Locks for the front door play an important role in its design, since the safety of the owner of the space being used and his family depends on the quality, strength and level of reliability of these mechanisms. There are many options for locking elements on the market, which differ in the level of reliability, workmanship, as well as the presence of secrets, which affects safety during operation. To choose the right product, you need to study the structure of door locks.

Lock on the front door

Types of locks by installation method

Consumers can choose one of three basic options for installing a locking element for their entrance doors:

- Built-in lock - installed at the production stage of the door leaf, cannot be removed, repaired or diagnosed without removing steel sheets and armor plates.

It is considered one of the most reliable mechanisms, since conductors are used during installation, and the lock itself is supplied as part of a batch, verified by a supplier, on the basis of a long-term contract with the factory.

Built-in lock

- A mortise lock is a mechanism that is built into door panels using a special cutting tool. The crossbar, cylinder or level plates are inserted into the body of the door leaf after cutting through the metal, after which they are fixed in such a way that there are no removable parts left on the surface of the product that interfere with the normal operation of the door.

Mortise lock

- A rim lock is the simplest design that can be installed at any stage of operation of the front door. It is easy to install, but does not meet the safety requirements of the premises owner.

Rim lock

The best option is to purchase a complete door frame with frame, hinges and locks, since such products are installed simultaneously at the factory and meet all the requirements for reliability, durability and increased safety.

Types of door locks

All locking devices include:

- fixing device;

- a special locking box made of metal;

- valve;

- key for moving the bolt.

Its purpose depends on the design of the door lock. The method of attaching locking mechanisms to the door device divides them into:

- mortise, they are installed inside;

- invoices are fixed on the inside of the doors.

It is necessary to remember that door locks and mortise locks are made for “left” and “right” doors; it is not recommended to turn them over when installing them. This may contribute to their abnormal functioning.

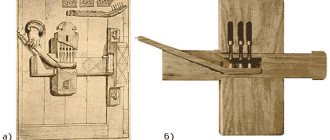

Mortise lock device.

There are universal door locks in which it is possible to switch from the left to the right door, and vice versa. This can be done by rearranging the deadbolt or latch. This operation is carried out without disassembling the entire lock.

A curious type of overhead door lock is the beam lock. It has two bolts. They move horizontally across the entire width of the door. This lock also protects the door from the side where the hinges are located.

The mortise type of door locks are more difficult to install, hence there is a high probability of a not particularly high-quality installation. The place of the door leaf where they are inserted is thoroughly weakened. And its closer location to the outer surface makes the doors more accessible to a burglar. We must pay tribute to mortise locks, which are less visible and more convenient to use.

Overhead door locks do not have the same disadvantages as mortise door locks. They are easier to install; they do not reduce the strength at the installation sites. Overhead locks work great on doors that open inward. This type of door lock perfectly protects against attacks from the outside, but it is not a hindrance to a burglar inside the room. Overhead locks have a drawback - they change the appearance of the doors for the worse.

Door lock diagram.

Nowadays they make door locks with multiple deadbolts. They are called multi-point locks. A reliable locking system is one whose bolts (crossbars) are distributed along the longest possible length of the door end.

The most well-known door lock mechanism is the mortise lock. It includes:

- frame;

- front plank part;

- drive lever;

- main action deadbolt;

- bolt with a special latch.

Regardless of what kind of fastening to the doors, the adaptation of the current locking mechanisms contains two components:

- secret, with its help the key to the lock is recognized;

- the actuator performs the locking.

Device of rim locks

Currently, such locking devices are practically not used for entrance doors. At the same time, in the country or in technical rooms, when using wooden or panel door panels, overhead structures are purchased due to ease of installation and low retail cost. The design of the rim lock includes the following parts:

- A basic stationary element that is fixed to the door leaf. On the interior side of the lock there is a rotary handle, and on the exterior there is a key cylinder.

- A counter hole with a steel plate on the frame of the door leaf, into which the lock tongue goes when closing the door with a key.

The device of the overhead locking element

When installing a rim lock, it is important to take into account the alignment of the locking bolt and the counter hole, since, with the slightest deviation, the tongue will not fall into the space intended for it, which causes difficulties with locking.

When should you disassemble the lock?

The structure of an interior door lock with a latch (photo shown below) should be known to those craftsmen who want to repair such a mechanism.

This is a fairly simple job, but it requires care. It is necessary to disassemble the lock, based on knowledge of its structure, in the following cases:

- The mechanism jams. Sometimes, due to shrinkage of the door leaf, certain problems arise when closing or opening the door. The lock will also need to be lubricated periodically to avoid jamming. In this case, it is also necessary to know the structure of the interior door lock with a latch.

- Breaking. Over time, the parts of the mechanism wear out under the influence of friction and other unfavorable factors. Even a new lock can quickly break if handled roughly. A breakdown requires disassembling the lock and replacing the failed part.

- Replacing the lock. This may need to be done if the room has been renovated, and the old handle does not harmonize with the interior. It may also be necessary to replace the lock if you need to install a modern mechanism. If it breaks, it will also need to be replaced.

- Rearrangement. If a new interior door was installed, you can install the old lock on it.

- Lost key. If the system is complex, you need to install a new lock. To do this, the old structure is dismantled. Otherwise, it will be impossible to get into the room.

In all of the above cases, you need to know how such a system works. Otherwise, you may damage or break the existing lock.

Installation of mortise and built-in locks

Such mechanisms are most often used to complete entrance doors in factories. The products are distinguished by the presence of a rotary lever, which drives a spring mechanism and an opening tongue. Even if the lock is not locked, the door is securely fixed in the narthex. Design features of mortise or built-in locks:

- Each product is equipped with a handle.

- All locks are equipped with a rotary, lever or other locking mechanism.

- To install the product, marking of the canvas from the end, facade and interior parts of the canvas is required.

Locking mechanism handle

- During installation, it is necessary to cut out part of the frame, as well as the leaf itself from the inner and outer panels of the door.

- All built-in locks are equipped with decorative overlays that disguise the installation location.

- When you turn the key, the locking steel tubular bolts are set in motion, which reliably block the door not only at the locations of the mechanism, but also along the entire perimeter of the door leaf.

- Unlike overhead products, they are characterized by increased reliability and burglary resistance.

Burglar-resistant mechanism

High-quality mortise or built-in locks are locked with keys, the bit of which has many ledges formed by laser ports. This greatly complicates the work of attackers, since it is almost impossible to find a duplicate. The most popular and reliable products are those made in Israel, Germany and America.

How to disassemble a lock with a handle or latch?

The mechanism with a handle has a relatively simple structure. This system is most often chosen for inserting locks into interior doors. There may be a non-locking latch or a more complex mechanism. A key may even be used here.

To repair the fittings, you must first remove the handle. To do this, you need to unscrew the screw that is located on the bottom or side of the handle. To do this, use a screwdriver. In some models of handles you will have to use a hex key.

Next, you can dismantle the cover that covers the fasteners. The screws need to be unscrewed with a screwdriver. If you have a screwdriver on hand, you can use it. The handle is removed along with the axial pin. This will allow you to gain access to the lock mechanism.

You need to unscrew the plate that is located at the end. It is held in place by 2 to 4 screws. This will allow you to remove the tongue and all other parts of the mechanism. They are simply pushed inward slightly. The inside of the mechanism can be reached through the hole where the handle was previously mounted.

The interior door lock device may have a latch. The operating principle of this design is in many ways similar to a mechanism with a handle. First, remove the part from the front side of the door. The screw is unscrewed from the side of the plug. The mechanism must be carefully removed, including from the opposite side.

You also need to unscrew the end plate and the internal structure is pushed through the hole from the handle.

Entrance door lock design

Each locking device, regardless of its type and installation method, consists of the following set of important parts:

- The crossbar is the main element in which the picking mechanism and a movable tongue with a spring drive are located.

Rigel

- The cylinder is a steel element with a hole for a key, which has different grooves that correspond to the counter grooves on the removable product for unlocking the lock.

It is inserted perpendicular to the door leaf, equipped with a rotating mechanism and a system of hooks to set the tongue in motion.

Larva

- The tongue is a flat steel element of increased strength that moves when a key or handle is turned, ensuring the door is locked when it penetrates through a hole in the body of the steel frame.

Tongue

- A push or turn handle is a lever connected to a rod that transmits force to the locking mechanism when opening.

- A strike plate with a hole - the part is installed on the vertical impost of the door frame, designed for convenient penetration of the tongue when locking the door.

Striker

- Masking plate - installed at the final stage of lock installation, hides all defects and parts of the mechanism. As a rule, it is a paired design, with the exception of cases where a one-sided lock is used - a rotary latch on the interior side.

Decorative plate

Lock production technologies have long stepped forward, and today it is very difficult for attackers to open even a simple lock with a mortise mechanism, since most keys have a laser cut, which is characterized by maximum accuracy, and without special expensive equipment, it is not possible to make a master key.

Laser cut key

Varieties

The design of the interior door lock may differ slightly depending on the type of product. There are the following types of interior locks:

- Fall ones. The tongue in the design that locks the door has a beveled shape. It fits into a recess on the opposite side. The tongue is mounted on a spring, which allows it to be retracted into the mounting hole when the door is closed. Once in the recess, it is pulled forward. To open the door with this mechanism, you will need to turn or press the handle. This is a fairly common lock device.

- Roller. This type of structure is used for interior doors with spring hinges. Here, instead of a tongue, a roller is installed. It is also mounted on a spring. When the sash is closed, it fits into the corresponding recess. This is how the door is fixed. If you pull the handle, the roller will spin and pop out of the recess. This way you can open the door.

- Magnetic. This is a simple design. The interior door lock with a magnetic latch allows this type to be used, for example, in a nursery. There is a magnet on one side of the door and a metal plate on the door frame. When closing they are attracted. To open the door, you need to lightly pull the handle. The magnet can act as a tongue. In this case, it is movable, which makes the design look like a halyard lock.

- With lock. In this case, using the latch can close the door. It cannot be opened from the opposite side. An interior door lock with a lock is suitable for bathrooms and toilets. The latch can be located on the handle or under it. It can also be installed in a separate outlet.

Classification of locks

One of the main parts of any lock is a cylinder with a rotating mechanism, which locks the tongue in the bolt and prevents the door from opening freely.

Such an element is called a secret lock and is unique, since no company in the world produces two identical mechanisms using a complex system of random coding. All secrets used in modern locking mechanisms are divided into the following basic types:

- Cylinder or rotary locks. They are a steel cylinder with an internal groove, along the edges of which pins on miniature springs are arranged. In the resting position, all parts are at the same distance from each other.

When the key is inserted, each of the pins follows the shape of the groove on the bit, which ensures the unlocking of the rotary mechanism.

Cylinder lock

- Lever locks are more complex mechanisms, consisting of many steel plates made of high-strength steel, tightly laid in relation to each other. The flat key has the shape of a butterfly with multi-stage grooved side edges.

When installing the call into the well and turning it, each lever is set in motion, turning at a certain angle until it reaches the desired position.

Levers

- Crossbar locks - the name of the mechanism already explains the principle of their operation - from the inside, such a lock is opened by pressing the rod locking bolts-latches.

Deadbolt key

From the front plane of the door, the spring mechanism is set in motion when the key is inserted through the hole with spring pins. The lever mechanism with hooks ensures freedom of movement of the crossbars, which facilitates the opening of the door.

Deadbolt lock

- Disc locks are less popular locks, the design of which is based on flat metal discs. The key is a rod element with several grooves at the very end.

Disc key

When the key is inserted into the hole and turned, each disk moves a certain number of degrees until it reaches the coding pattern, which opens the tongue of the locking device.

Disc lock

- Cross-shaped locks were widely used in Soviet times. Another name for them is “garage”. The bolt moves away in the body of the mortise structure when a key is installed in it and then turned. The shape of the locking element on the cut is an equilateral cross.

Such locks are considered one of the most unsafe, since an experienced burglar can open them with a regular screwdriver.

Cross lock

Some modern metal entrance doors from the higher price category are equipped with several locks at once, as well as combined locking devices. Such mechanisms are simultaneously supplied with two larvae, each of which has its own key.

Combination lock

Most often, the lever mechanism locks the blade using multi-directional crossbars, after which the second lock reliably blocks the key hole in the design of the first mechanism. It is almost impossible to open such locks without destroying the structure or the original key.

Secrecy mechanism

A lock is, first of all, a security mechanism that provides it with certain security properties or protective characteristics. The security mechanism is perhaps the most important thing in the design of the lock.

Within the framework of this material, we will not be able to talk in detail about each secrecy mechanism, since each of them deserves separate material. However, we will list the main ones that literally each of us has encountered.

Cylinder security mechanism

An English lock is a locking device that has a small key. It was developed by an English “techie” in the 19th century, so since then it has often been called “English”.

The familiar “lock cylinder”, which is familiar to everyone, is more correctly called a “cylinder security mechanism”. There are a wide variety of manufacturers, from cheap disposable and stupid ones to expensive highly protected ones of high European quality.

The advantages of the cylinder security mechanism include a small, convenient key and ease of control of the lock in general. The disadvantages are low resistance to vandalism and the need for protection from forceful opening methods, which we talked about about armored plates and armored linings here

If you are interested in how to choose a cylinder to replace the old one and what parameters you need to know for this, you can see this in the short video below:

Level secrecy mechanism

The second type of mechanism, often found on entrance doors and safes, is a lever mechanism, characterized by a large, long “butterfly key”.

A good lever lock is often cheaper than a good cylinder lock because it is easier to manufacture. And at the same time, the leveler often has greater resistance to vandalism.

But the huge disadvantage of a lever lock, which puts many people off, is a large, inconvenient key and not the most convenient way to control (not everyone has a turntable, and it turns only in a certain state of the lock).

Disc security mechanism

Another common type of lock security mechanism is the disc security mechanism.

It is characterized by the presence of a small semicircular key (or rectangular, if it is double-sided), with the corners for cutting secrets located on it, as well as the inability to remove the key without returning to the “original” position.

We are most often accustomed to seeing a disc security mechanism on padlocks. A little earlier, it was also found in apartment locks, for example, in overhead clickers and in mortise push-button locks.

I would like to emphasize that one cannot claim the advantages of a lock with one mechanism or another. Like any medal, there are “two sides” here too.

Any of the listed security mechanisms can be manufactured with high quality and have the highest security properties. Just like any of them can have disgusting characteristics, break quickly and open with “two hooks” in seconds.

Design features of popular locks used on entrance doors

Each of the types of locking devices listed above differs in its internal structure and operating principle. The most commonly used locking devices consist of the following structural elements:

- Lever mechanisms are the most reliable mechanisms, often installed even in burglar-proof safes.

- The main elements of this lock are steel plates - levers, the edges of which are processed to the shape of the key bit.

- Springs connecting all levers into a single structure.

- The rod is a flat tongue that is located inside the crossbar and is set in motion at a certain location of each lever. The coordinates of the location of the plates are a code algorithm for unlocking the lock.

Lever mechanism rod

- Holes for the key, made in the form of a wide flat slit. You can insert almost any key with a similar butterfly bit shape into the cylinder, but it is impossible to turn the product without each groove matching the levers.

Level lock well

- Cylinder or rotary locking mechanisms are characterized by ease of operation and relatively low retail cost. The design is based on the following elements:

- Steel cylinder.

Cylinder cylinder

- A rotating tongue with a hook that drives the bolt inside the bolt.

- Spring pins designed to change position when installing a key.

Cylinder locking pins

- Reciprocal grooves on the inner surface of the cylinder, when the spring pins coincide with which, ensure rotation of the lock and movement of the tongue.

- As a rule, such locks come with a through hole or with a one-sided key slot. In such cases, on the interior side, a knob is installed - a stationary key, which is driven by the fingers.

Vorotok

- When making a duplicate of such keys, you should save one original made at the factory in advance. The beard must contain the exact number of grooves of the same size as the product supplied with the cylinder.

Rotary lock key bit

- Combination locks - often installed in hotels, offices or entrances. Consist of the following elements:

- A set of mechanical buttons, or an electronic display with sensors.

- A system of hooks and springs that drives the deadbolt bolt when the correct combination is dialed.

Internal latch

- There is a latch on the reverse side of the lock for the possibility of reprogramming, if necessary, replacing the secret combination.

Mechanical coding device

Most locks are non-volatile. However, code devices with an electronic display require the installation of batteries, usually AA batteries. When using such a lock, you should replace the power supply sources in time, or choose combined designs that can also be opened using a standard key.

Electronic code device

How does the cylinder system work?

A similar design, similar to others, can be:

- mortise;

- overhead.

Door latch diagram.

The secret mechanism is hidden in the cylinder installed in the center of the lock. This system has several subtypes:

- unilateral;

- bilateral.

One-way system can be opened with a key, and only from a specific side, the other is equipped with two cylinders. This lock cannot be opened from the inside without a key.

Locking a building with a cylindrical device requires several specific steps.

First, the key must be inserted into a groove that has a limited protrusion, which is located in the cylinder.

One of the cylinder parts is always free to rotate if the inserted key fits. The body of such a design is always motionless. The actuator is the pins, and it is them that the key begins to lift. Due to the position of the pins, the operation of the device is regulated. For the mechanism to open, all encryption details must match.

Briefly about the main thing

Modern entrance doors are equipped with built-in or mortise locks. The most reliable are rotor or lever type designs from well-known manufacturers. When choosing a lock, you need to pay attention to the number of locking bolts - metal rods that block the door leaf around the entire perimeter. When purchasing battery-powered combination locks, you should additionally provide for the possibility of opening it mechanically, in case the batteries are discharged.

Reviews

According to those users who prefer overhead door lock models, the most reliable are electrical devices.

As for the manufacturer, Barrier and Mottura are in demand among domestic models.

Locks made in China are cheaper, but no less reliable. The main thing is that the price is not too low - this indicates poor quality of the metal.

Popular models are those whose body is made of cast iron. They are not afraid of mechanical damage, have increased strength, but the metal can burst from severe frosts.

Weak spots in cylinders

If it is almost impossible to open a cylinder lock with a non-original key, then such devices are not sufficiently protected from vandals; they can be drilled or knocked out. Protective elements help to resist, these are armored linings made of especially strong alloys. In order for this part to actually protect the larva from vandalism, it must be placed correctly. It is installed inside the door leaf, and not on top of metal or decorative trim. Armored linings must be installed on all cylinder locks, and especially where there is a high probability of breaking them by force.

How does a cylinder work?

There is a key passage in the rotor; a key moves along it, which changes the position of the pins. These elements are arranged in a secret combination that matches the pattern on the key. Ultimately, the pins, under the influence of the original key, are installed in one line. The new position of these elements allows the rotor and cam to turn. When the key is removed from the key hole, the locking pins, under the influence of springs, push the codes back into the rotor element, and locking occurs.

When someone else's key is taken, the code pattern of which does not match the secret combination of the cylinder, the pins cannot line up in the correct position, some will remain in the body, others in the rotor. In this case, the rotor will not turn. The more complex the combination, the more precisely all the elements are adjusted, the more difficult it is to open the cylinder with a non-original key.

Recommendations for use

If you want to ensure the most reliable and uninterrupted operation of a mortise lock, you need to know the features of its operation and the rules for caring for the mechanism. There is nothing complicated here, just follow the following recommendations:

- Regular lubrication. This must be done periodically, it all depends on the intensity of use of the lock. Experts recommend lubricating the mechanism 1-2 times a year. For cylinder locks, you can use oil or aerosol mixtures. It is enough to lubricate the lock bolt and close/open it several times. Graphite powder is blown into the lever locks, which can be purchased ready-made or made from the lead of a simple pencil. Some models of mortise locks have holes for lubrication.

Cylinder locks are lubricated with oil or special aerosols

- Cleaning the key. The main source that introduces dirt into the lock mechanism is the key. To prevent this, it must be cleaned regularly.

- Periodic cleaning of the lock. If the mechanism begins to turn difficult, then most likely it is very dirty. For cleaning, use a special product that is used to treat the keyhole. After 5–7 minutes, the dirt present in the larva will dissolve, and it can be removed by inserting and pulling out the key several times. You can't turn it around . Taking out the key each time, wipe the dirt off it until the lock is completely clean.

- If you do not have the skills to assemble/disassemble a mortise lock, then if problems arise, it is better to entrust this process to an experienced craftsman.

If you operate a mortise lock, adhering to the described recommendations, then it will fulfill its purpose not only during the warranty period, but also much longer.

Video: lubricating the lock

What to do if the key is stolen or lost

Although it is easy to change the cylinder lock cylinder if the keys are lost, you should not do this right away.

Many modern devices have a self-transcoding function. What does it mean? The cylinder is sold complete with a master key. If you lose your keys, you must insert the master key and turn it; recoding will occur, and it will be impossible to open the lock with the old keys. And you will need to make new duplicates of the master key. If the lock does not have a recoding function, it can be easily ordered at a service workshop by presenting the original key. Share: All reviews To category