The issue of thermal insulation of buildings always occupies a leading position, since it directly affects the costs of maintaining the building. In the face of increasingly stringent energy efficiency requirements for buildings, the thickness of the masonry must be doubled. And this will entail increased costs for the purchase of materials, additional load on the foundation and other difficulties. Almost all construction organizations use insulation, and the most impressive argument is its high thermal insulation properties. So how much brick does Penoplex replace, let's find out!

Thermal conductivity and density of penoplex, comparison with polystyrene foam PSB

A comparative table of the values of the thermal conductivity coefficient, density of penoplex and polystyrene polystyrene PSB of various brands in a dry state at a temperature of 20...30°C is presented.

Their operating temperature range is also indicated. Penoplex thermal insulation, in contrast to non-pressed polystyrene foam PSB, is produced at elevated temperatures and pressures with the addition of a foaming agent and extruded through an extruder. This production technology provides penoplex with a closed microporous structure.

Penoplex, compared to polystyrene foam PSB, has a lower thermal conductivity coefficient λ , which is 0.03...0.036 W/(m deg) . The thermal conductivity of penoplex is approximately 30% lower than that of such traditional insulation as mineral wool. It should be noted that the thermal conductivity coefficient of polystyrene foam PSB, depending on the brand, is in the range of 0.037...0.043 W/(m deg).

The maximum temperature for using Penoplex expanded polystyrene is 75°C. For PSB foam it is slightly higher and can reach 80°C. When heated above 75°C, penoplex does not melt, but its strength characteristics deteriorate. The manufacturer does not report how much the thermal conductivity coefficient of this thermal insulation material increases under such conditions.

Thermal conductivity and density of penoplex and expanded polystyrene PSB

| Brand of expanded polystyrene | λ, W/(m K) | ρ, kg/m 3 | trab, °С |

| Penoplex | |||

| Penoplex comfort slabs | 0,03 | 25…35 | -100…+75 |

| Penoplex Foundation | 0,03 | 29…33 | -100…+75 |

| Penoplex Roofing | 0,03 | 26…34 | -100…+75 |

| Penoplex segments grade 35 | 0,03 | 33…38 | -60…+75 |

| Penoplex segments grade 45 | 0,03 | 38…45 | -60…+75 |

| Penoplex Block | 0,036 | from 25 | -100…+75 |

| Penoplex 45 | 0,03 | 40…47 | -100…+75 |

| Penoplex Slope | 0,03 | from 22 | -100…+75 |

| Penoplex Facade | 0,03 | 25…33 | -100…+75 |

| Penoplex Wall | 0,03 | 25…32 | -70…+75 |

| Penoplex Geo | 0,03 | 28…36 | -100…+75 |

| Penoplex Base | 0,03 | from 22 | -100…+75 |

| Expanded polystyrene PSB (foam plastic) | |||

| PSB-15 | 0,042…0,043 | up to 15 | up to 80 |

| PSB-25 | 0,039…0,041 | 15…25 | up to 80 |

| PSB-35 | 0,037…0,038 | 25…35 | up to 80 |

| PSB-50 | 0,04…0,041 | 35…50 | up to 80 |

It should be noted that Penoplex thermal insulation, due to its closed microporous structure, practically does not absorb moisture, is not affected by mold, fungi and other microorganisms, and is an environmentally friendly and safe insulation for humans.

In addition, extruded polystyrene foam Penoplex has fairly high chemical resistance to many materials used in construction. However, some organic substances and solvents listed in the table below can cause insulation boards to soften, shrink, and even dissolve.

Source

Thermal conductivity of polystyrene foam - exact numbers

The ability to conduct heat is influenced by many factors, in particular:

- Layer thickness. Sometimes, in order to achieve high-quality energy savings, it is necessary to use a large amount of insulation. For example, the thermal conductivity of 5 cm foam plastic boards will be lower than 1 cm with the same density.

- Structure. The porous structure leads to increased insulating properties, because the cells contain air that perfectly retains heat.

- Humidity. During storage, slabs must be protected from moisture. This is due to the fact that liquid does not have a very favorable effect on the characteristics of thermal insulation foams: the more it accumulates, the worse it is.

- Average layer temperature. Its increase leads to a deterioration in the efficiency of the insulator.

Types of foam plastic and their indicators

There are a huge number of insulation boards on the construction market. In general, polystyrene foam has low thermal conductivity, but this varies depending on its type. Examples: sheets marked PSB-S 15 have a density of up to 15 kg/m3 and a thickness of 2 cm, while the described indicator is up to 0.037 W/(m*K) at an ambient temperature of 20-30 °C. Its value for sheets 2-50 cm marked PSB-S 35, with a density of no more than 35 kg/m3 and 16-25 kg/m3 marked PSB-S 25 of the same size is 0.033 W/(m*K) and 0.035 W/ (m*K) respectively.

The dependence of the thermal conductivity of foam insulation on its thickness is best seen when comparing it with various materials. Thus, a sheet of 50-60 mm replaces twice the volume of mineral wool, and 100 mm is equivalent to 123 mm of expanded polystyrene foam, which has approximately similar characteristics. Basalt wool also loses greatly. But the thermal conductivity of Penoplex is slightly lower than that of polystyrene foam: in order to obtain normal temperature conditions in the room, you will need 20 and 25 mm, respectively.

How do you know which sheets to buy?

In order to most effectively apply this or that insulation method, it is necessary to select the correct dimensions of the material. Calculations are performed according to the following algorithm:

- Find out the total thermal resistance. This is a constant value that depends on the climate in a particular region. For example, for the southern regions of Russia it is 2.8, and for the central zone - 4.2 kW/m2.

- Calculate the thermal resistance of the wall itself using the formula R = p / k, which can be done knowing its thickness (p) and the coefficient of ability to conduct heat (k).

- Based on constant indicators, find out what resistance value the insulation should have.

- Calculate the required value using the formula p = R * k, where R is the value from the previous step, and k is the calculated thermal conductivity coefficient for the foam.

As an example, it is worth finding out what layer of slabs with a density of 30 kg/m3 is needed for a wall of one brick (about 0.25 m) in one of the southern regions. The total thermal resistance should not be less than 2.8 kW/m2, despite the fact that the coefficient determined using special tables is 0.047 (W/m*k). Now you need to find out other parameters.

Coefficient for sand-lime brick k = 0.7 (W/m*k). You should calculate its thermal resistance:

R = 0.25 / 0.7 = 0.36 (kW/m2).

The same indicator is calculated for insulation:

R = 2.8 – 0.36 = 2.44 (kW/m2).

It remains to find out the thickness of the insulating layer:

p = 2.44 * 0.047 = 0.11 m.

You can also calculate this value for other conditions, for example, for a wall of 0.51 m, 70 mm insulation is suitable. Thus, when selecting the required sizes of polystyrene foam, time and money for laying the wall are saved. So, 10 cm of material with a density of 15-17 kg/m3 replaces the masonry of one brick, and if you take denser sheets, this will allow you to do without two rows of stone. It is traditionally believed that 2 cm of insulation is equivalent to about 50 cm of brick.

Penoplex 50 mm thick - properties and characteristics

Penoplex brand insulation is nothing more than extruded polystyrene foam. It belongs to a new generation of thermal insulators that are very effective in terms of heat conservation. In this article we will take a detailed look at penoplex: technical characteristics, pros and cons and areas of its application. To begin with, we note that this material is durable, almost does not absorb water at all and has a low thermal conductivity coefficient.

Description

PENOPLEX OSNOVA® is a highly efficient thermal insulation material of the latest generation, manufactured by extrusion from general-purpose polystyrene. Zero water absorption, high strength, environmental friendliness and low thermal conductivity are the main advantages of PENOPLEX insulation compared to other materials.

Application of PENOPLEX BASIS®

Intended for use in industrial and civil construction, it is a universal material for use in any structures (walls, roofs) where special requirements for loads on the structure are not imposed.

What density foam is best for different types of insulation?

High-density PSB is best used for insulating industrial facilities, utilities, parking lots, roads and sidewalks. It is used in industry and the highway sector. It is able to withstand high static and dynamic loads on the plane.

This begs the question, what is the best characteristic of polystyrene foam for insulating a house? Density 35 kg/m³ is the volumetric weight of polystyrene foam for insulating walls outside. Polystyrene PSB-S-35 and PSB-S-25 correspond to this density and are suitable for thermal insulation of facades of residential buildings. Its structure will not be destroyed by mechanical impact on the plane of the slabs.

The slabs are easy to install and process, allowing you to obtain a thermal insulation effect at low material costs. This is the most popular type of slab.

PSB-S-15 foam plastic slabs can also be used to insulate house facades. It is important to exclude static and shock loads on the surface of the insulation during operation of the building. It can also be used to fill voids in structures, insulate attics, insulate underground spaces and voids in ceilings.

All types of foam plastic must comply with the requirements of regulatory and technical documentation. When purchasing a product, pay attention to the appearance and structure of polystyrene boards.

Popular posts

- Chair for dressing table Chairs for dressing tables in Moscow - 189 Products Company from Moscow, delivery 29643 a In…

- Silicone sanitary sealant Silicone sanitary sealant white in Moscow - 1491 products Company from Moscow, delivery (tomorrow) 140...

- Shelf in the hallway Currently, there are a huge number of different options for shelves in the hallway, and this is directly ...

- Insulation of the floor in a wooden Insulation of the floor in a wooden house from below: materials and installation technology SHARE ON SOCIAL NETWORKS One of the common…

What to insulate with 50 mm penoplex

Penoplex with a sheet thickness of 50 mm is one of the most popular and popular. Due to the excellent price-quality ratio, the choice of buyers most often falls on it. It can be used to insulate:

The penoplex manufacturer has special subtypes of insulation for each of these purposes. Their technical characteristics will be discussed below.

The wall

For external insulation of wall surfaces, Penoplex “Wall” insulation was developed. The size of a sheet of such insulation is 120 by 60 cm. This means that one element of insulation can cover an area of 0.72 m2. This is a pretty good indicator, which will make it possible to finish a wall with a size of 10x4 meters in less than one day. The manufacturer has provided that special antioxidants and fire retardants be introduced into this type of penoplex. The former allow the insulation to resist the oxidizing effects of oxygen, while the latter reduce flammability. The structure of the insulation is designed in such a way that it interacts well with finishing mixtures. The ability to have sufficient adhesion prevents them from peeling off. The insulation can also withstand sufficient weight. Its resistance to compressive force is 0.2 MPa.

Note! When calculating the required amount of insulation for a specific area, it must be taken into account that with a material thickness of 50 mm, 8 units of insulation or 5.76 m2 are placed in the package.

Foundation

Due to its design and position, the foundation can experience significant temperature effects and cause up to 20% heat loss. That is why it is worth thinking about insulating it. Foam insulation “Foundation” 50 mm is perfect for these purposes. It does not contain fire retardant additives, so its cost may be slightly lower than wall insulation. The sheet size is standard, as mentioned in the previous version. The density of penoplex for these purposes has been increased, and now it is 33 kg/m3. This is necessary for greater compressive stability, because the foundation is backfilled and the soil around it is compacted. The tensile strength level also increased to 0.27 MPa. Paired with bitumen mastic, it can provide excellent waterproofing, which will reduce the likelihood of basement flooding.

Roofing

Roof insulation with penoplex can be done in two ways. One of them involves installing foam sheets 50 millimeters thick on the attic floor, and the second involves insulating the roofing itself, which is carried out from the inside. The use of penoplex in such areas of the building is very important, because heat rises by convection and will evaporate freely, increasing fuel costs. In this case, the environmental friendliness of the insulation also comes into play. The compression resistance of roofing foam is slightly lower than that of foundation foam. This is due to the fact that the roofs do not have such high loads. The thermal conductivity coefficient of such penoplex with a thickness of 50 mm is 0.03 W/(m×K).

The roof is the highest point of any building; if it is not shaded, it heats up more than other surfaces. This means that in the summer it will cause some inconvenience and will require funds for air conditioning. Penoplex allows you to solve this problem. Due to its properties, penoplex insulation prevents excess heat from entering the building. If the roofing material chosen is one based on sheet metal, then penoplex will also provide sound insulation so that the rain does not wake you up at night with the drumming of drums. The process of making insulation can be assessed in the video.

Other types of penoplex

One of the unique types of penoplex, which is most often produced with a sheet thickness of 50 mm, is insulation with index 45. It differs from all previous types in having a denser structure. The density of this penoplex is 45 kg/m3. With such a density and bending resistance of up to 0.7 MPa, it is excellent for laying under road surfaces. In areas that are characterized by significant seasonal precipitation and wet soil, it will prevent the rapid destruction of routes. Penoplex practically does not absorb water, so it will not let it through to the flooring. The thermal conductivity of penoplex 45 is at the level of 0.03 W/(m×K).

Penoplex insulation of this series is also perfect for insulating plinths and basements of buildings. In some buildings, the roof is usable; for example, it can be equipped with an observation deck or a landing spot for a helicopter. On the roofs of some multi-story buildings there may be a small truck crane for delivering goods or moving a cradle. This type of insulation is also perfect for heating mains. It allows you to minimize heat loss. In addition, due to negative moisture absorption, it protects pipes from corrosive effects. In the table below you can also see the characteristics of “Comfort” insulation - another universal line from the manufacturer.

Thermal conductivity of polystyrene foam + table

In this case, the thickness of polyethylene foam insulation can vary from 1 to 50 mm, and the shape can be in the form of:

Films, sheets and tiles without any coating, used mainly for thermal insulation of parts of various equipment, including refrigeration,- Polyethylene foam with double-sided film coating, which is used for insulating floors, foundations or basements. The polymer coating provides additional waterproofing of surfaces, and also protects the material itself from mechanical injury and sunlight.

- With foil on one or both sides, it is used in places where not only direct retention of warm air is required, but also reflection of thermal radiation and fire protection properties (roofs, walls, places behind heating radiators, internal surfaces of reflector heaters, etc.)

- In the form of tubes, polyethylene foam is used as a protective shell for water pipes, sewers, heating and air conditioning systems.

- In the form of a rope, it is used to cover seams and gaps in walls, window and door openings, etc.

Each type of polyethylene foam insulation can have self-adhesive surfaces for ease of installation.

IMPORTANT! For modern polyethylene foam insulation, finishing can be provided not only from film, but also from materials such as paper, lavsan and denser plastic. In these cases, it can be used without additional decorative and protective finishing.

Manufacturing technology

The equipment used is an extruder. Its name, arbitrary from the name of the head with dies located at the exit of the alloy from the unit, is extrusion.

The main component of the technological process is polystyrene granules. It is divided into several stages:

First

Second

Making the slab - staying in the holding chamber for 24 hours. All air is pumped out of the unit using a vacuum pump, and the material is left inside. It stabilizes, the pressure inside the granules filled with air is balanced.

Third

Blocks are formed in a closed type matrix. Steam is supplied inside the container under pressure. Residual moisture is lost. The aging stage ends for a day, with each new heating cycle increasing the density of the structure.

A moderately dried block is cut on a conveyor belt. Violation of technology leads to uneven edges. The cutting tool is a red-hot refractory steel string. The production uses equipment with an electronic program that controls the level of metal heating.

Source

Why is thermal insulation needed?

The relevance of thermal insulation is as follows:

Heat loss through the walls of a typical multi-storey residential building is 30-40% . To reduce heat loss, special thermal insulation materials are needed. The use of electric heaters in winter contributes to additional energy costs. It is more profitable to compensate for these costs by using high-quality thermal insulation material, which ensures heat retention in winter and coolness in the summer heat. At the same time, the cost of cooling the room with air conditioning will also be minimized.

In the case of industrial buildings using a metal frame, insulation helps protect the metal surface from corrosion, which is the most detrimental defect for this type of structure. And the service life of a brick building is determined by the number of freeze/thaw cycles. The impact of these cycles is perceived by the insulation, because the dew point is located in the thermal insulation material, and not in the wall material.

Such insulation allows you to increase the service life of the building many times.

Protection against increasing noise levels is achieved by using such noise-absorbing materials (thick mattresses, sound-reflecting wall panels).

The use of a thermal insulation system makes it possible to reduce the thickness of external walls, while increasing the internal area of the building.

Comparison of polystyrene foam with other thermal insulators

Insulation materials are used in construction to reduce the thickness of walls, ceilings, and roofing pie.

The structural materials of these power structures are covered with a heat insulator to distribute the properties:

- concrete, brick, wood provide a stable geometry of the building frame, strength sufficient for operational loads;

- expanded polystyrene creates a thermal barrier to reduce heat loss.

A 2 cm layer of this material successfully replaces:

- 27 cm of foam concrete;

- 37 cm brick;

- 20 cm of lumber;

- 4 cm mineral wool;

- 3 cm foam;

The main advantage of PSB-S is the preservation of properties upon contact with water. The disadvantage is that it melts when in contact with an open flame. The presence of fire retardants in the material cannot completely solve the fire safety problem. Therefore, expanded polystyrene is prohibited by SNiP standards for complete gluing of facades.

Only non-flammable basalt wool is allowed around window and door blocks, and in interfloor fireproof sections. The entire remaining plane of the outer wall can be protected with extruded polystyrene foam in order to save money.

Also read with this article:

How to choose the right insulation?

When choosing insulation, you need to pay attention to: affordability, scope of application, expert opinion and technical characteristics, which are the most important criterion.

Basic requirements for thermal insulation materials:

Thermal conductivity refers to the ability of a material to transfer heat. This property is characterized by the coefficient of thermal conductivity, on the basis of which the required thickness of the insulation is taken. Thermal insulation material with low thermal conductivity is the best choice.

Also, thermal conductivity is closely related to the concepts of density and thickness of insulation, so when choosing, you need to pay attention to these factors. The thermal conductivity of the same material can vary depending on density.

Density insulation material. Based on density, materials are divided into: extra light, light, medium, dense (hard). Lightweight materials include porous materials suitable for insulating walls, partitions, and ceilings. Thick insulation materials are better suited for insulating the outside.

The lower the density of the insulation, the lower the weight, and the higher the thermal conductivity. This is an indicator of the quality of insulation. And the low weight makes installation and installation easy. In the course of experimental studies, it was found that insulation with a density of 8 to 35 kg/m³ best retains heat and is suitable for insulating vertical structures indoors.

How does thermal conductivity depend on thickness ? There is a misconception that thick insulation will better retain heat indoors. This leads to unnecessary expenses. Too much insulation thickness can lead to disruption of natural ventilation and the room will be too stuffy.

And insufficient thickness of the insulation leads to the fact that the cold will penetrate through the thickness of the wall and condensation will form on the wall plane, the wall will inevitably become damp, and mold and mildew will appear.

If the calculation is ignored, a number of problems may arise, the solution of which will require large additional costs!

Factors affecting the thermal conductivity of expanded polystyrene

The density of materials shows the air content in them; with an increase in this characteristic, the thermal conductivity coefficient decreases. For expanded polystyrene, as the density increases from 10 to 35 kg/m3, it decreases from 0.044 units to 0.032 units.

To facilitate design calculations, insulation manufacturers add graphite to the composition, leveling the thermal conductivity of polystyrene foam of any density to a single value of 0.055 units.

Therefore, when purchasing EPS sheets on the construction market, the consumer does not need to check this characteristic of materials of different densities.

Advantages and disadvantages

Visually, both insulation materials appear identical. The materials are made from expanded polystyrene foam, but using different technologies. Changing the production method dramatically affects the characteristics of the resulting raw materials.

Styrofoam

The material is obtained by the action of steam on polystyrene granules. Due to the moderate temperature, the size of the components increases 50 times, they stick together, but do not melt. Microscopic gaps remain between the elements. The plastic balls are empty inside, so the raw material is light and airy.

Foam material Source e-pard.com

When buying polystyrene foam or penoplex, the user is looking for practical insulation. The option based on foam spheres is used in conditions of high humidity. The building material can be installed without vapor barrier. Due to the gaps in the structure, the raw materials provide good air exchange, and mold and fungi do not form on the surface.

Due to its low weight, insulation is used in frame structures. The building material has a low thermal conductivity coefficient and a long service life (20-30 years). Raw materials are produced in the form of flat blocks (sheets), which are easy to give the desired shape. When installed correctly, the parts do not change the geometry. Another advantage is the low price and soundproofing properties.

High flammability is the main disadvantage of the building material. The foam supports smoldering, causing the flame to spread to other components and start a fire. Under the influence of temperature, toxic substances that are dangerous to living organisms are released into the air.

Pros and cons of raw materials for insulation Source kaminguru.com

How do they do it?

This material is produced at enterprises from polystyrene granules using various kinds of additives, which ultimately improve its performance qualities. In the production of penoplex, the initial raw materials are previously exposed to high temperatures under high pressure. Next, a special catalyst for foaming is added to the mass. Then substances are added to the penoplex that increase its fire-resistant properties, ability to resist ultraviolet radiation, etc.

Table of thermal conductivity of materials

This factor is significant, especially in the case of insulating a residential building, since many materials emit formaldehyde, which affects the growth of cancerous tumors. Therefore, it is necessary to make a choice towards non-toxic and biologically neutral materials. From an environmental point of view, stone wool is considered the best thermal insulation material.

The material must be non-flammable and safe. Any material can burn, the difference is at what temperature it ignites. It is important that the insulation is self-extinguishing.

Those materials that are waterproof have an advantage, since moisture absorption leads to the fact that the effectiveness of the material becomes low and the useful characteristics of the insulation after a year of use are reduced by 50% or more.

On average, the service life of insulating materials ranges from 5 to 10-15 years. Thermal insulation materials containing cotton wool significantly reduce their effectiveness in the first years of service. But polyurethane foam has a service life of over 50 years .

What is contact allowed?

The advantage of 50 mm penoplex insulation, among other things, is that it is resistant to various types of paints, mortars, acids and alkalis. For example, such boards do not collapse upon contact with butane, ammonia, animal and vegetable fats, alcohol and water-based paints.

Penoplex material is resistant to various chemicals. However, some such substances can still have a negative effect on it. These include, for example:

gasoline and kerosene;

acetone and xylene;

Advantages and disadvantages of insulation

Types of polyurethane foam Advantages: seamless foam installation, durability, better heat and water insulation.

Disadvantages: high cost of material, instability to UV radiation.

Advantages: low thermal conductivity, low cost, ease of installation, water resistance.

Disadvantages: fragility, easy flammability, condensation.

Disadvantages: much more expensive than polystyrene foam, susceptibility to organic solvents, condensation formation.

Advantages: resistance to the formation of fungi, sound insulation, mechanical strength, fire resistance, non-flammability.

Disadvantages: higher cost compared to analogues.

Advantages: sound insulation, environmental friendliness, moisture resistance, affordable cost.

Disadvantages: thermal conductivity increases during operation, the need for special equipment for installation, and the possibility of shrinkage.

Advantages: low thermal conductivity, low vapor permeability, high noise insulation, ease of cutting and installation, environmental friendliness, flexibility, light weight.

Disadvantages: low strength, need for a ventilation gap.

Advantages: environmental friendliness, high ability to reflect heat, high noise insulation, moisture resistance, non-flammability, ease of transportation and installation, reflection of radiation exposure.

Disadvantages: low rigidity, difficulty in fastening the material; penofol alone is not enough as thermal insulation.

Features of installation work

Installation of thermal insulation made of foamed polyethylene is carried out in compliance with several general rules:

- Insulated surfaces must be prepared in advance - cleaned, leveled, sealed cracks and seams,

- All equipment must be turned off during insulation work.

- To connect the joints you will need glue, and to insulate the seams - self-adhesive tape,

- An air gap must be left between the surface and the insulation,

- Foil materials are installed with foil towards the room.

Special properties of extruded polystyrene foam "Penoplex"

Penoplex acquires unique performance qualities as a result of the peculiarities of its manufacture. At the beginning of the production process, a homogeneous liquid melt of polystyrene granules is obtained by heating. Then a foaming agent, which is carbon dioxide, is introduced into it under high pressure. It is evenly distributed throughout the entire volume of the melt.

At the final stage, foamed polystyrene undergoes a process of extrusion or extrusion through calibrated holes. This achieves special performance properties of extruded polystyrene foam that are not available to other insulation materials.

When the finished substance cools, carbon dioxide is replaced by air from the environment, and completely closed cells with a diameter of about eight hundredths of a millimeter are formed. As a result of the described transformations of the material, the technical characteristics of penoplex become unique. The most important characteristic of thermal insulation materials is thermal conductivity, and penoplex has one of the best parameters.

Penoplex production line

Quite low thermal conductivity coefficient

The low thermal conductivity coefficient of penoplex, amounting to 0.03 W*m*0C, is explained by its cellular structure. The parameter practically does not change over time, its fluctuations are extremely insignificant and range from one to three hundredths of the original value. In terms of this performance parameter, penoplex is superior to polystyrene foam and other heat insulators, for example, mineral wool. The thermal conductivity of penoplex in comparison with them is one of the lowest.

Almost does not absorb water

The hygroscopicity of the product is amazing: it practically does not absorb water. A slab completely placed in water absorbs moisture to only six-tenths of a percent of its volume over the course of a month. All of it is absorbed in the first ten days, then the process stops completely. Moisture penetrates only into the top layer of the extruded foam board.

"Penoplex" does not favor water

Almost no steam escapes

A sheet with a thickness of 20 mm practically does not allow water vapor to pass through, especially penoplex with a thickness of 50 mm or 100 mm. When finishing surfaces with penoplex, no additional vapor barrier is required. Vapor permeability practically does not differ in its characteristics from roofing felt. In some cases, for example, when finishing walls from the inside, this performance property is rather a disadvantage, since it does not allow the walls to breathe.

Has high compressive strength

The high compressive strength, ranging from two hundred to seven hundred pascals, depending on the application, is due to the homogeneity of the structure. Evenly distributed tiny cells improve the strength properties of the material. It does not change its size when squeezed. This allows the material to be used for thermal insulation of floors and other surfaces that experience heavy loads.

The Penoplex bulldozer will not crush

Processing and installing insulation is easy and simple

Installing and processing extruded foam is easy and simple. You can cut it using an ordinary sharpened knife. The slabs are lightweight, so working with them does not require significant physical effort. Installation can be carried out in adverse weather conditions: snow or rain.

Chemically - practically passive

Expanded polystyrene, from which penoplex is made, does not react chemically with most substances used in construction work. The following chemically aggressive substances do not have a negative effect on it:

Some organic solvents can soften and disrupt the shape of the insulation. These include: diesel fuel and gasoline, aromatic hydrocarbons (such as benzene and toluene), oil paints and tar, acetone, ethers. It is worth noting the high biological stability of the material: it does not rot or decompose.

Environmentalists have no questions about the material

If you follow technological standards during production, penoplex is an environmentally friendly material, environmentalists have no questions about it. You can work with the insulator without personal protective equipment. However, one must take into account its artificial origin and understand that chemical components can evaporate under the influence of certain factors, for example, during prolonged heating by direct sunlight.

Fire resistance is not ideal at all

Exposure to an open flame causes the polystyrene foam to ignite. The flammability class varies depending on the purpose of use. Impregnation of this material with compositions that prevent fire does not lead to its complete fire safety. When exposed to high temperatures, the material will melt, turning into a fluid mass that emits extremely toxic and caustic smoke.

Visual characteristics of the flammability of insulation materials

The overall result is that it lasts long and reliably

The service life of insulation is determined by the number of cycles of negative and positive temperatures that the material can withstand without destruction. This parameter shows the ability of the insulator to withstand seasonal changes in external temperatures.

Installation features

If the structure needs insulation, it is worth considering Penoplex Foundation as one of the heat insulator options.

Buying the required amount of material will not be a problem. As well as choosing dimensions and adjusting them to the configuration of the object being insulated. There is no need to use special tools when carrying out the work.

But the approach will be comprehensive.

- It is necessary to calculate the thickness of the insulator, eliminate possible accumulation of moisture, and also provide for cold bridges. Take it to the larger side when choosing thickness;

- If this is external vertical insulation, then dowels cannot be used for fixation. This leads to loss of the thermal insulation properties of the material. The same rule applies when installing slabs below ground level;

- To increase energy efficiency, it is better to use 2 layers of insulation. Therefore, 2 slabs 50 mm thick, laid with a shift, will be more effective and preferable than 1 slab 100 mm thick;

- To protect the foundation from the effects of drainage water, never lay insulation directly on the ground. You will need a layer in the form of a sand and gravel cushion, which is carefully compacted;

- Under ideal conditions, it is possible to make a thin concrete screed;

- The slabs should not be laid on surfaces that are not protected from moisture. In other words, waterproofing is carried out first, and only then the Penoplex Foundation is used;

- To fix it, glue is applied to the slab using the dot method and pressed against the surface. The smoother the base, the better. So it’s worth thinking about leveling even before waterproofing work;

- Pay special attention to the choice of glue. It must withstand the load of an aggressive environment and not be afraid of organic solvents;

- Installation using dowels is allowed when laying the insulator on the base. But you cannot take more than 4 dowels per sheet 50 mm thick.

As for me, there is nothing complicated in the installation technology of this heat insulator.

How many bricks does Penoplex replace?

Tightening requirements for heat and energy conservation of building structures requires at least a twofold increase in the thickness of walls and ceilings. For brick and concrete walls this figure is 90 and 110 mm, respectively. The problem is solved by using perfect facade and foundation thermal insulation. So how much brick does Penoplex replace, and why is this material considered optimal for insulating almost any building structure?

The Penoplex price list currently in effect in our company offers several types of insulation made from extruded polystyrene foam, the thermal conductivity coefficient of which will pleasantly surprise you.

The material is difficult to counterfeit, so the risk of purchasing a low-quality counterfeit is reduced to zero.

What properties of Penoplex determine the high level of consumer demand?

When choosing a material, its unique low thermal conductivity, light weight, simple installation and long service life are taken into account.

The disadvantages of Penoplex Facade, which you can buy from our company at any time of the year - zero vapor permeability and fairly low heat resistance, are partially or fully compensated by the use of façade systems with slot ventilation and the installation of heat-resistant protective and decorative coatings.

As for the insulation of underground structures, including foundation ones, in this case moisture- and frost-resistant polystyrene foam does not have a worthy alternative.

The strength of the foundation lining is sufficient to protect the waterproofing from damage by seasonal movements of heaving soils. The range of polystyrene foam insulation includes panels of different sizes: from 30 to 100 mm thick. In most central regions, panels with a thickness of 50-60 mm are in high demand. You can buy Penoplex 50 mm in Moscow with significant discounts at promotional and seasonal sales of building materials.

How much brickwork does Penoplex replace?

For those who plan to order Penoplex, the ratio of thermal insulation material to brick plays an important role. We will tell you about the most popular thickness of thermal insulation boards and their correspondence to the thickness of the brickwork.

Now that you have found out what wall thickness Penoplex replaces, there is no reason to put off the purchase of thermal insulation material - call us and order insulation at a favorable price today!

Expanded polystyrene insulation in country and cottage-type houses

Many developers use the material for external insulation of facades and ceiling structures of country houses, which are being converted for year-round living. The main range of applications for polystyrene foam insulation is finishing foundations, blind areas, and insulating cement screeds under floor tiles.

Unlike mineral wool, expanded polystyrene does not require film or mastic waterproofing, so it can be mounted directly on a flat ground surface.

The more than moderate cost of polystyrene foam materials is complemented by the possibility of do-it-yourself installation, which allows you to reduce the cost of thermal insulation work by 35-40%.

Buy high-quality Penoplex insulation from our company right now at a competitive price!

The entry was published in the General information section. Bookmark the permalink. (0 ratings, average: 0.00 out of 5) In order to rate a post, you must be a registered user of the site.

What do consumers think of the material: positive reviews

The technical characteristics of 50 mm penoplex are very good. Accordingly, the owners of country houses have a good opinion about this insulation. Consumers consider the advantages of penoplex, first of all, to be its very low degree of thermal conductivity. This material costs a little more than the same mineral wool. But it also insulates enclosing structures a little better.

Consumers consider this material particularly suitable for covering ceilings and loggias. Very effectively, as the owners of country houses note, such slabs insulate walls or floors. However, in both of these cases, many consumers advise laying them in at least 2 layers with offset seams. Using this technology, cold bridges can be easily eliminated and insulation can be made more effective.

Owners of country houses also consider the relative ease of installation to be an advantage of penoplex. Installing such slabs is somewhat more difficult than mineral wool. However, if necessary, it will not be difficult to install penoplex, even if you do it yourself. Such sheets are attached to various surfaces using special glue and dowels with large heads.

Technical characteristics of various types of material

Foam board is widely used for thermal insulation of building structure elements. As a result, depending on the purpose of use, the technical characteristics of individual types of material differ. Slabs are produced in thicknesses of 20, 30, 50 and 100 mm, of varying strength and flammability. For example, Penoplex 31 has low compressive strength, so it is used mainly for insulating pipelines and containers, and there are materials that are used for insulating airfield runways.

"Penoplex Wall" - for wall insulation

Penoplex Wall is used to insulate the walls of houses. The name appeared not so long ago; previously this material was labeled as Penoplex 31 with fire retardants. Its use for thermal insulation of plinths, building facades, internal and external walls of houses gives good results. At the same time, the walls are sheathed from the inside only if for some reason it is impossible to lay insulation on the outside. Summary of material characteristics are given in the table below.

Scope of use and main varieties

Most often, penoplex is used in private housing construction. In country houses, walls, ceilings, and roof slopes can be sheathed using this material. Very often, penoplex is used for floor insulation in houses, garages, and outbuildings. Of course, this material can also be used to insulate foundations, basement floors and even garden paths.

In private housing construction, the following types of penoplex are most often used:

“Comfort” - universal sheets with a density of 26 kg/m 3. This penoplex can be used to insulate floors, plinths, walls, roofs, etc. of absolutely any buildings.

“Foundation” with a density of 30 kg/m 3. This variety is intended for insulating heavily loaded structures, including plinths and garden paths.

“Wall” with a density of 26 kg/m 3. This penoplex is designed specifically for insulating walls and partitions. Slabs of this type, 50 mm thick, protect the interior of the house from the cold as effectively as 930 mm thick brickwork.

Styrex or penoplex?

Stirex is an extrusive polystyrene foam, like penoplex. At its core, the applicability of Styrex is justified where the applicability of penoplex is, that is, there are no decisive differences. Preference may be given to one material only if it is convenient to cut slabs of a given size, to reduce waste, and in case of increased strength requirements, since Styrex has better bending strength.

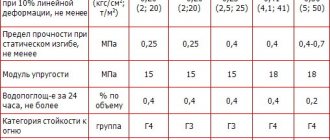

Physical properties of Styrex:

At large deltas of external and internal temperatures, the slightly lower thermal conductivity of Styrex makes this material more advantageous, however, with an average difference of 0.003 W/m*K this will be barely noticeable. The production of insulation under the Stirex brand is located in Ukraine.

Main brands of foam plastic

After foaming the polystyrene, the raw materials for the finished products are loaded into a container. Steam is injected into it under pressure. The granules foam and become saturated with air. At the next stage, the finished granules are dried from moisture; hot air is used for this.

When drying, the granules are shaken periodically. The finished granules are placed in bins that are calibrated according to foam grades. Molding occurs under pressure. When molding, the following types of foam are obtained, which differ in density:

- PSB-S-15;

- PSB-S-25;

- PSB-S-35;

- PSB-S-50.

The last number in the marking determines the density of the foam for insulation. Many developers do not know what the specific gravity of foam is. Density (specific gravity) is the mass of a product in its volume. The density of polystyrene grade PSB-S-15 is 15 kg/m³. Accordingly, one cubic meter of PSB-S-15 polystyrene boards weighs 15 kg.

The question arises of how to independently determine the density of foam plastic without special equipment. This is easy to do: you need to calculate the cubic capacity of the finished product and weigh it on the scales. To make a claim, the store must have in hand a state verification certificate of the scales. Weighing can be carried out directly in the store or at the construction warehouse of the materials supplier. This technical calculation of foam density will be the most optimal.

A product with low density has lower compressive strength. It is not able to withstand shock and static loads. The facade can be damaged when removing snow or leaves. Subsequent restoration of the coating and painting work will require additional costs. However, the low density of foam guarantees lower cost with the same thermal insulation properties. The choice of density is based on the scope of application of each brand of product.

PSB-S -15

This grade has the lowest compressive strength at a linear deformation of 10% (not less than 0.04 MPa). The tensile strength of PSB-S-15 foam when bending should not be lower than 0.07 MPa.

PSB-S-15 slabs provide good thermal insulation. Foam plastic, the density of which is not more than 15 kg/m³, has a thermal conductivity of 0.036 W/(m.k). This type of insulation is used to insulate unloaded structures and planes, such as building facades, roofs, ceilings, and gables.

PSB-25

Foam grades with a volumetric weight of 25 kg/m³ are the most popular among private developers. Medium-density slabs combine reasonable prices and good thermal insulation characteristics. This type is versatile and has proven itself well in insulating various structures.

The volumetric weight of foam is in the range of 15-25 kg/m³. The thermal conductivity of polystyrene foam with a volumetric weight of 25 kg/m³ should be less than 0.033 W/(m.k). The linear deformation indicator should not be lower than 0.15 MPa. Bending strength is 0.32 MPa.

PSB-S-35

PSB-S-35 slabs have a fairly wide range of applications. The density of polystyrene foam PSB-S-35 should be in the range of 25-35 kg/m³. This insulation will last up to 40 years. It is less fragile than PSB-S-15 and PSB-S-25. Strength and durability are achieved through closer bonding of styrene molecules.

The thermal conductivity of polystyrene with a volumetric weight of 35 kg/m³ should be less than 0.033 W/(m.k). Bending strength is 0.38 MPa, linear deformation index is 0.26 MPa. This is a hard and durable material.

PSB-S-50

PSB-S-50 is a dense foam that can withstand mechanical and impact loads. It is used for thermal insulation:

- foundations;

- pile foundations;

- floors of industrial enterprises;

- heated roads, parking lots and lots;

- plating of ships and floating craft.

Expanded polystyrene with a density of 45-50 kg/m³ is supplied to order due to low demand and high cost.

The thermal conductivity of such a material should be less than 0.033 W/(mk). The linear deformation indicator approaches 0.38 MPa. Bending strength is 0.42 MPa. This is the densest material.

Dimensions of material packages with a thickness of 20, 30, 50 and 100 mm

Manufacturers of these products produce insulation in the form of slabs measuring 600*1200 or 600*2400 mm. Sometimes the width can be 580 mm. The sheets are packaged, the number of plates in it varies and depends on the thickness of the extruded polystyrene foam. Depending on the purpose of use, the thickness of polystyrene foam may vary. One package of material with a thickness of 20 mm contains 20 slabs, 30 mm - 14 pcs., 50 mm - 8 pcs., 100 mm - 4 pcs. In practice, it is useful to know the amount of material per package by area, which is presented in the table below.

In conclusion, we note that penoplex is also produced in the form of substrates for various types of coatings, such as linoleum, laminate and parquet. Decorative interior elements, usually made of plaster, can also be made of expanded polystyrene, and they will hardly differ in appearance. The following video will complement your understanding of the properties of the material.

What is penoplex insulation, what is its thermal conductivity and what properties does it have in general? I often have to work with this material, so I am ready to answer the questions posed. In addition, I will give you the technical characteristics of this insulation, and tell you in what cases it makes sense to use it.

In the photo, penoplex is a universal and effective polymer insulation from a domestic manufacturer

Sheet sizes

All penoplex used in construction has standard dimensions. Thanks to this, it is very convenient to use it for cladding enclosing structures and make preliminary calculations of its required quantity.

The dimensions of 50 mm penoplex supplied to the modern market, in most cases, are 60x120 mm. These sheets are the most common and in demand among private developers.

Many owners of country houses who have decided to insulate their enclosing structures are also interested in how many pieces of 50-mm penoplex the manufacturers put into the packaging. Depending on the variety, such slabs can be sold at a time in 7-8 pieces. Sheathing using material from one package can thus cover 4.85 or 5.55 square meters of insulated surfaces.

Such sheets are widely used in both private and industrial construction. In the latter case, 50 mm foam boards measuring 60x240 mm can sometimes also be used. It is, of course, more convenient to cover the walls and foundations of high-rise buildings with such sheets.

This material is sold in absolutely all construction supermarkets. It is relatively inexpensive. The price for a package of 50 mm penoplex is about 1,500 rubles.

How to make the necessary calculations?

The value of R established by SNiP may vary depending on the climate of the region. For Moscow and the Moscow region, the walls of residential buildings must have a heat transfer resistance of at least 3.28 m2°C/W. Let's take this indicator as a standard and calculate how many bricks and, accordingly, Penoplex slabs are needed to fit into the frame.

The calculation formula looks like this:

δ = Rx*λ , where:

δ - wall thickness, m;

λ is the thermal conductivity of the wall material, W/m2°C.

R - heat transfer resistance, m2°C/W.

For traditional brickwork in the Moscow region, according to the formula, the parameter will be:

δ= 3.28x0.7 = 2.296 m.

The same wall, but made of Penoplex with a density of 30 kg/m3, will be thick: δ=3.28x0.037=0.12136 m, or 12 cm.

Now let’s calculate the difference: 2.296/0.12136=19 . It is exactly how many times thicker the brickwork must be than the Penoplex layer in order to meet one thermal insulation indicator.

What is penoplex

Characteristics

Let's compare the characteristics of penoplex and expanded polystyrene:

| Options | Penoplex | Expanded polystyrene |

| Thermal conductivity coefficient, W/mºK | 0,03 | 0,036-0,050 |

| Water absorption per day, % of volume | 0,2 | 2 |

| Density, kg/m3 | 28-45 | 15-35 |

| Compressive strength, MPa (10% deformation) | 0,25-0,5 | 0,05-0,2 |

In terms of thermal conductivity and strength, extruded polystyrene foam looks advantageous not only in comparison with polystyrene foam, but also with many other materials, such as mineral wool.

Comparison of thermal conductivity of extruded foam with other materials

As you can see, the technical characteristics of penoplex are higher.

General information

First of all, let's figure out what penoplex is. So, this material is extruded (extruded) polystyrene foam.

It must be said that in our country it is customary to call any extruded polystyrene foam foam. In fact, “Penoplex” is the name of the company that produces this type of insulation in Russia and other CIS countries. Therefore, further we will talk about extruded polystyrene foam from this company.

Let me remind you that extruded polystyrene foam is a polymer insulation that was invented in the middle of the last century. Essentially, this is the same polystyrene foam (foam), but manufactured using a special technology, as a result of which it acquires special qualities. In particular, the following differences from polystyrene foam can be distinguished:

Structure . If polystyrene foam has a granular structure, then penoplex is a more homogeneous cellular material;

Expanded polystyrene Penoplex, thickness: 30 mm

Clear filter

- Insulation materials Expanded polystyrene 175

- Foam plastic 47

- Wholesale 8503

- Discounts 117

- New items 16

Brand

- 2440

- TechnoNIKOL 1683

- Mosstroy-31 1480

- Technoplex 685

- Carbon Eco 378

- Extrol 305

- Carbon Prof 284

- KREDO 201

- Thermit 173

- Foam 160

- URSA 147

- Polyspen 91

- LLC PenoMaster 72

- Styrex 57

- Carbon Solid 54

- Teploizol 48

- RavaTHERM 42

- Stoplex 35

- Teploplast 31

- Fasadograd 31

- FORMAT 22

- Athlone 18

- Graphite 14

- Ravaterm 9

- Europlex 8

- Isoplex 8

- Drops 8

- Styropen 7

- Timplex 7

- Styrofoam 6

- Bateplex 6

- Plizeks 5

- ALASKA 5

- Polytherm 5

- Hitfom 5

Show all Brand Pressure type Condition Purpose Production method Thickness

- 507

- 50 mm 962

- 100 mm 471

- 20 mm 465

- 40 mm 393

- 80 mm 169

- 60 mm 95

- 120 mm 67

- 150 mm 67

- 250 mm 54

- 70 mm 54

- 180 mm 51

- 90 mm 50

- 130 mm 49

- 160 mm 49

- 200 mm 49

- 110 mm 48

- 140 mm 48

- 170 mm 48

- 190 mm 48

- 210 mm 45

- 220 mm 45

- 230 mm 45

- 240 mm 45

- 500 mm 43

- 600 mm 39

- 10 mm 35

- 400 mm 32

- 300 mm 29

- 1180mm 24

- 1000 mm 13

- 585 mm 10

- 5 mm 6

- 8 mm 6

- 0.05 mm 5

- 2 mm 5

Show all Country of origin Delivery Payment Availability

Expanded polystyrene Penoplex, thickness: 30 mm, buy products from reliable companies and suppliers at a favorable price. Submit your order or write a message.

By rating By price By alphabetical With photo List Gallery Products and services Companies

Demand

Goods and services in RUSSIA Search in Rostov-on-Don 175 goods and services from 106 suppliers

- from 5,250 rub./m3

- In stock

Wholesale / Retail

- 10.01.19

Decorative heat-insulating panels ZODIAC Material: Aluminum-galvanized sheet, aluminized paper, polyurethane foam Working surface size: 3.8 m * 0.38 m

Submit order Add to cart

- Industrial Holding AMK-Group 6 Online Chelyabinsk

- +7 show number

- Save supplier

- 33 reviews

- In stock

Wholesale

Available 20mm, 30mm, 40mm, 50mm, 100mm Mineral insulation OSB, DSP, fiberglass reinforcement, masonry mesh

Submit order Add to cart

- STROYKOMPLEKT 6 Online Kazan

- +7 show number

- Save supplier

- 4 reviews

- In stock

Wholesale / Retail

Penoplex is a modern material. This brand of thermal insulation boards is ideal for insulating country houses or city apartments (insulating walls, balconies, loggias).

Submit order Add to cart

- STROYTORG 2 Online Novosibirsk

- +7 show number

- Save supplier

- 2 reviews

- In stock

Wholesale / Retail

Wide range of high quality building materials. Prompt delivery using our own transport. Cargo handling. Consultation and assistance in choosing products. Call - we are always glad to see you!

Submit order Add to cart

- Chebykin A.N. 1 Online Rostov-on-Don

- +7 show number

- Save supplier

- 1 review

- In stock

Wholesale / Retail

This material is used in construction for thermal insulation on walls, ceilings, roofs and floors.

Submit order Add to cart

- Building materials database 5 Online Rostov-on-Don

- +7 show number

- Save supplier

- 9 reviews

- In stock

Wholesale / Retail

Suitable for insulating country houses (walls, floors, facade, roof, foundation, cellar, basement, bathhouse, sauna, swimming pool, gym) or city apartments (insulating walls, balconies, loggias). Does not absorb moisture. The warmest of all insulation materials.

Submit order Add to cart

- CONSTRUCTOR 1 Online Rostov-on-Don

- +7 show number

- Save supplier

- Add a review

- 1 more product from the supplier

- In stock

Wholesale

For use in private housing construction and renovation. Density / Size 32kg/m3 (1200x600x30). Quantity m3/m2 in 1 pack 50mm 12 pcs 0.2592m3 8.64m2

Submit order Add to cart

- CSK Southern Federal District 2 Online Rostov-on-Don

- +7 show number

- Save supplier

- Add a review

- In stock

Wholesale / Retail

Delivery of building materials seven days a week! Building materials (plasterboard, profiles, plaster, putty, tile adhesive, cement, expanded clay, crushed stone, brick, chipboard, chipboard, fibreboard, plywood, osb, primers, insulation, paint) wholesale and retail.

Submit order Add to cart

- Tikaradze D.R 3 Online Rostov-on-Don

- +7 show number

- Save supplier

- Add a review

- In stock

Wholesale / Retail

Thickness 30 mm. The material will create a hard, lightweight, moisture-resistant and continuous thermal insulation layer. Number of pieces per package: 14 pieces.

Submit order Add to cart

- Construction systems 7 Online Rostov-on-Don

- +7 show number

- Save supplier

- 2 reviews

- In stock

Wholesale / Retail

Size 600x1200x30 (0.2592 m3/8.64 m2). It is used for thermal insulation of roofs, walls, plinths, foundations and floors; they do not absorb moisture, therefore they are used for rooms with high levels of humidity. Service life more than 50 years.

Submit order Add to cart

- JOINT-SL 1 Online Rostov-on-Don

- +7 show number

- Save supplier

- 1 review

- 1 more product from the supplier

- In stock

Wholesale / Retail

ConTRAST is the official representative of the PENOPLEX plant! These are always wholesale prices! It's always fast delivery! This means always having the material in stock! Call and see for yourself!

Submit order Add to cart

- Trading House GC ConTRAST 5 Online Rostov-on-Don

- +7 show number

- Save supplier

- Add a review

- 7 more supplier products

- In stock

Wholesale / Retail

We sell building materials with delivery: hay sand - 30 rub./bag cement - from 240 rub./bag crushed stone - 60 rub./bag, plaster from 210 rub./m 30 kg dry building mixtures, glue, plaster, putty, plasterboard, profile, fasteners.

Submit order Add to cart

- StroyBaza-YUG 1 Online Rostov-on-Don

- +7 show number

- Save supplier

- Add a review

- In stock

Wholesale / Retail

The ConTRAST company, on dealer terms, sells PENOPLEX thermal insulation at wholesale prices of any thickness in any volume + components. Always available in our warehouse. Delivery throughout Krasnodar and the region! Same day pickup! Discounts! Call!

Submit order Add to cart

- Trading house ConTRAST 5 Online Krasnodar

- +7 show number

- Save supplier

- 1 review

- 1 more product from the supplier

- In stock

Wholesale / Retail

Use in industrial and civil construction.

Submit order Add to cart

- EKATERINODAR - STROY 1 Online Krasnodar

- +7 show number

- Save supplier

- 1 review

- 1 more product from the supplier

- In stock

Wholesale / Retail

Penoplex extrusion! All thicknesses are always available in stock: 20, 30, 40, 50, 60, 100 mm! Professional consultation and estimate FREE! We will quickly deliver anywhere in the region! Various components for insulation in stock! Call and leave requests!

Submit order Add to cart

- YugRegionSnab Online Znamensky

- +7 show number

- Save supplier

- Add a review

- 3 more supplier products

- In stock

Wholesale / Retail

Material for insulation of walls, ceilings, facades, plinths, foundations, floors. It is light in weight and easy to install. Does not absorb moisture.

Submit order Add to cart

- YugStroyTechnology 4 Online Krasnodar

- +7 show number

- Save supplier

- Add a review

- 5 more supplier products

- In stock

Wholesale / Retail

Manufacturer: Penoplex, Russia. Material group according to flammability: G4 (highly flammable). Environmental safety of the material: Safe. Thermal conductivity class: Low. Packaging: Pack. Material type: G (flammable). Material delivery form: Plate.

Submit order Add to cart

- ALEA Online Krasnodar

- +7 show number

- Save supplier

- Add a review

- 5 more supplier products

- In stock

Wholesale / Retail

PENOPLEX insulation - ALL SIZES: 20 mm, 30 mm, 40 mm, 50 mm, 100 mm. Always AVAILABLE in stock in Krasnodar: adhesive foam for penoplex, fasteners, mesh. Fast delivery throughout the city and region. Competent consultation. CALL THE SALES DEPARTMENT offers you favorable conditions for cooperation. Direct deliveries from the factory, manufacturer's warranty, transit delivery, volume and retail discounts. Our specialists will offer you materials of different price categories.

Submit order Add to cart

- LLC Insulation Technologies 5 Online Krasnodar

- +7 show number

- Save supplier

- 7 reviews

- 19 more supplier products

- In stock

Wholesale / Retail

Flammability group G4, compressive strength of at least 0.20 MPa. Edge shape: 30, 50 mm - L, 20 mm - straight. In 1 sheet 0.0208

Submit order Add to cart

- Formula Roofing 1 Online Krasnodar

- +7 show number

- Save supplier

- Add a review

- 1 more product from the supplier

- In stock

Wholesale / Retail

Thickness 30 mm. The material will create a hard, lightweight, moisture-resistant and continuous thermal insulation layer. Number of pieces per package: 14 pieces.

Submit order Add to cart

- TS Building Systems 7 Online Krasnodar

- +7 show number

- Save supplier

- Add a review

- In stock

Wholesale / Retail

Extrusion material for inversion roofing, floors, foundations, basements. Technical characteristics of penoplex: 1200x600x50 (0.252 m3)

Submit order Add to cart

- COMPANY TEPLY HOUSE 7 Online Izhevsk

- +7 show number

- Save supplier

- 34 reviews

- In stock

Wholesale / Retail

Guarantee of the BEST price for extruded polystyrene foam! Brand: Penoplex Country of origin: Russia Length (mm): 1185 Width (mm): 585 Thickness (mm): 30 Quantity per package (pcs): 13 Area per package (m2): 9.012

Submit order Add to cart

- Basic element Online Chelyabinsk

- +7 show number

- Save supplier

- 3 reviews

- 1 more product from the supplier

- In stock

Wholesale / Retail

Packaging: 12 pcs; 8.32 sq.m.; 0.25 m3. The material can be used for thermal insulation of floors on the ground and foundations of buildings for various purposes.

Submit order Add to cart

- Production and construction association Kub Online Krasnoyarsk

- +7 show number

- Save supplier

- 1 review

- 1 more product from the supplier

- In stock

Wholesale / Retail

thermal insulation boards, which are ideal for insulating walls, balconies, loggias. The use of Penoplex thermal insulation boards for thermal insulation of various enclosing structures allows us to avoid “cold bridges”,

Submit order Add to cart

- Afina South 2 Online Simferopol

- +7 show number

- Save supplier

- 4 reviews

- In stock

Wholesale / Retail

Penoplexes are made from extruded polystyrene foam, used for thermal insulation of residential and commercial premises.

Order

- WhereMaterial Online Moscow

- +7 show number

- Save supplier

- Add a review

- In stock

Wholesale / Retail

Thickness 30mm, length 1200mm, width 600mm. There are 14 slabs in the package = 10.08 m2 (0.3024 m3).

Submit order Add to cart

- A5 5 Online Novosibirsk

- +7 show number

- Save supplier

- 15 reviews

- To order

Wholesale / Retail

Thickness 30 mm. The material is used for insulation of roofs, walls, plinths, foundations and floors of buildings.

send an order

- Progress 2 Online Omsk

- +7 show number

- Save supplier

- Add a review

- 3 more supplier products

- In stock

Wholesale / Retail

Sheet, universal. Our company is an official dealer of many factories. Lowest prices in the region. Your own car park. Your own cars. Your own sales points.

Submit order Add to cart

- MegaproM 3 Online Omsk

- +7 show number

- Save supplier

- Add a review

- 1 more product from the supplier

- In stock

Wholesale / Retail

Density, kg/m3: 28.0-33.0; Compressive strength MPa: 0.25 Wide range of roofing and facade materials, mastic, roofing felt, glass insulation, polyurethane foam and sealants.

Submit order Add to cart

- Cybermarket 6 Online Perm

- +7 show number

- Save supplier

- 1 review

- 2 more supplier products

Place a request

Didn't find the product you're looking for?

Technoplex or penoplex, which is better and what are the differences?

The presented types of insulation are made from polystyrene. The production technology for these two types of products is the same. It is based on polystyrene foaming and subsequent extrusion. The result is a material whose volume consists of isolated cells filled with air. Their size is very small and can fluctuate around 0.1mm.

Both insulation materials have approximately the same volume of static air in the cells, which indicates approximate thermal conductivity values. The extrusive method of producing technoplex and penoplex allows one to obtain higher strength characteristics than that of expanded polystyrene produced by the non-press method.

Physical indicators of the technoplex:

Physical characteristics of penoplex:

Analysis of the indicators shows approximately the same properties of the materials. The choice of technoplex can be justified if there is a risk of water ingress, since its water absorption is slightly lower. At the same time, penoplex manufacturers indicate an increased value of bending strength. When used in these insulation materials under certain conditions, their difference will be leveled out by tolerances for these parameters, due to permissible differences in the number of air cells in a given volume.

Differences in materials based on the size of the products produced can be beneficial if cutting slabs from a particular manufacturer is beneficial in terms of the minimum amount of waste, based on the geometric features of a particular building.

Types of PPE insulation materials

At the moment, a huge range of products is produced, which can be called thermal insulation made of foamed polyethylene.

One of the differences between such products, which may not be visible from the outside, but is significant in operation, is the type of polyethylene foam from which they are made. This can be a “cross-linked” or “non-cross-linked” polymer, the first of which has higher physical and chemical properties (strength, operating temperature range, etc.). However, when choosing an insulating product for a particular purpose, the design of the product usually plays a large role.