The nodes are numerous and interconnected: handles, transmission-actuating segment (gearbox), strapping, strikers on the frame, hinges, locks, switches, blockers, trunnions, elbow joints (scissors).

Is the load increased due to the high optionality and significant weight of the PVC double-glazed window? Therefore, the need to replace fittings arises quite often due to wear and tear. They also change the system if you are not satisfied with its type, for example, they remove the rotary system and install a tilt-and-turn system instead.

Let's consider when it is necessary to change the fittings, whether it can be done with your own hands, how to do it step by step, what is required, mistakes, difficulties.

What does the procedure mean?

Window fittings mean auxiliary parts, executive elements that provide control, operation, and adjustment. This is a set of mechanisms that open/close and move the valves in different modes. Of course, the fittings can be changed, leaving the same old sashes. If only some parts are broken, then you can update them specifically , for example, just scissors or a pen.

The number of fittings, their types, and design may differ slightly depending on the model, brand, and especially on the range of optionality and type of mechanism. There are such systems:

- rotary (including shulpovy);

- tilt and turn;

- with horizontal suspension: mid-hanging, transom;

- types according to the direction of opening of the valves;

- parallel-sliding (sliding windows).

The hardware parts themselves are divided into groups: hinged, tilt-and-turn, and locking. Let's consider replacing the kit of the most popular type - tilt-and-turn. The principles of the procedure are similar for all other options, and for rotary varieties they are similar.

To summarize, fittings are all metal functional parts and control elements. These are hinges, handles, shut-off valves (gearbox, hooks, mating parts on the frame and tongues, pins on the doors), parts of the ventilation system that provide movement and retention in certain modes (switches, scissors).

Here is an example of a standard kit:

- Pen.

- Constipation:

- lower;

- main (turn-out);

- rear.

- Angle switches (gears): simple and for scissors.

- Scissors (turn-and-tilt bar) and tires (slats, strapping, that is, reinforcing metal strips, power frame).

- Hinges: sash and frame parts.

- Decorative overlays for hinges.

- Microlift: lever and strike plate.

- Blocker.

- The seal is also an element of the fittings.

- Additional elements depending on the complexity and additional options: the handle can be with a key lock, limiters against sudden opening, protection for children, anti-burglary elements.

If we consider the fittings of plastic windows in particular detail, it also includes:

- pins;

- self-tapping screws;

- linings;

- latches;

- hooks;

- trunnions.

There are plenty of diagrams on the net; the names of the parts may differ slightly, but it won’t be difficult to figure them out.

However, to replace it, it is enough for us to know the names of the main segments, as in the drawing below, on which other and smaller elements are located.

The list of all fittings is large; you might think that installation would be difficult, since each part will have to be fixed separately. But this is not so: you only need to assemble a few solid elements on which other parts are already installed, and a small number of small spare parts.

Important! After replacing the mechanism, it will be necessary to adjust the shutters horizontally, vertically, and according to the pressing force, so that there are no distortions. In addition, it is necessary to provide lubrication, which is vital for plastic windows due to their large weight, many moving parts, and seals.

Disabling the locking device when the open handle is jammed

Do not be alarmed if you open the handle and it suddenly gets stuck in this position. Most likely, the culprit is a triggered blocking device. It is available in many types of fittings to prevent possible breakdowns. The purpose of its installation is to prevent the handle from turning when the sash is installed in the tilted or tilted position. However, it happens that it sometimes works inappropriately. Most often, the reason for false alarms of the blocker is excessively fast manipulation of the handle. In order to disable the blocker or perform any repairs to the fittings inside the plastic window blocks, it is necessary to determine which brand a particular product belongs to.

When might it be required?

Details change in such cases:

- Breakdowns of a critical nature, when repairs do not give the desired results. In these cases, it is not necessary to change the entire system - if diagnostics are carried out and it is discovered that some specific parts are causing the incorrect operation, then only those can be updated.

- I am not happy with the optionality, for example, a rotating mechanism is installed, but it was decided to mount a tilt and turn mechanism.

This may not always be possible if the system types differ significantly in their design. If interchangeability is possible, then sometimes it is enough to change or deliver one or several units, but often it is necessary to radically update the entire system, as a rule, when products of a not particularly well-known brand are installed. - If the design does not work well: the doors often warp and begin to creak. In other words, if there is a desire to install better and more reliable products.

- Mechanisms become deformed and lose their geometry due to deficiencies in the fixing parts.

Incorrect operation of a plastic window does not always lead to a mandatory replacement of the fittings: for example, a sash misalignment often occurs over time due to natural wear and tear, and it is enough to adjust it. Stiff movement, not closing completely can occur due to irregular cleaning and lubrication (the mixture accumulates dirt over time, becomes abrasive, thick).

If irregularities are observed when setting window modes or fixing them in a certain position, then the scissors may have come out of the grooves, and it is enough to put them in their places. Looseness of the handle can be caused by spontaneous unscrewing of fasteners due to vibration - you just need to tighten them.

If we consider critical breakdowns that lead to the need for a complete or partial update of the fittings, then these are, for example, the following:

- The handle and its functional parts are broken.

Of course, if there are similar small spare parts, for example a retaining ring, then it is enough to replace them. But usually there are rarely any spare individual special small elements of the handle on the farm and they are difficult to find on sale. Two parts of a broken body can be attached with self-tapping screws and reinforced with metal plates, but most likely the part will not last long, since constant loads will destroy even the highest quality connection if the element is not solid. It is more advisable to buy a higher quality handle made of a strong alloy (not plastic or silumin). - The gearbox is broken (crushed, cracked).

This is the response actuator-rotary part on the frame, which transmits commands from the handle, located immediately opposite it on the frame. It is a bar with a ring with a square cutout, into which a tetrahedral handle pin fits. Signs of failure - the handle, which is in good working order by itself, rotates, while control commands are not transmitted to the rest of the fittings. Usually this causes a grinding or squeaking sound. - Iron parts, hooks, pins, scissors, etc. were bent, fell off, cracked, and the hinge was torn out.

- Problems are constantly observed, the window does not work well, often jams, warps, the movement is tight - this means that the set is of poor quality, and here it is advisable to make a complete replacement.

Accessories brand AUBI

During repairs, the sash must be vertical. In the “turn - tilt” position, the blocker associated with the top hinge assembly will also prevent the handle from turning. To resolve the problem, you should:

- find spring-loaded metal plastic;

- press it with your fingers, moving it to the sealing gasket;

- turn the handle.

Accessories brands GU, Winkhaus, Maso, Roto

In the mechanism of these fittings, under the base of the handle, there is a metal tongue protruding from the frame at a certain angle. If you press on it to make it parallel to the cut of the sash, the handle can be easily returned to the position that is normal for it.

If the desired effect is not achieved, you should check whether the locking device is touching the response mechanism bars installed on the frame. It may happen that as a result of temperature deformations, this element begins to slip. To eliminate this phenomenon it is necessary:

- open the window;

- find the counter element bar on the cut of the frame, designed to hold the blocker;

- unscrew the screws securing it;

- place a small spacer under the support of the counter element;

- install the element on the gasket in the space provided for it.

Thanks to the operations performed, adhesion between the blocking device and the restored counter element will be ensured on the target.

What tools are needed?

The following tools will be required for the job::

- Tape measure, pencil, felt-tip pen - for measurements.

- Drill/driver with drill bits. If they install a copy/analogue of the system and all the holes match, then there is no need to make new ones, but if the system differs in the specified parameter, then it will be necessary to drill other seats, for example, for hinges.

- Screwdrivers (or one, a screwdriver with a set of bits): Phillips, star, flat (useful for lifting strips and trims).

- Pliers, pliers - for auxiliary actions.

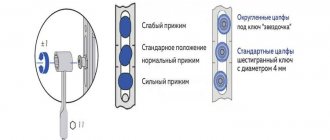

- Hex keys. In most cases, 4 mm, less often you come across models of fittings for 5 or 6 mm. These keys will also be used for final adjustment of the sash.

- Silicone grease (for seals, metal), machine oil, gun oil, WD for primary cleaning. Or special kits with care products for PVC double-glazed windows.

- Construction knife. Will be required when replacing the seal.

- One of the following tools: hacksaw, grinder, bolt cutter. For trimming/trimming strapping slats, slats. Metal scissors will not work as the parts are too thick.

- Special mounting handle for removing the sashes from their hinges. However, this can be done without it, but then you need to prepare a hammer to lightly tap the pin so that it comes out. The same mounting handle has a tetrahedral rod, that is, it can be used as a handle for a double-glazed window.

- Sponge and rags for cleaning – soft, non-abrasive (plastic is easy to scratch).

Separately, among the tools, we will highlight special templates (two: frame, per sash) for drilling holes for attaching hinges. You can do without them if you install an analogue, an exact copy, when the holes of these elements coincide. But if they install fittings with other options for placing hinges, then the specified tools must be available, since maximum accuracy is required.

Attention! When cleaning and lubricating plastic windows, you should completely avoid any products with solvents or cyanoacrylate - they corrode/weaken polymers and rubber.

The seal is lubricated only with silicone lubricants; products containing petroleum products (machine oil, grease) harm it. When cleaning, do not use abrasive brushes or sponges - if they are accidentally or intentionally passed over the plastic, it will lose its gloss due to micro-scratches.

How to remove/install a plastic window sash

To replace the seal on the sash, it must be removed. To do this, remove the decorative caps from the hinges. They need to be pulled or pushed up, sometimes towards themselves. Next, we begin to remove the sash. Just keep in mind that it is much heavier than it looks. Be prepared to take on some serious weight. If there are any assistants, it is better that they insure. The actions are:

- With our left hand we hold the sash from below. It will bear almost all the weight, so be prepared.

- We will work with the top loop. We need to remove the metal rod that holds the sash. It protrudes a few millimeters at the top.

The upper hinge on which the sash is held.

Take a regular screwdriver (flat-head, not Phillips), and press down the pin. It protrudes a few millimeters at the bottom. Insert a screwdriver into the resulting gap and press the rod even lower. Now you can grab it with your fingers (pliers) and pull it down. There is no need to pull it out completely, just pull it all the way (you will feel resistance).

How to remove a plastic sash from its hinges

- Now with our right hand we take hold of the upper corner of the sash (the left one is below), lift the sash a little, at the same time pushing it slightly towards ourselves, and remove it from the lower rod. That's it, the sash is free.

This is the bottom rod of the sash.

It is movable. Then the process of replacing the seal is similar: take out the old one, wipe the groove from dust, dry it, insert a new seal. Just before putting the PVC window sash in place, the bottom hinge pin must be cleaned and lubricated. This simple maneuver - with cleaning and lubricating the pin - allows you to get rid of the annoying squeak that is heard when opening and closing a plastic window or door.

When installing a plastic window sash, the procedure is reverse:

- We put the sash on the bottom pin.

- Place it vertically, aligning the top loop...

- Use your finger (screwdriver blade) to press on the rod until it pops out from above.

That's it, the PVC window sash is in place, the repair of the plastic window is completed. The process is simple, but for better understanding, watch the video.

Pros and cons of working independently

The advantage of doing it yourself is saving a significant amount , which would go into the master’s pocket. It should be taken into account that at the same time you can carry out lubrication and adjustment, for which they charge a separate fee.

If a similar kit is installed, then only ordinary tools are required, the scope of actions is reduced. The planks simply snap into place, the parts are placed in the same places with the holes, and this is a significant advantage of this case.

But if you install fittings from other brands, you will often need to drill holes, at least for the hinges, as in our example, you will need two additional tools - templates.

This is a disadvantage of this particular option for self-replacement, since the devices are special and it is unlikely that the average user will have them on the farm.

The disadvantage of doing it yourself is that it is quite a troublesome task : you need to select a kit, you will have to remove the heavy sashes, hang them again, you may have to cut the slats. At the end you will need to make adjustments and lubrication.

Difficulty manipulating the handle

There can be only two reasons for difficulties in manipulating the handle:

- sash sagging;

- drying out the lubricant present in the mechanism.

If there is sagging, it should be removed in accordance with the method described above. If there is no sagging, then the problem is certainly the state of lubrication. It should be remembered that the internal mechanism of plastic windows is very complex, and the handle is the only control that operates a large number of different components. All this mechanics with its numerous joints can work flawlessly only if it contains clean and high-quality lubricant. Therefore, it is always necessary to have a universal lubricant or one specially oriented for window fittings on hand. This will allow periodic lubrication of all moving components and elements present in the mechanism of the window structure.

If after performing the manipulations the handle does not move better, it makes sense to call a professional.

Possible difficulties and errors

Common mistakes when replacing PVC window fittings yourself:

- Placing the trunnions in the wrong position, their mismatch with the mating parts, hooks.

- Use of ordinary rather than elongated self-tapping screws (38...45 mm) for fastening hinges.

- Do not remove burrs when cutting slats.

- They forget to lubricate and clean.

- The order of an event is incorrect, if a specific version of it is provided for in the instructions for a certain product (below is an example of a VHS brand manual).

- Do not use templates when drilling new holes for hinges: even a fraction of a mm matters here. It is entirely possible to carry out this procedure manually, taking very careful measurements, but at the user’s own risk, it will be impossible to correct the error.

Replacing gaskets

Repair of plastic window mechanisms, repair and replacement of their fittings should be carried out as the window structures age. This provision fully applies to sealing gaskets. They should be replaced on average every 10 years. However, the condition of the gaskets is easily noticeable during normal visual inspection, so they should be replaced immediately if signs of aging are detected.

Before replacing, you should purchase a new sealing gasket, giving preference to German ones, which are of higher quality and greater durability. Replacing this element begins with removing the old seal from the frame groove. Then, the rubber cord of the new product you purchased is slowly inserted into the groove that has been previously washed and lubricated with glue so as to prevent it from being stretched or compressed.

So, we have told you about the main malfunctions of plastic windows, which can be eliminated on your own. If the defect in its functioning turns out to be more serious, we recommend seeking professional help from specialists engaged in this type of activity.

Tags:

- Home renovation

Rate the material:

How much does it cost: average prices

When ordering services, you must take into account that most companies do not work with customer materials , that is, you need to clarify which brand is used.

The cost includes the price of products and installation; there is a minimum amount for a free visit (for example, if the order is over 2,500 rubles). The figure depends on the brand of fittings: there are expensive products (MACO, ROTO), mid-segment (Winkhaus) and cheap (Turkish Vorne, Kale). They charge a separate fee for lubrication and adjustment - this significantly affects the final estimate.

Average prices for replacing a complete set of fittings (without cleaning, lubrication, adjustment) range from 4,000 to 6,000 rubles.

Features of window designs

Today, the construction market offers fittings for window frames made of wooden and plastic materials. To make an informed choice, consider the advantages and disadvantages of each of them.

Advantages and disadvantages of wooden windows

Among the advantages of using windows with wooden frames are the following:

- Wood is an environmentally friendly material. In addition, it has good thermal and sound insulation, as well as microventilation properties.

- Thanks to treatment with special protective compounds, wooden windows acquire fireproof properties.

- Also, modern wooden structures are durable due to treatment with special impregnations.

The following factors can be identified as disadvantages:

- high cost of material;

- its instability to damage by microorganisms and rotting;

- hygroscopicity.

Pros and cons of plastic window structures

Installation of window fittings on windows made of plastic material should take into account the following design features:

- The products have good thermal insulation characteristics, which will significantly reduce the financial costs of heating your home.

- These structures also have sufficient tightness. This will prevent noise from the street from entering the room.

- The modern polymer material from which the windows are made will allow you to avoid household worries associated with maintaining the structure throughout their service life. For example, the homeowner will not have to paint the frames to improve their appearance; he will not have to insulate the windows before the onset of winter to avoid cold penetration into the home.

- The structures have a long service life. At the same time, throughout their entire service they will not lose their functional qualities and aesthetic appeal.

- The cost of windows made of plastic material is lower than their wooden counterparts.

Despite such a number of advantages, plastic windows are also not without disadvantages. In particular, the following factors can be identified:

- insufficient ability to pass air, resulting in moisture accumulation;

- in case of mechanical damage, the plastic material cannot be restored;

- Another disadvantage of plastic is its high expansion coefficient. That is, with a significant increase in temperature, the window will expand, and with a decrease in temperature, it will shrink. As a result, there is a possibility of cracks appearing.

Free call to a surveyor

In order to understand the cost of plastic windows with high-quality window fittings, locking elements, hinges and handles, you need to invite our engineer

WHS Halo 60

An inexpensive option for glazing multi-storey buildings. It is 100% worth the investment in it.

Price from 5915 rub.

WHS Halo 72

Specially designed for the extreme Russian climate, an ideal glazing option.

Price from 7410 rub.

VEKA Mira

Refinement and perfection in everything, unsurpassed protection from bad weather, a worthy profile from VEKA.

Price from 7995 rub.