Installing a door to a bathroom is generally no different from other rooms. But there are still a number of nuances that need to be taken into account. The floor covering should have a gap of several millimeters with the canvas so as not to interfere with natural air exchange. A threshold is required; it will protect neighboring rooms from flooding. As a rule, bathroom doors open outward, but if the corridor is too narrow, it is worth opening inward.

Selecting a canvas

The first step in installing doors to the bathroom and toilet is choosing good quality material and a comfortable design. The bathroom is the most humid room in the house, so pay attention to moisture resistance and sound insulation.

Materials

First of all, decide what your door will be made of. There are several options depending on cost, design and level of durability.

- Polyvinyl chloride. Or, more simply, plastic. The most affordable option on the market, it looks attractive in the interior, despite the low cost. Keeps its shape well even with direct contact with water and is easy to clean.

- Glass. Moisture-resistant, durable material. It looks presentable, but is not suitable for all interiors. Glass breaks easily, but now there are options on the market made of tempered glass; they are resistant to minor impacts.

- Tree. The material is not friendly to moisture and, as a rule, is not suitable for baths and toilets. It can rot, become deformed and moldy. But if the layout is such that water will not get on the canvas, and the bathroom has powerful ventilation, you can safely consider wooden varieties.

- Chipboard. It looks like wood, but is essentially made from sawdust and wood debris. Lightweight, budget-friendly design, it will not last long in a damp room and is not recommended for installation in a bathroom.

Instagram @peletondesign

Instagram @krasnoderevshiki

Instagram @dvernaya_birja

Instagram @krasnoderevshiki

Constructions

The second stage is the choice of design. The number of square meters and your personal preferences play a role here. There are two most common ones.

- Sliding and hidden systems. Good for tight spaces because they save space. In terms of strength and sound insulation, they are inferior to classic swing doors.

- Swing systems. Classic version with an opening door. Takes up additional space when opening, but is more reliable and durable. A threshold is definitely needed.

Instagram @dvertsov.ru

Instagram @dvertsov.ru

Instagram @dvertsov.ru

Instagram @dvertsov.ru

Preparing the doorway

Before starting the main installation work, you need to prepare the doorway. To do this, working surfaces are checked with a level and tape measure. If there are differences in size, depressions or bumps, they need to be leveled. At the stage of preparing the doorway, you can change its width.

Important! When expanding the opening, you need to use a large grinder. Builders recommend not using impact power tools (jackhammer, hammer drill). It creates a powerful vibration that can destroy the wall.

After determining the dimensions of the opening and leveling the working surfaces, it is necessary to apply waterproofing. It will protect the box from the destructive effects of moisture and prevent fungus from developing. For this, waterproofing tape is used, which has a self-adhesive side. It needs to be glued around the perimeter of the opening.

How to install a bathroom door yourself

How to install a bathroom door with your own hands? Where to begin? First of all, measure the opening. If you are installing a swing model, set the dimensions for the threshold. Typically, this role is played by the lower part of the frame. Sometimes the kit contains only three parts - then you should order the threshold separately or make it yourself. 5 centimeters are laid on this part and from this level the height of the opening is measured taking into account the gap for ventilation. The canvas will be significantly higher, about 10 centimeters, compared to everything else in the apartment.

Please note that it is impossible to shorten models made of plastic and glass - this is important if the product is 2 meters high and the opening is smaller.

Unsplash

Unsplash

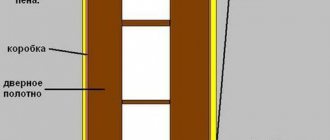

Box installation

Product selected and delivered - frame installation time. If the threshold is included, great, but if not, you need to cut it out yourself. In cases where there is already a difference between the floor in the bathroom and the corridor, you can do without a threshold.

If the frame consists of three elements, then the threshold is usually made: steel, stainless steel, aluminum, plastic and less popular - wood. Sometimes there are self-leveling ones made of concrete and even copper. Any non-slip material that provides good strength and moisture resistance and looks attractive can be used.

Instagram @doorwood.by

Instagram @krasnoderevshiki 5

Instagram @arttema61

The frame elements are assembled on the floor and adjusted to size. According to GOST, 3-4 millimeters should be left on the sides, about 20 between the floor and the canvas. The bottom end should have a distance of 6 millimeters from the threshold. The location of future hinges is calculated by retreating 25 centimeters from the top and bottom of the frame. In these places you need to make a selection with a chisel and secure the loops.

The frame is ready. It is lifted and installed inside the opening. Check that everything is level - use a level to do this. Once everything is adjusted, secure the frame to the wall with dowels and tuck in wooden wedges. They are pulled out after the final verification of the dimensions with a level. Foam is blown into the cracks from the outside and everything is left alone for three hours. After this, you will need to fill the foam from the inside and cover the threshold with silicone sealant. After a day, you need to check whether the frame is wobbly. If yes, then additional anchors are driven in.

Instagram @bogdana_o_mansarde

Instagram @dveri_academy

- Doors and partitions

How to assemble a frame for an interior door

Installation of the canvas

Before hanging, you need to prepare it: install a lock (usually at a height of 90 cm from the floor), install handles and hinges. Consider whether you need a latching mechanism.

The first hole is made for the lock. Nearby I mark a place for the handle. It is usually made flush with the keyway.

To work, you will need a 20 mm drill bit; this is what is used to make holes for the fittings. The lock is attached to the end using self-tapping screws and covered with linings. They put the handles on. The product must be attached to the opening and the places for the hinges must be marked. Holes are drilled through them, just like under a lock, inserted and secured with bolts. Everything is ready for installation.

Instagram @bogdana_o_mansarde

Instagram @bogdana_o_mansarde

Instagram @bogdana_o_mansarde

Fastening the platbands

After the wedges have been removed, the foam has been cut, the box is securely fastened in the opening, the product and fittings have been hung, it’s time to install the trim. This is the final stage of installation. The strips must be made of the same material as all other parts. It is necessary to retreat 3 millimeters from the edge of the box so that the platbands do not interfere when opening. The edges at the top are cut at an angle of 45 degrees. All gaps must be closed with extensions. The platbands are placed on self-tapping screws and the openings between them and the wall are foamed.

Instagram @krasnoderevshiki

Instagram @krasnoderevshiki

Instagram @doorwood.by

Presence or absence of a threshold

Bathroom doors with a threshold are preferable to avoid flooding of rooms

. When planning a renovation, you should pay attention to the threshold. It needs to be considered from an aesthetic and practical point of view. This element is part of the jamb structure and has the function of protecting against possible flooding of the corridor and rooms located below apartments in a multi-story building. Based on this, it is advisable to install a door with a threshold in the bathroom, protecting yourself from potential troubles and additional costs.

You can make a threshold from the following materials:

- stainless steel;

- bronze;

- solid wood

- brass;

- aluminum;

- plastic;

- concrete covered with tiles.

The height of the threshold varies between 2-5 cm. You should not make it higher, as people will trip over it. There must be air flow into the bathroom to ensure effective ventilation of the room. If overflow grids are not provided, the bar must be installed so that there is a gap of 2-4 mm between it and the canvas.

Installation of sliding doors

A sliding mechanism is a great way to save space. If you have a cramped bathroom, such designs are definitely worth a closer look. As a rule, the product itself includes all the necessary parts: guides, rollers, fittings, fasteners. If you need a lock - it is ordered additionally - this is another wooden stand into which the canvas will go and snap into place. Hanging a coupe structure is no more difficult than working with a classic mechanism. Follow the sequence of actions.

Step-by-step instruction

- Rollers are installed on top of the canvas and secured with screws.

- A small cut is made along the bottom edge, 1.5 centimeters deep and 3 millimeters wide.

- Measure the height of the door, plan the gap between it and the floor, and take into account the presence and size of the rollers on top.

- A guide is attached at the resulting distance from the floor. You can pre-install a wooden block and secure it to it, or use corner brackets.

- On the side, the rollers are placed on the guide and the product is hung.

- Finally, stabilizing stops are installed. To correctly calculate the distance, the product is expanded to its maximum width and a stop is inserted into the groove on the left, securing it with self-tapping screws. After all work, you should measure the vertical level again.

Instagram @dehaus_

Instagram @dehaus_

Instagram @dehaus_

Required Tools

Before you start dismantling the old panel, preparing the doorway and installing a new door frame, you should think about what tools you will need for the work and prepare them. Sample list:

- Hammer, pry bar, sledgehammer, pliers, hacksaw for wood and metal.

- Building level, plumb line, pencil, 3 meter tape measure.

- Screwdriver, hammer drill, large grinder (when expanding the opening).

Consumables include plastic, wooden and metal substrates, fasteners (anchor bolts, self-tapping screws, polyurethane foam, nails for trim) and accessories for power tools (diamond blades for an angle grinder, drills, drills, bits).

Care Tips

- Due to the fact that there is high humidity in the bathroom and constant contact of surfaces with water, the operating rules differ from the usual ones. First of all, this concerns cleaning. The surface often gets dirty from the inside - the dirt needs to be washed off with a soft material soaked in ordinary water. Do not use products with abrasives to avoid damaging the material.

- If you have a plastic product, prepare a solution for cleaning with alcohol or vinegar at the rate of 1/9 (1 part vinegar and 9 parts water).

- Lacquered doors cannot be cleaned using solvents.

- Veneer products are cleaned with wax polish or a spray with a similar composition.

- The wood is wiped with water and then impregnated with a protective agent.

- The glass will shine if you wipe it with vinegar water or window spray.

- It is better to rub the fittings with a dry soft cloth without chemicals.

Requirements

The bathroom is a special room in the house, so all the finishing and equipment for this room must be selected extremely carefully. The bathroom is characterized by high air humidity and frequent temperature changes. The result is the formation of condensation and the appearance of mold. The materials used for repairs must be moisture-resistant, not afraid of either heat or cold, and also tolerate washing with special detergents.

Thus, the structure and finishing of the threshold in the bathroom needs to be thought through very carefully. It is desirable that it be a monolithic structure without gaps or cracks. It must be strong and durable, have water-repellent properties, but at the same time, not be slippery. In addition, it must be made of durable, wear-resistant materials and, of course, be in harmony with the decoration of the bathroom and corridor. The task is not easy, but we can do it!

Procedure

Removing the old door

In principle, nothing special, but there is a small nuance. The box should not be broken out; if it does not give in, then cuts are made in several places, and it is removed from the opening in parts. Passages to bathrooms are in internal walls or partitions. Unlike load-bearing structures, they are not as strong. Excessive efforts and carelessness will only increase the amount of work - you will have to level and strengthen the ends of the walls.

Preparing the opening

- Complete stripping down to the base. This will allow, firstly, to determine the condition of the wall and draw up a list of necessary measures. Secondly, select the necessary materials and preparations.

- Formation of the opening. The door blocks have the correct geometry, and therefore significant curvatures and bevels are not allowed at the ends of the walls. In addition, the dimensions of the passage must correspond to the dimensions of the door frame, with only a small difference providing a technological gap around the perimeter (recommended within 10 mm).

- Processing the base. The fire protection agent and the method of its application are determined by the wall material. One of the effective methods is impregnation; Such preparation for door installation is more appropriate, since we are talking about damp rooms.

Fabric preparation

- Marking the frame for installing canopies. Considering the light weight of the doors, two hinges are enough.

- Drilling holes.

- Attaching hinges to the sash.

It is advisable to equip the canvas with fittings after installing the box; There will be plenty of time while the sealant dries.

After finishing work with the sash, it is recommended to prepare the jamb in the same way. After placing it in the opening, holding the door in a canopy, it is difficult to accurately mark it.

Box installation

- Markings are made to determine the locations of fasteners. This is necessary to ensure that the fixation of the jamb is as reliable as possible. The walls are not uniform everywhere, there may be individual defects, and therefore the anchors must sit “rigidly”.

- In the jamb, according to the diagram, holes are drilled for fasteners.

- After placing the box in the opening, it is leveled and fixed in the desired position with spacer wedges.

- Through the holes in the timber at the end parts of the wall, the fastener locations are marked.

- The jamb is removed and drilling is done in the opening.

- After installing the dowels, it is returned to its place, it is given the proper position, and the box is fastened. It is recommended to tighten the anchors through one, from different sides. At the same time, the spatial orientation of the jamb is controlled in order to prevent distortions in the structure. Otherwise, it will not be possible to install the door correctly - the door will not close tightly, difficulties will arise with attaching the canopies, installing the latch, and a number of other problems.

Sealing the opening. The gap (around the perimeter) between the box and the wall is filled with polyurethane foam.

Hanging the sash

This stage can be started only after the sealant has completely dried. As a rule, at average temperatures and humidity in the room, a day is enough.

The work is not difficult, but you can’t do it without an assistant. The canvas is raised, the second half of the hinges are aligned with the cutouts in the box, and they are screwed to it with self-tapping screws.

All that remains is to check the correct operation of the door and eliminate any identified shortcomings. Everything else - platbands, finishing of the opening - is at the discretion of the master, based on the general design style of the corridor. In principle, there cannot be a single recommendation for the final stage of installation.

Standard

Many manufacturers try to adhere to accepted international standards. The height is usually always the same and is 2 m. But the width is more difficult. Standards include sizes such as 40, 60, 70, 80, 90, 100 cm. Here is a simple comparison: in Khrushchev buildings the width of the door leaf is the same and equal to 60 cm, but in new type houses it is slightly larger and is already 70 cm .

Increasing the width of the doorway is not associated with the desire to improve living conditions. It’s just that today’s bathtubs and showers are much easier to install with a widened doorway, since they simply don’t fit into a narrower one. The widened opening is, of course, convenient, but due to it the area of the bathroom is significantly reduced. You already have to think about how to install the washing machine or position the sink.

For combined bathrooms, the standard opening width is usually 80 cm . Doors in individually designed houses and apartments are usually larger than this size. If, for example, you decide to install a Jacuzzi in the bathroom, then 80 cm will not be enough for you, which means that the opening will have to be expanded.

This is interesting: How to choose a glass bathtub - pros and cons

Assembly and installation

To learn how to properly install a bathroom door, you can watch a special training video and instructions with photos. It will help you understand the entire sequence of operations, which will speed up the process and avoid common mistakes.

First you need to check all parts of the box so that they are securely attached to each other. After all, installing bathroom doors begins with installing the frame.

Installation of the box in the opening and fastening of the canvas

If a ready-made door block is ordered, the leaf must be removed from its hinges and separated from the frame. After this, the box is inserted into the opening and its alignment begins. Using a level and a plumb line, compliance is achieved with respect to the coordinate axes of the building. Fixation of a given position is achieved using wedges. Then the parameters are checked again horizontally and vertically. Depending on the thickness of the box profile, spaces and cracks are covered.

After this, the doors to the bath and toilet are installed. Together with an assistant, the canvas is hung on the box. It is checked whether opening and closing occurs normally, whether there are any distortions and whether the locks work. If necessary, let the door stand for a while so that it settles. Afterwards the functionality is checked again.

To avoid distortion, the door hinges should be placed tightly on top of each other. Before fastening them inside, they are lubricated with plastic waterproof lubricants (solid oil, graphite grease), which will ensure long-term operation.

Installation procedure for doors made of wood and glass

The process has a number of features related to the weight of the structure and safety measures. The frame is given some time to stand and the sealant (spray foam) hardens. Only after this is the canvas hung in the toilet and bathroom.

The glass door to the bathroom, despite the fact that it is made of impact-resistant glass, needs protection. Therefore, it must be kept aside while the box is being assembled. It is advisable to protect the surface from impacts and scratches with cardboard.

It is also necessary to protect the tree, which is problematic to restore.

DIY

Having an idea of the sequence of processes, the master knows almost everything about how to install a bathroom door with his own hands. The main thing is to stock up on the necessary tools and the required number of fasteners.

To firmly secure the frame, first drill holes in it. Having placed it in the opening, they mark out places for holes in the wall. The box is removed and holes are made into which plastic plugs are inserted. Then the operation is repeated, screwing in self-tapping screws or anchors to securely fasten the doors to the bathroom.

After checking the functionality of the structure, we move on to the fittings. You can place the handle on a protruding square, which will protect the technological holes in the material from moisture.

Foaming technology

At the fastening stage, the bathroom block is treated with polyurethane foam. This is necessary to fill all possible voids and reliably isolate the room from moisture.

The polymer mass is applied along the height of the door, starting from the bottom and moving up. It is recommended to fill voids to a third of the volume. The foam will fill the rest itself, gradually expanding. And the master will have to fuss less, cutting off the frozen excess.

Experts note that bathroom doors should be hung only after the foam has completely dried. It lasts up to 10 hours, depending on the composition. The manufacturer reports the curing time on the foam packaging.

Only after this are the trims or decorative panels attached, completing the process of installing the interior group.

https://youtube.com/watch?v=S6nt97IAdgs

Curb tape

Waterproofing with curb tapes is one of the simplest, most convenient, fastest and most practical ways to eliminate leaks.

The material for making tapes is polyethylene. They can be self-adhesive or simple (attached with glue, sealant), of various widths, heights and lengths. The tape is flexible, does not break, does not crack, is resistant to stress, moisture, temperature changes, masks all existing irregularities, thanks to the presence of fungicides in the composition, and serves as protection against mold. It attracts with its aesthetic appearance and retains its qualities for several years.

The joint between the bathtub and the wall with rubberized tape

Types of coatings

Which material is most suitable for use in the bathroom and toilet is a very important question with which to start your choice. You should take into account not only the properties of a particular material, but also the final price of the finished product, as well as the external design of the product.

Eco-veneer is a modern high-tech material created on the basis of environmentally friendly polymers. Its main advantage is the combination of three factors: strength, environmental friendliness and accessibility. You will also be surprised by the spectacular design of the canvas, the richness of colors and the variety of models.

Natural veneer

For a very long time, veneer was practically the only alternative to expensive products made from solid wood and lower quality models made from softwood. Currently, there are two types of veneered doors.

Fine-line

Most products are manufactured in the segment of inexpensive, finely milled models with a weak paint coating with nitrocellulose varnishes, which have a bad effect on human health, especially under conditions of temperature fluctuations in the room. True, there are a small number of models manufactured using molding technology, in which manufacturers monitor the quality of the product and use only polyurethane varnishes. A non-professional can distinguish such products by the weight of the products, which should be at least 28-30 kilograms; you can use such products in plumbing rooms.

Tangential and radial veneer

It is a cut of natural wood, has a pronounced structure and coating pattern and has an excellent appearance. Used in the production of more expensive classic-style models produced using baguette technology, due to better processing, sanitary doors are more resistant to moisture and temperature changes.

Painted doors

The technology of painting a model with enamel has a number of advantages, especially relevant for rooms with increased impact on the coating; below we present the main ones:

- Maximum insulation of the materials from which the canvas is made from external influences

- Enamel, and especially varnished enamel, is almost completely resistant to external influence of moisture.

All of the above is relevant subject to compliance with all technological processes used in manufacturing. Grinding the milling places is responsible for the absence of surface roughness; multi-layer application of primers creates a solid basis for further application of paint to the canvas, creating the effect of complete isolation according to the principle of vacuum packaging. This effect is enhanced by acrylic varnish, which gives the product, in addition to a velvety or glossy effect, depending on the chosen varnish. Particular attention should be paid to the absence of chips on the frame; this must be monitored with increased vigilance, and if it occurs, be sure to restore the integrity of the outer layer. The ideal solution would be to use a colorless paint material.

Laminated products

The only advantages are the affordable price and a wide range of products, while the disadvantages include the quality of the products and the poor characteristics of the material made on the basis of ordinary paper. The disadvantages are especially obvious in places where plumbing is used, where due to the increased exposure to moisture, all the defects of the coating are maximally manifested.

PVC

Interior doors wrapped in PVC film (Poly Vinyl Chloride) can be used in conditions of sharp changes in moisture content in the air. The coating, like eco-veneer, has an almost 100% coefficient of resistance to moisture.

The only weak point is the ends of the fabric, where high-strength edge tape is used. It is worth paying close attention to the quality of gluing the edge to the structure, and also check with the manufacturer whether the glue used is waterproof

Array

Door leaves made from solid solid wood have always been considered the standard of real interior doors; thanks to their natural origin and classic design of the door structure and durability, they have gained popularity among most people. The only drawback is the prohibitively high cost, which is not affordable for everyone.

Economics of the project

The old doors were dismantled in advance, selected and new ones made of MDF produced in Kherson were purchased for 4,900 rubles. We gave another 560 rubles for the box and 500 for the APECS hinges. Those. for 2 sets we paid a total of 11,420 rubles.

I do not indicate the manufacturer, since I have no experience in using their products. But the indicated fittings have been known to me for a long time, and have not caused any complaints for many years.

We also purchased door handles from APECS, but we postponed installation until we finished the tiles and sewed up the gaps above the door. They cost us 840 rubles each.

Why didn't they install it right away?

The MDF will certainly draw water from the solution, so the door will change its position a little more. You need to give it time to get a high-quality result.

The box is also made of MDF.

You should add a bottle of polyurethane foam under the gun to the costs. Its purchase cost 240 rubles for 750 ml. Total total costs for materials are 13,340 rubles.

What will we save by installing it ourselves?

Door installers demand from 900 rubles for their work. But this is not the final cost, but an estimate. They charge this amount for impeccable conditions: assembled the box, stuck it in the gap, hung the door, foamed it and that’s it...

Since we don’t have perfect criteria, the cost automatically rose to 1.5 thousand per door. So 3,000 rubles in savings are at stake.

Material

The materials used for the production of doors to the bathroom (toilet, toilet) are subject to increased requirements due to the fact that there are often fluctuations in temperature and humidity in the room, and splashes of water and particles of cosmetics and detergents sometimes get on the door leaf. Steam condensation and accidental mechanical damage as a result of careless operation are also possible. Due to this:

- Solid wood door leaf must either be made of moisture-resistant wood species (larch, stained oak, teak) or have special protection against moisture. The use of valuable species significantly increases the cost of the product; moisture-resistant coatings require periodic renewal and, if applied insufficiently, may not perform basic functions. The best option for wooden moisture-resistant doors is a solid or prefabricated leaf and adjacent elements made of larch, covered with multi-layer acrylic varnish over a moisture-proof primer. The main advantage is a spectacular and solid appearance, a feeling of naturalness and rich texture. The advantages include excellent sound and heat insulating qualities. Wooden sheets must be cleaned with products specially designed for varnished surfaces;

- veneered chipboard or fibreboard, solid wood of low value. It has the same disadvantages as a solid wood door. In this case, the composite product is more susceptible to swelling and deformation, but has the advantage of a lower price. With insufficient ventilation and constant high humidity, the veneer may peel off from the surface. The appearance (depending on the veneer used and the finishing option) is not much inferior to solid wood door leaves. Sound and heat insulation is provided worse than with solid wood products. Cleaning of varnished veneer can only be carried out using special means;

- laminated chipboard, fiberboard and MDF. Due to lamination technology, these relatively cheap doors better withstand high temperatures and humidity. However, if the laminating layer is damaged, they quickly fail. Long-term operation of doors of this type requires good ventilation of the bathroom and careful handling of the surface. Depending on the quality of lamination, they can be cleaned easily or with some difficulty;

- glass in combination with various materials. A glass panel with a metal or plastic frame, a wooden frame or a frame made from wood substitutes must be tinted or frosted. In this case, the necessary privacy is ensured. The advantages of glass doors include the material’s immunity to humidity, temperature changes, and resistance to mechanical stress (for tempered or reinforced glass). However, the soundproofing properties of such a product are minimal, and resistance to external influences is limited by the characteristics of the edging material. The most practical models are made from a single sheet without edging or with a metal edging (to increase impact resistance);

- PVC. Doors are made from polymer materials that imitate wood or glass, with metal inserts to increase strength, and with glass inserts. At the same time, sometimes there are options that are similar in design to metal-plastic windows, but the glass in them is usually tinted or textured (matte, patterned, mirrored).

The choice of a specific material depends on the mode in which the room is used, how well the ventilation is arranged in it, whether sound and thermal insulation is required

In addition, the personal preferences of homeowners should be taken into account: for some connoisseurs of “free spaces”, the very presence of a door to the bathroom may not seem necessary

Additional decor

There are several other ways to add uniqueness to your door design.

- Craquelure varnish. If you apply it to a painted door leaf, small original cracks will appear on it.

- If available, moldings can be painted in a contrasting color. They are also easy to make with your own hands and decorate the door.

- Painting. This decoration will take a lot of time, but the result will be pleasing. For painting, minimal artistic abilities and limitless imagination are enough. You can draw anything: ornaments, flowers, ornate patterns, landscapes.

- The stencil is suitable for those who do not know how or are afraid to draw by hand. You can buy them in specialized stores or make them yourself from cardboard.

The basis

The collection process is a painstaking and quite responsible process. This stage will require care and responsibility.

It is worth measuring the racks and cutting them specifically to the size of the structure. It is recommended to assemble the base below, on the floor. The procedure needs a large space to work.

A horizontal crossbar is attached to the rack. Use a screwdriver to fix the canvas and screw in the screws.

There is an easier option with the main box already assembled. Instructions on how to install doors of this type with your own hands are much easier and do not require much time.

Method 1. For standard width (about 70 cm), the installation process goes through. If you want to reduce the opening, use a mounting block.

Method 2. “Thick” wall. To reduce the opening, use two bars. The joining of timber, frames, and extensions should be of different widths. It is worth noting that it is necessary to protect the material from the harmful effects of moisture. To do this, regardless of the conditions of use, apply silicone sealant in a thin strip.

Method 3. Installation process for a wide opening. In this matter, the size of the wall in diameter plays a significant role. The number of mounting bars depends on this indicator.