Nowadays, it is often necessary to use a seal for wooden doors. It helps to cope with the problem of drafts, the room becomes warmer. The seal must be installed when dust penetrates through the cracks in the door. Foreign odors from the street enter the room. It is very rare for a door to fit snugly into its frame. After installation there are gaps. Before buying a seal for wooden doors, you should understand its types and understand what functions it performs.

Functions

The main function of doors is to isolate residents; wooden door leaves are no exception. The better the insulation, the calmer a person feels in a living space. With the addition of a door seal, new characteristics appear:

- When the door closes, the contact of two surfaces results in a blow. In this case, the seal will take the blow, softening it. With it, the doors will last longer.

- Reduces the risk of chipping. With insulation, there will be no deformation of the door; it will not be able to “slant” to the side.

- Thermal insulation appears, since the sealant gasket closes the gaps between the door frame and the door itself. Thanks to this, heat is retained in the room.

- Sound insulation increases with insulation. The door fits tighter, the likelihood of hearing extraneous noise is reduced.

- Seals for wooden windows and doors reliably protect against dust.

- Drafts stop entering the house through cracks.

Door insulation with rollers

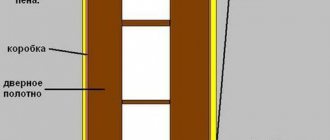

To close the joint between the door jamb and the sash, thick leatherette rollers are used. They do it this way:

- After measuring, cut out 4 pieces 10 cm wide. The length will be equal to the parameters of the sash.

- Fasten the strip with a stapler or nails with the wrong side facing out.

- A roller is formed from insulation. Place into the prepared leatherette strip.

- Wrap it, secure it - you get a reliable sealed gap.

It is not difficult to insulate the door yourself. It is important to follow the recommendations. Then the room will be warm, cozy, quiet.

What types of seals are there? Classification by purpose

A seal for wooden doors can be considered according to its purpose, as well as based on the material and method of its fastening. Each specific type of filler is used on different types of doors.

The seal for the front door is a thick rubber tube that is resistant to various influences. Due to its structure, rubber ensures heat retention in the room. The seal for wooden entrance doors can have different configurations.

Interior doors are in favorable conditions and are not affected by weather factors. The seal for them can be made of rubber or silicone. Some use plastic. Installation is most often carried out using glue.

For sliding wardrobes made of wood, a special self-adhesive tape is used as a seal. It has a special pile that prevents dust from penetrating into the cabinet.

Tips and tricks

The following recommendations should be followed:

- It is best to insulate a plastic door with glass, using an additional double-glazed window;

- it is necessary to pay equal attention to both the insulation of the canvas and the thresholds and the perimeter of the doorway;

- standard Chinese metal doors immediately need to replace the insulation.

The front door requires special attention when protecting from the cold. The entire perimeter should be insulated, and the door should be closed tightly and quietly using a seal. The insulation process for doors made of plastic and metal with wood is different.

Sources

- https://nedvigdom.ru/sposobi-uteplit-vhodnuyu-dver/

- https://chastnyjdom.ru/uteplit-dver-svoimi-rukami/

- https://ZnatokTepla.ru/utepliteli/uteplyaem-vhodnuyu-dver-v-kvartire.html

- https://svoyadver.ru/kvartira/uteplitel-dlya-vkhodnoy-dveri.html

- https://www.ivd.ru/stroitelstvo-i-remont/dveri-i-peregorodki/kak-uteplit-na-zimu-vhodnuyu-derevyannuyu-dver-v-chastnom-dome-57091

- https://www.tproekt.com/kak-uteplit-vkhodnuyu-dver/

- https://ZnatokTepla.ru/utepliteli/dver-v-chastnom-dome.html

[collapse]

How are seals classified by material?

The material used as a seal is selected taking into account the location of the door:

- The rubber seal is made of rubber. Silicate fillers are added to it. The material becomes resistant to external factors. It can withstand temperatures from -50 degrees to +120, while its properties remain unchanged. A rubber seal for wooden doors will last for many years, often the service life is from seven to nine years. Typically used on the front door. Available in white, black and brown.

- Plastic seals are considered one of the most durable; their service life can be up to 30 years. They are unchanged in any weather conditions, they are not afraid of frost. Another advantage of this type of seal is the ability to restore its shape even after mechanical damage. This type can be purchased in any color.

- Silicone seals are considered the most popular on the market these days. They have many advantages. They are not afraid of water or direct sunlight. Such a seal easily comes into shape after compression. It can last up to ten years. If the top layer becomes sticky to the touch, then it's time to change it. Over time, the material loses strength.

- The polyurethane seal is considered the most resistant to deformation. It protects sliding interior doors from impacts.

- It is believed that foam rubber has the shortest service life. If it gets exposed to water or sunlight, it may crumble. With sudden changes in temperature, foam rubber loses its qualities. Many people buy it because of the low price.

What are the different fastening methods?

An important point is how the seal is attached. He can be:

- Self-adhesive, have a sticky layer that is covered with a protective film. This type is easy to install. To do this, you need to properly prepare the surface. The disadvantage of this type is that the tape often comes off.

- The adhesive seal is quite difficult to install. You need to know how to apply glue with your own hands. It is necessary to choose a high-quality composition to ensure reliable adhesion to the surface. The method is reliable.

- The groove seal for wooden doors is used if there is a certain configuration. This method allows installation without additional elements. The advantage is his speed. Parts are easy to replace if necessary. Seals for wooden doors with a groove can be purchased at any hardware store. They are inexpensive.

- The seal for mortise wooden doors is mounted on specially prepared self-tapping screws. After fixing, it is recommended to fill the cracks with liquid sealant.

- Magnetic ones are not used on wooden door leaves.

Which of the tools

In addition to the insulation itself, you will also need tools. Minimum standard set:

- roulette;

- a flat board, lath or metal ruler;

- knife (stationery or kitchen);

- screwdriver;

- hacksaw or jigsaw;

- hammer;

- screwdriver or drill;

- pull out;

- furniture stapler.

It is possible that in some situations other devices may be needed. You should also prepare fittings and screws. Now we insulate wooden doors with our own hands according to the instructions below.

We prepare the necessary

First, let's do the preparatory work. Carefully remove the door from its hinges using a pry and lay it on a flat surface. Next, remove all the fittings and put them aside. If there is internal lining, carefully remove this layer as well.

How to choose the right sealant?

In this case, you shouldn’t rush and don’t take the first seal you find at a hardware store. Pre-requisite:

- Find out what the perimeter of the door is. Then it will be easy to understand what length of tape you should buy. For a standard door leaf, six meters of tape are required.

- Do not neglect the instructions on the boxes. From it you can get all the necessary information about the product. It is important to pay attention to the shelf life of the glue. If it has expired, then the adhesive composition has lost its properties. It will “fly off” or not even stick to anything.

- You can put a little pressure on the tape, if it recovers completely in the shortest possible time, then the material is of good quality.

- If you have tape that does not have an adhesive layer, you can use a sealant.

- Plastic and silicone seals are suitable for internal doors. The main function of the seal is to protect the apartment from drafts.

- If you need to insulate a wooden balcony door, it is better to choose an adhesive-based rubber seal. If there are small gaps, then you can opt for foam rubber.

Plastic

Installation of insulation is carried out similarly to wooden structures. A plastic door, which is covered with dermantine on top, will provide good protection from the cold. Only here it is necessary to replace the nails with construction glue. The process goes like this:

- remove the door;

- remove the fittings;

- install insulation;

- lubricate the structure and all elements, and then install the handles back;

- decorate the surface according to personal discretion.

How to install the product on a wooden front door?

To install a door seal for wooden doors you need:

- Find out the perimeter of the door frame, determine the length of the tape.

- Make a cast of the gap. You can use plasticine for this. It must be placed in a plastic bag and closed with a door.

- It is important to clean the area where the seal will be attached. There should be no dirt or dust left on the surface. You can degrease the work area with an alcohol solution. If you have a solvent on hand, you can use that too.

- When using glue, you need to remember that it is applied in a thin layer. It is evenly distributed with a spatula over the surface. The rubber layer is also covered with a layer of glue.

- It takes about ten minutes for the glue to dry, after which you can install the rubber tube. It must be pressed tightly against the desired surface, squeezing smoothly.

- The ends can be trimmed with a utility knife.

- The weatherstripping strip is then glued around the perimeter of the door.

It must be remembered that sealing depends on the number of layers glued along the contour of the door.

Purpose

It is believed that the main purpose of sealing windows and door blocks is thermal insulation.

But it is not so! The fact is that a high-quality seal allows you to implement other tasks, including:

- creating proper sound insulation;

- protection of the premises from penetration of water and moisture from outside;

- creating a barrier protecting against dust and odors, etc.

How is the seal glued to an interior wooden door?

The seal for wooden doors in an apartment is glued directly to the frame. It is advisable to choose it in the same tone as the door itself. In this case, the latter will look more harmonious.

If the tape needs to be replaced with a new one, then you need to carefully remove the old one. Along with it, you need to remove nails from the surface, as well as traces of glue.

To avoid staining the door frame, you can cover it with masking tape. After this, you can glue a new tape. It is necessary to obtain a completely closed perimeter; the excess part of the tape can be cut off with a stationery knife. The cut is made at an angle of 45 degrees. When the work is finished, you can remove the masking tape from the door frame.

If a person chooses a self-adhesive sealant, he must ideally prepare the surface for work. There should be no dirt left on it. The door leaf needs to be sanded. After this, the surface is degreased. When work has begun, it is better to remove the protective film gradually so that the glue does not have time to dry before the tape comes into contact with the surface.

Criterias of choice

When choosing insulation for a street door, consider the following points:

- the thickness of the thermal insulation must correspond to the operating parameters of the structure being equipped and not create obstacles to the normal functioning of the elements of the entrance group;

- the total mass of insulation and sheathing complete with fasteners should not contribute to the weight of the fabric.

When arranging thermal insulation for the street door of a country house, it is allowed to use materials with not very high durability characteristics, since a low intensity of use is assumed. To insulate the entrance block in a private house, strict requirements are imposed on the selection of materials and installation in order to eliminate rapid wear and tear and the need for repeated thermal insulation work.