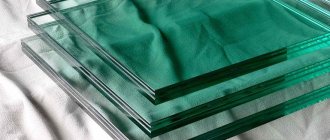

Everyone knows such a building material as glass, which has a wide range of applications in different fields of activity. But it cannot boast of particular strength, so it is gradually being replaced by innovative materials - tempered glass and triplex, which have higher technical qualities.

If earlier people did not have much choice, and they had to use ordinary glass both when glazing buildings and in the production of various glass products, now many are interested in what is better, triplex or tempered glass? It is quite difficult to answer this question, because everything here depends on certain conditions and the scope of their application.

Differences in manufacturing technologies

Tempered glass is made from ordinary sheet material, which is heated in special furnaces at a temperature of 700°C. Then it is sharply cooled with air jets to 30°C. Another effective technique is to use special coolants as a quenching medium to accelerate the heat transfer process.

Such liquids can be:

- molten salts;

- mineral oils;

- metals;

- organosilicon solutions.

Hardening the material using various molten metals is also relevant. Thanks to this technology, the material acquires high strength and resistance to various temperature influences.

Triplex during the production process is not exposed to high temperatures (unlike tempered glass). It is a multilayer material consisting of polymers glued together into a single whole. The liquid polymer is applied to the glass under the influence of ultraviolet light, and when hardened, it reliably holds them together.

There are several options for making triplex:

- Filling. In this case, polymer liquid is poured between the glasses.

- Film. Polyvinyl butyral film is placed between the glasses, and the products are placed in an autoclave for gluing.

- Non-autoclave. Products are made from film and glass using vacuum heating to the desired temperature in the chamber.

Triplex can be made from both ordinary (raw) glass and tempered glass. Consequently, the quality of the material will have different qualities and performance characteristics. That is, material made from tempered glass will be the most durable and reliable. But its cost will also be higher.

What functions do glass on watches perform?

The main purpose of the glass is, of course, to protect the dial and hands from external damage , as well as from the ingress of water and small particles, such as dust and dirt. Therefore, its choice should be treated with special care in order to maintain the durability and good appearance of the watch.

Graphic representation of glass functions on a wristwatch

Previously, all watch glasses were made exclusively from quartz or rock crystal (another name for quartz), but now the industry has stepped far forward and offers various analogues, such as polycarbonate, sapphire fiber, plexiglass and others.

It is these glass materials that we will talk about next. Let's start with, perhaps, the most common ones - sapphire and mineral.

Differences in operation and technical qualities

To make it easier to decide which material to order, it is worth considering that they have certain differences:

- different manufacturing techniques;

- its technical and operational qualities (safety, durability, heat resistance, light transmittance);

- different range of applications.

| Materials | pros | Minuses |

| Triplex |

|

|

| Strained glass |

|

|

Considering the features of both materials, it is worth highlighting the fact that triplex allows you to implement any design solutions. Since in its production multi-colored or plain films (can be with prints and ornaments), fabrics (which are rolled between double-glazed windows) are selected.

Also, in its production, nano-technology “Smart glass” can be used (that is, it is glass with a variable degree of transparency, which has recently been in great demand when arranging modern interiors and public institutions).

But tempered glass is a universal material often found in indoor interiors. It does not have such great decoration possibilities (except for the use of sandblasting patterns and ceramic printing). Its only disadvantage is the impossibility of processing after production.

That is, if you need to make a hole in the finished material, it will most likely simply collapse. Therefore, before ordering its production, you need to think through everything to the smallest detail. Since it is possible to change the shape, size or make a hole in the glass only until it is hardened.

Durability and safety

Tempered glass has quite high strength indicators (it is 5 times stronger than ordinary glass). And the strength of triplex depends on what kind of glass was used in its manufacture. The use of two ordinary glasses in its production makes it possible to make the material several times stronger and more reliable than ordinary glass. And if tempered glass was used in its manufacture, then such a product will have the highest levels of strength and reliability.

Reference! Triplex, 13 mm thick, is used in the manufacture of armored and bulletproof products.

As for safety, both of these materials are completely harmless. Such glass is almost impossible to break and damage. But if this does happen, both materials do not shatter into sharp fragments, so it is impossible to get hurt by them.

XYG (China)

Xinyi Group Glass is a Hong Kong brand. Since 1988, it has been known all over the world for its product prices. But this does not mean bad quality. In 2005, the company was listed on the Asian stock exchange. The corporation has a production base of six factories in the cities of Yingkou, Tianjin, Wushan and others. The total number of full-time employees exceeds 15 thousand people.

Advantages:

- brand prevalence in the Russian Federation

- low defect rate

- perfect surface

- low cost.

Flaws:

- rain sensors and mirror mounts are rare

- There are discrepancies with the passport dimensions of car models

- the softness of the glass, and therefore the fragility of rubbing with brushes.

But for the Russian consumer, these shortcomings are compensated by the low cost of XYG, and their demand is compensated by the model range.

Mechanical resistance

Both materials have fairly high resistance to various types of loads. But they can also be broken with some effort. If you break tempered glass, it will shatter into many small pieces. The fragments will have blunt edges that cannot be injured. With a strong impact, 1 square meter of tempered glass will shatter into approximately 180 small fragments.

As for triplex, it is much more difficult to break it, since it has particularly high strength indicators. But if you still succeed in doing this, the material will not shatter into numerous fragments, but only a cobweb will run along it. Since the glass will still remain attached to the adhesive or special film used in its production.

Application of tempered glass and triplex

| Material | Scope of application |

| Triplex |

|

| Strained glass |

|

Considering the scope of application of triplex and tempered glass, you can see that the second option is usually used under standard and domestic conditions. That is, shower stalls, office partitions, windows and various interior items are made from tempered glass.

But the scope of use of triplex is much wider, and it is most often used in industrial areas. Windshields for cars, planes, trains, etc. are made from it. technology. Since this material is highly impact-resistant, and under strong mechanical stress it does not shatter into many sharp fragments (although tempered glass also has this advantage).

Bent tempered glass, which is widely used in facade glazing, deserves special attention. It gives buildings an original and aesthetic appearance, emphasizing the smoothness of their architectural curves combined with the elegance of style. It is also in demand in the production of glass furniture, which is characterized by high durability and exclusivity. It is also used in the production of functional shower cabins, refrigeration and commercial equipment.

Attention! Triplex is widely in demand in the manufacture of bulletproof windows and doors, partitions. Such products are installed in rooms with increased safety requirements. It is also used in both domestic and standard conditions. But here it is worth considering that the cost of this material is much higher than tempered glass.

Triplex, in the production of double-glazed windows, attracts consumers not only with its high technical characteristics, but also with its aesthetics. Such windows are extremely safe and have a high level of sound insulation. Therefore, such double-glazed windows are widely used in glazing commercial and industrial facilities, private houses and city apartments.

Thanks to the presence of several glasses, fastened together with an adhesive solution or a special film, the material, even if damaged, continues to hold its shape and does not crumble into numerous fragments. The thickness of the film placed between the double-glazed windows is about 1.5 mm. Such windows boast resistance to scratches and other damage, which is why they are often used in glazing shops and shopping centers.

The list of applications for triplex and tempered glass is endless. Both of these materials are used in different fields of activity due to their unique technical characteristics and impeccable appearance.

Cost difference

For many consumers, the choice of one material or another is based on the final cost. That is, people are guided not so much by the scope of use of the material and its technical qualities, but by the cost. But this is strictly not recommended. Since everywhere there are standards and requirements for both glazing and the manufacture of various glass objects.

Comparing the cost, it is worth noting that triplex costs several times higher than tempered glass:

- cost of 1 sq.m. tempered glass, 12 mm thick, varies within 2 thousand rubles;

- cost of 1 sq.m. hardened triplex, 6 mm + 6 mm thick, costs from 32,000 rubles.

To summarize, we can say that the choice of material should be made based on personal wishes and preferences, the scope of their application, and financial capabilities (since both materials have a significant difference in price, and expensive triplex is not always rational to use in everyday life). Some glass structures are best made only from triplex, while for others, tempered glass is the ideal choice.

In any case, triplex has higher impact resistance, enormous possibilities for decoration (which is important when implementing creative design solutions), and higher sound insulation (this should be taken into account by those who live in noisy areas). But tempered glass has better light transmittance, heat resistance and a more favorable price.

AGC (Asahi Glass Co. - Japan)

Production began in 1900. Perhaps some people consider this company to be the best, this is due to the 100-year-old fame of the brand.

Its products are really high quality, its main customers are auto giants such as: BMW, Toyota, Nissan, Honda and domestic factories: VAZ, GAZ, PAZ, UAZ. The concern operates more than 300 subsidiaries around the world, including Russia. AGC products produced in the Russian Federation are relatively inexpensive. Among their advantages:

- good value for money

- many varieties

- availability of all necessary accessories for each specific car model.

According to customer reviews, no shortcomings have been noticed yet.