Locking mechanisms of this group are considered reliable, and therefore are recommended (in combination with cylinder models) for installation on entrance doors. The lever lock is characterized by a simple design, a sufficient degree of security and an affordable price. And if you consider that manufacturers are constantly adding new products to the market, then the interest in models of this type is understandable.

Design Features

Frame

In most locks, this is a regular steel box with an opening lid. This solution facilitates free access to the mechanism. However, there are samples on sale without it. Such locks are attached to a metal base (safe leaf, iron door leaf), which serves as the missing sidewall.

Bolt

- Constipation. They are steel pins (called crossbars) or plates. The number of such parts determines the level of security, since the reliability of fixing the door leaf depends on this.

- Toothed comb. This structural element is responsible for moving the bolts and is located on the shank of the bolt. The disadvantage of old-style lever-type locks was that the comb teeth were very strong. Therefore, the hacking was carried out quite quickly and accurately, quietly, with the help of so-called “rolls” (a type of master key that completely repeats the configuration of the key, but without protrusions and grooves on its end part).

The new lock models have a “zest”. One clove (sometimes several) is weakened; a hole is drilled in it. When you try to open it, it breaks off, and all further manipulations with the master key will not give any result. The disadvantage of this engineering solution is that after this the lever lock will have to be repaired, since it can no longer be opened even with your own key.

- Shank stand. Its purpose is to prevent the bolts from moving, even under mechanical influence on them in the “closed” position of the lock. That is, it will not be possible to move (unscrew) them without a key. Manufacturers took into account that a popular method among burglars is to open locks by drilling out the rack, and therefore it is reliably protected. Options - armor plate, steel ball placed inside, the material of the part itself (high-strength alloy).

Levers

These coding elements are nothing more than steel plates, differing in geometry and configuration, thickness, displacement method and a number of other characteristics. But their only purpose is to ensure the level of secrecy of the castle. That is why mechanisms of this type are called lever mechanisms.

Key

The materials for manufacturing are most often aluminum alloys, brass or low-alloy steel. It is a metal rod with a head at one end and barbs at the other. Their number, height, location on the sides determine the encoding. The only drawback of the lever wrench is its long length. Carrying even one copy with you is not entirely convenient; with several it is much more troublesome. In all other respects, there are only advantages - a high level of secrecy, ease of unlocking and making a duplicate according to the sample.

"Key" question

The smooth operation and reliability of the lock largely depends on the key. Understanding this, Guardian designers pay serious attention to the development of high-quality keys. They are manufactured using the hot stamping method. The material used is brass. Unlike the casting method, there are fewer hidden pores on the finished key (namely, they are the culprits of possible damage to the key, which may break).

The manufacturer provides an official guarantee for the lock - 5 years. However, the consumer must be aware: the key can only be used for its intended purpose. This is not a general-purpose tool that can be used to try to open a bottle cap or scratch something on a metal surface. You shouldn’t put much effort into turning the key in the lock. If something goes wrong, it is better to stop immediately and contact customer service. A working lock should open easily and simply.

Operating principle of the lever mechanism

The secretion plates are located on the same axis, coinciding with the center of the well. Turning the key leads to their displacement, the magnitude of which is determined by the configuration of each lever. As a result, the crossbars move. If the key is not original, then you will not be able to open the locking mechanism.

Theoretically, lever locks can be recoded. All you have to do is swap the plates. But then you will need another key, and therefore this technique is not practiced. Considering the low cost of this type of constipation, it is easier to replace it with a new model. Although recently locks of this group have appeared on the market, the set of which includes spare keys and a lever block. This makes it possible to independently change the mechanism code (if necessary) and continue to use it at the installation site.

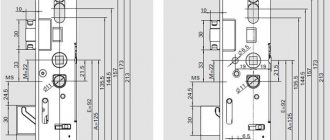

Replacing the larva

Most often, a cylinder lock is installed on Chinese doors, because this is the only model that combines good security and low cost. In addition, if it breaks, most often it is enough to simply replace the cylinder, rather than completely replacing the mechanism, as is the case with other types of locks.

Replacing the larva occurs in several stages:

- The cover is being dismantled. To do this, you need to unscrew the bolts located at the top and bottom;

- A long bolt is attached to the end part, slightly above the main fixing bolts, which also needs to be removed;

- Next, you need to insert a key into the lock hole, turning which makes it possible to remove the mechanism cylinder itself;

- A new one is installed in place of the old cylinder and, to do this, it is also necessary to turn the key;

- At the last stage, all fasteners removed earlier are installed in place.

Since standard locks for Chinese entrance doors have not proven themselves to be the best, it is recommended to replace them with more reliable ones after purchasing the door leaf. The only condition is that the new lock be the same size and with the same parameters as the old one that was dismantled. This is the only way to increase the reliability of the structure and protect your home from the penetration of ill-wishers.

Types of lever-type locks

- Mounted. They are more often called “barn”, since the main area of application is locking gates, garage doors, summer cottages, utility rooms, and the like. The simplest and cheapest lock modifications.

- Invoices. They are easy to install, since when mounted on a door leaf, all you need is to drill a hole in it for the well. These modifications of locks are considered universal, since they can be mounted on any sash, regardless of its material and thickness.

- Mortise. These are samples built into the base, and therefore are installed, as a rule, on frame doors. And then, there is a limitation in the parameters of the wooden frame, since the selection of material reduces the strength of the structure in this area.

How to assemble an interior door lock. Locking latch

The design of a door lock for an interior door can be more complex. If the design includes a latch, this design is more advanced. This device has not only a tongue, but also a special mechanism. It locks the latch in the desired position. The tongue is responsible for opening and closing.

The latch holds the door in the closed position. This locking device allows you to completely close the sash from the inside. If such a mechanism jams, it will be quite difficult to disassemble such a lock. Its main task is to hold the door leaf in the closed position.

The mechanism with a lock is mounted in the bathroom or toilet. Quite often, such locks are installed in offices and studies. It is the purpose of the room that often determines the choice of lock.

Since it is quite difficult to open a mechanism with a lock, it is recommended to purchase a mechanism of the middle and high-price category. Cheap locks can quickly fail, leading to many problems. When purchasing, you need to pay attention to how the tongue moves. It should move smoothly. Otherwise the product is of poor quality. The mechanism for returning the latch to its original position also requires attention.

The design of an interior door lock with a latch may vary. This depends on the type of handle and the method of attaching it to the canvas. In this case, the locking mechanism can be push-button or lever. The second of these options can be found on sale more often. They are more convenient and reliable.

Features of lever-type mechanisms

Pros:

- Reliability. Such locks are unpretentious; if handled carefully, they will serve without fail for many years and provide a sufficient level of protection for the object.

- Difficult to open. The specific design of individual parts and the coding method eliminate the possibility of selecting master keys. If such locks are unlocked, it is only by force, with the help of electric tools. Therefore, it is definitely not possible to deal with them in a few minutes.

- Ease of use. The design of the lever lock is such that the entry of dust and dirt into the well is not critical for it. But in relation to cylinder analogues, it’s the other way around; even slight clogging of their larvae can cause great difficulties with opening/closing.

Minuses:

- Increased wear of the mechanism. In order for the lock to serve for a long time, a number of conditions must be met. The first is regular maintenance, which involves removing dirt from the inside of the case and lubricating the rubbing parts. Secondly, be careful when handling the lock. Great forces when turning the key lead to metal deformation. The result is a gradual increase in gaps, the appearance of distortions, and loosening of the crossbars.

- Long key. The inconvenience this causes has already been said.

- Through well. How relevant this point is is a separate question. But many users note that cold air and noise enter the room from the street through it.

Tips for choosing a lock

Dimensions, configuration of grooves on the key, color of the case (fastening strip) and similar nuances are at your personal discretion. But there are a number of points that must be clarified at the place of purchase.

- Safety class. No less than third. For cheap Chinese models it is at level 1 - 2. It is unlikely that such a lock will provide reliable protection for the object.

- Execution of crossbars. Only in a reinforced version, made of high quality steel.

- Drill protection. What is she provided with?

- Installation feature. Lever locks, like doors, are divided into left- and right-handed models.

- Key quality. Ideally, the beards should have strictly right angles with careful grinding of the edges.

- Equipment. It is desirable that, in addition to fasteners, there are elements that ensure recoding of the mechanism (noted above).

- Manufacturer. Among Russian locks with a lever mechanism, products under the brands “Prosam”, “Kerberos”, “Gerion”, “Mettem” deserve attention. Foreign companies supply high-quality locks “Securemme”, “Abloy”, “Mul-T-Lok”, “Cisa”, “Kale”, “Mottura” to the Russian Federation.

When choosing a locking mechanism, it is quite logical to focus not on its price, but on the cost of what will be “protected” by the locking device. Chinese products are only suitable for scaring away those who want to profit from other people's goods. For a professional burglar, opening it is a matter of minutes.

The lever lock has its own advantages, and most importantly, it is easy to use and inexpensive. But experts do not recommend using it as the only means of protecting an object. It is good as an additional locking mechanism in a multi-stage security system.