The level of protection of a living space from noise and drafts is not limited to the front door. No less hope is placed on interior structures. The reliability of the door depends on the material of the door leaf, as well as the type and quality of fastening elements. The review provides detailed information about the types of rubber seals for interior doors, recommendations for their selection and installation of the structure. As a supplement, we have collected tips on how to clean the seal and get rid of squeaks during its operation.

Types of rubber seals for interior doors

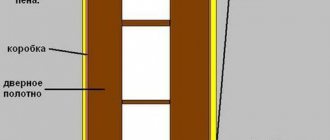

The seal is an elastic gasket with a different cross-section. The main purpose of the consumable element:

- increases the level of heat and noise insulation;

- protects the object from impacts;

- blocks smoke, steam and odors.

Sealing rubber is used to seal entrance and interior doors. Gaskets installed on indoor installations are made from a softer and more plastic material compared to outdoor ones. This enhances the sound insulation of the home and facilitates smooth and quiet closing of the door. Various raw materials are used as material for the production of tape, allowing the creation of several modifications that differ in shape and function. Shades are matched to the color of the door leaf.

Regardless of the profile of the sealing rubber (L-shaped or D-shaped), the thickness is 1 cm. A product with this size hides cracks well and unnoticeably.

The range of offers of rubber seals for interior doors is small, but when choosing an element it is important to understand the difference between each of them:

- Rubber . In practice, rubber seals are rarely used when installing interior furnishings and are more often in demand for installing entrance structures. Rubber is preferred for its flexibility, providing a tight fit, as well as high endurance. Good flexibility is a sign of product durability.

- Silicone . According to the operating criteria, silicone is similar to rubber. The main difference is that it is not subject to manufacturing changes by adding special impurities designed to increase its durability. For this reason, silicone elements are used only for interior doors, where the impact of external factors is less aggressive compared to street doors.

- Foam rubber . Door insulation made of foam rubber is a cheap sealant. It is practically not in demand due to its low aesthetic characteristics and fragility - from 3 to 6 months. During operation of the interior door, the rubber seal loses its original shape, decreasing in volume. This reduces the functionality of the element and causes the need to replace it.

- Felt . Felt tape is useful when installing a sliding door, which helps save room space. The element is not particularly protected from noise and drafts, but it prevents dust from entering the living room or kitchen.

According to the installation method, sealing rubber bands are divided into self-adhesive and those installed using self-tapping screws or self-tapping screws. Additionally, there is grouping by purpose:

- Thresholds . They are attached to the lower end of the canvas and serve as a replacement for a regular threshold. The tape presses tightly to the floor, and its self-adjusting property hides gaps in the presence of uneven floor coverings.

- Outline . They are placed around the perimeter of the door structure, between the leaf and the frame. The pliability of the seal contributes to its rapid recovery after pressing. Among the main advantages of this type of insulation are increased noise protection, versatility and ease of installation.

What to look for when purchasing?

When choosing a seal for steel doors, you need to carefully inspect it and check its quality.

In particular, you should perform the following actions:

- Read the label on the product, which indicates the expiration date, all the necessary information about the seal and the material used for its manufacture.

- By pressing it is worth checking the elasticity and tightness characteristics. The material should be medium hard, then it will not interfere with the door closing well. When pressed, it should quickly restore its original shape. This is a sign of high quality material.

- If the seal is on self-adhesive tape, then you need to find out the expiration date of the glue. Otherwise it could just dry out. Also, small particles of fiberglass should be applied to the adhesive part.

Most often you can find such products on sale from Germany, Sweden, Poland or Turkey. A good product should not harden when the temperature drops, or peel off when it fluctuates; release toxic compounds into the air.

Which seal should I choose?

Sealing tapes for interior curtains are made from various materials. Regardless of this, all elastic bands are designed to reliably seal the canvas without leaving gaps in the structure. In accordance with the main evaluation criteria, all products meet standard requirements:

- high quality, ensuring a long service life of the structure;

- compliance, expressed in recovery after compression;

- wear resistance, preserving the properties of the product in case of mechanical damage;

- impenetrability, blocking the penetration of dust, noise and drafts into the room;

- softness, which contributes to good shock absorption and muffling of impacts of the leaf on the door frame.

Some manufacturers of interior doors initially equip them with strip fittings. When purchasing these products, there is no need to think about additional sealing. Otherwise, the rubber seal must be purchased and installed separately. To achieve the tightest fit with the canvas, it is important to choose the right product. The main criterion is the size of the gap to be eliminated.

For the installation of interior doors, a narrow profile of the same color as the frame and leaf is used. The arrangement of internal structures is carried out using elements made of soft materials. Rubber seals provide better silent and tight insulation.

To insulate the door to the bathroom, a silicone seal is selected. The environmentally friendly material can withstand temperature changes and high humidity that are typical for this room.

Functions

The main function of doors is to isolate residents; wooden door leaves are no exception. The better the insulation, the calmer a person feels in a living space. With the addition of a door seal, new characteristics appear:

- When the door closes, the contact of two surfaces results in a blow. In this case, the seal will take the blow, softening it. With it, the doors will last longer.

- Reduces the risk of chipping. With insulation, there will be no deformation of the door; it will not be able to “slant” to the side.

- Thermal insulation appears, since the sealant gasket closes the gaps between the door frame and the door itself. Thanks to this, heat is retained in the room.

- Sound insulation increases with insulation. The door fits tighter, the likelihood of hearing extraneous noise is reduced.

- Seals for wooden windows and doors reliably protect against dust.

- Drafts stop entering the house through cracks.

DIY installation

The procedure for attaching a rubber seal to an interior door consists of several simple steps:

- Removing the old element if it exists.

- Cleaning and degreasing the surface after the old tape.

- Cutting a strip of the required length with a margin of 2 cm at each end if you purchase a self-adhesive base.

- Removing the protective film from one of the ends and applying it to the desired location.

- Gradual removal of the film and gluing the tape to the frame, constantly monitoring the evenness.

- Gluing the elastic overlapping at the corners.

- Forming corners after carefully gluing the sides. Using a utility knife, make a cut in the corner at a 45-degree angle and remove the trimmings.

Installation of the seal is carried out independently or is included in the service of calling a master installer. An alternative method of installing the sealing element is dictated by its type. If the tape is not self-adhesive, self-tapping screws or self-tapping screws will be required. The fastening scheme is popular among craftsmen who independently equip their homes.

The groove installation approach is due to the fact that the seal fits into the groove of the box. The difficult part is finishing the corner areas. Experienced specialists fasten the elastic exactly end-to-end. Beginners are advised to trim the material carefully to avoid unnecessary trimming. The grooved installation method is advantageous compared to the first one, because the level of sealing in this case is an order of magnitude higher.

When laying rubber and silicone sealing gum, it is important to completely eliminate tension. Otherwise, an unacceptable voltage will form inside the insulating layer, which will affect the performance properties of the tape.

Why do rubber bands squeak and what to do?

In practice, the creaking of the rubber seal on an interior door often causes displacement, which appears for two reasons:

- Incorrect installation of the canvas . The basis for this is incorrect measurement or inaccurate installation of the structure in the space between the doors.

- Curvature of thresholds or walls . The situation is more common in a private house, when the building settles. Improper construction of high-rise buildings also causes cracks and leads to loosening of walls and deformation of thresholds.

Depending on the complexity of the situation, squeaking is eliminated in one of the following ways:

- Tightening the fasteners . The adjustment of the hinge mechanism is carried out using tools, in particular, a 17 socket wrench and a hexagon. The middle loops are weakened first. The sash is pulled back and the leaf is pressed against the door frame. The nut is tightened until the squeak is eliminated. If the sound persists, the steps are repeated with the upper and lower loops.

- Lubrication . Elimination of squeaking is carried out by lubricating the seals with various compounds: litol, grease, diesel oil, silicone and petroleum jelly. If the cylinder is equipped with a sprayer, application is carried out on a rag and then passed over the sealing rubber band. When lubricating the doors with lithol, the canvas is first removed from the hinges. The lubrication procedure is repeated 2-3 times. A universal remedy in the form of Vaseline does not require removing the door; just carefully walk it along the hinges. For convenience, use a regular piece of cotton wool and a match.

How to clean the seal?

The products used to lubricate the sealing tape to eliminate squeaking are also suitable for cleaning it from dirt and grease.

For example, litol is a multi-purpose waterproof lubricant with a high melting point, low volatility and high stability. The main advantage of the composition is that the subsequent appearance of contamination is minimized. To clean the seal, lithol is applied to a rag, which just needs to be walked around the perimeter of the tape.

A product similar to lithol is solidol. Regular maintenance of the structure keeps it in its original form and eliminates the need for complex restoration efforts.

How to install the product on a wooden front door?

To install a door seal for wooden doors you need:

- Find out the perimeter of the door frame, determine the length of the tape.

- Make a cast of the gap. You can use plasticine for this. It must be placed in a plastic bag and closed with a door.

- It is important to clean the area where the seal will be attached. There should be no dirt or dust left on the surface. You can degrease the work area with an alcohol solution. If you have a solvent on hand, you can use that too.

- When using glue, you need to remember that it is applied in a thin layer. It is evenly distributed with a spatula over the surface. The rubber layer is also covered with a layer of glue.

- It takes about ten minutes for the glue to dry, after which you can install the rubber tube. It must be pressed tightly against the desired surface, squeezing smoothly.

- The ends can be trimmed with a utility knife.

- The weatherstripping strip is then glued around the perimeter of the door.

It must be remembered that sealing depends on the number of layers glued along the contour of the door.

How to change rubber bands?

If the service life of the sealing tape has expired or it no longer meets the stated requirements, the element must be replaced with a new one. First of all, a sealant of the required shade and geometry is selected. If everything is simple with the first parameter, then geometry requires special understanding. All existing parameters conditionally belong to one of three groups:

- The sealing rubber under the rebate is straight-fitting. When the seat into which the tape is inserted is located on the same plane as the door leaf.

- Sealing element under the rebate with an angle of 90°. Selected if the line is perpendicular to the canvas.

- Self-adhesive seal. Relevant if there is no seat in the door.

After a new seal has been selected, the old one is dismantled. The area is cleared of remnants of the previous tape and degreased. Depending on the type of sealing tape selected, it is fastened with preliminary adjustment of the length of the elastic band and cutting of the ends.

When purchasing an interior door, the choice of seal for it deserves no less attention than the door leaf itself. An incorrectly selected rubber band reduces noise insulation, throughput and, as a result, overall expectations from the design.

Classification: main types

Seals are produced by many manufacturers and differ in the following parameters:

- Material type. It can be rubber, silicone, polyethylene foam, plastic, foam rubber.

- Construction . The material in question can be made entirely of one material or be equipped with a metal clamping strip.

- Fastening system . The seals are self-adhesive (an adhesive substance is applied to one side, protected by paper tape) or attached to self-tapping screws. But the latter can only be installed on wooden doors.

For reference. You can make a seal yourself by wrapping a strip of foam rubber in leatherette or artificial leather. Another option for eliminating door gaps is to insulate the entire structure (see How to insulate a metal entrance door) and install an overlap around the perimeter of the door leaf.

As a rule, the seal is sold in the form of a roll, the length of the tape is about 6 meters - this is just enough for installation on a standard door. In the package you will find installation instructions and fasteners, if needed. But for a metal door, self-adhesive seals are mainly used.