Plastic windows are installed everywhere today. They are distinguished by durability, high performance characteristics and beautiful appearance. But it happens that holes appear in them. These may be traces from removed screws, cracks, dents from external influences and other defects.

When choosing how to repair a hole in a plastic window, you should pay attention to the most popular methods. They can be roughly divided into 3 types: pouring a liquid inside (sealant, plastic, putty), sealing with something solid (a plug or a piece of plastic), external “restoration” (gluing a film or cover for a window sill).

Source hostingkartinok.com

The best ways to repair and restore PVC window sills

The window sill is an integral part of the window opening.

And since PVC windows are now a big priority, this part should also be made of plastic. Without this element, the interior of the room looks unfinished and uncomfortable. But with prolonged and improper use of window sills on a variety of surfaces, this part of the window may require restoration. And we don’t always know how to update and how to repair a plastic window sill if cracks and chips appear, not to mention the change in color and deformation.

Removing the plate

If all of the above methods for restoring window sills are not suitable or the plastic is very swollen, and you no longer know how to seal the plastic window sill, you can try to radically get rid of the problem by completely replacing the part.

Dismantling the element requires some effort:

- Cut off the mounting foam and carefully pull the element towards you, holding the slopes.

- We remove the vacated space from garbage.

- We place the new plate according to the dimensions of the old window sill.

- We supply support rails.

- Lubricate the side of the connection between the plate and the window with silicone sealant.

- We install the new window sill into the slot, checking it with a level.

- We fill the voids with polyurethane foam, and place a weight on top of the part.

- Remove the protective film after the foam has dried.

Important! Before giving preference to PVC windows, you should pay attention to the fact that some companies provide a guarantee for replacing the window sill if it is damaged. .

If the window sill is severely damaged, it is recommended to replace it

Installing a PVC window sill is not such a complicated process, but it requires attention and perseverance. If you choose between replacing a plastic window sill and restoring it, then the second option, of course, is more attractive in terms of saving money, the absence of waste and the variety of color palettes. And if you use a plastic cover, then the list of materials from which the window sill can be made is not limited to plastic. It can be concrete, wood, brick and metal.

It turns out that dismantling and restoring window sills with your own hands generally depends on the deformation of structures, the availability of funds and free time. And in order for this interior detail to serve for many years, you should use it for its intended purpose and properly care for the plastic texture using products specifically intended for it.

Source: domzastroika.ru

How to seal holes in a plastic window frame

In fact, there are several ways to solve the problem with holes in the frame. All of them will be correct, but the result may be different. The choice, of course, will be entirely up to the window owners.

Ways to eliminate holes in a plastic frame:

- The hole in the frame can be sealed using liquid plastic (Cosmofen 345 or Cosmofen plus). It is enough to apply it into the hole and then give it time to harden. It is advisable to apply it liberally, and after hardening, carefully cut off the excess, as it may sag a little during the hardening process, and the surface may end up with a hole.

There are other ways to solve the problem with a hole in a plastic window, which will be discussed further.

okna-remont.org

After installing plastic windows, owners may encounter various problems. In some cases, after a while it is necessary to adjust the window, or there may be cases where it is necessary to repair a plastic window. For example, to attach blinds to a window, you need to drill a hole for a self-tapping screw and screw them on. However, if the blinds need to be removed and they are no longer needed, then something needs to be done with the remaining holes from the screws, because they spoil the aesthetic appearance of the window.

Other causes of cracks

- Damage to double-glazed windows can result from installation errors. If the installation is carried out correctly, the structure is distributed evenly throughout the entire support. In this case, the same load is created on all glasses. If the linings are narrower than the glass unit, one of the glasses will not rest on them, which will lead to a crack.

- The crack may be the result of a manufacturing defect. This is a situation in which the narrow lining is located between the outer or middle glass, and the wide one is located under the middle or inner glass. In this design, the load distribution rule is not observed and the entire system must be replaced free of charge.

- If there is a displacement of the glass in a double-glazed window relative to each other, then the glass that rested on the lining may burst.

- In extremely rare situations, a crack may occur due to sudden changes in temperature and pressure. For this case, special standards have been developed that define acceptable technical characteristics and optimal window sizes for various buildings.

Elimination methods

Before you begin to repair a crack in a double-glazed window, you need to choose the appropriate method. The choice largely depends on the location of the crack and the size of the crack.

If the glass is damaged in the corner, you can use glue. Of course, this method will ruin the appearance of the structure.

If a crack has formed at the edge or in the middle, then replacement is indispensable. In the future, such a crack can spread over the entire surface. The work can be done in 2 ways.

- Glass replacement. To do this, you need to remove the glass unit and separate the glass. Choose a suitable canvas taking into account the thickness. Clean the surface. Connect the elements using sealant. After hardening, put the glass unit in place.

- Replace the glass unit. Remove the old unit and install a new one in its place. However, they must be identical in size. This method is less labor-intensive and ensures the preservation of the insulating properties of the structure.

If it is not possible to unpack the window on site, it is recommended to remove the sash and carry out work on a prepared surface.

How to repair a hole in a plastic window

One of the most vulnerable places in the house, where heat loss most often occurs, is the windows. Of course, it is impossible to provide ideal heat and noise insulation in this place, but everyone can reduce the noise level and heat loss to a minimum. The thing is that the cause of increased noise and heat loss is the cracks in the windows. This applies not only to old wooden windows, but also to more modern metal-plastic ones. We will talk about how and what to cover cracks in windows in this article.

Causes of cracks in windows

As one wise man said, it is better to eliminate the cause of the disease than to constantly treat the consequences. The same should be done with cracks in windows. To do this, it is enough to understand the reason for their appearance and eliminate it once and for all.

Reason one: crooked installation

It's no secret that the level of professionalism of the craftsman determines how durable and reliable a particular structure will be. It's the same with windows. Mistakes at the window installation stage lead to drafts coming from under the window and noise from the street preventing you from sleeping.

It is almost impossible to control the quality of work. To do this you need to have certain knowledge. But something can still be done. You just need to check how well all the gaps between the window frame and the opening are sealed. This can be done using a simple lighter, bringing its flame to the joints. You should also pay attention to the outside of the window. The places where the frame adjoins the opening must also be reliably caulked or blown with foam, and their surface must be painted over or puttied. The same is true on the inside.

Reason two: wear of the seal

Unfortunately, timeless building materials do not yet exist, and during use, cracks appear in the windows. And in combination with installation errors, their service life will only decrease.

The same places where the window frame meets the opening are problematic. If for some reason the sealing materials have not been painted or plastered, they will quickly wear out under the influence of temperature changes, ultraviolet radiation, wind and precipitation. Polyurethane foam, even that which is intended for external work, becomes distorted, gradually exposing the voids between the window and the wall. Foam rubber or other sealant dries out, crumbles and blows out, thereby widening the cracks. To extend the life of the seal, it is enough to carry out an inspection every two to three years and maintain the integrity of the protective layer. It is best to do this in the spring, when it is already warm and there is no precipitation.

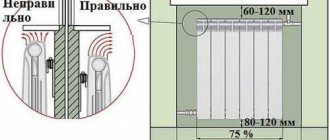

Blows from under the sill of a plastic or wooden window

The reasons why it blows from below the window sill are due to an insufficient amount of mounting foam, which is used to fill the distance between the wall and the window sill after installation, or due to its subsidence.

How and with what to seal foam under the windowsill

There are two options for eliminating blowing.

Sealing foam under the window sill The first one is suitable, if the window was installed recently and work on decorating the window opening has not yet been carried out, you can remove the window sill and blow foam over the junction of the wall and the window frame. After this, install the window sill in place.

Window sill repair process on video

Drywall installation

A sheet of plasterboard is a building material in which gypsum is placed between layers of cardboard. The material is indispensable for hiding various wall defects, so it is recommended for slopes.

Its advantages include:

- wide range of uses. Suitable for all types of windows;

- can be used to finish slopes of any size;

- low price;

- quick installation;

- environmental Safety;

- painted in different colors.

How to seal holes from self-tapping screws in a metal-plastic frame

The surface of the metal-plastic frame is made of PVC - a substance obtained as a result of chemical reactions and compounds. Since this material is artificial, it means that it can be restored with high efficiency - returning its original insulating properties and original appearance.

Read more about PVC material and profiles made from this material here.

The easiest and surest way to repair a frame is to call a team of specialists who will repair the holes quickly and efficiently. However, the obvious disadvantage of this method is its high cost. After all, large companies will not waste their time on trifles, and little-known companies risk aggravating the situation, since amateurs may come instead of professionals.

The second way to repair a plastic window frame is to seal the holes yourself. To do this, it is best to use a special sealant for products made of solid PVC. One of the representatives of substances of this class is liquid plastic Cosmofen 345.

The process of sealing a hole from a self-tapping screw in a window frame with sealant is quite simple and consists of several sequential steps:

- Degrease the frame surface around the hole using solvent.

- Fill the hole from the screw with sealant so that the substance comes out of the hole.

- Wait the recommended time until the product completely hardens.

- Cut off excess product flush (level) with the window frame.

- Remaining sealant around the hole can be removed with a solvent, but it is best to use the same brand of solvent as the sealant.

This is a general description that applies to most sealants. However, you should act in accordance with the instructions for use of the product you are using.

Instead of sealant, you can also use moisture-resistant putty, liquid nails, or any brand of silicone sealant. The main thing is that the product is compatible with PVC.

The third way to hide screw holes in a plastic frame is to glue furniture pads. If the shade of the lining matches the color of the window frame, then the holes will be almost invisible when looking at the overall picture of the window. In a detailed examination, the tubercles will be visible.

To glue the overlays, you need to purchase PVC glue and the overlays themselves. The whole process will take a matter of seconds, especially if the glue is fast-acting.

White crack sealant

You can also use sealant to seal holes from self-tapping screws. Today there are a huge number of them, but acrylic sealant is best suited for sealing cracks and holes.

To seal the cracks you need to do the following:

- First of all, the surface of the crack needs to be cleaned of all kinds of dirt, putty, and debris.

- Then the entire surface around the hole needs to be sealed with masking tape so as not to smudge it.

- After this, you need to take white acrylic sealant with a special syringe. Why do you need acrylic sealant? Because silicone cannot be painted if necessary.

- Next, the gap or hole is sealed using sealant. After applying the sealant, the surface must be leveled with a wet finger or cloth.

- Leave the sealant until completely dry. If necessary, the sealant can be painted.

It blows from the cracks between the plastic elements (sash-impost, window).

Sometimes it blows from the joints of the plastic profile, not in the corners, of course, where it is welded, but, for example, in the impost-frame assembly (see photo - the connection of the vertical and horizontal profile (there is no gap)).

If there is a gap here, this means that the production is not in complete order and one of the window elements is smaller than the required size. The problem can be solved by sealing with silicone or tape. It makes sense to seal this unit from the outside as well.

It often blows from a similar unit (with a gap) near a balcony door or window. The solution to the problem is the same as above. You can seal the gap with silicone. It really won't be pretty. The simplest and most correct solution, in our opinion, is to seal the gap with tape. It will stop blowing, you will survive the winter, and in the summer you will remove the tape. Repeat next year.

The materials on this page of the site are the subject of intellectual property (Civil Code of the Russian Federation Chapter 70. Copyright) and are protected. _____________________________________________________________________________________________________