The construction market is filled with many types of insulation materials. They come in rolls, slabs, backfill and sprayed. Since the assortment is very large, it can be difficult to make the right and informed choice. What can I say if there are more than 6 types of foam materials alone? We are talking about Ravaterm, Polyspen, Stirex, Penofol, Penoplex and Technoplex. The materials are used for internal and external insulation. Which material is better? To do this, you need to understand the features of each material, its advantages and disadvantages. Most experts recommend using Penoplex or Technoplex.

Why are they so good? Technoplex or Penoplex, which is better? What if you compare them with other materials? This is exactly what we will do.

Technoplex or penoplex: what to choose?

The house should not only be beautiful and comfortable, but also warm.

Therefore, it is very important to choose the right insulation. There are many different insulation materials on the construction market. This article will tell you about such modern insulation materials as Technoplex and Penoplex, how they differ and which one is better to choose. Let's start with what they consist of. Both insulation is made of extruded polystyrene foam (EPS). EPS is heated polystyrene (the familiar white foam balls) and a foaming agent.

High-quality technoplex insulation and its advantages

What is Technoplex? This is extruded polystyrene foam, which is used to insulate balconies, loggias, interior walls, facades of private houses, and can also be used to install heated floors.

The insulation is used for thermal protection of private houses, insulation of balconies, outbuildings, including as a substrate for a “warm water floor”

Eps insulation

This is a unique material that has the following properties:

- low water absorption, almost equal to zero;

- high strength;

- not subject to rotting;

- low thermal conductivity;

- high frost resistance;

- non-toxic to humans;

- easy to install;

- durability;

- light weight;

- environmental friendliness.

The disadvantages of polystyrene foam insulation include:

- strong flammability and intolerance to direct sunlight. This is important to know, because storing polystyrene foam in the sun can completely ruin the material, and this will be unpleasant ;

- Although manufacturers claim that polystyrene foam is not chewed by mice, consumer reviews show the opposite;

- And of course the price, which is quite high.

But what is the difference between Technoplex and Penoplex? What's better?

Extruded polystyrene foam

Technoplex is a tile insulation made of extruded polystyrene foam with graphite particles.

Thanks to graphite, the plates acquire a gray color and increased strength. 50 mm of technoplex is equivalent to a 600 mm wide foam block wall. Technoplex is recommended for use for interior work. Produced by Technoplex.

Insulation is produced in the form of slabs of various widths, lengths and thicknesses:

- Length – 1180/1200 mm.

- Width – 580/600 mm.

- Thickness – 20, 30, 40, 50, 100 mm.

Technoplex is operated at temperatures from -70 0 C to +75 0 C. Its water absorption is only 0.2% - this is a very good indicator. Thermal conductivity is 0.032 W/(m*K).

Extruded polystyrene foam and technoplex: application features

High-quality thermal insulation is necessary for any living space. Therefore, during the construction or renovation of a house, it is advisable to use durable, well-proven insulation materials.

Technoplex is a warm material that can be used at all stages of housing construction, be it facades or internal partitions, heated floors, balconies or garages.

Features of external use of technoplex:

- On the outside, slabs of material 100 mm thick are used;

- Before installing them, the surface is leveled and primed;

- Technoplex is fixed using a certain adhesive composition;

- The slabs are laid starting from the bottom, tightly touching each other;

- Each row should shift by half a sheet compared to the previous one;

- After the glue has dried, the material must be secured with plastic dowels, and the outside must be reinforced with fiberglass mesh and the surface must be plastered.

As for interior decoration, sheets of material up to 40 mm thick are used for such purposes. The insulation itself is glued, leaving a small space between the insulation and the finish for ventilation.

During installation of heated floors, Technoplex is laid directly on the screed and covered with polyethylene. A backing with foil is placed on top, and then the cable mats are fixed. After this, everything is filled with concrete.

When insulating the floor along the joists, polystyrene foam is placed on the waterproofing located between the bars. And all the connecting points are foamed.

Due to the fact that Technoplex does not change its characteristics even in difficult conditions, it is sometimes used for thermal insulation of underground areas of blind areas and foundations of houses.

Extruded polystyrene foam

Penoplex is a tile insulation made from extruded polystyrene foam.

Unique thermal insulation characteristics are achieved thanks to the smallest cells filled with air. Penoplex has a bright and recognizable orange color. Penoplex has excellent chemical resistance, but it is important to know that it is absolutely not resistant to gasoline (just like Technoplex). Due to its good strength properties, Penoplex can be used for external insulation.

There are different types in the Penoplex line (their names speak for themselves):

- roofing (insulation of attics and roofs of various configurations);

- wall (basement, walls, partitions, facade are insulated);

- foundation (used as insulation for the basement and floor of the first floor);

- comfort (can be used for any work, but is especially well suited for insulating apartments and balconies);

- 45 (has the best characteristics of all types, used in road construction and bridge construction).

. Penoplex is available in standard width and length - 600 mm by 1200 mm, respectively. But the thickness varies - from 20 mm to 150 mm.

Penoplex is used at temperatures from -50 0 C to +75 0 C. Water absorption - 0.4% - slightly worse than Technoplex, but still a very high figure. Thermal conductivity is 0.03 W/(m*K).

Technical characteristics of penoplex:

- low thermal conductivity coefficient 0.03 W/m·ºK;

- high strength (both compressive and bending);

- low water absorption (no more than 0.2 - 0.4% by volume in 24 hours);

- maximum vapor permeability coefficient 0.007-0.008 mg/m·h·Pa);

- simple installation work

- service life of at least 50 years;

- clean product from an environmental point of view: no toxicity, no rotting;

- operating mode within -50…+75ºС.

We suggest taking a closer look at each aspect separately:

Good moisture resistance

Moisture absorption is a very important parameter for insulation. Therefore, a special test was organized for Penoplex. The insulating tiles were dipped into water and left there for thirty days. A little moisture was absorbed only at the very beginning of the month. And after that, the water stopped being absorbed into the insulation.

After a set month, the volume of “accepted” water was on average at the level of 0.5% of the volume of the test sample. This means that water can only enter the outer pores of the insulator, which may have been damaged during cutting of the material. But moisture does not get inside the structure.

Low thermal conductivity

If you compare Penoplex insulation with similar products, its thermal conductivity will be significantly lower. The thermal conductivity coefficient of Penoplex during operation remains practically unchanged. That is why not only attics, but also foundations and even basements are insulated with the material.

Since Penoplex does not absorb water, it can be used in regions with high humidity levels. During construction, you will not need an additional waterproofing protective layer against water.

Comparison

The main technical characteristics of insulation are its thermal conductivity, water absorption and operating temperature.

The flammability group for both insulation materials is G4 (highly flammable). Their prices differ by 10% (Technoplex is more expensive).

After comparing them, it is clear that there are no significant differences between these insulation materials.

Yes, Technoplex has slightly better characteristics, but the cost is also higher. Despite the fact that Penoplex is cheaper, with individual construction the savings are insignificant.

Insulation of the facade: stages of installation of Penoplex slabs with glue

The process of insulating a façade with penoplex slabs is as follows:

- Surface preparation . Contaminants and the old cladding layer are removed from the working base. If there are mold spots, they are treated separately (disinfected with copper sulfate). If necessary, the surface is leveled and primed.

- Installation . The sheets are glued in rows, from bottom to top, with bandaging (offset) of the seams. The adhesive composition is applied to the foam sheet in two crosswise lines. In an alternative method, if the glue is applied to the work surface, it is done in a continuous layer. Each slab is pressed against the wall, its position is checked by level.

What to choose

If we compare these two insulation materials, then Technoplex is more technologically advanced and has better qualities, but the difference between it and Penoplex is so insignificant that it is impossible to say for sure which one should be chosen.

By choosing polystyrene foam insulation, regardless of whether it is Technoplex or Penoplex, you can get not only thermal insulation, but also sound and vapor barrier.

However, it is worth remembering that polystyrene foam is still a chemical insulation, not a natural one. Therefore, when burned, it releases very caustic substances.

Modern technologies do not stand still, and today liquid foam has become widespread. Details here: https://teplo.guru/uteplenie/utepliteli/zhidkiy-penoplast.html

What can replace technoplex: photos of the material and its analogues

Despite all its advantages, Technoplex is not the only insulation on the domestic market. Thanks to the wide range of products, you can find something to replace it with if you compare it with other materials.

The scope of application of penoplex includes individual and industrial construction

Most companies on the market offer thermal insulation materials that are similar in properties to slabs produced.

The most popular analogues of technoplex are:

- Ursa is a group of insulation materials made from fiberglass;

- Stirex is a high-quality insulating material, similar in characteristics to technoplex:

- Polyspen - is not afraid of fire and contains additives that help extinguish the flame;

- Primaplex is a high-quality, popular blue insulator;

- Penoplex is the main competitor of technoplex, which often replaces it;

- Thermite is a heat insulator that is not afraid of combustion, since Thermit has the highest flammability class G1;

- Carbon is another TechnoNIKOL product that is actively used in industrial and private construction;

- Epps is a fairly common thermal insulator with high-quality characteristics, painted in different colors: orange, blue, yellow, white and gray;

- Bateplex is a high-quality, high-performance analogue of technoplex.

Similar characteristics of insulation from different companies are explained by the use of the same material - extruded polystyrene foam. Therefore, by choosing products from any of the above companies, you can be sure that the thermal insulation will not let you down.

The difference between Technoplex and Penoplex: which is better?

After the construction of a building, the owners always wonder what kind of insulation is best to use for, strictly speaking, thermal insulation of the home.

And this question is quite reasonable, since the construction market has a colossal number of different insulation materials, which, as it seems to many, only specialists can compare in terms of efficiency.

Insulation of the room with Penoplex

Fortunately, this is a misconception, and everyone can figure out which insulation is better. It is only necessary to have information and technical parameters of the analyzed thermal insulation materials.

And given the fact that Penoplex and Technoplex are now the most popular insulation materials, this article will focus on which of these insulation materials is better, and what is the difference between them.

Comparison with other insulation materials

Other materials are also used as insulation. They all have certain features and disadvantages that are worth remembering.

Below we compare Penoplex and:

- Expanded polystyrene . It is produced using a non-press method, due to which the strength and density are reduced. Almost all technical characteristics of polystyrene foam are lower in comparison with Penoplex. The exception is vapor permeability: it is much higher, and therefore it is better to use insulation in rooms with high humidity.

- Styrofoam . Its characteristics are similar to expanded polystyrene.

Foam insulation Source tildacdn.com

- Styrex . Stirex and Penoplex have almost identical characteristics.

- Mineral wool . Made from mineral raw materials by heat treatment. It has different densities (up to 300 kg/cubic meter) and high vapor permeability, can absorb up to 1% moisture. At the same time, mineral wool can withstand temperatures up to +450 degrees. It is best used in rooms with high humidity and in fire hazardous places (workshops, garages, industrial facilities).

- Extrol . It has the same characteristics as Penoplex, but is produced not only in the form of slabs, but also in the form of cylinders or semicircular segments. It is convenient to use for thermal insulation of pipes.

When choosing a material, it is important to pay attention not only to the properties of the insulation, but also to the form of release and the ease of working with them.

Types, technical properties and purpose

Since this year, product differentiation has been introduced depending on the purpose and area of implementation. This allows you to quickly determine the appropriate type of insulation with a set of features for a certain type of work, facilitating very effective use.

Several types of extruded polystyrene are available:

WALL, or penoplex 31 with fire retardants

Designed for insulation of surfaces without dynamic or static load. It is optimal for insulating the walls of facades, partitions, swimming pools, wells, heating networks, and water supply systems.

Characteristics:

FOUNDATION, or penoplex 35 without fire retardant

The slabs are designed to withstand enormous overloads and vary in strength. Ideal for road surfaces, foundations, floors, and basement equipment.

The presence of a waterproof barrier allows groundwater to be drained from the underground part of the house.

Characteristics:

ROOFING, or penoplex 35

The slabs are designed to insulate roofs and attic spaces of any type, taking into account weather precipitation and temperature changes. Currently, it is used for flat roofs with winter gardens or parking lots placed on it (inversion roofing).

Characteristics:

COMFORT, or penoplex 31C

Universal slabs are suitable for insulating loggias, balconies, walls and floors of saunas, and mansions. It is characterized by increased water resistance and provides a better local climate.

Due to technical features, slabs of this type are especially tightly adjacent to each other.

Characteristics:

Penoplex 45

It is used for thermal protection of take-off surfaces and roads, protects against subsidence, deformation, and swelling of the canvas. Designed for enormous loads: can withstand the weight of an aircraft in regions with low temperatures.

The strongest retains its characteristics for a long time.

Characteristics:

Dimensions, thickness and cost

The stability of thermal insulation parameters allows the use of slabs of medium thickness from 35 to 50 mm.

This is average for a typical solution in a temperate climate.

The increased thickness of penoplex up to 70 mm is most used in the northern regions, where the temperature often drops to 0 C. This approach is justified, especially since the average thickness of the remaining insulation reaches mm.

The dimensions of the slabs are standardized by the manufacturer to the usual mm in length and mm in width.

Compared to other types of insulation, the cost of penoplex is quite high: the cost of 1 square meter of sheet is on average $5. If modified with improved properties, including fire retardant additives, then the cost will be $ per 1 sq.m.

Heat conduction and moisture absorption

The thermal conductivity coefficient is one of the main parameters for insulation. The thermal conductivity parameter of the first is on average in the range from 0.028 to 0.031 W/mK, it all depends on the operating conditions. The second has an identical thermal conductivity parameter of 0.031 W/mK. It turns out that the effectiveness of materials in this area is the same.

The same applies to water absorption of materials. The first has an indicator of up to 0.2% of the volume per day, just like the second. This is truly surprising and shows that each of the materials copes well with moisture and resists it. Therefore, if anyone asks whether Penoplex or mineral wool is better, then we can confidently say that the first option. When wet, mineral wool loses its properties.

Production technology and scope

The specifics of penoplex production are focused on improving the strength and technical characteristics.

It is given special characteristics by the process of extrusion from raw materials in special furnaces.

First, polystyrene granules are mixed with a foaming agent under conditions of high humidity and temperature. The catalyst is a composition of carbon dioxide (CO2) and freon. The polystyrene foam composition is melted in ovens and resembles fluffy cream.

Then, through the extrusion installation, the substance begins to be extruded, the freon evaporates evenly, and the cells are filled with normal air.

The use of penoplex in the construction industry has virtually no restrictions and, thanks to its technical features, can significantly reduce the costs of other consumables and energy resources.

Currently, a heat insulator is needed in various weather conditions for insulation and protection:

- foundations and walls of low-rise buildings;

- balconies and loggias;

- pools and wells;

- ceilings and basements;

- floors and ceilings;

- water supply systems;

- airfield runways;

- railways and roads;

Penoplex of various categories is widely used in the process of reconstruction of buildings due to its highest resistance to changes in the external environment and chemical influences.

Used for the production of sandwich panels.

Properties

The main properties of the insulation meet the requirements of building standards:

- Low thermal conductivity coefficient. The average level corresponds to 0.–0. W/m. The indicator is the best in the class of insulation. At the same time, its difference from similar ones in, for example, mineral wool, is not so significant. But the combination of low thermal conductivity with increased structure density gives noticeable advantages. The fundamental factor is the constancy of the indicator; significant fluctuations in different criteria are not recorded, therefore the use of penoplex is allowed without an additional moisture-proof layer both on roofs and attics, and on foundations, floors, and basements.

- Fire resistance.

Fire resistance is characterized by categories G3 or G4, which means a moderate level that exceeds the characteristics of foam plastic that supports combustion. Operating temperatures from ° to +70°C are applicable for polystyrene foam. In open fire conditions, destruction occurs. The melting process begins, but not combustion. Some types of penoplex differ in the increased treatment with chemical reagents to exhibit self-extinguishing. This improved quality corresponds to complete fire safety under extended operating temperature conditions. Moisture resistance. Water absorption of extruded polystyrene foam is 0.4% of the size over a period of 28 days.

Moisture gets only into the outer pores of the insulation, which are opened when cutting and installing the slabs. Closed cells are kept constant. In practice, one can say that it does not allow water to pass through. For insulation of facades and roofs of buildings, such water resistance characteristics are extremely important.

High compressive elasticity. This figure is equal to kg/m3 and is unsurpassed among polystyrene foam insulation materials. Compressive resistance is achieved due to the uniform distribution of small cells with good adhesion, improving strength properties.

Penoplex does not change dimensions even under enormous loads. The slabs are extremely difficult to break. Only a small thickness of 20 mm is susceptible to damage, but along the fault line there is no crumbling or crushing, unlike other similar insulation.

- Weak vapor permeability. Increased resistance is reflected in equal indicators of penoplex with a height of 2 cm and a layer of roofing material.

- Long service life. The warranty period for implementation is 50 years, taking into account atmospheric action. Under suitable weather conditions, the slabs will last significantly longer while maintaining all their own characteristics.

- Environmentally friendly.

The use of freon in the manufacture of insulation is completely harmless: this type is non-flammable, non-toxic, and does not cause destruction to the ozone layer. Environmental characteristics are interconnected with the biostability of the insulation and the absence of toxic substances.is not subject to biodecomposition, therefore it does not require the development of special storage criteria; the slabs can be located on sites without shelter from precipitation or temperature changes.

- Availability of installation and processing . You can cut the slab with an ordinary stationery knife. The low weight allows you to independently sheathe the walls without additional effort in the construction of special frames. adheres well to glue. Weather conditions do not interfere with installation.

- Resistance to brutal substances. Most of the compositions and preparations are not capable of destroying penoplex, which does not react with them.

These include organic and inorganic acids, alkalis, water-based paints, salt solutions, ammonia, cement or concrete mixtures, alcohols and oils, bleach. Extruded polystyrene foam is virtually not characterized by chemical activity. Attention! The exceptions are ethers, gasolines, formaldehydes, and oil-based paints. - High sound insulation. In personal home construction, the sound insulation factor is extremely important. Penoplex solves this problem.

TechnoNIKOL and Penoplex are the main producers of extruded polystyrene foam in the Russian Federation; their products are rightfully needed in personal and industrial construction.

Their cost, performance and performance properties are largely identical; the question of which brand is better to choose is quite relevant. Some users believe that there is no difference at all between Technoplex and Penoplex and that the only difference is the color and size of the slabs; others give in their reviews significant arguments in favor of their chosen manufacturer. Only a comparison of the range and properties will help you find the truth.

- Technical specifications

- Comparison of Technoplex and Penoplex

- Which is better to choose?

Description, personality and characteristics

Technoplex is a specialized brand of expanded polystyrene from TechnoNIKOL, manufactured using an extrusion method with the addition of nano-sized graphite particles.

This insulation is produced in the form of dense, non-shrinkable, silver-colored slabs of regular size (it is noteworthy that, upon agreement with the manufacturer, Technoplex slabs with other dimensions can be purchased). The recommended scope of implementation mainly affects internal work: thermal insulation of floors, balconies, partitions and ceilings.

Penoplex is made in the same way, but with the addition of certain brands of fire retardants. This allows you to significantly expand the operating range, making it virtually universally suitable. Construction workers are advised to choose this type when protecting foundation structures from freezing (including buried ones), insulating roofs, floors, and facade walls. The size of Penoplex slabs is always the same: × mm, thickness varies from 20 to mm.

The color of the insulation is orange.

Both varieties tolerate temperature changes well, maintain a stable shape and characteristics during operation, and are resistant to biological effects. Both Technoplex and Penoplex have slabs with an L-shaped edge; they are recommended to be purchased if it is necessary to eliminate cold bridges. Like any other XPS polystyrene foam, they are afraid of organic solvents and compounds with toluenes and acetone, but are inert to other chemical reagents.

Comparison of features and prices

Penoplex is represented by 10 brands for personal and industrial use, TechnoNIKOL - 9 (of which only one is Technoplex).

A review of the assortment indicates that Penoplex focuses on professional construction, while its rival focuses on personal construction. Despite the loud statements of manufacturers, there are no design differences between brands. The average cost of 1 m2 of Penoplex insulation with a width of 50 mm is rubles, for Technoplex with similar qualities - , but with wholesale purchases or third-hand purchases this difference is partly erased.

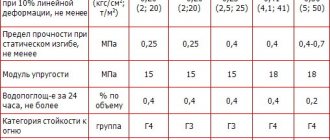

The results of a comparison of the main features taking into account the declared data of the manufacturers are summarized in the table:

Material characteristics

Now we will consider in detail the types and technical characteristics of Penoplex insulation.

Penoplex is produced in several types, which we will consider below (characteristics of Penoplex 50 mm, 20 or 100 mm - the parameters given below will be the same for material of any thickness).

Penoplex 31 Standard

The material is often used for thermal insulation of floors, foundations, pipelines, and swimming pool bowls.

The technical characteristics of Penoplex of this brand allow it to be used for insulation of various structures, including underground networks. In addition, Penoplex 31 C is the most effective in constructing shallow foundations.

The characteristics of Penoplex 31 C (standard) are as follows:

- Material flammability group G4.

- Density is 28-30.8 kg/m³.

- At 10 percent linear deformation, the compressive density of the material is 0.25 MPa.

- During static bending, the tensile strength of Penoplex 35 reaches a value of 15 MPa.

- The water absorption of this brand of insulation in 24 hours is no more than 0.4 percent, while in 30 days this figure reaches only 0.5 percent.

- The operating temperature range is very impressive (from -50° to +75°), as a result, this material can be used even in the most severe weather conditions.

- Penoplex 35 is the most popular type. It is used in construction for thermal insulation of walls, ceilings, floors, and foundations.

Penoplex 35

The characteristics of Penoplex 35 are as follows:

- Penoplex 35 - extruded boards with a density of 25-30.5 kg/m³.

- The properties of Penoplex of this type are identical to the technical characteristics of the previous type. The material is used for thermal insulation of structures, buildings, enclosing structures and foundations. When producing this insulation, an effective fire retardant is added to the raw material, which increases its resistance to combustion (group G1).

Penoplex 45 can withstand heavy mechanical loads, which makes it possible to use it for thermal insulation in industrial, production and warehouse premises, as well as for the construction of roads and railways.

Penoplex 45

Characteristics of Penoplex 45:

- Material flammability group G4.

- Density is 28-37 kg/m³.

- The density of the material at 10% linear deformation reaches 0.25 MPa.

- During static bending, the tensile strength of Penoplex 45 reaches a value of 18 MPa.

- Water absorption in 24 hours and 30 days, the operating temperature range is identical to the above brands.

Penoplex 75

Penoplex 75 differs from similar materials in density (40-53 kg/m³) and scope. It is used on airfield runways and in aircraft hangars. Flammability group G4.

Selection and prices

The cost of Penoplex directly depends on the density and size of the material.

All prices below are indicated for 1 cubic meter of heat insulator.

The price of Penoplex 20 mm grade 31 C ranges from 3600-3900 rubles, grade 35 - 3800-4200 rubles, 45 - 5300-5800 rubles. The price of Penoplex 30 mm and the price of Penoplex 50 mm differ slightly from the cost of 20 mm insulation boards.

The price of Penoplex 100 mm depends on the specific brand of this insulation. The manufacturer offers users 100 mm Penoplex only 31 (3700-4000 rubles) and 35 (4000-4300 rubles) brands.

The most popular type of Penoplex in individual construction has become grade 35. Trade enterprises offer this insulation for 4.5 thousand rubles. This is the price of Penoplex per m³, while the price of Penoplex per m² starts at around 100 rubles per “square” (sheet 20 mm thick).

It should be borne in mind that it is better to buy material only in whole packages - in this case, you can be sure that when opening the package the material was not damaged and was not stored in an unfavorable “climate”. The minimum thickness of Penoplex is two centimeters.

What is better: technoplex or penoplex?

Given the abundance of offers of various types of thermal insulation, choosing the appropriate material for insulation is quite difficult. Ravaterm, polyspen, stirex, penofol, penoplex and technoplex are just some of the foam materials used for insulation of external and internal premises. There is not much truthful information about what modern insulation based on styrene polymers is, so many experts prefer to collect practical reviews on which is better, technoplex or penoplex. This is a complex and time-consuming path, so first it is better to compare the characteristics and draw a conclusion about how penoplex and technoplex differ, and what is the difference between them.

Penoplex

“Penoplex” is a heat-insulating extruded polystyrene foam, which is produced by the same name, and is distinguished by high technical properties, thanks to which the material has become extremely popular.

Its production is similar to that of Technoplex: polystyrene granules are heated at high temperatures and mixed under pressure with a foaming agent until a homogeneous structure is obtained. The mixture is passed through extruders, cooled and cut into sheets.

The plates are orange. The material consists of small cells filled with air. They are firmly closed and do not allow heat and air to pass through.

"Penoplex" is used:

- For floor insulation (under or on a screed, when installing a floor on joists or when installing a “warm floor”);

- When insulating a non-residential basement, thermal insulation of internal walls or facade;

- On roofs (for flat or green roofs);

- For insulation of wells and septic tanks;

- When installing platforms and paths, when constructing a blind area around the house.

Using Penoplex Source avrora-sm.ru

When using Penoplex, it is important to remember that it does not conduct moisture, and therefore it is necessary to have a good ventilation system, otherwise problems may arise. It is also necessary to select the thickness of the insulation so that the dew point falls on the material itself, and not on the wall.

"Penoplex" is available in several versions:

- " Wall ". They are distinguished by a rough surface on which finishing materials adhere better.

- " Comfort ". The edge is made in the shape of the letter "G". During installation, this guarantees stronger adhesion and the absence of gaps.

- " Foundation ". Used where structures are subject to high loads (for screeds) or where fire resistance requirements are lower (for floors or foundations).

- " Roof ". They have a “U”-shaped notch, which makes the connection more durable.

These types differ in thickness, density, elasticity and bending strength. For example, “Penoplex” “Foundation” and “Roofing” are more dense and elastic, their tensile strength is higher.

Advantages and disadvantages

It is impossible to decide how penoplex differs from technoplex and which is better without analyzing the pros and cons of the material. Both insulation materials are very similar to each other.

Penoplex Source ko-online.com.ua

What is foamed polystyrene

Penoplex is produced by the company of the same name using its original technology and is pressure-foamed, extruded polystyrene. Approximately the same data can be found from open sources about Technoplex insulation produced by the TechnoNIKOL company. The details of the technological process are not reported by Technonikol and Penoplex, but based on fragmentary data, the following conclusion can be drawn:

The general picture of the production of technoplex and penoplex is the same, but there are slight differences in the composition of the materials and strength characteristics. According to TechnoNIKOL, the technoplex contains a small amount of amorphous carbon or graphite to make it easier for rolling rolls to form a sheet of the required thickness.

The difference between foamed polystyrenes

As mentioned above, the use of liquid and powder gas-forming agents is better, so products obtained using this technology have stable thermal insulation characteristics. Although, this cannot be called the only reason why Technoplex and Penoplex do not contain freon. There are two more:

- Sealed cells of new material that have not yet been used have remnants of freon. Formally, it is called safe, but in reality it is better not to deal with it. It can cause lung problems in children.

- Over time, the gas will be forced out of the cells by air and humidity. And if dirty raw materials containing styrene were used in the manufacture of the material, then the contents will penetrate into the external environment.

And if technical grades of EPS, such as Penofol, are used to treat foundations, highways, and plinths, then the presence of freon in the composition does not affect the material in any way. But to insulate your home, it is better to use safe products. Therefore, the answer to the question: Penoplex or Penofol, which is better, can be answered - the first option.

How do you know which is better Penoplex or expanded polystyrene? After all, many recommend insulating with foam plastic, because it has a low price and excellent characteristics. To answer this question, you need to know how penoplex differs from expanded polystyrene. Let's start with production technology.

Technoplex, Penoplex and even Penofol are created during the extrusion process. This allows you to obtain a very dense linear structure, which affects the material’s resistance to water and humidity, as well as strength. Therefore, foam plastic is somewhat worse than materials created by extrusion methods.

Comparing technoplex and penoplex

In fact, the composition of technoplex and penoplex is much more complex; it includes stabilizers, fire retardants, antioxidants and substances that slow down secondary polymerization. The difference may be in temperature, pressure and the use of gas-forming agent.

What is the difference between foamed polystyrenes?

What is the difference? The powder or liquid gas-forming agent can be better mixed and distributed throughout the volume of polystyrene granules, so such insulation materials have more stable thermal insulation characteristics.

But this is not the only reason why the modern production of technoplex and penoplex refuses to use freon:

- In the sealed cells of new, unused material, freon gas remains for some time, which is formally considered safe, but in practice it is better to get rid of it, since it often leads to lung problems, especially in children;

- Over time, the gas is replaced by air and water vapor. If not the purest raw materials with styrene residues were used for the production of expanded polystyrene, then gradually part of the contents of the technoplex cells will be squeezed out into the environment.

For “technical” grades of EPS, for example, penofol, such processes are not of particular importance. According to the manufacturer, penofol is best used for insulating foundations, basement parts of buildings, and for use in the construction of highways, so a mixture of freon and carbon dioxide is used for its production. The contact compressive strength of penofol is approximately equal to the strength characteristics of technoplex.

Often, contractor companies recommend that developers use foam insulation, motivating their offer with a low price. To understand which is better, penoplex or expanded polystyrene, it is worth remembering the production technology.

The use of the extrusion process makes it possible to obtain a linearly oriented structure and very dense elongated pores. As a result, extruded polystyrene foam resists water and water vapor significantly better, and has higher bending and compressive strength. Therefore, all extruded polymer foams used for insulation - penofol, technoplex, penoplex - have the best strength characteristics, which makes them different from expanded polystyrene, or in other words - polystyrene foam.

Main characteristics of technoplex and penoplex

The most reliable way to determine which insulation is better is to compare their main characteristics. The most important parameter is thermal conductivity; for penoplex the coefficient is 0.029-0.030 W/m∙K, for technoplex – 0.030 W/m∙K. The difference is negligible, so both materials retain heat equally well.

The second characteristic concerns strength. According to reviews, penoplex cuts better and is less deformed during installation. The bending strength of technoplex is almost two times lower than that of penoplex, but its manufacturer initially states that its products are better used for internal thermal insulation, and penoplex better withstands pressure from heaving of the soil and the mass of the concrete foundation.

The third characteristic concerns water absorption. In this part, penoplex resists water better than TechnoNIKOL products, almost twice as much - 0.1% versus 0.2%. But both indicators are significantly better than those of foam plastic - 0.5% and mineral wool - almost 10%. In addition, extruded polystyrene foam practically does not change its characteristics even after thousands of freeze-thaw cycles.

The last factor is the price of insulation; in this case, technoplex looks better, whose cost per square meter is 10-15% lower than its competitor.

Comparison of polystyrene foam with other types of insulation

The main competitors of expanded polystyrene foam are mineral felts and fiber mats. When asked what is better, penoplex or mineral wool, it can be argued that for private one- or two-story buildings it is better to use penoplex as the most effective thermal insulator. For the exterior decoration of high-rise buildings, it is better to use mineral wool, for one reason - absolute fire safety. Expanded polystyrene, even with flame retardant additives, can emit large amounts of toxic gases when heated at high temperatures, so for high-rise buildings it is better to avoid unnecessary risks.

On the other hand, it is better not to use mineral wool for damp basements and semi-basements, since the fiber instantly absorbs water. In addition, in the production of certain brands of mineral or basalt wool, phenol-formaldehyde resin is used, which is highly toxic and carcinogenic. In general, it is better not to use such brands for insulating residential premises.

One of the competitors for technoplex is isolon, a material based on foamed and modified polyethylene. Of all the listed materials, Izolon is best suited for insulating walls and ceilings inside residential premises. The coefficient of thermal conductivity and water absorption of polyethylene foam of the PPE brand is almost equal to the similar characteristics of technoplex. The PPE layer can withstand prolonged heating up to 80 o C for 24 hours. Izolon PPE has good sound and noise insulation, and the main advantage is that the environmental friendliness and safety of such thermal insulation is better than that of the most expensive brands of EPS.

Polyethylene foam, even with strong heating, does not emit toxic decomposition products. The main disadvantage of the material is its excessive flexibility and softness. Isolon laid on the wall requires additional finishing with rigid boards, for example, plasterboard or MDF. It is impossible to lay a layer of plaster or paste wallpaper over isolon, so it is better to use it in conjunction with external EPS insulation.

Technoplex

Technoplex insulation is an extruded synthetic material that has proven itself well in construction. It is made from polystyrene granules: under high temperature and pressure they are mixed with graphite (it gives the sheets a gray-silver color) and a foaming composition. The mixture is poured into molds and pressed. After hardening, the sheets are cut to standard sizes.

The material is available in 2 versions:

- 118*58 cm;

- 120*60 cm.

The thickness varies - from 2 to 10 cm. The edges of the sheets have a special edge, thanks to which the parts fit together better and do not form gaps.

The result is a homogeneous structure with closed gas cells. Since almost all 100% of the pores are closed, the material has good technical characteristics: being light in weight, it is resistant to deformation and bending, retains heat well and almost does not absorb moisture.

"Technoplex" is used in a variety of areas:

- During the construction of private houses, for example, if the external cladding is made of sandwich panels, as well as when insulating the foundation;

- When arranging outbuildings;

Technoplex Source krov-m.ru

- For insulation of balconies and loggias, floors, including when installing “warm floors”;

- When insulating roofs, attics, interior, internal and external walls.

In addition, insulation is often used in the construction of railways and roads, and in the construction of refrigeration chambers.

Advantages and disadvantages

"Technoplex" is used in various fields of construction and repair due to its high technical characteristics. But, like any material, it has its pros and cons. It is important to know about them when analyzing how penoplex differs from technoplex.

The advantages of insulation include:

- Has high thermal insulation rates. Technoplex is 1.5 times more effective than polystyrene foam and 2 times more effective than glass wool.

- It tolerates temperature changes well and does not deform due to heat or frost. The sheets can withstand from -70 to +75 degrees.

- It practically does not absorb moisture, and therefore does not swell or rot. It can be used in conditions of high humidity.

- Does not shrink and can be used for a long time. Bacteria and mold also do not develop inside the material.

- The insulation is not susceptible to rodent attacks.

Technoplex is easy to cut Source cstor.nn2.ru

- The material is easy to use and process: it does not fray or crumble, the proposed shape and size are most convenient to use. Its installation does not require special skills or the use of special equipment.

- It has low weight and thin thickness. When used, it does not increase the weight of the building and does not reduce the usable area inside.

- The average service life is 50 years. At the same time, the characteristics of the material do not change over time.

Also, Technoplex is an environmentally friendly material. It does not contain substances hazardous to health and, subject to operating conditions, the insulation is completely safe.

Its disadvantages include:

- Flammability. "Technoplex" has a flammability class of G4, it is highly flammable and emits acrid smoke when burned.

- The material is easily destroyed by ultraviolet radiation. Open packaging should not be stored under the sun; keeping the insulation outdoors for a long time is not recommended at all. Installation is best done on a cloudy day.

- When working, do not use organic solvents, as the sheets begin to collapse.

Foundation insulation Source remontnik.ru

It is also noted that the price of Technoplex is higher than that of other popular insulation materials. If the volume of work is large, the cost of the material may be too high.

See also: Catalog of companies that specialize in home insulation