In houses made of aerated concrete blocks, metal products are usually installed as entrance doors. Iron structures are considered strong and reliable. But it is important to install such a product correctly. Otherwise, thieves can easily tear out the door leaf without opening the locks. Installing an entrance door to a house made of aerated concrete is possible with your own hands. But for everything to be successful, you need to understand what aerated blocks are, what features structures made from them have, as well as know the installation technology, follow certain instructions, and advice from experts.

What is aerated concrete

Aerated concrete is a building material consisting of cement, sand, water and lime. It is a type of cellular concrete. It is distinguished by its environmental friendliness, low weight and porosity. Today, high-rise urban and private houses are often built from aerated concrete. Aerated concrete blocks are easy to transport and install. Laying is done using glue. Houses made from this building material are highly sound insulated and warm. Aerated concrete walls are very durable, but porous. Therefore, preparing openings and inserting doors and windows into them has some nuances.

Preparing the opening for installation

Such work should begin immediately after the opening is completed. Having laid out a wall, it is always difficult to cut an opening under a door block. Its dimensions should be slightly higher and wider than the structure planned for installation. To accurately mark the opening and arrange the cuts, you will need:

- reciprocating saw;

- building level;

- roulette.

In order to strengthen the top, ten-centimeter grooves are cut in the side sections of the walls, reinforcing rods are inserted, pulled apart and secured with wedges. During finishing work, void areas are filled with quick-hardening solutions.

Installing an entrance door into an aerated concrete wall: preparatory work

Before you install a metal door in aerated concrete, you should prepare everything. Then the work will be easier, faster and without unnecessary fuss, during which serious mistakes can be made. You need to buy a door block. It is important to accurately measure the opening to determine the dimensions of the product. It is recommended to order the design taking into account technological and installation gaps. The leaf with the door frame should be 2-6 cm smaller than the opening.

If there is an old door structure, then it needs to be dismantled. The passage is measured after this to obtain more accurate data. The opening in the wall made of aerated blocks must be prepared. Experts advise covering the surface with a waterproofing material. It is desirable that it be made in the form of self-adhesive tape. It is also recommended to apply a primer to the sides of the aisle. Walls made of cellular concrete are hygroscopic. Moisture can penetrate into the joints. High-quality waterproofing will prevent this. The surface should be further strengthened.

We need to prepare the workplace. It is necessary to remove everything that may interfere with the installation of the entrance door in aerated concrete. Items nearby should be covered with film to prevent accidental damage or contamination.

Plastering the slope

Beacon profiles are installed on the prepared and primed surface.

With their help, it is easier to create a smooth surface for the applied solution. Beacons can be secured using mortar. It is better to use gypsum mortar, it sets quickly and you can proceed to the next stage sooner.

Place small piles of mortar in two or three places along the length of each end and install beacons. Using a bubble level, adjust the position of the beacons in one plane.

When the solution under the beacons has hardened, you can begin to fill the slope with cement-sand mortar.

Cement and sand are mixed in a ratio of 1:4 and thoroughly mixed with a mixer attachment inserted into a drill at low speed. The solution should be similar in thickness to curd mass. You can add a little gypsum.

Using a trowel and spatula, apply the solution to the doorway slope and level it along the beacons.

As soon as the solution has dried, which is at least a day, you can begin applying the starting and finishing putty. The dried finishing putty is finally compared using an abrasive mesh. After this, you can open the slope with paint.

What materials and tools are needed?

In order for the installation of a door in aerated concrete to be successful, you must have certain tools and devices. You will need the following:

- level;

- hammer;

- perforator for creating holes;

- anchor;

- Screwdriver Set;

- knife;

- dowels;

- chisel;

- electric drill;

- tape measure at least three meters;

- square;

- welding device;

- iron corner.

Polyurethane foam will also come in handy. Wooden wedges may be needed. With such a set of devices, you will be able to efficiently insert a metal entrance door into a gas-block passage yourself.

Prefabricated aerated concrete lintels

Factory autoclaved material has a height of 20 or 25 cm. The depth of support must be at least 250 millimeters. In order not to violate the height of the row, additional elements are produced.

The number of bars is selected according to the thickness of the block. For walls 40 cm thick, install two 15 cm bars and one 10 cm. For walls 50 cm, take two 15 cm bars and two 10 cm.

Standard Size Chart:

| Height | Thickness | Length |

| 250 | 100 | 1250 |

| 1500 | ||

| 2000 | ||

| 150 | 1250 | |

| 1500 | ||

| 2000 |

The industry produces materials in accordance with GOST 31359 - 2007 “Autoclave-hardening cellular concrete”. They are light in weight and can be easily installed by hand using an adhesive solution.

The surface after installation is smooth. This makes finishing work easier. Their disadvantage is their high price.

Note! Aerated concrete quickly breaks down in a humid environment. Remove material from packaging as you use it.

Installing a metal door in an aerated concrete wall: mounting methods

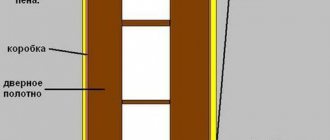

Inserting a metal door into an aerated concrete partition has a number of nuances. The work can be done using different methods.

The door frame is attached to aerated concrete:

- using a mortgage;

- anchor fastening;

- using a wooden structure (creating a wooden frame);

- fastening to a metal frame.

Do-it-yourself installation of a metal entrance door in a house made of aerated concrete can be done using any of the above methods. You just need to know the technology, instructions and strictly follow them. Each installation method has its own characteristics, nuances, advantages and disadvantages.

Method No. 1: using a mortgage

This option for mounting the front door is very popular. Mortgages are made from iron corners. The cross-section of the metal must be at least 10x7.5x0.8 cm. “Legs” of 0.8-1 cm reinforcement are welded to the iron structure in increments of 60-90 cm. Areas in contact with aerated concrete masonry must be coated with an anti-corrosion compound. How many mortgages need to be used depends on the dimensions of the doorway. For example, for a typical size opening (210 cm) three mortgages are required. The box is fixed with anchors. The gaps are filled with polyurethane foam.

Method No. 2: using anchors

This method of installing a door frame with a panel is optimal for narrow and relatively light door models. The fastening elements that are supplied to the door block upon sale are not suitable for its implementation. Instead, they use anchors for cellular concrete. Such products for fixation are classified into adhesive and spacer. When using fasteners of the first type, special holes are drilled in the doorway. They are filled with polymer glue. Anchor bolts are inserted into the prepared holes. The hardened composite composition securely holds the fasteners. If the installation is carried out with expansion anchors, then the working shank is screwed into the wall. It is divided into parts, forming a spacer. The bolt is securely held in the loose aerated concrete structure. The mounted door block is checked for evenness and finally fixed. The gaps are filled with polyurethane foam.

Method No. 3: using a wooden structure

If you need to install a metal entrance door with two leaves, you should use a wooden frame. This option is relevant for aerated concrete garages. They usually install entrance structures made of two panels. Such door blocks weigh a lot. Therefore, an unprepared opening will quickly begin to deform and crumble. To avoid this, wooden wedges or embedded beams or thick plywood are installed in the areas where the anchors are attached. Due to this, the load is evenly distributed over the doorway, which prevents its rapid destruction. A thin and light iron door is mounted on panels or beams, fixed at the edges of the passage with glue and bolts. Bulky door blocks are installed on a full-fledged wooden frame made of strong beams. It is better to attach it with adhesive anchors. Before fixing, it is important to dry the selected wooden material and treat it with a solution that protects it from swelling from water and damage from insects. The door frame and hinges are attached to a frame made of wood, and the doors are hung. The seams are sealed with polyurethane foam.

Method number 4: using a metal frame

Fastening a door leaf with a frame to a frame made of iron plates is considered a proven installation option. It is suitable for cases where the iron door is massive and thick. This is an excellent option for strengthening a doorway in an aerated concrete wall. For this purpose, a welded frame is constructed. It is created from 3.5-5 cm steel corners. The frame is tightened with jumpers to increase strength and inserted into the doorway.

Installation of the entrance door is carried out as follows:

- The corner is cut according to the dimensions of the door passage. Two parts are required for mounting on the outside and on the inside.

- Metal profiles are applied to the door opening and welded at the ends. As a result, there should be two arches in the shape of the letter P.

- The frame is fixed on the wall with special elements (anchors). The jumpers are welded on and additionally secured with self-tapping screws.

- The door is secured to the frame with self-tapping screws. In this case, it is important to wedge the frame and insert the sash correctly. The evenness of the structure is checked using a level.

- The performance of the door block is assessed. If there are problems, check the installation of the door frame, adjust the awnings.

Once the door is installed, you can seal the gaps with foam. After time, the sealant hardens. Then everything unnecessary is cut off.

Anchor mounting

It is considered the cheapest and easiest installation method. For fastening, special anchors are used that are suitable for cellular materials. Aerated concrete anchors are devices that are screwed into the block. At the moment of tightening, the fastener is divided into two parts and securely fixed in the wall. To increase reliability and strength, an adhesive mass is used. Before screwing in, holes are made in the wall, which are filled with glue, and the anchors are screwed into them. After hardening, the polymers securely hold the fasteners, preventing the door from loosening or falling out.

Features of installing a door with a thermal break in aerated concrete

Installing a door with a thermal break in aerated concrete avoids the formation of condensation at the points of contact between external and internal metal elements. But the installation of such structures has a number of features. Entrance doors with a thermal break should be installed exclusively in the center of the doorway in a false frame. They must be raised 10-18 cm from the floor level. This will minimize the likelihood of condensation formation. The doors will be in a temperature range of 0 degrees. The thermal break will additionally cut off frost.

MDF

This material undoubtedly has the best aesthetic qualities, and also greater strength and wear resistance than other materials.

The elements are secured using small nails, clamps or self-tapping screws.

The main thing is that each type of fastening does not interfere with the installation of the following slope elements.

Corners and fastening points are covered with platbands or corners, which are glued throughout the entire structure using liquid nails.

MDF is the most popular material for slopes, and the maximum number of ready-made solutions is produced from it. Therefore, installation of such slopes is usually the simplest.

Support depth

This parameter usually depends on the type of jumpers.

- Load-bearing structure made of aerated concrete with reinforcement : maximum opening - 1 m 75 cm, support depth - 25 cm. No additional insulation is required.

- Load-bearing reinforced concrete structures with permanent formwork made of U-block structures: maximum opening - 3 m, depth of support on the masonry - 25 cm. No additional insulation is required.

- Monolithic load-bearing structures made of reinforced concrete . Must correspond to the lengths of the beams - 35 cm. Additional insulation is required. Reinforcement is performed - 1 m 20 cm. The reinforcement protrudes beyond the dimensions of the opening by 50 cm. It is recommended to carry out ordinary reinforcement above the openings.

- Monolithic non-load-bearing reinforced concrete structures 200 cm 35 cm : maximum opening - 1 m 20 cm, depth of support on the masonry - 20 cm. Additional insulation is required. It is a non-load-bearing structure using a metal corner as a base. Recess is required at the base of the masonry.

The lintel is ready: we saw through the opening

After the cement mortar has completely hardened and the lintel is firmly in the wall, you can begin sawing the opening directly.

The arrangement of the opening is carried out using the following technologies:

1. Rope cutting. This is a relatively new method that involves the use of wire saws, usually hydraulically driven. As a working attachment in such tools, special diamond-coated ropes are used. Diamond cutting using wire saws is currently considered a fairly effective method; it allows you to make cuts in walls of any thickness, regardless of the density of the material.

2. Diamond drilling. The use of hammer drills is not recommended for making openings in load-bearing walls.

Attention! Vibrations that are inevitably created when using hammer drills can lead to destruction or a decrease in the strength of structural elements of the house.

Therefore, diamond drilling is used as a safe alternative to impact tools. The use of diamond bits with a diameter of up to 650 millimeters allows you to work extremely quickly - the passage speed is within 40 millimeters per minute.

3. Diamond cutting of concrete. To work, you will need a wall saw equipped with a diamond blade. Such tools are suitable for use even in the most difficult cases. At the same time, diamond cutting of concrete is carried out as quickly as possible, and the level of noise and vibration is low, of course, provided that the tool and attachments are of sufficient quality and in good working order.

So, we are convinced that arranging openings in load-bearing walls is not an easy task, technically complex and time-consuming. In addition to the fact that the master will need certain knowledge and experience, it is necessary to take into account that there is another serious factor - the threat of collapse of load-bearing structures if the technology is violated or safety rules are not followed.

However, if you have basic skills in working with construction tools and subject to careful planning of the work, the task of sawing an opening in a load-bearing wall is quite within the capabilities of a novice builder.