A locksmith or a seller of locks and hardware often has to deal with philistine myths and legends regarding the subject of our work. And the emergence of such myths and legends in most cases is associated with low literacy of both consumers and many salespeople. A person does not master the topic, and in order to explain some incomprehensible point, he has to use imagination, which often borders on feeblemindedness.

Here we will talk to you about lever locks. Let's look at their structure, and also discuss the legends and absurdities that surround the level castle.

Locks with keys of this type are called level locks, and not level ones, as some call them.

From the word “suvald”, and not from the verb “suvat”. We'll talk about the origin of this unusual name below.

Locks with a lever type mechanism are among the most ancient in the world. In one of the previous materials, where we looked at general information on castles, there was an introductory part about an Egyptian castle that appeared about 4000 years ago. So, despite the fact that the code elements of the Egyptian lock were pins, in terms of its operating principle it was more similar to a lever lock, because the bolt was controlled directly by a key, and not by some drive elements. And the Egyptian castle is the first official mention of castles in the world.

Sometimes lever locks are called safe locks. It is not clear who was the first to use this incorrect definition: cunning sellers who, using the word “safe,” wanted to emphasize the secrecy of the goods being sold, or ordinary people who hoped that the magic word “safe” would elevate their locks to the rank of inaccessible.

A safe lock is called a safe lock because it is intended to be used only on a safe. Installing a safe lock on an apartment door or anywhere else other than a safe door is extremely difficult. But if you get smart and install it, then it’s impossible to use it. A safe lock can only be opened and closed from the outside. Even if some kind of “babyka” gets inside the safe, it should not be able to open the lock from the inside.

Once again, a safe lock is not one that has a specific type of mechanism, but one that is designed to be installed and operated specifically on the safe door. There are safe locks with a lever type mechanism. But not all lever locks are safe. Within the framework of this material, we are talking about apartment locks with a lever-type mechanism, and they are not safe. It is wrong to talk about some kind of safe-keeping in relation to these locks.

We will study a lock with a lever type mechanism in detail. We will look at each component in detail, find out the purpose of each detail, and only after that we will assemble the lever lock and through the transparent cover we will see the principle of operation of the lever lock.

Go!

Frame

Like any other lock, a lever lock has a body. The case, roughly speaking, is a metal box in which all the components of the lock are placed and operate. In most cases, the case is closed with a lid, as in our case.

But there are lever locks in which there is no cover, and the package of code elements is pressed and held in the body by a metal sheet, the base of the door on which the lock is mounted. This occurs most often on safes and metal boxes.

In some cases, the lever lock cover is made of heat-treated steel. Such locks are better able to withstand forceful opening methods, but the cost of a lock with such a cover, of course, increases.

In our case, the lever lock has a non-heat-treated body and cover, which are galvanized.

What are the types

There are 3 types of devices of this type.

- Sheds or sheds are used to restrict access to garages, garden plots, sheds, and gates. This group of devices is the most budget-friendly, widespread and quite simple.

- The overheads are quite easy to install. You just need to provide a hole for the master key. The devices are universal and can be mounted in any convenient place, regardless of the thickness and the material itself.

- Locks with figured cutouts are built into the base and mounted on the end of the doors. Limitation in the thickness of the base - structural strength is reduced at the installation site.

Using useful tips when choosing, you can understand the features and operating principle of this device.

Level lock hasp

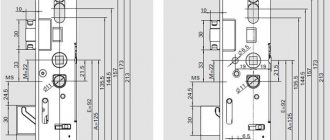

Direct locking of the door is carried out by the lock bolt. In a lever lock, the bolt in most cases looks like this:

The pins, fingers and plates that come out of the body represent the bolt or crossbar if there are several of them. It is the crossbars that secure the door leaf.

In addition to the visible part, the lock in particular and the lever lock have a hidden part of the bolt, which cannot be seen without disassembling the lock. In particular, this is the shank of the bolt. The shank is a steel plate that is fixedly connected to the crossbars.

There are several important locations on the shank:

Tooth comb

Through it, the key of the lever lock moves the bolt.

Literally 8-10 years ago there was such a type of hacking of a lever lock as opening with a roll.

The so-called pre-fabricated “roll” was inserted into the hole of the lever lock. The shape of the package was very similar to the key of a lever lock, only it had no teeth. The roll was made of very hard alloys, hardened steel of certain grades, etc. With the help of a lever that was attached to the handle, the package was rotated with enormous effort in the lever lock, breaking the levers and forcibly moving the lock bolt. I moved it just through the toothed comb. The hacking method was very fast and relatively quiet.

But about ten years ago, manufacturers introduced an elegant solution into their locks, which provided 100% protection against opening the lever lock with a roll. Artificially weakened toothed comb. The lock we have shown shows that the lock tooth has been artificially weakened by a drilled hole.

Now, when you try to open such a lock with a roll, the weakened tooth will break and will not let the intruder inside. True, after this the lock will no longer open with the original key, but that’s a different question. He coped with his main task - he did not let the swindler inside. With the introduction of an artificially weakened toothed comb, the method of opening a lever lock with a roll disappeared completely. Ten years ago this was often talked about, and law enforcement officers often greeted hacked lever locks with a roll. Today this no longer occurs.

We've moved away from the topic a little, let's continue to look at the lock bolt.

Bolt shank stand

In addition to the toothed comb, the bolt shank has such an important detail as the bolt shank stand. We especially draw your attention to this detail and repeat its name: the bolt shank stand. In our case, here it is:

The bolt shank post is the part through which the lock bolt is locked. If, with a completely closed lock, you press on the bolts, trying to push them inside with your hand, then it is the post that will prevent the bolt from sliding, it will rest against the code elements.

There is a method for opening lever locks, such as removing the bolt shank post by drilling. If you surf the Internet, you can even dig up some templates that show the exact location of the stand on a closed lock, if you center the template along the keyhole.

Drilling out the rack, both previously and now, is a very popular method of opening lever locks in the criminal environment. Therefore, many manufacturers by default make the stand from hard alloys (for example, hardened steel), or introduce something hard into its body, such as a steel ball. You can even additionally protect this important element of the lever lock with an armor plate.

Some individuals, having gathered “tops” from the Internet about drilling, begin to convince others (and us sellers, after all, we are the most stupid, we don’t know anything about our product, we’re just waiting for someone to come and tell us) that drilling Locks are completely useless products, since they are easily, quickly and relatively quietly drilled. In this case, we usually ask - what and when was the last time a person drilled and held a power tool in his hands? In half the cases, it turns out that the sofa opener standing in front of you doesn’t have a drill or a “shurik” at all.

Our company’s specialists have repeatedly had to use the method of drilling out the pillar in the event of an emergency opening of a door, in the event of the loss of keys or in the event of a broken lock. We confidently assert that opening a lock using the pinhole drilling method is a hemorrhoidal and difficult task. When drilling out the bolt shank post, you can get stuck for a very long time - you can spend up to two hours poking around on a call. At the same time, drilling out the shank stand is a difficult to predict process. When drilling, the lock can become very clogged; chips can form at the drilling site, which will continue to lock the bolt; in the end, the bolt can become warped, because in some models of locks the movement of the bolt is positioned along the rack. There were cases when a drill broke in a drilled hole; those who drilled two objects superimposed on each other in a horizontal plane know that this happens. And now it will take some time to crumble the broken drill and pull it out of the hole, and only then continue drilling.

In short, the process is incredibly hemorrhoidal. Of course, with experience and with an increase in the number of drilled locks, the time for this action decreases. But those people who professionally provide services for emergency opening of locks and doors have moved away from drilling towards other types of opening, including because drilling is long, difficult and poorly predictable.

The bolt shank post is in most cases made in the form of a square. But there are a wide variety of forms of racks. For example, in some domestic locks the post may be round in cross-section - this shape simplifies the opening of the lock using intelligent methods, using master keys.

In most cases, the shank of the bolt has an anti-pick design. In our case, we see that the rack has an anti-pick groove. We'll see how it works further.

On heavy-duty locks, where there are exits along the vertical drive (for rods), the bolt shank often has a detail for controlling the exits for the rods. This is not the case in our example.

Well, now about the code elements!

Main or auxiliary?

Many people tend to buy a lock for a metal door as an additional one. A lever lock can be perfect for this role. Good to know:

- The main lock is the one to which the handle is attached. Most often it comes with a latch.

- The main lock is located at the level of the handle, the additional one is located above it.

If, for example, you use a handle in the form of a staple rather than a push handle, then you can choose a lock without a latch.

Levers

The code elements of lever locks are plates of different shapes and are called levers.

One theory states that the word "lever" comes from the German word Zuhaltung, which translates to blocking or locking. And the code element itself in German sounds like Zuhalt. In our country, this word has been somewhat transformed and turned into the word “tsugal”, which is now extremely rare.

There are quite a large number of types of levers. They may differ from each other in shape, material used, method of movement, thickness, dimensions, method of anti-corrosion treatment, etc. But all levers now and previously have a very similar structure, and also have the same functions.

Roughly speaking, a lever is a metal plate of a certain shape with some holes. Let's pay attention to the code labyrinth of the lever.

It is here that the bolt shank strut walks and dances as it moves. We will see this with you later. The code labyrinth is formed by code protrusions.

The post of the bolt shank rests against them when they try to open the lock with the wrong key, when they hammer in the bolt from the end. It is against the code protrusions of the lever that the post of the bolt shank rubs when they try to open the lock with master keys.

The distance between the code protrusions is called the code groove. It can also be called a “pass-through groove”.

The code groove is the distance or gap between the edges of the tops of the code lugs. It is through the code groove that the post passes, and with it the bolt, when the lock is opened or closed with the correct key.

The more accurate the lock, the smaller the code groove of this lock, the more difficult it is to open intelligently. In a high-quality lever lock, the code groove is 0.4 - 0.6 millimeters larger than the thickness of the bolt shank post.

The code groove is extremely rarely made with a smaller gap relative to the stand. Because after some time, the key with which you open or close the lock will wear out a little. If the gap between the stand and the code protrusions is very tiny, then the original keys will stop working in the lock very, very soon, say, after 5,000 opening and closing cycles. But for the average family this is very, very little. In other words, the size of the gap determines not only the secrecy of the lever lock, but also, to some extent, the service life.

Our company’s specialists quite often have to go to emergency openings of safes when all the keys are lost. And quite often you come across Soviet-era safes with old ugly lever locks.

These are one and a half meter supposedly fireproof cabinets that weigh three hundred kilograms. Level locks on these safes worked for 50-60 years (safes began to be produced in the post-war period). And they will work for a huge number of years.

Why? Just because the code groove is several millimeters larger in comparison with the thickness of the rack.

Yes, such a lock can last 200 years. But what is its disadvantage? The fact is that without damage, with very little experience and some tools, it can be opened in seconds in the literal sense of the word. That is, due to the huge gap, the lock has very low protection against even the simplest intelligent types of opening. To be fair, it should be noted that such ugly locks are no longer produced today.

But let's return to our levers.

As you can see, the code protrusions can contain so-called “anti-pick grooves”. They represent some kind of recess or depression.

The counter-pick groove is present on the bolt shank post.

They work or catch each other in the following way.

As mentioned earlier, if you try to press the bolt into the lock body, it will rest just against the code protrusions through the post. That is, friction forces will arise between the bolt shank stand and the code protrusions of the levers. When performing an intelligent opening, the task is to align the lever so that the passage groove stands exactly opposite the rack, that is, so that the code protrusions stop blocking the bolt. And for this we should raise the lever. But when lifting the lever, at some point it will happen when the groove of the bolt shank post falls into the anti-pick groove of the code protrusion and further movement of the lever will thereby be blocked.

This is a fairly elegant and low-cost solution.

Today, anti-pick grooves of this type are found on most lever locks of domestic and foreign production.

According to the method of movement, there are two types of levers, the so-called swinging type...

...and translational plane-parallel type.

In our case, the levers are of the second type. Under the action of the key, it moves along the housing racks within the groove holes.

In most cases, levers are loaded with spring force. The spring is needed to return the lever to its original position, resetting the typed code.

In most modern locks, each lever has its own separate spring. Sometimes a wire spring is used, as in our case. That is, the spring is a hardened steel wire bent into a certain shape. Some locks use coil springs that are inserted into a separate unit.

A small percentage of locks used and still use so-called “band” springs, which simultaneously load all existing levers. From the point of view of operation, the shape of the lever does not matter much, as long as it is correctly designed from a mechanical point of view and suitable materials are used in its manufacture.

And the variety of shapes of lever springs is more likely related to the production characteristics of a particular manufacturer and the design features of a particular model.

Well, let’s consider, perhaps, the last important location of the code element - the key window and the working edge. Each of you probably already understood that the movement of the lever is carried out by a key. So, the place where the key touches when turning on the lever is called the “working edge”.

And that space, near the lever, where the key turns, is called the “key window”.

There is nothing interesting in the working edge of the lever. Its shape depends on the design features of a particular model.

But the key window comes in two types: open and closed.

On the levers of the lock, which we are now examining, there is an open key window. And here in this image:

key window is closed. And in this case, pay attention that the key works with both bits when turning.

OK it's all over Now. The most complex element of the level lock is considered.

Just a little bit left and we'll start assembling it!

How to choose

When purchasing, the consumer himself determines the size, body and, in particular, the mounting strip, key, all this is at his discretion.

What to pay attention to:

- Safety class must be at least 3;

- Quality of crossbars;

- Intrusion protection;

- Design features of the new lock during installation;

- Key quality;

- Equipment.

To avoid mistakes when choosing, it is necessary to take into account some circumstances. There is no doubt that when repairing it is better to take a device from a good manufacturer. This is a guarantee of quality, good construction materials, plus, as a result, protection against burglary. When purchasing, you need to pay attention to the presence of an additional lever, which allows you to change master keys over time without replacing the lock.

To ensure greater reliability when building a house and installing a lock, you should pay attention to locking devices with keys that have bits on both sides. It is difficult to pick these locks even with a master key.

Manufacturers of high-quality locking devices of this type are brands of Russian, Italian, English and Turkish production. These are: “Prosam”, “Kerberos”, “Gerion”, “Mettem”. Among foreign ones are “Securemme”, “Abloy”, “Mul-T-Lock”, “Cisa”, “Kale”, “Mottura.

Level lock key

The last component of the lever lock that we need to consider is, of course, the key.

The lever lock has a characteristic key. Some call it a “safe”, some call it a “butterfly”. Neither one nor the other is correct, but to hell with it.

The key of a lever lock is in most cases made of brass, much less often of steel or aluminum alloys.

The key of a lever lock, like any other, has a head, or head, which we hold when we open the lock with it. Often the name of the castle or manufacturer is located here, sometimes the logo is also located.

In some cases, the head shape is patented and used by some manufacturer under a patent. This means that other lock manufacturers do not have the right to use keys with the same head shape for their locks.

The lever wrench has a fairly long shaft.

It is needed not only to deliver the working part to the lock body (after all, the levers are in the body, and the body itself is hidden in the door - you need to somehow reach the code mechanism...), but also to position the key in the keyhole . The height of the key secret is measured and designed in the lever lock precisely from the center of the rod, which in turn is positioned along the keyhole.

The most important part of the lever wrench, its working part, is the bits.

There are single-bit and double-bit keys. The bit of the lever key contains the drive tooth, or the place by which the bolt moves. In our example, the drive tooth is contained in the middle of the key bit. And of course, the drive tooth is contained on both bits - the bolt must be moved with each half-turn.

In addition to the drive tooth, the key bit contains secretion heights. Each height of the secret interacts in the lock with one specific lever, raising it to the required height at each half-turn.

The lock we are considering has 8 code elements and eight levers. They are located on opposite sides of the bolt shank. Therefore, our lever key bit has the following structure relative to the mechanism.

The second beard is similar in structure to the first beard, the only difference being that the height of the secretions is slightly different.

The height of the secret, as you already understood, determines how high the lever rises when you turn the key. Whether the bolt will move depends on the correspondence of the height of the secret on the key to the specific passage groove in the code labyrinth of the lever.

Regarding the heights of the key secret, about the correspondence of the code protrusions of the lever, we will most likely talk in subsequent materials, where we will talk about how the number of code combinations for a particular lock model is set and what it all depends on.

This material is already overloaded with information, so let’s not insert formulas into it.

On one of the key bits there is a guide protrusion or simply a guide. There is a corresponding cut under it in the keyhole of the castle.

The guide is designed to correctly orient the key inside the lever lock body. The guide helps us insert the key into the lock with the correct side, and also prevents it from jumping out when inserted. When we insert the lever wrench into the well, we insert it all the way - it is the guide that rests against the body.

The guide can look not only like a protrusion, but also like a recess or groove in the bit of a lever wrench.

What to look for when choosing

The main feature that you need to pay attention to when choosing is the material from which the device is made, as well as other parameters:

- Frame. The side of the device that is directly adjacent to the door must be made of hardened steel. In addition, a special armored lining is used. It is installed to make it difficult to drill out the shank. Even if the burglar has a scheme, opening it due to the armored lining makes it very difficult, almost impossible.

- Levers. The greater their number, the more difficult it is to open such a device. In reliable devices, 6 to 8 levers are installed. Their number can be easily calculated by the notches on the key bits. Each notch corresponds to its own lever.

- Crossbars. They are made of strong steel, inside which a special armored rod is installed, making it difficult to cut. The crossbar cover is made of hardened steel to make it difficult to physically knock down the door. The more steel parts there are in the product, the more difficult it is to open the door. Therefore, despite the cost, it makes no sense to save on the lock.

- Mechanism protective curtains. This is a fairly recent invention in the lock industry. If the key is incorrect, the protective curtain will lower when turning and clamp the master key inside, preventing it from coming out in either direction.

Assembling a level lock

Now let's stuff everything we discussed above into the case and try to assemble something similar to a lever lock.

In our case, the code mechanism of the lever lock contains eight levers. Four are located on one side of the bolt shank, four on the other.

Sometimes the security mechanism of a lever lock is called a “lever package”. Well, because the levers are laid out each strictly in a certain sequence relative to the given code on the key.

In order to reduce friction forces, in order to make the operation of the lever lock more comfortable and the mechanism more durable, the levers in the package are usually separated in some way. In our case, the levers are separated from each other by washers and metal spacers. Some locks have plastic gaskets. Well, in most castles the levers are separated from each other by bulges, bulges on the surface of the lever itself.

In the lock we are considering, the lever package is separated by the bolt shank.

They also say that the lever lock package is 4+4. This means that four levers in the mechanism are located before the bolt shank, and four - after.

Description of the device and principle of operation

These devices are anti-vandal. If someone plans to damage the lock, they will not be able to do so, since the entry of distracted objects does not result in a breakdown of the structural system. Moreover, if the lever block is located above the key, then debris does not affect its operation at all. The same cannot be said about the cylinder mechanism, which can be damaged even by a match. In addition, in order to do their dirty deed in a house with a cylinder security system, approaching the bolt, burglars only need to remove the cylinder. While the level structure is highly resistant to mechanical damage , that is, it even resists drilling and sawing.

How does the mechanism work? The operating principle of the device is quite simple. There are levers inside the castle; they can be seen in the photo. They interact with another element - the stand, which is responsible for the movement of the mechanism's crossbars. The levers, taking the closed position, ensure reliable blocking of the rack. The key is equipped with special grooves that come into contact with the grooves of the levers. When it turns, they rise and take a strictly defined position. Only after this the levers release the rack, which ensures the movement of the crossbars. This is how the lever system works.

The higher the class, the greater the reliability

Requirements for the technical features of lever locks are fixed at the level of the interstate standard, in force since January 1, 2013, GOST 5089-2011. This important document was signed by the highest construction authorities in nine countries. There are 4 security classes of locks. The following characteristics influence whether a product belongs to one or another class:

- How reliably and without failures does the lock work?

- What is its secrecy?

- How the mechanism can resist unauthorized opening.

To buy a lever lock for a metal door that meets your wishes, it is useful to familiarize yourself with the following information:

- First (lowest) class. This type of lock is chosen for installation in interior doors, as well as for utility rooms.

- Second (normal security properties). Suitable for apartments and offices, the protection of which does not have any special requirements.

- Third (increased properties). Locks of this class are installed on metal entrance doors, as well as on reinforced doors of premises that are rented out for security.

- Fourth (high properties). Such locks guarantee maximum security. They are installed to ensure that special security requirements are met. Often used for reinforced metal entrance doors of residential and non-residential premises, which are accepted for security and insured.

In addition to the above examples of use, locks of classes 3 and 4 are required to be installed on particularly dangerous objects (where there is a risk of terrorist actions), as well as at the entrance to premises with important communications (for example, an elevator shaft or the technical floor of a building).

creates reliable multi-point locks. The locking mechanism activates the vertical rods. Deviators, auxiliary devices for locking, can be connected to them, among other things.