Category: Door locks (3 ratings, average: 5,00 out of 5)

Published 08/01/2021 · Comments: · Reading time: 7 min · Views: Post Views: 16,507

The main task of a door lock is to prevent unauthorized access, so it must meet certain reliability criteria, which are established depending on the characteristics of the room or spaces. The internal structure of the locking mechanism is a basic nuance that should always be taken into account when selecting a lock.

In an era of intense technological progress, security systems are constantly being improved. Leading brands are constantly offering new means of protection, and they are usually based on classic mechanisms that are thoroughly redesigned.

When choosing a door lock, is the reliability of the device a priority criterion for you?

Not really

How to assemble a lock for a dacha, for a private apartment, house, office, so that it becomes an effective protection against an intruder - just choose the right model, taking into account the features of the internal structure and installation method.

Selecting a lock by installation method

Photo: Types of door locks

Modern locking devices are divided into three types:

- mounted;

- invoices;

- mortise

And if the installation of a padlock requires only the presence of hinges, then the installation of a door lock with a handle requires a stationary insertion using a specialized tool.

Preparing for assembly

As a rule, in order to repair a door lock or mortise lock, you first need to disassemble it. Before installing a new device on the door, it is disassembled in order to exclude defects or to remove a foreign body (if any). In order to repair the lock, you will definitely have to disassemble it.

It often happens that amateur repairmen disassemble the device for the purpose of repair, but after that they cannot put it back together. From the outside it looks quite funny and absurd, but experts say that this happens quite often.

You can find yourself in such an absurd situation even when the lock is not removed from the door, but is partially disassembled for cleaning or lubrication. It is enough for one spring to be missing and the device will not function correctly. In order to avoid such a situation, there is no need to rush to open the device case. First you need to get the device diagram and study it carefully. As a rule, the diagram comes complete with the lock; if it is lost, you can look it up on the Internet. The scheme will allow you to study:

- Complete set of components and their location.

- The principle of fastening elements.

- Functionality of each component.

The scheme is not the only thing that may be required. The locking device cannot be disassembled with bare hands, so you will have to prepare a special tool:

- screwdriver;

- the original key that opens the secret mechanism;

- tweezers, awl;

- lock lubricant.

Rim lock

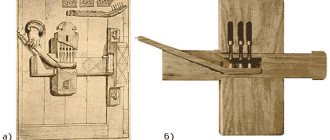

The device of the rim lock photo

Overhead options do not require special preparation of the canvas, excessive effort and time. This is an ideal solution for situations where the door leaf does not structurally require a lock. The overhead-type design has a sufficient level of resistance to opening and a good degree of privacy, especially if you choose the electromechanical option.

The rim lock device consists of:

- face plate;

- drive lever;

- a set of keys;

- housings where the locking element is hidden;

- response component.

The presence of all the above details should be carefully checked at the time of purchase.

How to assemble a door lock with a latch can be read in the instructions included in the delivery kit. For installation you will need a minimum of tools: a screwdriver with different attachments (a drill is required), a pencil and tape measure, a chisel, a Phillips screwdriver, and a hammer.

Before assembling the rim lock, determine the location where the lock will be located (usually it is installed at a height of about 150 cm). Next, take the template, which is usually included in the delivery kit, and mark the door leaf, noting the future position of the screws and the hole for the locking mechanism.

Expert opinion

Sergey Dymchuk

Expert of our site. He has been working in the field of door production and installation for more than 10 years. Implemented hundreds of different projects. Helps make the content of our site interesting and useful.

Ask a Question

When installing a mortise door lock, the integrity of the door leaf is not affected at all, because only one hole is required for installation.

Now drill holes in the corners to a depth similar to the length of the mounting bracket. The central hole must be through, so prepare a long drill in advance and make sure that during drilling, the drill or screwdriver is always in a horizontal position. Next, use a feather drill to make a notch. After this, secure the overhead door lock using self-tapping screws and move the lock tongue out. Now place the bar on the loot in the desired position and secure it with self-tapping screws. Install the protective ring from the outside using a hammer.

Photo: Types of overhead door locks

Preparatory work

You should begin installing a metal door yourself by taking measurements. To measure the front door, you need to use a tape measure to determine the distance from the floor to the top edge of the opening and from one side to the other. To get the correct result, you need to take 2-3 measurements of height and width, since the opening may be uneven. To determine the thickness of the wall, measurements are taken from edge to edge of the slope on each side. All results must be written down: based on these numbers, specialists from a trade organization will help you choose a metal door.

When installing a metal entrance door with your own hands in an apartment building, you cannot change the direction of opening the door. This parameter is assessed from the outside, standing facing the canvas and determining the side on which the loops are located. The position of the loops determines the direction L (loops on the left) or R (loops on the right).

Preparing the opening

Before installing steel doors, you need to prepare the opening:

- remove the old door;

- clean the edges of the walls from sealing material;

- if necessary, level and widen the entrance.

If the measurements were taken correctly, then no additional work to expand or narrow the opening will be required. The metal door should be slightly smaller than the hole in the wall. The gap must be at least 2 cm on each side of the frame. The gaps are needed to align the box vertically and horizontally, and after installation they are sealed.

If during the repair process it is planned to replace the door with a larger or smaller one, it will be necessary to change the size of the opening and prepare the installation site for the metal frame. To expand, part of the wall is removed using the appropriate tool. In stone buildings, a hammer drill is used, and in wooden buildings, a saw is used.

When narrowing the opening, additional elements are used. Most often they are wooden blocks of the required thickness. The extensions are secured to the wall with anchors or nails.

Dismantling the loot

The difficulty of dismantling the door opening will depend on what material the walls of the house are built from

If it is gas, foam or expanded clay concrete, then all dismantling work must be carried out with great care - it is important not to spoil the fragile masonry, which is prone to chipping

In general, the procedure is as follows:

- the door leaf is removed from the hinges;

- the box is cut with a grinder or hacksaw into several parts.

- The cut pieces are dismantled using a crowbar or crowbar.

Cleaning the doorway

Cleaning consists of removing old fasteners, flimsy plaster mixture and, if any, polyurethane foam from the ends and adjacent areas.

But if the house is old and the front door has been in use for decades, then it is necessary to check the floor beam that is installed above the doorway. If its quality leaves much to be desired, then you should think about how to replace it. It is better not to carry out this repair operation with your own hands.

Pay attention to the area below the threshold. Typically, in brick houses that have been in use for a long time, wide openings are formed filled with loose brick material, so this debris must be gotten rid of

Sealing cracks and voids

When all defects in the doorway are discovered, they must be repaired with ordinary cement-sand mortar, which is diluted in a ratio of 1:3 (1 part cement to 3 parts sand). Large voids are filled with broken or solid bricks and mortar. Small ones - only with a cement mixture, the same applies to cracks. Before sealing the latter, it is recommended to use a deep penetration primer. It will not only hold together the grains of wall material, but will also go deeper into the thickness of the concrete, making it more durable.

There is no need to level the surfaces of the ends of the doorway. You can raise the floor by pouring screed, or level the area under the threshold.

Dismantling the old structure

Reinstalling the door begins with dismantling the old entrance block. When performing this operation proceed as follows:

- remove the old fabric from the hinges (if the hinges are one-piece, the easiest way is to unscrew the fastening screws);

- remove the fastening elements of the box (nails or anchors), and cut off the pins or plates on old steel products with a grinder;

- The wooden box is sawn and taken out piece by piece.

Dismantling the entrance metal box is quite simple: if there is no goal to preserve it, use a grinder to saw through the welded structure and knock it out with a hammer. Difficulties can be caused by removing a small door structure, which may be hampered by previously unnoticed fasteners, but with the help of a crowbar or crowbar it will be possible to solve this problem.

Mortise lock

This option is considered more reliable than the previous option, since the mortise lock device with a latch is installed inside the blade, which minimizes the possibility of it being squeezed out (if you follow the advice in the instructions “How to assemble a lock”).

Don't miss: What types of locks are there and how to choose the right lock?

The door lock circuit consists of several elements:

- pin;

- handle;

- locking mechanism;

- larva;

- decorative overlay;

- reply part

Expert opinion

Sergey Dymchuk

Expert of our site. He has been working in the field of door production and installation for more than 10 years. Implemented hundreds of different projects. Helps make the content of our site interesting and useful.

Ask a Question

Availability of components depends on the installation location. For example, a mortise lock with a latch does not have a code cylinder.

Mortise door lock device with a handle for preliminary preparation of the following tools: pencil, tape measure, drill, chisel (semicircular and flat), screwdriver, hammer.

The algorithm is as follows:

- mark the door leaf, drawing contours along the side and end parts;

- prepare a socket for inserting a lock;

- insert the lock into the door leaf;

- secure the mechanism with screws and install handles and decorative trims;

- If present, install a striker plate.

Photo: Mortise door lock

Design and principle of operation

The design of an electromagnetic lock (EML) is relatively simple. The main elements of the device are a core with a coil located in the housing. Most often, the core is made of transformer steel, which reduces residual magnetization when the lock is opened. A special paint coating is also used for this. However, this does not allow achieving complete elimination of accumulated energy.

In most electromagnetic locks, the core is a set of plates connected in the shape of the letter “W”. However, there are devices in which this element has a one-piece design. This solution has one significant drawback: the residual stress accumulates quite intensively. To eliminate this negative effect, a capacitor with a capacity of at least 200 μF is introduced into the design.

In this video you will learn how to install an electromagnetic lock:

https://youtube.com/watch?v=7o6i7CPsPJw

To make a winding with a large number of turns, a copper conductor coated with enamel is used. The lock body material is most often aluminum or stainless steel. You can also find plastic devices on the market, but they break down relatively quickly. The operating principle of an electromagnetic lock is not very complicated.

Voltage is supplied through the terminals to the coil and housing. As a result, the magnetic elements of the device are activated and the EMZ is closed. When the voltage is removed, an oscillatory circuit with alternating current is created. The presence of a capacitor in the design allows the discharge process to be carried out through the core winding and its polarity changes, which leads to the opening of the device. The residual current is sent for magnetization reversal.

Types of modern locks

Not many people know how a door lock works. Types of locking systems are classified based on the internal structure of the mortise door lock. The following types exist:

- rack and pinion;

- levelers;

- cylindrical.

Each type has its own advantages and disadvantages. To increase the difficulty of unauthorized access, security experts recommend installing several types of locks on the external door.

Rack locks

Rack door lock photo

Rack and pinion locking systems do not have a high degree of protection against opening, and are most often installed in utility rooms, garages, wickets, and gates. If the combination matches, then with pressure the bolt is pulled through with the key, freeing access to the object. Otherwise, the system will not react in any way if the code cutting is not suitable.

How does a door lock work?

The door lock diagram looks like this:

- crossbar mechanism, consisting of a metal bar in which grooves are cut;

- keyhole;

- springs responsible for the movement of the locking bolt;

- external deadbolt

Depending on the chosen model, the door lock design can have from one to three bolts. Most often you can find a double-crossbar mechanism on sale.

The main advantages of the rack and pinion system are simplicity of design and low probability of breakdown. The main disadvantages are considered to be low tamper resistance, the high cost of producing duplicates if lost, and the bulky size of the keys.

Don't miss: How to remove a broken key from a lock

Lever lock on the door

Photo: Level door lock

The principle of operation of the locking mechanism is to arrange lever plates in the correct order, which change their position based on the notches on the key.

What does a lever mechanism with a latch consist of? This includes:

- leveler plate systems;

- keyhole;

- plates for attaching levers;

- crossbar plates that open/close the door when the levers match in a certain sequence.

Door lock device with handle photo

The design of a door lock has a characteristic sequence - the more levers the manufacturer has provided, the more complex the code pattern, and, accordingly, the higher the category of its reliability (opening by selecting a combination takes more time).

Currently, two types of door lever lock structures are offered on the market:

- with one way key. This design is considered not reliable enough, and it is usually installed on additional or interior doors. Some manufacturers have already abandoned the production of such devices, switching to more advanced ones;

- with double-sided key. The structure of the external door lock assumes that the key, interacting with the lever plates, is active on both the right and left sides, which significantly increases the security class.

According to experts, a reliable mortise lock consists of:

- no less than six levers. This number of secrets allows you to generate approximately 100 thousand code combinations, and 8 plates increase the variability to 250 thousand;

- additional armored linings that hide the locking elements from drilling and breaking;

- reinforced crossbars that are difficult to cut;

- false grooves that can confuse a potential burglar, thereby increasing the time required to access the premises, which plays a decisive role;

- a replaceable lever block, which will allow you to quickly change the coding if the keys are lost or stolen;

- availability of a special key for recoding. The presence of such an accessory allows you to change the set of keys yourself, if necessary.

Don't miss: How to open Cyfral intercom models 20 and 2094 without a key

English (cylinder) door lock

Photo: English (cylinder) door lock

The English door lock received its classic name from the country of its invention. In Russia, it is more often called cylinder based on the shape of the code system, which resembles a cylinder.

The device of a mortise-type door lock with a cylinder mechanism is:

- outer casing, most often made of durable steel;

- code and locking pins;

- the core where the code system is located;

- key holes.

The lock in cross-section is a hollow cylinder with a system of longitudinal grooves, where plates with transverse slots, applied in a random order, are placed.

Photo: Mortise lock with cylinder mechanism

There are both pin and frame types.

Cylinder locks are classified according to the location of the pin system inside the glass:

- single-sided, placed in a single row, at a single level;

- double-sided, locking parts are located in two rows, which is reflected in the cutting of the key;

- cruciform. The well has a characteristic shape, and the pins that lock the door are placed in three or four rows, which significantly increases the degree of secrecy;

- rotary The pins move in a vertical position, but also rotate, complicating the ability to select a code;

- conical system. Here the pins are located in many planes, which minimizes the possibility of unauthorized access.

Advantages and disadvantages

The cylinder lock is quite easy to install, maintain and replace. If the key is lost or the mechanism breaks down, you can easily change the cylinder, which allows you to significantly save on the purchase of a new system. Security experts know many ways to hack such a mechanism, but modern models are generally resistant to most of them. There are many options on the market: from the most budget ones, with a simple code, to expensive ones, where there are several types of secrets and many additional technical solutions that provide a high class of protection.

Scheme of a mortise lock with a cylinder mechanism

When choosing a lock, it is worth remembering that even the most expensive core and system will not be able to create adequate protection if the basic installation rules are violated. For example, if the larva is not recessed enough into the door leaf, an attacker can tear it out. You should also always remember that even the most modern and expensive option cannot provide 100% security. Its main task is to make access to the premises as difficult as possible, which in most cases will make attempts to break into it impractical.

Where to start

Going straight to the store, as they say now, is counterproductive. First of all, you need to figure out what is really necessary - to change the lock on the iron door or its cylinder. In the latter case, everything will come down to small costs, both in money and time.

Steel doors are usually equipped with lever or cylinder locks. The keys to the first ones are a rod, at the end of which there is a plate with cutouts. Here you will have to think about how to replace the lock on a metal door, since it does not have the usual security insert.

If the model is cylinder, then in most cases it is enough to install a new cylinder. Locking devices of this type are supplied with a flat key with teeth along the entire length of the working part. This is a simpler repair option.