double-glazed window needs to be installed.

When you have already identified these points, it’s time to understand how to choose the right wooden windows themselves.

If you find it difficult to determine which windows you need, then our company’s specialists will recommend you the best option applicable to your requirements.

Rule #1. Wood

No, not the type of tree itself - that, by and large, does not matter. Wooden windows made of pine or larch, just like wooden windows made of oak, will last you 70 years. But what you need to pay attention to is that the frame is not made of solid wood, but of three-layer laminated veneer lumber. And, the second factor is that the core of the tree is not used in production.

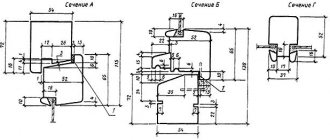

It’s clear that no one will allow you to cut the frame to see if there are annual rings inside. But reputable companies that produce wooden windows will definitely provide you with a cross-sectional sample of the wood from which the frame itself is made. You can look for yourself in the corner of the window - the timber is clearly visible there.

The wood must be clean, without resin pockets, serrations, knots, etc.

Window Selection Options

Design

Most window designs use at least one blind sash (transom). It allows you to increase the area of light penetration without reducing the strength of the frame itself. In addition, the absence of opening mechanisms significantly reduces the cost of such an element.

However, sashes are still needed to ventilate and maintain windows. Their number is determined by the width of the opening, permissible loads on the frame and fittings, but at the same time is subject to the requirements to maintain high light transmittance of the entire window.

Opening direction

If previously windows could only swing inward (apartment) or outward (for private houses), now with the advent of new mechanisms in the manufacture of frames, other interesting solutions can be implemented:

1. Hinged windows are a convenient way to ventilate rooms. To do this, it is enough that there is one flap in the window block. True, such mechanisms are usually not used in their pure form, but are supplemented with swing hinges.

2. Hung windows are the opposite of hinged windows. The sash is mounted on special mechanisms at the top and opens with a “visor”. It is most convenient to use such frames in wide but low openings or when glazing the attic roof. However, there are also separate hanging vents in window blocks.

3. Vertical-lifting – this option, fashionable abroad, has not really caught on with us. When opened, the lift frame saves space, but if it is not securely secured, it may fall back with a crash and cause injury. Another disadvantage of such structures is poor thermal insulation.

4. Sliding – the best option for windows with large sashes that create too much stress on regular hinges. Such models are chosen for glazing balconies, verandas and loggias, so that open doors do not “eat up” pieces of an already cramped space.

5. Mid-turn - a non-standard solution that combines the simplicity of casement windows and the convenience of sliding structures. When opened, the sashes move on levers closer to the center of the window, without touching the slopes.

Important: external opening windows can only be used on the ground floor, since by reaching for the handle of an open sash you risk falling out onto the street. In addition, such frames require careful fastening, otherwise over time the window block itself will fall out.

Impost or shtulp?

An impost is the central beam of a double-leaf window frame, to which the closed sashes are adjacent. When the windows are open, this design does not look very attractive, dividing the opening into two parts. But this is its only minus.

The impost porch provides a tighter connection of the sashes in the closed position, that is, better heat and sound insulation. In addition, it serves as an additional stiffening rib, thanks to which the window unit (especially if it is large) will last longer.

Casement windows do not have partitions, so when closing the sashes simply close together. With this solution, it is very difficult to obtain a truly hermetically sealed porch at the border of two frames - not every manufacturer manages to create such a proven design. And inexperienced installers can completely nullify all the efforts of the developers.

On the other hand, the absence of an internal divider makes the frame lighter (that is, cheaper) and increases the width of the glazing by several centimeters. If the window opening is small and you want to save a little, you can consider this option.

Glazing features

Since glazing occupies a large area of the window, its characteristics will determine the protective properties of the entire structure. The main role here is played by the number of air chambers between the glasses. It is high time to abandon conventional double glazing under glazing beads - due to their low thermal insulation. So here we will only talk about sealed bags.

Today manufacturers offer the following options:

1. Single-chamber double-glazed windows (2 sheets)

The simplest type of glazing, which is suitable for unheated rooms or southern climates with their mild winters. Such blocks have the lowest heat transfer resistance of 0.32-0.37 m2 °C/W, and already at -10..-15 degrees the glass begins to freeze from the inside. The noise insulation here is also not great (no more than 25 dB of external sounds are cut off), so single-chamber double-glazed windows can only be recommended for residents of quiet areas.

2. Double-glazed windows

A good choice for most private houses and city apartments. The thermal resistance of such structures reaches 0.44-0.58 m2 °C/W, plus they cut off 30-39 dB of external noise. But these indicators largely depend on the width of the gaps between the glasses. If the windows in the apartment overlook a highway or a busy street, it is better that the air gap facing outward is larger than the inner one.

3. Three-chamber double-glazed windows

The warmest and “quiest” windows that perfectly cope with their protective functions even at -30 ° C thanks to a thermal resistance of over 0.65 m2 ° C / W. However, due to the total thickness of the glass, their light transmittance is noticeably reduced. In addition, such a double-glazed window requires a powerful frame, sufficient width of the opening walls, and such a structure weighs a lot, creating an excessive load on the fittings.

Glass coating

Usually people choose transparent double-glazed windows without any special properties. But if necessary, you can order glass with a coating that completely changes their characteristics:

1. Tinting - relevant for shading windows facing south, or if you want to hide from the prying eyes of neighbors from the house opposite.

2. Triplex - such blocks are made using the same technology as automobile ones. Several sheets are glued together with a transparent film, which provides greater strength and safety even if the window is broken. Relevant for residents of lower floors and the private sector.

3. Energy-saving spraying - guarantees maximum thermal insulation, reducing heat loss by up to 10%. True, for this, additional argon is added to the internal chambers of the glass unit. There are also so-called noise-proof windows. Only here it is no longer spraying that is used, but a special system for assembling a double-glazed window from transparent sheets of different thicknesses.

Profile characteristics (for plastic windows)

Hollow plastic profile chambers serve not only to facilitate the design and reduce material consumption. They remove condensation and form air pockets that reduce heat and sound conductivity from the frame. Accordingly, the more cameras inside the selected profile, the warmer and “quieter” the window will be.

1. Three-chamber profiles have a width of 58-62 mm - this is an economical option, designed for effective operation at outdoor temperatures not lower than -15 ° C.

2. 4-5 chambers increase the profile width to 62-74 mm - such windows are suitable for moderate and severe climates.

3. 6-7 cameras (80-90 mm) have only the best frames in the premium segment. But, firstly, they cannot always be found from contractors, and secondly, in terms of their insulating characteristics, they are not so far from standard five-chamber structures.

Be sure to pay attention to the class of windows - it will tell you what thickness of plastic was used in their production:

1. A - the strongest and most durable frames with external wall thicknesses of 2.8 mm and 2.5 mm internal walls.

2. B - the outer plastic walls of this profile have a thickness of 2.5-2.8 mm, the inner ones are 2-2.5.

3. C – this includes structures that do not fall into any of the above classes.

Wood type (for wooden windows)

Manufacturers of wooden frames offer a fairly wide selection of designs from a wide variety of, sometimes very exotic, types of wood.

Most often there are three types of wood on sale:

1. Oak

Oak frames are the most durable, and with proper care their service life reaches 100 years. True, the finished structures are quite heavy and create a high load on the fasteners and hinges. Oak wood is dense and resistant to rot, but pests love it very much, so the raw materials undergo special treatment with chemical compounds in production. So there is no need to talk about 100% environmental friendliness of impregnated lumber.

2. Larch

An ideal option, although slightly less durable than oak. Larch has natural protection from pests, moisture, rot and practically does not require chemical treatment. Another advantage of solid larch is its average weight: the fittings for such windows can be used of a standard type - it will hold up.

3. Pine

The most common, cheap, but short-lived option. Soft wood requires careful handling, as it easily becomes chipped and dented, even during installation. Also, the paintwork on pine will have to be renewed more often, otherwise bluish “dead spots” will begin to appear on the frame. In order to at least slightly extend the service life of such windows, they are impregnated with various compounds during production, tightly clogging the natural pores. But the warm amber color of pine will effectively complement any eco-friendly interior.

Rule #2. Frame

We won’t say that it shouldn’t have distortions, and that’s clear. But pay attention to some nuances:

- Corner connection - tongue-and-groove or dowel. No matter what they tell you, the dovetail connection is the most unreliable.

| The most unreliable “Dovetail” connection!!! |

- The lower parts of the sash and frame must be protected with an aluminum profile.

| The photo shows that aluminum protection is installed |

- The glazing beads must have an overlap on the sash.

- The profile of the frame and sash is rounded for uniform distribution of the paint coating.

- The end part of the frame at the assembly seam should not be flat, but profiled.

- The lower part of the frame must have quarters both outside and inside, for installing a window sill and ebb.

Rule #4. Double-glazed window

Install a regular double-glazed window, energy-saving, with increased security, etc. – the choice is yours. in Moscow recommends energy-saving double-glazed windows, their cost is not much higher than usual, and their quality is much more reliable.

But the thickness of the glass unit must be at least 78mm. It goes without saying that the company from which you are going to order wooden windows is obliged to provide a full package of documents for double-glazed windows: certifications, technical characteristics, compliance with GOST.

The sealing of double-glazed windows must be made with neutral silicone (non-biting) with protection from UV rays.

Rule #5. Accessories

You can save money by choosing the type of wood, it really doesn't matter. But you can’t save on accessories! It must be of high quality and extremely reliable, preferably made in Germany or Austria. No sagging is allowed on the fittings for wooden windows - this factor indicates that it was made in violation of technological processes and is unlikely to be made of strong materials.

The hinges, of course, must be adjustable.

We work only with well-known manufacturers of window fittings and recommend that our clients install fittings with increased burglary protection. This will ensure high security for your home.

No. 6. Ventilation of wooden euro windows

Manufacturers often list their ability to breathe as the main advantages of wooden euro-windows. Of course, natural wood allows air to pass through well, but in the production of windows it is treated with a lot of protective agents, varnishes and primers, and these materials significantly reduce its ability to pass air through. On average, this design passes 3 liters of air per hour, while only one person needs 60 liters per hour. That is why additional window ventilation , which in wooden euro-windows is implemented in one of the following ways :

- micro-slit ventilation ensures a slight opening of the window sash, due to which normal air exchange occurs, but at the same time heat and sound insulation is maintained at a sufficient level;

- The comb allows you to open the window to the required level. This is the simplest and cheapest design possible, which allows you to leave both the smallest gap and a fairly decent one;

- window, well known to us from old windows, can provide an excellent level of ventilation in wooden euro-windows. When it opens, fresh air rushes upward, providing soft and effective ventilation. The only negative is the reduction in the transparent part of the window.

Ventilation valves are not usually used in wooden euro-windows, but to ensure more efficient ventilation, you can use a ventilation valve built into the wall. Its arrangement is more expensive and labor-intensive, but the result is worth it.

Rule #6. Production time

A high-quality wooden window cannot be made in three days. If a window manufacturing company promises you this, run away without looking back. The window is manufactured for at least a month, where you are guaranteed the installation of wooden windows with double-glazed windows in a week, they will obviously put in low-quality defective copies.

And finally, a few additional criteria that cannot be discounted when choosing wooden windows:

- The company must have its own production. This quickly resolves many issues, from price to possible repairs.

- The company's specialists must know everything about glazing. If your questions cause a stupor in a company employee or you receive vague general answers, then you will receive the same window - vague and general.

- The company must have a wide range of window sills, sills, colors, etc. This fact indicates the viability of the company. A portfolio of completed work is also welcome.

- Documentation is required. If they unfoundedly tell you that “we are the best,” this is suspicious. But if you observe diplomas, certificates, awards, read reviews, then this is a completely different matter.

- High-quality wooden windows cannot be cheap! Budget options with a reduced cost mean saving on something significant: either fittings or material. The price should be realistic, but not too low or too high.

- The company's readiness to conclude a contract for the manufacture and installation of wooden windows. If for some reason the company refuses to do this, feel free to go in search of a more qualified manufacturer.

These are, perhaps, all the most important rules for choosing wooden windows. We hope you find them useful.

Krauts works with quality, honesty and transparency. We produce only such windows that we will not be ashamed of even after 30-40 years. Call to get a consultation and check our competence!

No. 5. Wooden euro-window seals

In order for the window to be as airtight as possible and reliably protect it from drafts and other negative influences of the external environment, some of its most critical places need to be sealed. Conscientious manufacturers use sealant in the following places:

the area where the double-glazed window is adjacent to the “profile”, it is often also called the area of glazing beads;- glass joint area;

- the vestibule area, i.e. along the perimeter of the opening sash.

For all these areas, sealant of different widths and section shapes can be used, but this is not as important as what material the sealant is made of.

As a rule, the seal for wooden euro-windows is made from the following materials:

- rubber. The cheapest material, its service life and some performance qualities significantly depend on additives. The best option is a seal made of vulcanized rubber and filled with carbon black. However, all rubber seals have one significant drawback - at low temperatures, elasticity is lost, and over time the material becomes completely deformed;

- EPDM seal boasts an excellent price-quality ratio. The material tolerates temperature changes and other weather vagaries well, does not lose shape over time, is resistant to compression, and can be used for about 20 years;

- silicone seal has record indicators of durability, resistance to sunlight, humidity, chemicals, it does not lose its properties over time, but is very expensive, so it is used extremely rarely;

- PVC seals are made from a mixture of polyvinyl chloride and plasticized nitrile rubbers. The material turns out to be cheap, and that’s where its advantages end. Disadvantages include poor elasticity, rapid wear, and intolerance to low temperatures. Because of these disadvantages, the material is now practically not used, but, nevertheless, not the most conscientious manufacturers continue to use such a sealant.

Some manufacturers and sellers talk about using a rubber-silicone seal , which supposedly has the advantages of both materials. This is nothing more than an advertising gimmick, and most often thermoplastic rubber is hidden under this name.