assets/from_origin/upload/resize_cache/iblock/fe6/600_450_2/fe6d5eac29e02746b15559280a31a34c.jpg From this article you will learn:

- What types of interior doors are there?

- How to choose an interior door to replace

- How to replace an interior door leaf

- How to replace an entire interior door

No residential building can do without interior doors. When, sooner or later, the time comes to make changes to the interior, it may be necessary to replace the doors if they are absolutely not suitable for the chosen new style. How to choose doors in Moscow and whether replacing interior doors can be done with your own hands - this is discussed in our article.

Types of interior doors

First, let's briefly talk about the features of interior doors.

Device

Until recently, the main material for the manufacture of such structures was exclusively wood. The geometric dimensions and physical properties of the boards used in this process determine the main methods of making doors.

According to the design of the product there are:

- paneled;

- panel

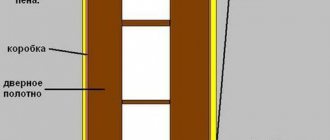

Paneled doors have a rather complex structure, which consists of the following elements:

- Standing drawer.

- Baguette.

- Panel.

- Lower and upper drawers.

The supporting structure is made of solid boards and consists of gratings with several openings. The frame consists of vertical and horizontal elements joined together using glued tenon joints.

The openings in the frame are filled with figured panels, which are secured in different ways. This can be thin lath beads or tongue-and-groove joints. Large-width natural wood panels are made from a blank that is glued together from two boards. This eliminates the possibility of cracking of the part.

The panel door consists of:

- MDF.

- Veneer.

- Honeycomb filler.

- Wooden frame.

- Frame reinforcement elements.

Modern panel doors are made of natural wood frames covered with MDF panels. Cardboard honeycombs are most often used as filler. Such a door has a relatively low weight, with sufficient structural strength. This type of door leaf can be either solid or with glazed openings. The cost of such products is significantly lower than that of paneled ones.

Finishing material

Previously, interior doors were made exclusively from natural wood of various species. Currently, composite materials, polymers and glass are widely used in the production of door leaves. Laminated wood fiber panels are increasingly used as coatings for common types of interior doors.

Solid wood doors are mainly made from valuable wood species:

- hornbeam;

- oak;

- nut;

- teak;

- ash

Premium class samples are often made from exotic types of raw materials: rosewood, Karelian birch, red, ebony or black Coromandel wood. Such doors are usually made by specialized studios according to special orders and original designs.

By design, solid wood products can be either paneled or panel. The latter have a smooth surface with an original pattern.

To improve the appearance of products made from inexpensive types of wood, different types of coatings are often used. One of the most common technologies is veneering. The basis of the door in this case is usually inexpensive pine lumber or chipboard. Veneer made from valuable wood species is glued onto the board on both sides, which are subsequently sanded and covered with furniture varnish.

This technology is applicable in the production of both panel doors with smooth external surfaces and with embossed ones. Veneered products are environmentally friendly; natural wood and special wood glue are used for their production. When using them, it is necessary to maintain a certain temperature in the room and avoid humidity.

Polymer materials are widely used in the production of door panels. Frames assembled from relatively inexpensive pine boards are lined with polyvinyl chloride panels. For rigidity, the structure is reinforced with additional bars and covered with decorative plastic plates.

When producing polymer panels, their outer surface is given a texture that imitates wood of different species. Additionally, a film with a corresponding pattern is applied to it.

In recent years, transparent structures have become increasingly popular in interiors. In a home environment, glass doors look quite presentable. They separate rooms and at the same time expand the space. For the manufacture of such doors, impact-resistant glass with a thickness of at least 8 mm is used, which gives them sufficient strength.

To install such a canvas, canopies specially designed for this purpose are used. Given the significant weight of the products, quite high strength requirements are imposed on door frames. Glass sliding structures have gained the greatest popularity among consumers.

Preparing the doorway

The principle of preparing a doorway for installation of a new door depends on the type of door leaf chosen. So, if you choose a hinged door (sliding), a mandatory step is to thoroughly plaster the walls in the area of the doorway on the side where the door is hung. In addition, you should take into account the dimensions of the selected product. Quite often it is necessary to expand or reduce the size of the doorway.

Under no circumstances should the expansion procedure be carried out using a hammer. For these purposes, a hammer drill with a special blade-shaped attachment should be used. Expansion is carried out by successively removing small sections of walls to the required level.

Reducing the opening is done by building up the walls using plaster. It should be remembered that it is better to carry out the procedure symmetrically, on both sides of the opening. However, the use of plaster is acceptable for minor differences in dimensions. In other cases, pouring cement or even laying bricks or concrete blocks is used.

It is worth considering that polyurethane foam does not have sufficient strength characteristics to ensure high-quality retention of the door frame. Therefore, using polyurethane foam as a means of narrowing the opening will have a short-term effect. Subsequently, the door structure will hold very weakly and over time may become significantly distorted, even to the point of falling out.

The main thing you should pay attention to when deciding to reduce the passage is the need to subsequently carry large furniture and equipment through it. Do not narrow the opening between living rooms. It is also necessary to take into account the indentations for technological and installation gaps. In swing type doors they are 70 – 100 mm wide and 50 – 70 mm high.

How to choose the right interior door to replace

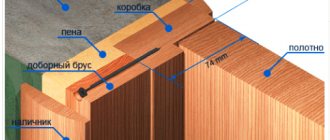

First of all, any door is not just a door leaf. They are almost always sold in kits, which include a box, trim on both sides, etc. if necessary, so-called “additions”.

There is a “golden rule”: the door leaf and frame must be made of the same type of material!

The choice of doors should not be approached in the same way as purchasing furniture. With a certain external similarity of these interior items, the load on the doors is tens, or even hundreds of times more intense than on the cabinets. No matter how important appearance is, the main emphasis is still on build quality and strength characteristics.

You should always go to the salon with a tape measure so that you can independently check the dimensions and geometric correctness of the frame and door leaf. Diagonal measurements must be taken - the difference should not exceed 1 mm. If it is larger, then you should refuse to purchase a rhinestone - the door or frame is uneven, skewed, and therefore was made by some unskilled artisans.

The reliability and quality of fastening of glass inserts must be checked - they should not rattle or vibrate, otherwise they will not last long. It is worth checking with the sellers and in the technical documentation which specific glass is installed on the canvas and what seals are used. High-quality Belgian and Italian glass deserves the best reviews.

Recommended articles on this topic:

- Arrangement of a small apartment

- Stages of renovation in an apartment

- Turnkey cosmetic repairs

It is imperative to literally “feel” all the seams at the joints of the parts of the canvas or box - they must be smooth, beautiful, stable, without any signs of discrepancy.

Typically, the doors will be supplied with appropriate fittings in the form of locks and handles. If there is such an opportunity, then you should not take on the responsibility of inserting them yourself - this can be done by qualified salon technicians.

One more thing. Interior doors do not belong to those groups of products that require mandatory certification of conformity and quality. Therefore, in this matter, you can rely on the conscientiousness of the store employees, the ratings of door manufacturers, your own life experience, attentiveness and common sense.

Final finishing

- If finishing work continues in the room, it is better to remove the door panels and cover the frames with film. Do not secure the film with tape: it will leave traces. You can use masking tape.

- After finishing the finishing work, we will close the gap between the frame and the wall with platbands.

- We close the screw heads with plastic furniture plugs in the color of the box.

- We install handles, locks, latches, and bolts.

- Don't forget to install stops for the door leaves. They allow you to limit the range of rotation of doors, protect furniture and the doors themselves from damage.

You can be creative in the design of the space above the door

- Apartment

How to decorate a doorway: 35 interesting ideas

Do-it-yourself replacement of interior doors

It is recommended that before starting work, draw up a drawing on which you must accurately indicate all the dimensions taken from the opening, the door frame and the door leaf. This scheme will help you quickly complete work without being distracted by measuring each part during the installation process.

Then you can go in two ways - replace only the leaf or the entire door along with the frame.

Replacing the canvas

Replacing the canvas begins with removing the hinges. As you know, door hinges consist of two parts, one of which is attached to the door, and the second to the door jamb. In some models, the axial rod is permanently fixed inside the element, which is mounted on the vertical post of the jamb, and in another part, installed on the door leaf, there is a hole where the rod should go.

When removing a door hung on such hinges, you need to install a pry bar under its lower edge and apply a little force to lift the door. It is best if there is a second worker who will support the door in an upright position and then help remove it completely.

Another type of canopy in which the axle rod is inserted from the top and passes through both parts of the hinge. In order to dismantle a door hung on such hinges, it is enough to pull out the rods installed in them, which have a kind of mushroom-shaped cap on top. Place a reliable wide screwdriver under it, and, tapping its handle, pull the pin out of the loop.

If only the door leaf is replaced, the new door will have to be adjusted to fit the existing opening, based on the dimensions of the old one. You need to take the exact dimensions from it and transfer them to a new canvas.

You can do it differently - the new door is laid on a flat surface, and the old dismantled door is placed on top of it. The canvases are aligned along the top and along the vertical edge of the door on the side where the handle will be installed. If the new canvas is larger in size than the old one, it will need to be adjusted. Using a pencil, lines are drawn on it, along which an excess fragment is sawed off from the new canvas.

When the new door is adjusted to size, you need to mark the places where the hinges will be attached. To carry out this process accurately, you need to put the old door on the new leaf and very accurately align them with each other. At the end of the new door, mark the areas where the hinges will be installed, focusing on the old door leaf.

The next step is to install hinges in the prepared recesses. They must be installed so that the plane of the metal plate is flush with the surface of the door end.

When the hinges fit well, you can move on to making holes for installing the lock and handle.

What will you need for the job?

No complex preparatory work is required. It is enough to have the simplest tools on hand: a tape measure with a pencil, a level, a hammer, a drill and a jigsaw, a chisel and a grinder. This work can be done independently, but it is better with a partner. This makes it more convenient and reduces the risk of straining your back, especially if the door leaf is quite heavy, for example, made of natural wood.

Frame installation

Before interior doors are installed, work is done to secure the frame to the doorway. This procedure is not particularly difficult and its detailed execution can be clearly seen in almost any video of door installation.

The frame is placed in such a way that there is no protrusion from any side. After this, 3 holes are made in it on each side for fastenings. After adjusting the vertical parts to the level, drilling into the wall is carried out through the prepared holes. This prepares the holes for fastening.

The procedure for securing the frame itself is carried out by placing dowels or glazing beads in the holes and fixing the box with screws or self-tapping screws.

Sliding

Sliding doors save a lot of interior space. This door is convenient, functional, it looks impressive and fits organically into any interior. These doors have varieties that differ in their opening system. HS portal are doors that, when opened, first rise and then can be moved to the side. The FS portal is a so-called “accordion” - a very interesting look.

Based on the type of doors, structures are divided into single-leaf and double-leaf. You can often find a parallel or radial type. Such doors can open in one or both directions.

The following materials are used in the production of sliding doors:

- plastic;

- tree;

- glass.

This type of door is often decorated by applying photo printing on it, covering it with PVC film, stained glass or natural materials such as veneer, bamboo and others. The frame is most often made of aluminum. This door can be used not only in a private house or apartment, but also in a country house, country house or cottage.

Consumables and tools

Everything you need to install an interior door yourself is listed below:

- hacksaw or saw;

- chisel;

- miter box;

- building level;

- Phillips screwdriver or screwdriver;

- tape measure at least 3 m;

- polyurethane foam;

- hammer;

- dowels and screws;

- pencil;

- sealing tape;

- spirit level – short (50 cm) and long (180 cm);

- universal screws;

- knife;

- square;

- wedges - wooden or plastic;

- finishing nails.

Without lock

Dismantling a simple locking handle without a lock is not particularly difficult, because there is no locking mechanism inside the blade.

As a rule, all handles without a lock for interior doors have a similar design, so dismantling them is not particularly difficult. However, the installation diagram may differ depending on the type of structure.

The easiest way to remove standard round handles is to simply unscrew the two screws that secure the handle to the blade, after which the handle can be removed. Handles of other shapes are also unscrewed in a similar way.

Some designs include decorative overlays. In this case, first remove the decorative element, and then unscrew the screws holding the handle.

Door leaf installation

Work is carried out after the frame is securely fastened in the passage. However, before hanging the product, it is important to increase the reliability of the structure. To do this, the remaining gaps between the frame and the wall are blown out using polyurethane foam. In this case, it is necessary to place special spacers in the box, which will avoid damage and distortion of the structure when the foam expands.

The sash is hung from the open door position. To do this, the product is lifted above the counter pin in the frame and placed on it. If necessary, the position of the door relative to the floor and walls is adjusted by tightening the fastening elements of the hinges. After this, the product is checked several times for correct placement by opening and closing.

The final stage of installation of a new interior door is the installation of platbands. After marking the decorative strip, it is cut using a circular saw or a fine-toothed hacksaw. The upper sections are cut at an acute angle of 45 degrees. After the fitting procedure, the planks are installed. To fasten them, use construction adhesive or finishing nails. It is also permissible to use self-tapping screws and then disguise them with decorative plugs to match the trim. After reading our instructions, you will now easily understand how to easily change interior doors yourself and avoid mistakes.