A rack and pinion lock is one of the most common options for locking garage doors. The article describes the scope of application of this locking device, its advantages and disadvantages, design and operating principle. You will get an idea of the forward and reverse mechanisms, the features of the key, and get acquainted with the selection principle, average cost and manufacturers.

Unpretentious and good Source kwadratura24.ru

Scope of application of rack locks

In their modern form, rack locks appeared during the period of industrialization. These simple devices were widespread during the Soviet period, and today, despite the abundance of more complex and advanced models, they do not lose their popularity. The scope of application of rack (another name is deadbolt) locks is quite wide; they can be found on street gates, doors of utility and technical rooms, sheds, change houses and shell trade pavilions.

Very often they are installed on garage doors. The rack lock for the garage is fastened from the inside using an overhead method; to metal doors (gates) with bolts, to wooden ones - using self-tapping screws. In residential premises it is often used as an additional locking device.

Negative qualities

The main disadvantage of rack locks is their low burglary resistance. The above describes methods that are known to many. For burglars, there is no problem with how to open a deadbolt lock. This is done with an ordinary pocket knife.

Modern security structures refuse to protect an object if the canvas protects only one rack lock. They consider this device to be ineffective in adequately protecting property.

Such rack models have non-standard sizes and differ in shape. If a replacement is required, it is difficult to find another lock due to the mismatch of the seat.

Castle design

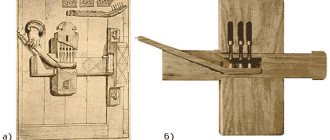

Like the mechanism of the old design, the rack and pinion lock is simple in design. Its design consists of four parts:

- Frame . Locks are made both industrially and artisanally, so the body has a variety of sizes and shapes and is made of different alloys (usually steel, plain or galvanized).

Rack and pinion lock design Source hochyvseznat.ru

- Rail (crossbar, deadbolt). Locking device; as a rule, a rectangular metal rod on which several grooves are milled (cut) at a selected angle. The number, width, depth and angle of inclination of the grooves are selected arbitrarily. Typically there are devices with two or three crossbars. Many models have one large crossbar with a classic rectangular shape.

- Spring . Presses (pushes out) the rack when the lock closes.

- Key . A long rod with a round or rectangular cross-section (also flat). It is the most labor-intensive (and therefore expensive) part to manufacture.

Advantages

Rack and pinion devices are designed for long-term operation. They are unpretentious, trouble-free, and never jam. Opening does not require much effort; even children can easily handle them.

Today, such devices are no longer as popular as in previous years, so their cost is low and accessible to everyone.

Rack and pinion mechanism

Features of the key and the principle of operation of the mechanism

The key is the most labor-intensive element of the device due to the need for its instrumental processing. The difficulty lies in maintaining the dimensions when cutting and further adjusting the resulting grooves - they must have a width and angle that exactly matches the grooves on the slats. The accuracy of the dimensions (the experience of the master) determines whether the operation of the bolt mechanism will be flawless.

Components of the mechanism Source imagesait.ru

Cutting on the key is done one-sided or two-sided; After its completion, manual finishing is required. Making a duplicate deadbolt key is not so easy and quite expensive. You will need to select a workpiece of the desired shape, length and thickness, and then cut the correct grooves (the slightest deviation will lead to jamming and jamming of the mechanism, which is very unpleasant).

The internal rack and pinion garage lock has a feature that is different from other models: it does not have a secret mechanism. The rack is driven by a spring. To open (or close) a door, the key is not turned in the key hole; It is enough to simply drown it, pressing all the way. In this case, the grooves on the key are sequentially combined with the internal grooves of the rack. When they are all engaged, turning the key finally compresses the spring, the rack moves inside the body, opening the door.

Scheme of fastening a lock with two rectangular bolts Source rykovodstvo.ru

See also: Catalog of companies that specialize in interior redevelopment of houses.

In addition to the forward motion mechanism described above, there is a variety - a reverse rack and pinion lock. The device is structurally a little more complex, which allows it to be considered a more reliable option. To open such a lock, you need to perform the following set of actions:

- The key is completely immersed in the well .

- In order for the lock to unlock and open , the key is turned a quarter turn and then pulled towards you.

- To extract the key , the steps are performed in reverse order.

- close a lock (of any design) manually by holding the bolt in the retracted position with your fingers and slamming the door.

Pros and cons of rack and pinion locks

Despite the outdated design, many people opt for a rack and pinion garage door lock. Buying such a device means taking advantage of the following advantages:

- Strength and durability . The extremely simple design of the mechanism, consisting of a lock, slats and springs, makes it especially wear-resistant. Rack and pinion locks work for 30-40 years without breaking or jamming with active daily use.

Marking a key blank Source www.stroidetail.ru

- Easy operation . A quick and convenient way to lock doors that does not require any special effort.

- Unpretentiousness . The castle is undemanding to weather conditions; it works equally reliably throughout the year, is indifferent to humidity, and is not afraid of ice. This set of qualities makes the rack lock an ideal option for outdoor use.

- Budget price . The rack locks offered on the market are significantly superior to other models in terms of their affordability. The low cost is due to the easy-to-manufacture mechanism and competition with more advanced locking systems.

- Easy installation and maintenance . Rack locks have no restrictions for installation; They are easy to attach to any door of suitable thickness. Like any metal mechanism, the lock needs periodic lubrication, which is placed in the keyhole, using a key.

Installation process

It is worth noting right away that without special installation skills, it is better to turn to specialists. To install a garage rack lock, you will need the following tools:

- electric drill;

- metal drills;

- screwdrivers;

- Bulgarian;

- pliers;

- self-tapping screws;

- rulers;

- knife;

- core - a tool (machinery) for marking the location of a future hole.

When working, it is necessary to protect your eyes with special glasses. The installation process consists of the following steps:

- Determine the location for mounting the mechanism and the height for ease of operation.

- Mark the points for drilling holes, applying the lock to the door, taking into account the contours of the key insertion.

- The door end is marked according to the thickness of the lock.

- Drill holes and mark the boundaries of the device installation. You should get the upper and lower lines of a rectangular structure, which is cut out with a grinder.

- A lock is placed in the niche made, and holes for self-tapping screws are marked.

- Check the design, first fixing the device.

- The lock is removed and the location of the key is marked on the metal gate leaf. Drill a hole for the keyhole.

- Install the crossbar device and secure it securely. Check the functioning of the structure. The lock must work without jamming, stopping, or applying maximum effort.

- They install the overlays on the structure and check its functioning again.

- Mark the holes for the movement of the slats in the door end. Drill carefully. The same procedure is performed on the second garage door.

The marking and drilling of holes must be very precise for the operation of the device to be effective.

Choosing a rack lock

The unique property of an internal garage lock, which can be purchased at any specialized store, is that it is almost impossible to accidentally break it. Despite the simplicity of the mechanism, high-quality models are supplied with a quality certificate indicating the parameters. There are certain requirements for the lock rack:

- The movement of the rack in the body should be free and smooth. Sticking indicates that the clearance with the housing is insufficient or uneven; It is obvious that this lock is a low quality product.

- The fixation of the rack in the extended position must be reliable. Otherwise, the use of force will cause the bolt to return to the body and the door will open.

- The rail is made of a fairly hard alloy capable of withstanding a force load of 200-300 kg.

- The size (diameter) of the sliding rods should match the size of the holes as closely as possible.

- When purchasing a product, make sure that there are no signs of rust or dents .

Video description

About the garage reverse lock in the following video:

When choosing, you need to pay attention to the compliance of the dimensions and weight of the product with the thickness of the garage door. The thickness of the metal leaf to which the lock will be attached should not be thinner than 4 mm, otherwise the heavy mechanism will cause deformation of the metal.

Technologies do not stand still; In order to increase the security class of overhead rack locks, their design is becoming more complex. Multi-locking devices are offered on the market, supplemented with anti-burglary pins. The mechanisms are equipped with safety latches and devices that include locking using the door handle (when closing, it must be raised to a predetermined angle). Various improvements allow the lock to better resist burglary attempts.

Manufacturers

Among all the manufacturers, it is worth noting these popular and most reliable ones, since they have managed to establish themselves and have shown that their products are of the highest quality and the price is quite reasonable for their performance. We advise you to pay attention to brands such as KFV, Maxbar, Elementis. By the way, the last presented brand is Chinese, but the others are no less quality.

The cost of such products is quite small and is only about five dollars. Of course, you will need to overpay money for additional features such as security mechanisms, additional keys, etc. The price of rack and pinion electromechanical locks can reach fifty dollars or more.

Rack lock cost

Thanks to the versatility of a simple design with retractable bolts mounted on a rail that interacts with a key, such locking devices are undiminished in popularity.

Reverse lock Source icaev.ru

The price of products varies over a fairly wide range. It depends on the degree of complexity and reliability of the lock, on the size and material of the locking system. If you are thinking of installing a rack lock for your garage, you can buy a similar product in Moscow and the region at the following average prices:

- Model with one rectangular crossbar - 380 rubles, with two rectangular crossbars - 490 rubles.

- Model with 3 cylindrical crossbars . The price is in the range of 550-600 rubles.

- Model with a rectangular bolt, with a cross-shaped key (with the possibility of replacing the security mechanism): 900-1000 rubles.

- Reinforced lock , 3 cylindrical bolts, opens from the inside with a handle - 1100 rubles; with 4 crossbars - 1200 rub.

- The model is similar to the previous one, additionally equipped with a latch (can be locked from the inside) - 1300 rubles.

- Model with four crossbars and a latch under the handle, opens from the inside with a key - 2150-2600 rubles.

- Maxbar Castle (Germany). Main locking: bolt with latch, additional locking: locking pins. Price: 2900-3300 rub.

- Mottura Castle (Italy). In various models (which are divided into right and left) there are 3-5 crossbars; price - 6500-6700 rub.

Mid-price lock Source okna-blitz.ru

Interior models

If we consider the question of how the design of door locks works, we should definitely consider interior models. The design of a standard interior door lock can be divided into a separate category, since, unlike previous models, these products have a special design.

The circuit of such a door lock is combined with a handle. In this case, in addition to the latch, there is an outlet to the handle, which sets the halyard tongue in motion due to its connection with a rectangular cross-section rotary pin. Depending on the type of handle, such mechanisms are divided into three categories:

- rotary round;

- nobs;

- push.

Types of locks for interior doors

The design of an interior lock is almost completely identical to that of a mortise lock, but here the exit under the handle often has more space. It is impossible to make a high-quality lock on a door with your own hands without certain skills, but understanding their structure will be useful for every owner.

Locking devices of this type are mainly installed in garages and sheds; they are often equipped with utility room doors and gates. But it is not recommended to use them on entrance doors - with some persistence you can open a rack lock without a key. This article will help those who for some reason lost it (broke it) and cannot gain access to their personal garage.