Locks, Accessories

To protect themselves and their homes, people install reliable, high-quality, burglary-proof locks on their front doors. But there are times when it is necessary to open such a mechanism. Such an embarrassment occurs due to negligence - the door slammed, and the keys were left inside the apartment or house. How to open the lock in this case?

First of all, decide on the question - who will open the mechanism? If you open it yourself, there is a possibility of damage to the internal or external parts of the mechanism. Therefore, if you do not have sufficient skills in this matter, then use the services of professional people.

Exterior of the castle

There is a large selection of different modifications of locking mechanisms on the market. Their differences come down to the burglary resistance class, operating principle and installation method. Cylinder and lever locks are becoming common mechanisms for entrance doors.

Level lock design

Before you start opening a lever lock, study its structure. The design of the mechanism is based on secret plates that rotate under the pressure of the teeth of the key. The lever lock is considered one of the most reliable, durable and almost impossible to open illegally. But what to do with such a mechanism if the key is lost or left inside the apartment?

Door lever lock design

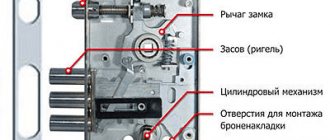

Let's look at the structure of the device. The lock consists of a steel box and a cover. The material of steel varies in different varieties. The use of heat-resistant steel in the lid design will give the locking mechanism strength against forceful break-ins, but its cost is many times higher.

The pressure plate is made of various metal alloys. It provides auxiliary protection of the mechanism from outside interference. The door is locked using a bolt. When the key is turned in the keyhole, the fingers and secret plates move outward from the bowels of the lock. These mechanisms act on the crossbars, and they close the door.

All of the above listed parts of the locking lever mechanism are visible, but this device also has hidden parts. They cannot be seen without disassembling the lock. These elements include the shank, which has a rigid, stationary coupling with the crossbars. The shank has a comb and a stand. The first, under the influence of the key, moves the bolt, and the second provides blocking when trying to open the mechanism by pressing on the bolts.

The stand on the shank has a square shape. Levers (plates) in different modifications have different structures. They are made from excellent alloys, differ in size and method of movement. Regardless of the configuration, there is a “labyrinth” in the lock, in which the shank post passes, performing a working function. This “labyrinth” is equipped with depressions and projections called code slots.

Castle Maze

For the lever locking mechanism, the key is made in the form of a handle, a long rod, a head and a bit. When the key turns in the lock, the plates are affected and the shank moves through the “labyrinth”.

Opening interior doors

Opening an interior door causes the least problems, since simple locks are often installed in such structures. Such designs are equipped with a latch on one side and a keyhole on the other. Parents of inquisitive children often have to face this problem. A child can easily slam the door and turn the handle, but the reverse process may cause difficulties for him. Then parents are faced with two tasks at once: how to open the lock, and how to keep the door itself safe and sound. Here's what to do in this situation:

- inspect the structure of the lock, the shape of the well;

- select a tool that can be inserted into the well;

- Carefully open the door, being careful not to damage the door leaf and lock.

The choice of tool depends on the shape of the keyhole. If it is round, then you will need a thin hard object: an awl, an unbent paper clip, a knitting needle or a toothpick. For a well with an elongated shape, you will need something flat: a screwdriver, a nail file, scissors or a knife. To open the door lock, you need to insert the tool into the hole. While pressing on it, turn the door handle. The main thing is not to overdo it so that the tool does not break and get stuck in the well.

There is another way to open a slammed door. To do this, insert a flat object between the end of the door and the frame, which needs to be used to slightly push the latch towards the lock. It is enough to move it just a few millimeters.

If the lock has a hole on each side, and a key remains inserted in one of them, it will not be difficult to deal with the problem if the design does not provide a threshold. You need to push the spread out newspaper under the door as far as possible. Then, with a sharp object, we push the key out of the hole, which should fall onto the newspaper. We take it out and open the door.

Tools for breaking the door mechanism

Opening a lever lock begins with determining how to perform this procedure. There are two methods to open the locking mechanism. In the first case, using rough pressure on the lock, it is broken. At the same time, its internal parts become incapacitated, and as a result, a new mechanism will have to be installed on the door. The second method will allow you to open the lever lock carefully, but after this the device will have to be repaired.

In the process of opening the door, regardless of the chosen method, you will need auxiliary tools:

- electric drill;

- bent scrap;

- knitting needle;

- nail file;

- hairpin;

- chisel;

- tweezers;

- Bulgarian;

- gas-burner;

- hammer.

To open the lever mechanism, other tools and devices are also useful. It all depends on the capabilities and ingenuity of individuals.

Methods for opening a lock

Before you begin opening the constipation, you need to decide what method will be used to do this. There are only two of them: rude and intellectual. The second method leaves the lock intact, but leads to minor repairs. The first, on the contrary, renders the lock inoperable, and sometimes forces you to replace the entire door.

Any of these methods requires the use of a variety of auxiliary devices and devices. Here is a small list of them:

- “Crowbar” or simply a curved crowbar;

- Electric drill;

- Nail file;

- Hairpin;

- Knitting needle;

- Bulgarian;

- Chisel;

- Hammer;

- Tweezers;

- Gas welding.

This is only an approximate list, since anyone can use those devices that are convenient and necessary for them.

Any of the listed methods and auxiliary devices require certain skills, so choose simple methods and devices that are familiar to you.

How to open a lever lock?

If this is your first time opening a lever lock, do not expect a positive result. The hacking method and the abilities of the performer play a role.

One of the options for opening a lock without a key is to use a “roll-up”. To do this, you will need a thin screwdriver with a curved end and a knitting needle with a hook at the end. The first step is to insert a screwdriver into the hole instead of a key. It is pushed in all the way and turns, creating a load on the mechanism. Next, a knitting needle is inserted and an attempt is made to displace the plates inside the lock, while simultaneously turning the “roll”.

Application of the “roll-up”

If the screwdriver turns, it means the lever has moved and you can proceed to the next plates. Carrying out such manipulations, slowly open the lock.

The second option would be drilling. Depending on the specific model of the locking mechanism and its design, the shank stand is drilled. The process continues until the door falls through. When this happens, the lock crumbles and is further opened using a curved knitting needle.

Advantages of lever mechanisms

The lever lock is highly valued for the following characteristics:

- High protection against burglary. Some models, equipped with armored linings and reinforced crossbars, are a full-fledged anti-vandal device. It can only be opened with a professional tool.

- Uninterrupted operation. If you open the lock with the “original” key, problems usually do not arise during the entire life of the mechanism. It is durable and low maintenance.

The security properties of the lock depend on the number and thickness of the levers, the material of the case, and additional protection. Models from the Italian manufacturer CISA and Russian are widely in demand.

Self-impression

Today, a new method has emerged that allows you to open doors with lever locks. It is called “self-impression”. To carry out the process, you only need a self-dialing key. Having a self-impression key in your arsenal, you will open the door in a couple of minutes. Although this mechanism is considered one of the most reliable and burglar-resistant, if you have this key, even a child can open such a door.

The main salvation for lever locks is the difficulty of acquiring a self-impression key. The technology for its production is complex. Skills in working with tool drawings are required, as well as high-quality factory equipment with expensive tooling. In connection with the primary reason for the difficulty of obtaining a key, a second one arises - high cost. You won’t be able to find such a tool in everyday life, but on the Internet its cost reaches $1,000.

Emergency opening services

Before you open a lever lock without a key with your own hands, you need to carefully weigh everything, since without the proper experience this can lead to irreparable consequences.

To avoid such unpleasant consequences, it is best to seek qualified help. Now there are many companies that, for a certain fee, are ready to help cope with this problem. In any case, the cost of the lock opening service will be significantly lower than the subsequent replacement of the lock or the entire door. On average, the price of work ranges from one and a half to two thousand rubles. If it is a complex mechanism, the cost of the operation can reach up to four thousand. But in any case, you get an open door without any damage.

When you contact the emergency opening service, specialists promptly arrive at the specified address and open the lock without causing any defects. To carry out the work, it is necessary to provide documentary evidence that the person applying lives at the specified address. An autopsy is carried out after presenting a document confirming residence or after interviewing neighbors. Being professionals in their own business, the company’s specialists will open a lock of any design, even one as reliable as a lever lock, without causing material damage. Therefore, it is best not to try to open the doors yourself, so as not to aggravate the situation.

The principle of operation of a key with “self-impression”

The tool is made in the form of a rod, which has a diameter smaller than that of the key that fits the lock. Movable pins are installed in the product body. They act on the lock levers. For each lock model, a different number of pins is selected, equal to the code elements. The pins in the key body do not dangle, but begin to move solely under the influence of the load on them. On the opposite side of the pins there is a handle, thanks to which you can use the key.

Movable pins in the housing

Self-impression consists in adjusting the pins to the code elements of the lock. First, the key is inserted into the keyhole and pushes the bolt to open it. At the same time, the bolt presses on the code protrusions of the plates. Those elements of the levers that are not set according to the code will be clamped with a bolt, and their further movement will be impossible. To get around this, the key is raised and lowered several times inside the lock. The clamped plates press on the movable pins of the self-impression key, while the free ones remain in place. After such manipulations, the lock will open in a few minutes.

The resulting drawing of the key secrets

To prevent self-impression from causing your door to be opened, take additional security measures. First of all, in addition to the lever lock, install a cylinder lock. When trying to break into an apartment, a criminal will open one mechanism, and for another he will need a different set of tools to select the key.

Double lock installation

Another remedy is to install an electromechanical invisible lock. No one has yet been able to open such a unit. The only thing that makes installing this element difficult is its cost, but is it really worth saving on safety?

Voted over 291 times, average rating 4.2

Comments

Unfortunately, there are no comments or reviews yet, but you can leave your...

Add a comment Cancel reply

We recommend reading

Locks, Fittings What types of latches and locks are used for sliding doors, and how do they work? The convenience of sliding doors is ensured by a special principle...

Locks, Accessories What should you pay attention to when choosing a lock for your bathroom door? The bathroom is a special place in the home where comfort and coziness are important. IN …

Locks, Accessories We install an electromechanical lock on a plastic door with our own hands When installing a door in any room, the owner assumes...

Locks, Accessories How to lubricate a door lock Any lock requires maintenance, then it will serve you longer without...

Master key

The pick key for round locks is recommended for opening tubular locks and is a specialized tool used to open locks without a key. The master key we advertise is perfect for easily opening iron doors to Novomatic or Igrosoft slot machines, as well as to payment acceptance devices, etc., where tubular locks are installed.

In principle, our key can open any round locks, both on doors and inside devices and terminals. You can open the lock without a master key, for example, using force methods of opening the lock. But this is not required if you have our master key.

A master key or, more correctly, a universal key for machines and terminals is used to unlock round, tubular, locks with 7 or 8 pressure needles. Precisely unlocking, not picking the lock.

The technological principle of operation of the master key is not so complicated and consists in the following: to determine the code combination, the clamping rods at the master key, due to the controlled stroke force, are installed as accurately as possible in such a code position so that they can later be fixed and easily turned in the lock.

The voltage for different types of locks can vary greatly, but this can be easily adjusted by tightening or loosening the movement of the clamping rods with special nuts at the end of the master key.

Master key for round locks is recommended for opening tubular locks

Attention! The master key does not use any method for breaking when opening, but does it easily and freely, leaving no noticeable signs of unlocking or scratches on the lock, as if opened with a native key.

How to use a master key to open tubular locks

We stick the master key into the experimental lock so that the empty space (where the rod is missing) coincides with the outer groove in the lock. In short, the master key should easily fit into the lock like a natural key. After this, we press on the master key and turn it a little on the sides, for example: several pressures inside the lock and a couple of turns in different directions; if the lock does not budge, we repeat several more times of pressures and turns.

If the lock still cannot be opened, we return the rods at the master key to their original position; to do this, you need to press a special button on the handle and move the rods all the way down. After this, we repeat the unlocking operation from the very beginning.

The proposed master key captures much less evidence during opening, even than the original key. And it takes more than enough time. There is no need to use any special tools or high burglar skills.

Tool for drilling the cylinder

Before work, it is better to prepare everything in advance so that during the process you do not have to interrupt and look for missing equipment. The main tool is an electric drill with a sufficient level of power and adjustable rotation speed. It is better to take a tool that operates from the mains, so that the battery does not unexpectedly run out during operation.

A thin metal drill is selected for the drill, slightly thicker than the bore hole, usually 3-5 mm is enough. For convenience, it is also recommended to take a center punch, with which you can mark the entry point of the drill; in this case, the drill will not jump off the relief surface of the core and will not damage the lock body or the surface of the door leaf. Instead of a punch, you can use a thin awl.

In some cases, 6 and 19 mm drills are selected for greater effect. The first drill is used for additional boring of the hole in order to accurately drill all the pins and pick up the lock. A thick drill corresponds to the diameter of the entire cylinder and is used if it is impossible to pick up the stopper through a small recess. But you need to understand that after such a hack it will not be possible to replace only the core, since the entire lock is damaged, so you will have to buy a new one.

To open a broken lock, you will also need a thin flat-head screwdriver, which will tighten the stopper, hook, or bent wire to latch the lock.

What you will need

- Tensioner pick (tensioner): Many items can serve as tensioner for you. They should be strong and not break when the cylinder is pulled, and be thin enough to fit slightly into the keyhole. The end of the tensioner should not be too thin and fall into the keyhole all the way to the end. It should also be small in size to allow enough room for the second pick to maneuver freely when both tools are inside. You can use a small hex wrench that tapers at the end or a flathead screwdriver.

- Hook Pick: You can use a pin or paperclip. To make a master key from a paper clip, straighten it and bend one of the ends 90 degrees. You can also bend one end into a small loop. Needle nose pliers will make the process much easier. Choose items made of strong metal for picks, otherwise they will bend when pressure is applied to the pins. Picks made from a hacksaw blade work best. Hair bobby pins are also a good material for a pick. Cut off the rounded ends of the bobby pin and make a right angle out of it, and then bend one of the edges 90 degrees.

How to drill

A drill of the smallest thickness is installed at the entry point indicated by the center punch, after which the drill is turned on. The first millimeters are passed at minimum speed without excessive pressure on the drill, then you can add speed. A minimum of effort and speed will allow the drill to move slightly into the metal without breaking. During the entire drilling process, it is not recommended to rush and work at maximum speed, as this can lead to breakage of the drill, after which you will have to look for a new one, which takes a lot of time.

The drill is installed perpendicular to the borehole, gradually tilting at an angle, which makes it possible to quickly get to the pins and damage them. Experts recommend soaking the drill in mineral oil every couple of minutes to make work easier.

If you notice that the cylinder has become harder to drill, and the drill itself is biting or sticking, reduce the speed, reverse and remove the drill from the recess. It would be a good idea to blow out any metal shavings that would interfere with the interior view.

As soon as you feel that you have reached the last pin, change the drill to a thicker one. This will allow you to drill out the lock cylinder until the pins are completely destroyed. How to do this using the front door as an example is shown in the video below.

How can you close the door if there is no key?

It all depends on the type of lock. There are no problems with systems that slam shut. With others, the task of closing the door is more difficult. But nothing is impossible.

If the lock has a handle that moves down or up, then any metal pipe will be needed. You can use a mop pipe. Tape the pipe to the handle so that it points toward the floor. Then the door simply closes - and that’s it, it can no longer be opened. The pipe will simply hit the floor when you try to press the handle. This is one of the possible options for how you can close the front door without a key.

To make the choice conscious

The fundamental principle of our work is to inform consumers as much as possible so that they make an informed choice. When ordering a lock for entrance doors, it is useful to consider various points:

- Purpose of the premises (house, store, office, bank).

- Requirements for the level of protection. For example, there is no particular need to install a 4th security class lock on interior doors in a secure office. But giving it preference when choosing a lock for an apartment door in a building where asocial neighbors live is a completely justified step.

- Entrance door design.

- Number of locks.

To better understand the cost of Guardian products, you can contact official regional dealers. You can also get more detailed advice from them on different types of locks and their distinctive features.

Why might it not be possible to drill out the door lock cylinder?

To improve the protective properties of their locks and prevent mechanical opening, many manufacturers install special hardened pins that cannot be drilled with conventional metal drills. To drill such cylinders, it is necessary to purchase drills with carbide tips and special sharpening. As a rule, purchasing these drills does not make sense because of their high cost and fragility of the cutting part. You can break several expensive drills and end up not achieving your goal.

If you were unable to drill out the cylinder on your own or are not sure that it will work, you can contact our lock picking service for help by calling +7 (499) 130-83-20. Qualified technicians are always ready to come to your aid and will open the door or replace the lock cylinder quickly and inexpensively. Call! Your masterpozamkam.ru

Preliminary preparation

Before drilling out the cylinder, you need to know exactly what category the lock belongs to, that is, its burglary resistance class and type. In addition, it will not be superfluous to know whether the mechanism is equipped with protective armored linings on the outside or inside of the door, in which part the secret pins are located and their number.

The burglary resistance class is specified in the product passport; locks of classes 3 and 4 are considered the most reliable; accordingly, breaking such a mechanism is much more difficult.

By type, locks are divided into cross-shaped cylinder, pin cylinder, overhead lever and armored. The most common is a cylinder lock, the cylinder of which can be drilled out and then replaced with a new similar one. But it is worth considering the quality of the material and the equipment of the cylinder lock. For example, the cheaper the mechanism, the easier it is to saw out. More expensive analogues are equipped during assembly with hard inclusions inside the well, on which drills break off. The hardened steel of the locking mechanism, its core and the pins inside are also not amenable to drilling, even with a high-quality drill for hard metals.

Of course, in a budget product you can drill out the cylinder yourself and replace it with a similar one with a new set of keys, which is very convenient for those who often forget or lose their keys. This will not work with a high-quality, expensive lock; you will have to call a specialist with master keys, wasting your time and money. But do not forget that such a device will more reliably protect personal space and property in the apartment.

Taking care of consumer safety

Guardian doors provide effective security measures for lever locks. In particular:

- To provide resistance when trying to rip open the door leaf and exert force, the lock pocket has a structure of square profile rods made of steel.

- In the lock area, the door leaf reaches a metal thickness of up to 6 mm. This is typical for all door blocks with the exception of DS 1, DS 6, DS 10 and Factor.

- The bolts of the bolts and locks are protected in the door leaf and frame from ripping open and mechanical influence. To do this, special steel plates are installed (welded) in the areas where they are located (DS 2 with armored package, DS 3U, DS 4, DS 8U, DS 9 with armored package).

- To protect lever locks for metal doors from breaking by vandalism, armor plates are used. They are made from steel containing manganese grade 65G, 2 mm thick. Such plates are installed on the main lock. Their hard structure and specific surface irregularities make it difficult to drill out key walls.

- To counteract attempts to knock out the lock through the key hole, the armor plate provides optimal dimensions for the hole.

Replacing the lock cylinder and checking its functionality

After purchasing a new door core, you need to install it immediately. It is advisable to lubricate the inside of the lock where the cylinder will be inserted. The installation process is the reverse of removal.

The peculiarity of this work is the correct installation of the cylinder in the door and the installation of the mounting bolt in the desired hole.

When replacing the lock cylinder, you need to be extremely careful

You also need to be extremely careful so that the larva does not fall inside the door; it is unlikely that you will be able to get it out.

To do this, you can move the cylinder a little so that the bolt takes its place. The key is in the “Closed” position.

After replacing the core, you must check the lock for functionality. To do this, gently turn the key in the lock of the slightly open door; it should turn freely and not slow down. The lock should not creak or click. Only after this can you close the door and turn the key again. The locking mechanism should close smoothly.

Preliminary preparation

Before drilling out the cylinder, you need to know exactly what category the lock belongs to, that is, its burglary resistance class and type. In addition, it will not be superfluous to know whether the mechanism is equipped with protective armored linings on the outside or inside of the door, in which part the secret pins are located and their number.

The burglary resistance class is specified in the product passport; locks of classes 3 and 4 are considered the most reliable; accordingly, breaking such a mechanism is much more difficult.

By type, locks are divided into cross-shaped cylinder, pin cylinder, overhead lever and armored. The most common is a cylinder lock, the cylinder of which can be drilled out and then replaced with a new similar one. But it is worth considering the quality of the material and the equipment of the cylinder lock. For example, the cheaper the mechanism, the easier it is to saw out. More expensive analogues are equipped during assembly with hard inclusions inside the well, on which drills break off. The hardened steel of the locking mechanism, its core and the pins inside are also not amenable to drilling, even with a high-quality drill for hard metals.

Of course, in a budget product you can drill out the cylinder yourself and replace it with a similar one with a new set of keys, which is very convenient for those who often forget or lose their keys. This will not work with a high-quality, expensive lock; you will have to call a specialist with master keys, wasting your time and money. But do not forget that such a device will more reliably protect personal space and property in the apartment.

Inspect the locking mechanism

Determine what?

- Presence/absence of armor plate.

- The degree of protection of the larva, including from unauthorized removal. Many models of cylinder locks provide for this, and therefore special inclusions made of hard alloys are placed in the borehole. When you try to open the door in this way, the drill quickly breaks.

Based on visual diagnostics, you can understand:

- how to drill out the lock cylinder correctly and what needs to be prepared;

- is it worth doing? This statement may seem strange to some, and therefore something needs to be clarified. To remove the core in some models of locks installed in doors, it is not necessary to drill it; the larva can simply be knocked out with a hammer and a fairly strong screwdriver (or a piece of metal rod). And this will take much less time, and the technology itself is so primitive that even a teenager can handle this work.

Prepare everything you need

- electric/drill. It is desirable that it has a speed control function, and that the tool runs on mains power rather than battery power. In the absence of one, a screwdriver will also help;

- extension cord (carrying);

- drill. There is a rule - its diameter should slightly exceed the width of the slot into which the key is inserted (for most cylinder lock cylinders it should be 3 mm); quite enough for accurate drilling. But this is the main working tool. For primary drilling, smaller analogues will be needed. For example, at 0.5 and 1.2.

- punch, hammer, screwdriver with a narrow blade;

- machine oil.

Tool for drilling the cylinder

Before work, it is better to prepare everything in advance so that during the process you do not have to interrupt and look for missing equipment. The main tool is an electric drill with a sufficient level of power and adjustable rotation speed. It is better to take a tool that operates from the mains, so that the battery does not unexpectedly run out during operation.

A thin metal drill is selected for the drill, slightly thicker than the bore hole, usually 3-5 mm is enough. For convenience, it is also recommended to take a center punch, with which you can mark the entry point of the drill; in this case, the drill will not jump off the relief surface of the core and will not damage the lock body or the surface of the door leaf. Instead of a punch, you can use a thin awl.

In some cases, 6 and 19 mm drills are selected for greater effect. The first drill is used for additional boring of the hole in order to accurately drill all the pins and pick up the lock. A thick drill corresponds to the diameter of the entire cylinder and is used if it is impossible to pick up the stopper through a small recess. But you need to understand that after such a hack it will not be possible to replace only the core, since the entire lock is damaged, so you will have to buy a new one.

To open a broken lock, you will also need a thin flat-head screwdriver, which will tighten the stopper, hook, or bent wire to latch the lock.

Definition of the "working" point

Everything is clear about how to drill out the larva - with an electric drill. But where exactly to install the drill is an important question. Regardless of the modification of the cylinder lock (pin, plate, disk), the “channel” must pass near the installation of the security elements. Then the larva will come out quite easily.

There is one more rule for this - the optimal drilling point is ¼ of the length of the slot above its lower edge. That is, the well is conventionally divided in half, twice; there will be no error.

Preparation of the work area

Before you start directly drilling the lock, you must prevent the possibility of the tip of the tool sliding on the metal. Therefore, the “entry point” is marked with a center punch, otherwise there is a high probability of damage to the cladding, insulation and door leaf material.

How to drill

A drill of the smallest thickness is installed at the entry point indicated by the center punch, after which the drill is turned on. The first millimeters are passed at minimum speed without excessive pressure on the drill, then you can add speed. A minimum of effort and speed will allow the drill to move slightly into the metal without breaking. During the entire drilling process, it is not recommended to rush and work at maximum speed, as this can lead to breakage of the drill, after which you will have to look for a new one, which takes a lot of time.

The drill is installed perpendicular to the borehole, gradually tilting at an angle, which makes it possible to quickly get to the pins and damage them. Experts recommend soaking the drill in mineral oil every couple of minutes to make work easier.

If you notice that the cylinder has become harder to drill, and the drill itself is biting or sticking, reduce the speed, reverse and remove the drill from the recess. It would be a good idea to blow out any metal shavings that would interfere with the interior view.

As soon as you feel that you have reached the last pin, change the drill to a thicker one. This will allow you to drill out the lock cylinder until the pins are completely destroyed. How to do this using the front door as an example is shown in the video below.

Lock-type drilling technology

It is recommended to install a lock with a cross-shaped cylinder in interior doors and doors leading to offices, retail or utility rooms, in other words, in those rooms that are additionally protected by more durable doors or alarms. To open such a lock, you will need to drill a hole just above the keyhole to the pins, and then tighten the lock with an awl or a thin screwdriver. Simultaneously with raising the stopper, the bolt is pulled back using a hook made of thin wire, which will cause the bolt to move inward and open the door.

The cylinder with pins is drilled in a similar way, and then rotated inside using a thin tool, such as a screwdriver.

The keyhole is drilled using a 3 mm drill. To prevent the drill from breaking, it is recommended to place it strictly perpendicular to the borehole hole. If drilling does not help, you will need to make another hole above the hole, and then use a hook to move the bolt.

An overhead lever lock is drilled where the post is attached to the edge of the bolt, usually just above the center of the bore hole. After drilling the rack, the lever lock is opened with a non-original key of a similar type or its blank for a future duplicate. But you should understand that drilling will only help if the product is not equipped with additional protective devices.

Locking mechanisms made of hardened steel or armored with linings are drilled using a heavy-duty carbide-tipped drill. Finding such a drill is problematic; in addition, it is quite expensive, and you will have to work hard to drill it. Therefore, it is easier to leave this matter to a specialist, whose call will cost approximately the same amount as a heavy-duty metal drill.

Pins are destroyed, what to do next?

Take your time with the final destruction of the larva after drilling the pins. In most cases, it is enough to place a flat-head screwdriver inside the drilled recess and twist to open the lock. If the lock does not open with a screwdriver the first time, most likely the pins are not completely sawn or the core is equipped with additional protection against hacking. In this case, try drilling the hole with a slightly thicker drill and repeat the action with a screwdriver or hook.

Features of removing the cylinder on a damaged lock

It’s easy to remove the larva with your own hands:

- At the end of the lock, unscrew and completely pull out the screw holding the secret mechanism in the lock.

- The key is inserted into the hole and turned so that the pin is aligned with the body, that is, the secret is open and does not interfere with removing the cylinder; you need to turn the key 10-15%.

- By pulling the key, which cannot come out of the cylinder, it is removed along with the cylinder from the lock.

There is an armor plate on the outside of the door, so it is easier to pull out the cylinder from the inside.

Degree of security of locks of different series

If you want to buy a lock for a metal door, you should pay attention to its characteristics. Several series of locks have been developed. Let's consider several of them, corresponding to the 4th class of burglary resistance:

- The 50 Strong Security series has over 1.6 million security combinations. Powerful crossbars of wide diameter (15.8 mm) are installed. An enhanced degree of protection against typical methods is provided.

- Level locks for metal doors of the 20 series are provided with security - more than 2 billion. Large crossbars with a diameter of 18 mm are installed. The vertical drive allows you to lock the door on 3 sides.

- Using the 70 ReStart series lever locks, you will provide optimal protection against unauthorized entry. Instead of changing the front door lock, you can use the recoding option (a unique system for recoding the lock from the end is installed). The bolts are installed with a diameter of 18 mm, the security of the lever locks is more than 10 thousand combinations for each series.

These lever locks for metal doors come with a 5-year manufacturer's warranty.