As a rule, such windows are equipped with a PVC window sill. They look organic, are easy to clean and have a reasonable price.

However, recently the installation of a wooden window sill with a PVC window has been gaining popularity, which is associated not only with the newfangled trend, but also, above all, with the fact that during the heating season, it better withstands the temperature stress from the radiator. You can install it yourself, or you can use the service of a specialized organization.

Is it suitable for PVC structures?

For houses that have a radial heating system with a heating temperature of 95 C, in which heating devices are installed under a PVC window block, it is better to initially provide for the installation of wooden window sills.

They can withstand ambient temperatures above 100 C, and PVC products only 60 C. At higher temperatures, the plastic heats up and releases toxins into the room.

Wood is environmentally friendly, more durable and looks much more presentable. This tabletop integrates well into the PVC window block and can be made with a natural color or painted to match the window frame. With proper installation and operation, it can last at least 50 years.

Design ideas

Often, a window sill performs a very specific function: it allows you to save space and money by avoiding the purchase of additional furniture. In the kitchen, for example, a sink, work or dining area is placed opposite the window. Below there will be room for legs (if there is supposed to be food on it) or space for cabinets and household appliances.

In a child's room or bedroom, it is convenient to install a desktop in the window area. To do this, the window sill is made wider (not forgetting to cut out ventilation holes in it!) and additionally reinforced with brackets or legs.

The photo shows a wide countertop under the window in the kitchen

An equally common option is to install a sofa under the window. The main role here is played by the height of the window sill itself - it is advisable that it should not be higher than 50-55 cm. If you are lucky, feel free to make the panel wider, put a mattress, pillows and a blanket on it.

Requirements

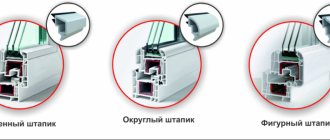

Their main types vary from wide ones, used for flowers, to narrow ones - only for window decoration. They can be with or without a launch behind the wall, rectangular or specially shaped to order.

Wooden window sills for PVC windows must meet certain requirements :

By size: narrow - up to 10 cm, wide - 100 cm, in increments of 10 mm; with a length from 0.9 to 3 m in increments of 100 mm; thickness from 30 to 50 mm.- By type of wood: coniferous species, tropical species, oak and ash above grade II and any tree resistant to biological damage.

- Resistant to temperature changes.

- Moisture resistance, with humidity levels less than 10%.

- The wood material must be uniform; there should be no chips, cracks or dents on the wood.

- Preliminary antiseptic and fire protection treatment must be carried out, as well as thermal modification of wood to increase the service life.

Pressing

The resulting mixture is fed into the press. Pressing takes place in two stages: 1-cold and 2-hot. Moreover, before hot pressing, a sandwich of decorative and protective films (up to 6 layers) is laid on the workpiece. This allows them to maintain absolute strength, color and meet hygienic requirements for a long time. Since immediately after the production of blanks, at temperatures above 160°C, the own adhesive ability of the resins of the base material and decorative material is activated. Unlike the simple gluing method, the resins adhere without a seam. Thus, the surface and the window sill material itself are fused. After hot pressing, excess films are cut off with special knives, and the window sill is sent to packaging. A distinctive feature of the technology for the production of Werzalit material from chipboard and MDF is that the formation of the board and the shaping and coating with decorative protective films occurs in one stage.

The article uses information from the website www.polymery.ru

Ten Leonid

What type of wood is best to choose?

All wooden window sills can be classified as either budget or expensive and high-quality. The first include products made from pine, chestnut and larch.

They do not stand out for their beautiful texture and durability, so they are placed in places where they will not be particularly noticeable, for example, in utility rooms and utility rooms. The second group includes beech and oak products with excellent texture, strength and durability.

Differences in types of wood used for the manufacture of window sills for PVC blocks:

- Coniferous species require careful handling during operation, since temperature changes and high humidity can lead to deformation of the structure.

- Hardwood beech and oak hornbeam are very difficult to process, but have excellent texture and strength characteristics.

- Economy option: pine, larch and chestnut, low price and low performance, can be used for rooms where high aesthetics are not required, for example in utility rooms, boiler rooms and laundry rooms.

- Elite types of wood: mahogany, mahogany and ebony, meranti, have the highest price, have excellent design and strength characteristics.

Necessary equipment for production

The production line for window sill boards includes the following equipment:

- The extruder is designed (single-screw and twin-screw) to soften a mixture of PVC and various additives by pressing through holes of a certain diameter. The extruder consists of a heated cylinder, screw, mesh, and forming head;

- a tool designed for die, dry and wet calibration, which includes a vacuum loader and a calibration table;

- a puller or, in other words, a vacuum exhaust device;

- saw for cutting manufactured products;

- device for laying finished products.

Equipment from different manufacturers differs in power, productivity (kg/hour), and possible width of the products produced. In addition, the recommended composition of raw materials is included with the extrusion line. When purchasing equipment, you must consider its dimensions . These may vary depending on the brand, but the average line length is 24m.

Installation tools

After the type of wood is selected, the size of the product is determined; as a rule, it should be 10-15 cm longer than the window opening in length, and protrude 10 cm beyond the cut of the wall. The workpiece must be pre-sanded and polished in order to have a decent appearance .

In order to install a wooden window sill already made to size under a metal-plastic window block on your own, the owner must prepare the following tools and building materials :

- measuring tools: level, square and tape measure for taking measurements;

- regular saw;

- Bulgarian;

- brush for pre-treating wood with antiseptics;

- spatula for working with cement mortar;

- polyurethane foam;

- cement and sand;

- sandpaper;

- wood antiseptic.

The main functions of the window sill.

The purpose of the window sill is as follows:

- closing the remaining mounting opening after installing the window;

- giving the opening a harmonious and finished look;

- ensure proper circulation of hot air from heating radiators;

- additional space for small items on a temporary or permanent basis.

Showing imagination and ingenuity, people make the following window sills:

- Greenhouse. If you make a large window sill that harmonizes with the furniture or decoration, you can put many flower pots with plants, turning the room into a flower garden rich in aromas.

- Desktop. This option is applicable to rooms of any size. The design can be folding and fixed to accommodate one or more windows.

- Sofa. It is used temporarily or permanently as a place where you can have a good time admiring the surrounding scenery.

- Kitchen countertop. An excellent solution for a housewife who always lacks a workplace. The panel can be used for cooking and eating.

A competent approach to the manufacture of a window sill will allow you to solve several problems at once in terms of design and optimization of its usable area.

How to install it yourself?

Before installing it, carefully prepare the workplace, clearing it of dust and dirt and leveling it. The quality of installation will depend not only on the product itself, but also on how well the base is prepared.

Features of installing a wooden window sill on a PVC window:

When taking measurements, the gaps should not be more than 4 cm, otherwise the foam will not be able to compensate for them, in this case it is better to fill with cement mortar.

To do this, a board in the form of formwork is attached to the wall, into which the solution is poured. As the latter, you can use tile adhesive or a plaster mixture.- If, to compensate, it is necessary to remove gaps up to 1 cm, place pieces of wood or drywall at intervals of up to 30 cm.

- The plane is checked with a laser level.

- To ensure the window sill is better secured, recess it into the slopes along the edges to a depth of 1 cm.

- The top line of the recess is made at the level of the bottom line of the window structure.

- You need to add another 2 cm to the dimensions of the window opening in order to recess the ends.

- For plastic frames, take into account that the plane will go under it about 1.5 cm.

- And the protrusion beyond the base plane is selected individually according to the actual dimensions of the window sill.

- In the case where a heating device is located underneath, it must not be overlapped by more than 50% of its width, so as not to create resistance to heat convection in the room.

- It is also necessary to take into account the material for the “ears” up to 3 cm on each side.

- It is recommended to round the corners of the window sill with a jigsaw to prevent children from getting hurt.

- Sand the cut corners with No. 240 sandpaper.

- They process the window sill and wait for it to dry, and only then proceed with installation.

- Foam is applied under the window to close any cracks.

- The product is placed in its place and pressed down as much as possible, for example, with eggplants filled with water.

- Near the frame itself, the product is not pressed with additional weight, since it must be pressed against the frame on its own.

- Next, it is treated with paint, varnish or stain.

If there is no additional load or its mass is insufficient, boards are laid on the product along the entire length and propped up with bars resting on the upper horizontal slope.

Repair

Like any product, a wooden window sill requires compliance with the rules of its operation, otherwise urgent repairs will be needed. During operation, it is necessary to limit the ingress of moisture onto its surface, and use only special polishes and cleaning agents when cleaning. But sometimes there is a desire to update the window sill and radically change the design of the room or be forced to carry out its renovation.

If the wooden window sill is used incorrectly, repairs may be required after some time.

Repairs may be caused by the following reasons: the appearance of cracks, dents, chips or cracked paint on the surface. In the latter case, we update only the surface of the window sill by removing the old layer of paint and applying a new one. In more serious cases, it is also possible to repair an installed wooden window sill with your own hands. To do this, after removing paint or varnish from the surface, putty is applied to the place of the chip, crack or recess. After drying, the surface is sanded with sandpaper. After removing the dust with a vacuum cleaner, you need to degrease the surface and then apply a new layer of coating. This will complete the repairs. The algorithm for how to repair wooden window sills with your own hands is quite simple. How much such repairs will cost depends on the materials used.

Now it has become fashionable to choose window sills from natural materials. Wood is perfect for this. Noble texture, absence of chemical emissions when exposed to sunlight, strength and reliability - all this distinguishes this type of product from its polymer analogues. In the absence of fashion for curtains and curtains, the window should look impeccable and the first thing that will catch your eye will be the window sill. That is why models made of oak or larch are so valued, filling the room with the aroma of natural wood or pine needles.

Difficulties and errors

The technology for installing wooden window sills is somewhat different from installing plastic ones, so many inexperienced performers often make unforgivable mistakes, which is why they have to completely dismantle them in the future.

The most common mistakes include the following :

- Incorrect wood type selected.

- The workpiece has high humidity.

- There is no horizontal surface for the base.

- No preliminary preparation of the workplace was carried out and the wood was not treated with an antiseptic.

- When installing the wedges, they went beyond the edge of the opening wall.

- When applying foam, the top surface of the countertop is dirty and not cleaned in a timely manner, which has hardened and when removed, its finish will be damaged.

How to make slopes on wooden and plastic windows

There are several ways to install parts. Let's look at two of them in detail.

For construction foam

The technology is suitable for plastic and wooden window systems. The material for filling voids and at the same time as an adhesive composition is construction foam.

Instructions for work

- The panels need to be adjusted to fit the openings. To do this, they are cut exactly to the size of the base. It is especially important to measure and trim corners carefully.

- The cut boards are put in place and secured in the corners with self-tapping screws. The panels are placed with one edge into the frame grooves. Then the free space is foamed. This is done taking into account the fact that the material will increase three times during the polymerization process.

- Leave until completely dry. If necessary, install spacers to prevent the panels from warping.

If insulation is required, special sandwich panels with insulation are chosen. But you can do it differently. A heat insulator is attached to the tree. Usually this is mineral wool. It is precisely adjusted to the size of the elements. Polyethylene is placed on top of the insulation and secured with tape. The panels are fastened to each other. The system assembled in this way is installed in the frame grooves and foamed.

Instagram neifeld_home

Instagram otvertkin.ru

On the frame

This method is used to finish uneven openings. A universal cladding method, used outside and inside the building. The frame allows for additional thermal insulation of the slope structure.

Sequence of installation on the frame

- They put up the frame. To assemble it, use a metal profile or wooden blocks. The elements are installed strictly in one plane. This is easy to control using a building level.

- The free space between the base and the batten is filled with insulation. Choose penoplex, polystyrene foam or similar materials.

- The finishing panels are fixed to the frame. This can be done in different ways: put them on liquid nails or secure them with self-tapping screws. In the latter case, the fasteners are recessed into the part. The resulting recesses are covered with decorative plugs.

- The free space between the panel and the base is foamed. The compacted area is covered with masking tape. The material is allowed to harden. This takes about 12 hours.

- Remove excess hardened foam from the open assembly seam. Cover it with a decorative corner.

If, when installing wooden slopes on wooden windows, lining was chosen as finishing, it is fixed to the frame. All work is carried out similarly to the second method. The only difference is in the method of fixing the elements. They are attached to clamps (these are special fasteners for lining) or, in their absence, to self-tapping screws.

Treatment

Upon completion of the sanding stage, the countertop must be treated with various compounds.

First of all, an antiseptic to protect against mold and mildew. adjacent to the battery, which is poorly ventilated, and in the event of moisture formation, becomes an ideal place for fungi, should be subject to such treatment

The processing technology is chosen by the owner; the wood under the window can be treated with wax or mastic and an external varnish coating. These compounds preserve the natural grain of the wood and at the same time further increase its service life because they protect the wood from moisture.

The need to finish slopes from the outside

So, for everyone it seems that finishing window slopes is, first of all, decorating the facade of the house. Of course, not without this, but there are other overriding goals. One of them is the gap between the walls of the house and the outer planes of the window frames. This gap is a mandatory attribute that compensates for shrinkage of the house or its other movements.

If you don't leave it, the window will warp over time, the glass will squeeze out, which means it will have to be replaced. Nobody needs unexpected expenses. Moreover, windows are not cheap.

But what is a gap? This is a cold bridge through which cold air will penetrate into the rooms of a private house in winter. To avoid this, the opening between the window frame and the walls of the house is filled with thermal insulation material. And although today the market is filled with modern insulation materials, it is still necessary to create protection from natural precipitation, which reduces the service life of any building material.

The gap between the window frame and the wall of the house is filled with polyurethane foam Source homemasters.ru

And this primarily concerns insulation materials with their porous structure. Moisture quickly penetrates inside, reducing their thermal insulation characteristics. That is, over time, the thermal insulation layer becomes unusable and has to be replaced with a new one. Even foamed polyurethane in the form of polyurethane foam, which today is used more often than other insulation materials in the process of thermal insulation of installed windows, does not withstand sunlight. Under their influence, it darkens, crumbles and peels off.

All this requires the creation of a special barrier that would become a barrier to these natural loads. That is, a building material that is more resistant to these loads should be used. In this case, the material used will in any case have thermal insulation properties. That is, the resistance of the joint between the frame and the walls to low temperatures increases.

But man is always drawn to beauty. Therefore, the finishing of window slopes gives an attractive appearance. It turns out that with one finishing operation two of the most important problems are solved at once: increasing the decorativeness of the facade of a wooden house and protecting the insulation from the negative effects of natural loads.

The window must be aesthetically pleasing Source kak-peresadit.ru

Pros and cons of use

The aesthetics and beauty of all kinds of wooden forms and the variety of fiber patterns are not in doubt. Therefore, a wooden window sill has many advantages :

- Environmental Safety.

- Versatility to take any shape.

- Natural color scheme.

- Excellent thermal insulation.

- Long service life up to 50 years, with proper operation.

- High strength, especially for oak.

Some of the disadvantages of wooden products for PVC windows include the need to treat them with antiseptics, high fire hazard and moisture absorption, as well as the requirement for constant replacement of the outer covering.

Content

- 1 Technology for the production of plastic window sills 1.1 Line for the production of plastic window sills

- 1.2 Quality of extruded PVC window sill

- 1.3 Lamination of PVC window sills

- 2.1 Fresh wood and nothing else

Prices for services

If the owner of an apartment or house decides to install wooden window sills under metal-plastic windows with the involvement of a construction company, he will need to plan the costs of both purchasing the product and paying for the work.

The cost of a window sill depends on the type of wood, its thickness, level of processing and size, and the cost of installation work will depend on the volume, the degree of readiness of the window structure for installing the countertop and its cost, all calculations are carried out per 1.m.p.

Average prices for wooden window sills and installation with a standard size LxWxD = 2200x400x40 mm, 3 layers of coating and with a 6-year guarantee:

- Beech, material - 6450 rubles, installation - 5500 rubles, total - 11950 rubles.

- Oak, 7975 rubles, 5500 rubles, total - 13475 rubles.

- Ash, 8250 rubles, 5500 rubles, total - 13750 rubles.

- Pine, 4250 rubles, 5500 rubles, total - 9750 rubles.

By trusting professionals, you get the best

If you want to buy a wooden window sill inexpensively in Moscow, please contact us by phone. Many years of experience, professionalism of employees, well-established relationships with reliable suppliers, the lowest prices in the region are the key advantages of the TBM Market company.

We work in the interests of the consumer. We provide competent free consultations regarding issues of purchase, delivery and technical characteristics of the product, convenient payment methods. We listen carefully to the requests and wishes of our clients. We consider their feedback and trust to be strong evidence of our competence, responsibility and integrity.