Depending on the builders’ choice of technology and material for constructing walls, openings in buildings can have different configurations - there are windows with and without quarter windows. The existing differences do not have a fundamental impact on the main characteristics of the houses. However, the further choice of methods for measuring and installing window structures depends on them. To avoid mistakes when choosing windows, determining their correct dimensions and during installation, we recommend that you read the useful information from this article.

What is a quarter in a window opening?

Not many people will be able to distinguish this type of window when viewed from the street. This can only be done at close range. An opening of this type has a small side that runs along the entire facade plane. The name of the technology comes from the fact that during construction work, the brickwork on the front side of the building protrudes by a quarter of the length of the brick.

Advantages

Quarter installation offers various advantages:

- the window properly fulfills its purpose;

- protect it from falling and ensure stabilization of the structure;

- a better level of tightness is ensured, since the presence of protrusions does not allow moisture to enter the installation seams;

- provides additional protection from drafts;

- installation in this case is easier than usual, because the sides act as an additional reference point for the boundary and workers save time to complete the process.

Thanks to the advantages of this type of installation, the structure can function properly. However, the most important advantage is the level of tightness of this method of installing window openings. This allows you to significantly reduce heat loss in the room, eliminate fogging of glass and the formation of mold on elements. The window quarter extends the entire service life of the structure and its adjacent components.

Quarter windows have a particular advantage in houses made of concrete and wood. The protrusion covers the structure and is used as additional support. It allows you to install this type of opening strictly in accordance with GOST. Windows with a quarter and without a quarter differ only in the facade projections. No knowledge of construction is required. Any average person can notice the difference.

Dimensions of brickwork: we build structures with the required accuracy

When constructing various buildings and structures from building stone, one of the parameters requiring the strictest control is the size of the brickwork. Maintaining the dimensions is necessary, first of all, so that the actual design parameters coincide with the design ones.

A variety of devices are used for this, but you still need to know the basic numbers at the stage of planning the work. In our article we will provide background information that will be useful to you if you do the laying yourself.

Without control, the result will be unpredictable

Dimensional Control Devices

The accuracy of sizing depends on what tools we use for this.

That is why, in addition to various devices intended directly for masonry (trowel, jointing, hammer-pick), a mason’s “work suitcase” must contain the following:

- A tape measure is the simplest, and at the same time the most reliable tool for determining linear dimensions. For construction work, it is preferable to use tape measures with steel or polymer cloth, at least 10 meters in length.

Please note! To ensure maximum compliance of the masonry parameters with the dimensions indicated in the plan, the tape measure must be verified accordingly.

When constructing residential buildings, this is highly desirable, but for outbuildings you can do without verification.

- Level . As a rule, two types of levels are used on construction sites: laser levels to form a general plan and control the tension of mooring cords, and ordinary levels to check the straightness of masonry sections. The length of the level should be from 1 to 2 meters.

- Square _ An indispensable thing for checking the squareness of the laid masonry. Of course, this can be done using a level, but the simpler the device, the more reliable it is.

- Plumb . Used to control vertical planes. When constructing one-story buildings, the weight of the plumb line should be from 200 to 400 grams, and when laying at a height - up to a kilogram. Accordingly, the diameter and strength of the cord should be selected accordingly.

- The row lath (order) is an indispensable tool for any mason. It is a wooden block or corner with a section of 50x50 mm, on which marks are made corresponding to the dimensions of the brick used. So, when using single blocks with a thickness of 65 mm, markings are applied in increments of 77 mm (65 mm - the brick itself + 12 mm thickness of the seam).

Tool set

Note! To construct masonry in accordance with the given dimensions, you can use both factory-made and hand-made row slats.

Brick and its sizes

Naturally, the process of masonry construction is also influenced by its individual elements. When planning work and calculating the amount of material, we must always take into account the actual size of the brick used.

Brick sizes

The dimensions of the building blocks used for laying walls and their subsequent cladding have been standardized for a long time.

Of course, there are also non-standard models on the market (they are distinguished by their original design and fairly high price), but still the bulk consists of blocks of several standard sizes:

- Single - marked with the index 1-NF, has dimensions 250 x 120 x 65 mm.

- “Euroblock” – 0.7-NF, 250 x 85 x 65 mm.

- Single modular - 1,3-NF, dimensions 288 x 138 x 65 mm.

- One-and-a-half brick - 1.4-NF, 250 x 120 x 80 mm.

Double brick is sometimes called building stone. This type of material is marked with indices from 2.1 to 3.2-NF and has dimensions from 250 x 120 x 140 to 250 x 180 x 140 mm.

Please note! Using materials such as double sand-lime brick M 150 for masonry significantly speeds up the work, since fewer horizontal rows have to be laid.

At the same time, the significant mass of a single block complicates its precise positioning, and the unpresentable appearance of the masonry requires additional external finishing.

Photos of blocks of non-standard shape and dimensions

European brick manufacturers produce bricks in a size chart that is slightly different from the domestic one. For this reason, it is very difficult to combine bricks from European and Russian manufacturers in one masonry. If this is done, it is only for the construction of various elements.

Masonry and thermal characteristics

The key factor determining the mechanical characteristics of the building under construction and its ability to effectively retain heat is the thickness of its walls.

And here two aspects should be highlighted:

- On the one hand, the structural strength of almost all models of brick and building stone used today is very high. As a rule, to provide sufficiently reliable support for a two- or three-story building with all floors and communications, masonry with a thickness of 250 mm is sufficient.

- However, both baked clay and the sand-lime mixture used to produce silicate blocks have relatively high thermal conductivity. It is for this reason that hollow bricks are often used to construct the walls of residential buildings, and they try to make the walls themselves thicker than necessary from the point of view of mechanical strength.

The thinner the masonry, the better it conducts heat

Please note! An alternative to thickening the walls is to use multi-layer structures, with thermal insulation material placed between the main load-bearing wall and the decorative brick cladding.

But this technology is more expensive both in terms of finance and time.

The most commonly used masonry sizes today include:

- Half-brick masonry – 120 mm wide. Most often, this variety is used for the construction of interior partitions.

- Brickwork – 250 mm.

- One and a half bricks - 380 mm.

- Two and two and a half - 510 and 640 mm, respectively.

What is a quarter window

The ceiling without a quarter is distinguished by the absence of a sharp transition from the interior part of the masonry to the façade. This is fraught with the fact that during installation the forward movement of the structure is not limited by anything.

Openings without a quarter are common in the private sector, because... people are trying to make construction easier and cheaper for themselves. In addition, when erecting buildings from foam blocks, which are often used for construction, it is quite difficult to create protrusions in window openings.

Flaws

Despite all of the above, the absence of a quarter does not have a strong impact on the general characteristics of the window opening.

If you use another method, difficulties may arise:

- you will need to additionally protect the installation seam;

- the use of PSUL sealing tape is difficult;

- It will take more time to correctly position the windows and fix them.

If the builders were careless when installing the windows, after some time the installation seam may begin to leak air. The foam will quickly become unusable. As a result, condensation and fungus will appear on the window. If a person wants to avoid these consequences, it is necessary to correctly measure and install the window structure.

General provisions and information: how to take measurements correctly for a plastic window

First of all, you need to know that the depth of the opening is initially determined, and only then everything else. It is very important to take into account all the nuances, without exception, otherwise you may later find yourself in a situation where the delivered window simply does not fit, and the installer, and even the manufacturer, seem to have absolutely nothing to do with this, because you provided them with the wrong dimensions yourself. Therefore, treat the work with full responsibility, so that the Dunno principle “it will do” does not become the reason for wasting money, because the design costs far from a penny.

Helpful advice

Measuring plastic windows with your own hands should only be done if the installer for some reason cannot perform such actions. It would be optimal to entrust such a complex and responsible matter to a real professional, and avoid many annoying misunderstandings and unnecessary problems.

So, the measurement of the opening for plastic windows should be carried out both from the inside and from the outside of the building. This is how the depth of the opening is determined. It often happens that when taking qualitative measurements, it suddenly turns out that your window opening has a very significant skew, then the dimensions of the final product will have to be increased, according to the measurements of the skew itself. Most often, such problems can be observed in panel buildings, where large slabs and blocks already come cast from the factory.

After you have already measured the window opening from the outside, you should also measure the inside of it, and then compare the results. This will help you take a sensible look at the situation, because ideally all the numbers should practically coincide, but if not, this will also have to be taken into account when making the final calculation. You can correct unevenness by installing plastic slopes, and experienced craftsmen do not recommend abandoning such accessories, as they perform many functions other than decorative ones. For example, they prevent the appearance of condensation and increased humidity, which can lead to the formation of black mold, which will be very difficult to combat later.

Measuring features

The features of measuring overlap with and without a quarter are different. When measuring a window, you need to take into account various factors. If this is neglected, it can lead to dire consequences. There are many subtleties involved when performing the procedure. If a person does not have experience, he will not be able to do the job well. Important moments will be hidden from his attention. This does not incur financial losses, since the service is provided by companies free of charge.

Sometimes the price of installation depends on the size of the window structures. In this case, you will have to measure them yourself.

Why is it better to entrust measurements to professionals?

Many window customers consider this procedure a simple matter that they can handle on their own. Inexperienced property owners think that it is enough to be extremely careful, know how to measure a window, and everything will be fine. This is a misconception. There are quite a lot of nuances that a person without practical experience has no idea about. In the end, the measurement seems to have been done correctly in all respects, but it is not entirely correct. For example, in old houses there may be a fairly large distance between the window frames and the walls, which is filled with wooden backing bars, felt and construction waste, and then plastered. In half of such situations, non-specialists limit themselves to measuring the old frame, when they need to get to the wall itself. In addition, in the process of taking dimensions, possible distortions of window openings are identified and the optimal type of fastening elements is determined. All these facts speak in favor of the fact that it is better to entrust the measurements to competent professionals.

Important! Today, the vast majority of reputable companies do not charge a fee for measurements if the client orders windows. So a serious customer saves absolutely nothing by independently determining the dimensions of the openings, and the procedure of measuring on their own loses all meaning.

Window quarter size

According to the standard, the window quarter is 65 mm. In reality, these numbers may be different.

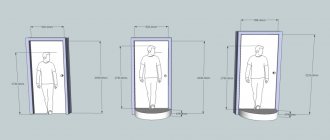

The frame can go behind the openings:

- 15-20 mm from above;

- on the sides by 20-40 mm;

- From the bottom of the staging profile, the frame is raised by 10-30 mm relative to the edge of the clearance.

You will need to determine how much the profile frame will overlap with the protruding section of the wall. There are certain regulations to control them, but compliance with them is not always possible. Part of the window structure may not conform to the recommended dimensions. In this case, it is necessary to reduce the overlap to such a size that the window can fit into the internal opening. If this is neglected, problems may arise during installation of the structure.

Placement of windows on the house plan

When drawing up a project for a future home, it is inevitable to go through the following stages:

- determination of the area allocated for windows and the size of window openings;

- choice of the type of binding or its scheme - in cases of non-standard design;

- drawing openings on the house plan drawing.

The ratio of the total area of light openings of all living rooms and kitchens in the house to the total floor area of these rooms should not exceed 1:5.5. The smallest ratio for each of these rooms should be 1:8, in bathrooms and showers - 1:4, corridors and utility rooms - from 1:15 and above.

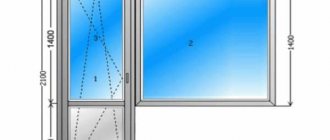

In adj. 1 presents the nomenclature of window blocks and balcony doors, as well as the specification of design sketches of windows and balcony doors, manufactured products of Zabudova OJSC, as well as windows and balcony doors made of VEKO PVC profiles of the SOFTLINE system.

Example 1. Determining the area of light openings

We take as a basis the house plan shown in Fig. 1.

Rice. 1. Plan of the designed house: 1 – room; 2 – room; 3 – room; 4 – common room; 5 – kitchen; 6 – hallway; 7 – bathroom; 8 – restroom; 9 – entrance vestibule; 10 – combustion chamber

It is necessary to design windows in the common room (4), rooms (1, 2, 3), kitchen (5) and furnace room (10).

When determining the size of a window, it is advisable to adhere to the maximum height for a room of a given nature. The height (from floor to ceiling) of living rooms and kitchens must be at least 2.5 m, the height of window sills above floor level in rooms with central heating is from 0.8 m, respectively, the width of the window leaf is determined by the design capabilities of the partitions.

The location of the window opening in the outer wall is shown in Fig. 2.

Rice. 2. Location of the window opening: 1 – left partition; 2 – width of the window opening; 3 – right pier; 4 – overall size of the wall length; 5 – height of the wall above the window; 6 – height of the window opening; 7 – height from window sill to floor; 8 – room height

We take the height of the room to be 2.5 m, and the height of the window sill to be 0.8 m, we find that the height of the window opening remains 1.7 m minus the height of the partition above the window opening. The height of the wall above the opening depends on the design features and is formed by lintels covering the window openings (Fig. 3).

Rice. 3. Upper wall above the window opening

The minimum value of this distance is 200 mm, it is necessary for laying heating system pipes, as well as for hanging a cornice.

We get the height of the window opening equal to:

Npr = Npom – Npd – Nv.pr = 2.5 – 0.8 – 0.2 = 1.5 m.

We select the width of the opening according to the table. 1 adj. 1, knowing that the ratio of the total area of light openings in living rooms and kitchens to the total floor area of these rooms should not exceed 1:5.5. The smallest ratio for each of these rooms should be 1:8.

Dimensions of openings at a height of 15 dm (Table 1, Appendix 1): 15×6 dm;

15×7.5; 15x9; 15×12; 15×13.5; 15x15; 15x18; 15×21 dm.

The area of the common room is 20.16 m2.

The area of the first window is 0.9 m2, the area ratio is 1:22. The area of the second window is 1.125 m2, the area ratio is 1:18. The area of the third window is 1.667 m2, the area ratio is 1:12. The area of the fourth window is 1.8 m2, the area ratio is 1:11. The area of the fifth window is 2.025 m2, the area ratio is 1:10. The area of the sixth window is 2.25 m2, the area ratio is 1:9.

The area of the seventh window is 2.7 m2, the area ratio is 1:7. The area of the eighth window is 3.15 m2, the area ratio is 1:6.

From the calculation it can be seen that window openings of the following sizes are suitable for a common room: 15×18 dm – 1:7; 15×21 dm – 1:6.

If necessary, based on design features or in order to give architectural expressiveness to the facade, instead of one window, two or more can be designed. Then, when calculating the areas of the windows, they are summed up. For example, two windows 15x12 dm have a total area of 3.6 m2, the ratio to the area of the common room is 1:5.6, and three windows 15x7.5 dm have an area of 3.375 m2, the ratio of the areas is 1:6.

The outer wall of the common room has a length of 5.6 m, taking into account the purpose of the building and to give greater expressiveness to the facade, from the four available options, we select a window opening of 15x18 dm with a ratio of 1:7. From the table 2 adj. 1 we take a sketch of the window design (Fig. 4).

| Double-leaf window | Three-leaf window | Window with a window, |

| with impost | with two imposts | three-leaf with two imposts |

Rice. 4. Sketches of window design measuring 15×18 dm

Based on the described methodology, window openings are selected for the remaining rooms:

- kitchen – 15×18 dm, area ratio – 1:6.7; room 1 – 15×18 dm, area ratio – 1:7;

- room 2 – two windows 15×12 dm, area ratio – 1:5.5; room 3 – 15×18 dm, area ratio – 1:6.8;

- furnace - the dimensions of the window facing outside are determined at the rate of at least 0.3 m2 of window per 10 m3 of room.

In our case, the furnace area is 5.07 m2, the height of the room is 2.5 m, we obtain the volume of the room equal to 12.7 m3. This volume corresponds to a window opening with an area of at least 0.38 m2. The area value is obtained by mathematical proportion. According to the table 1 adj. 1 select a window opening with an area of at least 0.38 m2. We accept an opening measuring 9x6 dm with an area of 0.54 m2.

The calculations are summarized in table. 1.

Table 1. Calculation of the area of light openings

| Apartment type | The name of a room | Area, m2 | Attitude | ||

| light openings | gender | premises | Houses | ||

| House | common room | 2,7 | 20,16 | 1:7 | 1:6,6 |

| Kitchen | 2,7 | 18,15 | 1:6,7 | ||

| Room 1 | 2,7 | 19,8 | 1:7 | ||

| Room 2 | 3,6 | 19,95 | 1:5,5 | ||

| Room 3 | 2,7 | 18,48 | 1:6,8 | ||

Conclusion : the requirements of TKP 45-3.02-230–2010 are met.

After determining the area of light openings, they proceed to drawing window openings on the plan of a residential building (Fig. 5).

Rice. 5. Plan of a residential building with window openings

Sequencing

The design is measured in a certain sequence:

- determination of opening parameters;

- determining the internal dimensions of the frame;

- calculation of possible deviations from the norm based on the data obtained above;

- determining the size of the elevation of the lower part of the window above the plane of the opening;

- calculation of frame parameters.

Discuss in advance with the team of window workers what measures will be taken to protect the installation seam from harmful environmental factors; it may be necessary to knock down brick irregularities on the wall or panel. In general, window openings are similar in structure to door openings.

How to properly measure a window using improvised means

To find out whether there is a quarter in the window or whether it is solid, it is worth taking several measurements, both inside the house and outside.

Correct measurement of a window opening for a plastic window implies taking into account the possible distortion of the wooden structure PHOTO: fabrikaokon.ru

You need to do the following:

- measure all parameters: height, width and length;

- calculate the dimensions of internal and external structures;

- add into the calculation the dimensions of additional parts, ebb and flow and mosquito nets.

After all the parameters have been calculated, it is necessary to agree with the manufacturer and installer of the structures on the type of binding, color, type of glass unit and other details.

How to correctly measure a glass unit for replacement

Before measuring the window opening for a plastic window, it is worth considering that in wooden buildings there are often no protrusions, which means you can choose another suitable place on the wall to install the fasteners.

If the windows are multi-level, measurements are carried out in several stages PHOTO: oconto.ru

When measuring a window opening for PVC windows, first write down the width, and only then the height and length. If the dimensions are not the same, subtract 50 from the smallest indicator. This is necessary for installing the mounting seam in the future.

The thickness of the window sills must be taken into account. Most often it is 30 mm PHOTO: plastikovye-ocna.ru

If desired, you can insulate the stand profile, which should also be taken into account when calculating PHOTO: plastikovye-ocna.ru

Options and selection of PVC panels

All types of plastic panels are made on the basis of polyvinyl chloride. In this case, the products are divided into 2 types.

The first option is panels that are made entirely of high quality PVC or vinyl. The structure of such elements is homogeneous, which ensures the strength and reliability of the products. Such PVC panels are in demand on the market and are often used for cladding the facades of buildings.

PVC panels can imitate any material for facade finishing

The second type of PVC products is combined and consists of two layers. The outer shell protects the panels from fading and exposure to atmospheric factors, and the inner layer provides rigidity and strength to the elements. Such panels are more expensive and are rarely used for facade finishing.

Panels are elements with holes for fastening

Depending on the appearance, PVC products are divided into the following types according to the type of simulated surface:

- stone; brick; wood, timber; marble.

External differences do not affect the characteristics of products and are taken into account only when developing the facade design

When choosing a material, you should pay attention to its thickness, which can be 15, 17, 18, 21 mm. A specific option is selected depending on the climatic conditions of the region

It is also important to take into account the installation principle by which the elements will be attached. Panels can be mounted horizontally or vertically

In the first case, small panels are chosen, and for vertical installation, products with large parameters are needed, covering the entire height of the wall.

Common Mistakes

When measuring a window opening, it is necessary to take into account common mistakes.

- It is important to check whether the walls are even and there are no large chips or distortions in the horizontal and vertical planes.

- Many people forget to take into account that the distance between the walls increases when dismantling the old product.

If incorrect or inaccurate endpoints are determined, the following problems may arise during the installation phase.

- The appearance of significant gaps along the perimeter. To correct the defect, you will have to purchase an additional bottle of polyurethane foam. During operation, the frame deforms and it begins to let in cold air and dust. A double-glazed window will not protect the room from humidity, which can lead to the appearance of fungus. Mold causes various diseases, such as allergies or asthma.

- A mistake can lead to an increase in the size of the profile and a frame made to your dimensions simply will not fit. Correcting this defect is much more difficult. To do this, you will have to remove part of the wall, and this is a labor-intensive process, noisy and dirty type of work, which increases the repair time and its cost. Special equipment is required to remove concrete or masonry.

Over time, the frames in the apartment do not close well, the plastic does not look so snow-white, and the deformed fittings creak. To replace them, it is necessary to measure the plastic windows. This stage is very important, as well as installation.

Work order

Proper use of masonry mortar.

As a rule, when sealing an unnecessary doorway with brick, a partition thickness of 12 cm (half a brick) is maintained, since this structure does not bear any load; the upper part of the existing wall is held by a lintel. A window in an external fence can also be laid in half a brick, provided that additional insulation is provided.

To ensure that a blocked door can bear the load from hanging cabinets or any household appliances, the usual method of laying stones is used - on spoons. In this case, it is necessary to bandage the seams by half or a third of the length of the brick. Sometimes another method of embedding is used - a one-and-a-half hollow stone 88 mm high is laid with a bandage on the edge. But it should be taken into account that such a partition will not be able to bear additional load.

The work is carried out in the following order:

- Prepare a simple cement-sand mortar of M50 grade, using 1 part M400 cement to 5 parts well-sifted sand. Another option is to purchase ready-made masonry mixture and mix it with water, following the instructions on the bag.

- Moisten the base and sides of the opening with water. Place 1 row of stones near the installation site, cut the last one to the required size.

- Carefully spread the mortar to the length of 2-3 stones and begin laying 1 row. After each laid brick, pull the mortar to its side with a trowel, and then press it with the next stone.

- Apply the mortar to the end of the last brick in advance and put it in place. To maintain the thickness of the seam, the stones must be tapped.

- Fill the entire opening in this way, focusing on the plane of the existing wall. Do not allow the masonry to bulge or cave in; to do this, constantly check the wall, applying an even plank to it. Another option is to pull the mooring line and navigate along it.

In a situation where it is necessary to pass heating pipes made of PPR, metal-plastic or metal through the gap being laid, steel sleeves (cases) are placed in the partition. Their diameter must be greater than the outer size of the pipe. The length of the case is selected so that its ends extend beyond the surface of the masonry by 2-3 cm.

After the mortar has hardened, the structure must be lined so that the door covered with bricks does not differ in appearance from the rest of the walls. Choose the appropriate type of finishing - plaster, drywall or other material.

Preventing window fogging

If you are doing the repairs yourself, take a closer look at the PVC window. On the frame you will find a drainage hole that goes all the way through. It is left just so that condensation does not accumulate on the windows. The price of the window is not important - all manufacturers leave a similar hole. When installing the mount yourself, drill a straight hole. This will be enough to securely install a frame that will serve you for many years.

Expert commentary

Vladislav Dobronravov

Leading technical specialist at Okna-Media company

One more word of caution. Today, in any city there is a huge number of construction stores that sell a wide range of standard mounting plates. They look good and really make installation of the balcony unit easy. The danger is that such a mount will not even support the weight of the open window sashes. There is no need to talk about other loads. The mount simply becomes deformed, and you will incur additional costs to replace it.

Now you have sufficient knowledge that will allow you to glaze a balcony or loggia easily and without problems. And even if you don’t yet dare to do your own repairs, you are already competent enough to supervise invited workers. You can be sure that no matter who installs your windows, the work will be done efficiently and your home will become warm and cozy.

Preparatory stage

The wall of any building can be constructed from different materials. But experts give their preference to brick. It is especially beneficial to use this material in low-rise structures. Brick has the following advantages:

Preparing bricks for laying.

- strength;

- resistance to moisture;

- fire resistance;

- variety of shapes, sizes and material features.

Brick is a universal material. With its help, the thickness of the masonry can be from 0.5-2.5 bricks. This type of development has the following difficulties:

- frequent reinstallation if the structure is poorly vertical;

- difficulty maintaining the thinness of the seam;

- heavy attachment of the partition to load-bearing walls, floor, ceiling.

To lay a quarter brick wall you will need special tools. Well-chosen tools will help you mix the mortar, lay the bricks correctly, and make checks and measurements along the way (control over the accuracy of the object’s geometry). You can’t do without the following tools at a construction site:

- Trowels are a product for filling joints with mortar, leveling them and removing excess mortar. This is a steel spatula with a plastic or wooden handle - the main tool of a mason.

- Mortar shovels - use them to level and apply mortar to the walls.

- Joints - devices for working with seams. They come in a variety of sizes and cross-section profiles to suit the thickness and shape of the seam.

- Hammer-pick - a tool for crushing bricks into halves, quarters, and trimming them.

- Mops are cleaning devices for smoothing seams. It looks like a rubber plate with flanges.

To control the masonry you will need:

Necessary tools for masonry.

- plumb line - a tool for checking the verticality of the partition and the angle of the masonry;

- level for construction - it is used to check verticality and horizontality;

- the rule is a device for checking the quality of the front surfaces of the wall, this is a strip (often made of duralumin) up to 1.2 m long;

- a wooden square - it is used to check the squareness of the corners when building walls;

- a tape measure is an indispensable tool for measuring the dimensions of materials and walls; a folding meter can also be used for these purposes;

- cord-mooring - to check the correct position of the bricks in a mile;

- ordering made of wood - used for marking rows in masonry, it looks like a strip with many notches.

How to frame an opening

Window edging, like brick laying of any other architectural elements of the facade, can only be done during the construction of the wall, or during renovation, when windows are replaced. Their appearance will largely depend on the design of the lintels in the openings. They can be reinforced concrete, brick (arched or wedge-shaped) or metal (steel angle or profile). So:

Brick cladding of a window opening, which is called a “quarter” in construction, is the most popular type of architectural facade decoration. At the same time, the facing brick is laid with the butt forward, protruding beyond the surface of the masonry by a fourth of the brick body - hence the name.

Window openings when faced with quarter brick

To lay out the quarters, use halves of bricks, which must be cut with a grinder and a diamond wheel before starting work. Based on the standard brick length (25 cm), the size of a half will be 12.5 cm. Accordingly, a quarter is 6.25 cm. When cutting, you can deviate from these dimensions by no more than 7-10 mm. If the protruding part of the window frame is too small, there is no point in it at all. Too large quarters can create a different kind of problem - the window opening will be too wide, and in order to seal the gaps after installing the window, you will have to fill the gaps with foam that are too large

During the construction of walls, window areas must be particularly carefully reinforced. Particular attention should be paid to controlling the verticality of the masonry and the horizontality of the rows. If the master’s level is always at hand, then the window openings will have the correct shape

The window covering must be connected to the wall masonry with a reinforcing wire mesh 3 mm thick (cell 50*50).

Steel corner in the opening

- To lay out the quarter, it is most convenient to block the opening with a steel corner. For this purpose, the size 100*100 or 120*120 is usually used. Before installation, it should be coated with any anti-corrosion compound, or simply painted. The corner is mounted so that it does not protrude inward due to the quarters. A concrete lintel will be installed five centimeters above the corner.

- In order for the row of masonry that will be carried out along the corner to be flush with the general plane of the wall, the bricks will have to be cut in thickness. A window that is not rectangular in shape, but, say, arched, is framed in a similar way, only instead of a corner, the opening is covered with a wooden template, according to which a quarter is drawn.

- After the mortar has hardened in the masonry, the template is removed and the seams are carefully cleaned. To create a double frame, as in the example below, the first row of the quarter is overlapped with the same pattern. Following the facing brick is backfill masonry, which is also covered with a template so that an arch is formed on both sides.

Arched window with brick frame

In general, there are at least a dozen options for laying facing bricks around the perimeter of the window. Moreover, the display can be done not only with a poke forward, but also with a spoon; they can be beautifully combined, creating a beautiful composition above the window. Spoons can be placed either standing or lying down. For example, by alternating three vertical and three horizontal spoons, you can get a pattern that resembles a chessboard. And by alternating spoons and pokes, you get a jagged pattern. A figure can be made above the lintel, resembling a gable roof or a house roof or a dome. So, the design possibilities for window cladding are quite extensive.

Removing the old window

Before installing a new window, of course, you need to remove the old one. The procedure is simple and does not take much time.

- For blind windows, remove the glazing beads, then remove the glass. Then the sashes are removed.

- Several cuts are made on the frame with a regular saw or grinder, but then a special circle for concrete is needed. Then the frame is removed in parts using a crowbar or other convenient tool.

- The final stage is dismantling the window sill. The wooden one is removed, as is the frame. Concrete is broken with a hammer. This completes the dismantling of the old window. All that remains is to remove the garbage.