Axton foam cleaner, 0.5 l. Photo by Leroy Merlin

One of the positive characteristics of polyurethane foam is its excellent adhesion to many building materials . But when polyurethane sealant gets on surrounding objects, floor coverings, clothes and hands, this advantage turns into a disadvantage. Since getting rid of contaminants will not be easy. There is a wide range of products for removing fresh and dried stains, but cleaners are most effective.

Composition and characteristics of the remover

In accordance with GOST, the cleaner is a colorless transparent mixture of organic solvents and propellant gas . Used to remove remnants of polyurethane foam, to wash and clean the gun, to wash polyurethane sealant from clothing and skin surfaces. Production is carried out in accordance with the rules of GOST , which prescribes the safety of use and the possibility of use without any special protective equipment for the respiratory tract. In addition, the standard specifies the degree of flammability and explosion hazard during prolonged heating.

Therefore, when purchasing a purifier, it is necessary to check the availability of a certificate of conformity. The packaging must contain the following designation - “ ROSS VE.AD83.H04410 ”. If it is, then the product passes all the necessary tests.

Manufacturers produce a significant range of products designed to remove foam from various surfaces. Despite the variety of options, the components present in the products are largely similar. The main elements are:

- the basis is acetone or another element that is safer in characteristics and ensures the removal of hardened foam;

- various industrial solvents;

- compressed gas , which facilitates the release of the cleaner from the aerosol can;

- Special polymer additives may be present .

Work on removing polyurethane sealants from various surfaces should be carried out taking into account the characteristics of the cleaner. It is recommended to know them before starting to work with foam:

- due to the components present in the composition, cleaners are easily flammable , which requires applying the product away from open sources of fire;

- options for cleaners for removing fresh foam than for hardened polyurethane, since the second type of pollution is more difficult to remove;

- The safety of the products has been confirmed by tests, but if they come into contact with the skin, allergic reactions may occur;

- the use of personal protective equipment is not necessary, but experts recommend the use of goggles, a respirator and gloves;

- Before performing work, it is recommended to study in detail the instructions , which provide information on application and storage conditions.

Basic rules of care

If the tool is used for work frequently, then to extend its service life it is recommended to follow a few simple rules.

- Store the gun with a screwed-on container that still contains foam that has not expired.

- If the polyurethane foam runs out, remove the packaging and be sure to rinse the device. As long as the solution is fresh, this is quite easy to do.

- If you replace the cylinder with a product from another manufacturer, it is recommended to rinse the device. Different companies produce sealants that differ in composition. The mixture resulting from mixing them is sometimes impossible to remove.

By following these simple recommendations, you will not only preserve your working tool, but also save your time. It will take much more time to clean a gun from dried polyurethane foam than to free it from fresh solution.

A short video that clearly shows all the cleaning methods:

Pros and cons of foam removers

The cleaners contain a significant amount of chemical components that soften the polyurethane sealant and, as a result, allow it to be easily removed from various surfaces without harming them. There are options on sale for working with various surfaces ; separate cleaners are suitable for removing polyurethane from hands.

Regardless of the type of product, its use does not cause difficulties for performers of various skill levels in the field of construction. The cleaner promotes a targeted effect on contamination, this is especially true for aerosol products. The main advantage of cleaners in comparison with other products is their high efficiency .

Foam cleaner Penosil 0.34 l. Photo by Leroy Merlin

The main drawback is the aggressiveness of the components present in the composition. As a result, it is necessary to observe safety precautions and follow the instructions provided by the manufacturer. Failure to follow the recommendations and rules can lead to health problems. Choosing a cleaner is also not an easy procedure ; you need to take into account the surface of the base you are working with and the condition of the foam. In addition, it is recommended to test the product on the surface without fail, so as not to aggravate its condition. A significant part of the options have a pungent and unpleasant odor.

Types: liquids for removing old foam and more

Today there are several types of special cleaners. Special foam removers are primarily divided into:

Foam cleaner MASTERTEX PREMIUM 500 ml. for removing fresh and hardened foam. Photo by Maxidom

Substances designed to remove fresh (liquid) foam has just been applied and has not yet hardened. Non-concentrated formulations allow you to remove fresh foam from work surfaces, tools, and clothing. These products are also suitable for washing construction guns . After completing the work, it is necessary to unscrew the container with polyurethane foam and release the remaining polyurethane sealant by pressing the trigger. After this, screw a bottle of cleaner onto the gun, pull the trigger and release it as soon as the nozzle flushes, perform the operation several times.

Substances intended to remove dried contaminants . Concentrated compounds with a significant proportion of acetone in the composition soften hardened polyurethane, which makes it possible to subsequently remove it mechanically.

The action of the cleaner is based on the dissolution of foam , which, after applying the product to it, begins to dissolve, decrease in size, collapse, and disappear. However, some stains may remain. When working with frozen contaminants, preliminary mechanical treatment may be required . Using a knife or blade, you need to cut off the top part of the dried polyurethane mass. It is necessary to try to remove as much foam as possible . Anything that cannot be removed mechanically should be softened with a cleaner.

In addition, there is a classification according to the form of release :

1) In aerosol cans of various capacities , containers of 500 ml are most often found. Cleaners in spray form are a colorless substance that is uniform, free from impurities and lumps. The cylinders are equipped with a spray nozzle , for installation of which it is necessary to remove the protective cap. In addition, aerosol cans are suitable for installing a mounting gun. The use of cylinders is characterized by convenience, simplicity, and efficiency . Cylinder cleaners provide quick and effective cleaning of the internal and external elements of guns, container valves, work surfaces and clothing. Easy to apply to hard to reach places .

2) Liquids , for application of which a clean cloth is required. A cloth must be moistened in the product, treated, and soaked in the stain; you can place cotton pads soaked in the product on both sides of the stain. You need to wait a while, most often a few minutes, until the foam softens. After the foam becomes soft, it must be removed from the surface using a sponge or brush.

3) Wipes soaked in a cleaning solution are often classified as a separate category. Wipes are suitable for removing minor stains. Mechanically strong and dust-free wipes are supplied in convenient packaging that protects products from premature drying.

4) They are extremely rare, but they are still available on sale in the form of a paste with a gel-like consistency.

What do you need to remember about the rules for working with foam?

When starting to perform certain operations with polyurethane foam, you should know certain nuances that will help you avoid foam getting on surrounding objects or allow you to remove it without problems.

- The work area - floors, furniture and other objects should be protected with film or newspapers.

- Hands should be protected from foam getting on the skin with gloves.

- If you are performing a large-scale task, it is recommended to wear clothes that you don’t mind ruining. Well, or at least use a plastic apron, which you can then throw away without regret.

- Hair should also be protected with some kind of headdress, maybe even an improvised one - a scarf, Panama hat, bandana, etc.

- It is advisable to always have a polyurethane foam remover on hand. The faster you can use it, the better and more “painless” the cleaning of skin, clothing, and other surfaces will be. If the foam has time to set or be absorbed, then it will be much more difficult to clean it.

- If foam gets on any surface, you must try to remove it so that it does not smear. This can be done, for example, carefully with a narrow spatula. Then the remaining dirt must be immediately filled in or wiped with the selected cleaner. It is difficult, and sometimes even impossible, to remove foam that has been spread in a thin layer and has penetrated into the structure of another material.

- If the foam hits a surface that does not absorb moisture and other substances in one compact drop, then it would be better to wait for it to dry completely. Once the polyurethane foam expands, it can be easily cut or simply torn from concrete, polished surfaces, and even from some fabrics. However, this method is not suitable for laminate and linoleum, since the foam adheres to these materials very well and can damage the protective layer of the coating when it is torn off. Therefore, it is better to remove it immediately after contact.

- Do not try to wash your hands, tools or any surfaces contaminated by polyurethane foam in the usual way. The foam hardens quickly when exposed to water, and it will then be even more difficult to clean it off.

So, it is best to prevent foam from getting in at all. But, alas, it doesn’t always work out that way. Therefore, it is necessary to use compounds designed to remove foam and use proven methods for cleaning various surfaces from such contaminants.

Manufacturers of fresh and frozen mixture: KUDO and others

To get what you need, i.e. To achieve a high-quality result, you need to choose the right cleaner. The variety of options often complicates the choice; it is difficult for an unprepared performer to understand. Therefore, you should provide information about manufacturers (brands) of quality products:

Polyurethane foam cleaner Tytan Prof Eco 0.5 l. Photo by Leroy Merlin

The Polish brand Tytan offers a professional eco-cleaner for removing uncured foam and glue, designed for cleaning cylinder valves and guns, does not leave marks on PVC and other plastics, comes in a 500 ml aerosol can.

The Belgian ]Soudal[/anchor] offers a cleaner in an aerosol can (500 ml.), which is designed to remove uncured foam, for cleaning guns and canister nozzles, as well as a paste product for removing hardened polyurethane, supplied in a plastic container (100 ml .) complete with brush and plastic spatula.

The Finnish brand Makroflex produces a cleaning liquid for removing uncured foam, characterized by economical consumption and fast action. It is possible to find Soudal cleaning wipes in the assortment of individual supplying companies.

TECHNONICOL (Russia) offers a cleaner from the PROFESSIONAL series for removing uncured foam; the intended materials are metal, wood, and plastic.

Penosil (Estonia) provides a choice of a product for removing fresh foam from work surfaces, tools, clothing, cleaning guns, valves, and a product for removing hardened foam from working tools and various surfaces: PVC, wood, metal.

The Russian brand KUDO offers several product options: professional and household cleaners labeled “FOAM&GUN CLEANER” in 650 ml containers. to remove uncured one-component foam, work with plastic and painted surfaces must be done carefully, it is recommended to do a test; Cleaner labeled “DONEWELL” is a new product for removing fresh polyurethane stains.

Soudal foam cleaner 0.1 l. Photo by Leroy Merlin

In addition, cleaners are offered under other brands:

- Axton , for removing fresh polyurethane from the surfaces of a gun, hands and other objects, based on acetone;

- Kraftool , removes uncured foam from guns, clothing and other surfaces, does not contain freon;

- IRFIX , a universal solution for removing uncured foam and polyurethane adhesive, does not react with PVC and other plastics;

- Masterteks , for removing fresh and hardened foam from the outer surfaces of the gun, valves and caps;

- STAYER , a composition for removing fresh foam from a gun, leather and other surfaces, does not scratch the base, suitable for professional use;

- JETFIX , cleaner in a 450 ml aerosol can. to remove residues of uncured foam and polyurethane adhesive;

- OPPA , for removing uncured foam from tools, clothing and work surfaces.

This is not a complete list of brands; other offers can be found on the suppliers’ websites.

Foaming agent for the production of foam concrete

The production technology of this building material does not cause any particular difficulties. This is one of the significant advantages of foam concrete over many analogues - you can prepare the blocks yourself. Consequently, the developer is spared the need to transport them to the site (which is often associated with the destruction of samples), which means it becomes possible to somewhat reduce the final cost of construction of any structure. The main thing is to choose the right foaming agent. What is it, what is its composition, can you prepare it yourself or will you have to buy it? The answers to all the reader’s questions regarding the nuances of foam concrete production are in this article.

The starting raw material is the so-called cement paste, which is a solution of a certain consistency. The mixture for foam concrete consists of cement and sand, to which the required amount of water is added while mixing. But the solution itself does not form a porous structure. To obtain clogged cells, a foaming agent is introduced into it. This mass is loaded into molds and kept in them until the cement hardens completely. The resulting stone is called foam concrete. All technological operations are performed by hand, which allows us to significantly reduce the cost of the material.

Types of foaming agents for the production of foam concrete blocks

Such special additives are sold in various packaging - cans, cans, barrels. They are homogeneous in composition, but differ in the components that are used to obtain the foaming agent. In addition, the product is supplied to the market in the form of a finished construction liquid or concentrate. All that remains is to load the required amount of substance into the foam generator. To make the right choice, you should know what characterizes each type of product.

1. Protein foaming agents.

Such additives are considered more advanced. Using a foam generator, a composition is obtained that fully complies with the requirements of GOST No. 25485 of 1989. What do protein or protein foaming agents provide?

Such foaming agents are considered the best option for producing cellular concrete intended for the construction of residential buildings. The only negative is that it is difficult to find products from domestic manufacturers on the market. And the cost of imported ones “bites”. In addition, you will need a foam generator for foam concrete, and hardly anyone will buy it for a one-time job.

These are the main reasons why developers in the private sector prefer to prepare such additives with their own hands. Although the problem with the foam generator is solvable. The installation can either be purchased (for large-scale construction) or rented (for one-time work).

The only plus is the lower price compared to natural formulations. Such additives are used mainly for the production of low grade foam concrete.

- The stone's readiness time increases.

- High strength of foam concrete cannot be achieved. Otherwise, its independent production with such an additive is unprofitable. You will need not only a foam generator, but also a pressure unit.

- The choice of plasticizers is difficult, since synthetics react with some of them.

How to obtain a foaming agent for foam concrete

What to consider when purchasing a supplement has already been noted. A much more interesting question is how to make a foaming agent yourself, at home. Let's consider the main stages.

*All proportional ratios are based on g/m3 of foam concrete.

The most common recipe for a natural supplement

- Wood glue – 65.

- Soda (caustic) – 16.

- Rosin (pine) – 60.

1. Making “soap” for the foaming agent. Separately prepare a soda solution (approximate density - 1.2 kg/dm3) and rosin crumble. The pieces are crushed and sifted through a fine strainer. The soda solution is placed on the fire, and after boiling, ground rosin is poured into it. Approximate calculation – 1.5 kg/l. The resulting mixture is constantly stirred and kept under boiling conditions for about 90 - 120 minutes, after which it is removed from the heat.

2. Preparing the glue. After grinding, it must be soaked for a day (1 kg per bucket of water). After this, the dishes are placed on the fire, heated to 60 - 70 °C and mixed well until the solids are completely dissolved.

3. Preparation of the foaming agent mixture. Cooled “soap” is introduced into the resulting adhesive mass. Component ratio: for 6 hours of glue – 1 hour of soap solution.

With this method of producing the additive, you can do without a foam generator.

Price of equipment and materials

The range of foam concentrates offered on the market is huge. It seems that almost all companies at least somehow connected with the construction industry are engaged in its production. But if you analyze the price tags, it turns out that the average cost per unit of goods lies within small limits.

For the foaming agent itself you will have to pay approximately 89 - 156 rubles / kg (or 57 - 72 rubles / l). But cellular concrete is not used in its “pure” form. Depending on the specifics of construction, the stone is given (enhanced) certain properties. This means that you will need special additives (plasticizers) for foam concrete. The price of such compositions starts from 66 rubles/kg. If you want to get colored foam concrete blocks, you will have to buy pigments (on average - 96 rubles / kg).

If it is not possible to make a foam generator for foam concrete yourself, then you will have to spend money on it. The approximate price of the simplest installation is 17,890 rubles. Not to be confused with cheaper foam generators! Such units are not used in construction. As a rule, all such models are used for foaming compositions intended for cleaning premises.

Such preparation significantly improves the quality of cleaning contaminated surfaces, but such installations are not suitable for the production of a foaming agent in the production of cellular concrete.

- Significant reduction in the preparation time of artificial stone.

- The mass of foam concrete loaded into the mold becomes more stable.

- The absence of “chemistry” in the composition of the foaming agent (only natural components) does not affect the environmental “purity” of the stone.

- Possibility of producing blocks with increased density.

Characteristics

To form a building material that meets GOST, a chemical substance must have the following features:

The material must be environmentally friendly.

- homogeneity;

- possibility of interaction with substances that accelerate hardening and plasticizers;

- possibility of precise dosing;

- environmental friendliness;

- efficiency;

- long shelf life;

- foam consistency;

- ease of conversion;

- durability of foam in cement mixture.

To form a building material that meets GOST, a chemical substance must have the following features:

Characteristics

Concrete foaming agent can be organic or synthetic. Synthetics, compared to natural products, have a lower price and are used for the production of low-quality products.

When using chemistry, the block production time increases. The strength of foam concrete will be lower. An attempt to improve quality will lead to an increase in production costs and a decrease in its profitability.

Retail chains in Moscow and other big cities offer a wide selection of domestic and imported synthetic materials. For remote areas, purchases can be made through online stores.

The price per kg of foam former varies from 70 rubles. and higher. You can use synthetics both in schemes based on barotechnology and in classic versions with a foam generator:

- Barotechnology is a less expensive and simple process. The basic components of artificial stone - water, cement, sand or ash - are introduced into a sealed mixer along with a foaming agent. The pressure in the mixing container is then increased, at which the composition is mixed. During the stirring process, the solution becomes saturated with air. To accelerate and regulate structure formation, it is possible to use functional additives.

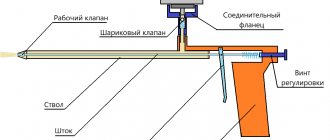

- A foam generator is needed to produce foam separately. It is a container into which the foam former is poured. The composition from it is fed into the mixing chamber, where it is combined with air from a pump or compressor. The emulsion flows through a jet or Laval nozzle into a foam cartridge designed to foam the starting material. The output is foam, the quality of which changes due to the adjustment of the valves for supplying the foaming emulsion and air. They are placed in front of the mixing chamber together with shut-off valves.

- Barotechnology is a less expensive and simple process. The basic components of artificial stone - water, cement, sand or ash - are introduced into a sealed mixer along with a foaming agent. The pressure in the mixing container is then increased, at which the composition is mixed. During the stirring process, the solution becomes saturated with air. To accelerate and regulate structure formation, it is possible to use functional additives.

- A foam generator is needed to produce foam separately. It is a container into which the foam former is poured. The composition from it is fed into the mixing chamber, where it is combined with air from a pump or compressor. The emulsion flows through a jet or Laval nozzle into a foam cartridge designed to foam the starting material. The output is foam, the quality of which changes due to the adjustment of the valves for supplying the foaming emulsion and air. They are placed in front of the mixing chamber together with shut-off valves.

Anti-foam analogues: Dimexide and others

Many performers prefer to save money and, as an alternative to special means, use improvised pharmacological and chemical substances : vegetable oil, soap solution, soda, vinegar, Cosmofen, white spirit, acetone, kerosene, gasoline, solvents.

Classic laundry soap. Photo by Maxidom

Each of the tools is recommended to be used to solve specific problems. There are separate recommendations for removing foam from doors, others from clothes and hands, and others from plastic windows and other surfaces. In each case, there are products that cannot be used for certain stain removal jobs. For example, Dimexide is an excellent foam remover, but using a pharmaceutical hand cleaner can lead to an overdose and allergic reactions.

White spirit 1 l. Photo by Leroy Merlin

Despite a number of alternative solutions, you need to remember that cleaners show the best results . Therefore, before carrying out work using polyurethane foam, it is recommended to purchase a special product, of a similar brand with polyurethane sealant, to increase efficiency.

How can I clean the gun?

Mechanical cleaning of the instrument and disassembly is a radical method, but effective. If the mounting foam has frozen inside the gun, then it is unlikely to be completely removed from the cavity of the tool. Therefore, with each subsequent use, the output flow power of the sealant will weaken, as the substance will cling to frozen residues.

If the sealant has hardened, then it can be cleaned from the hardened polyurethane foam using the washing method. In this case, you need to act quickly and prudently. You need to buy a special cleaning composition.

Washing the instrument is carried out in the following sequence:

- The can of sealant is removed, and a can of cleaning mixture or aerosol is installed in its place.

- Then you need to press the trigger mechanism - liquid will flow from the barrel of the tool. You must hold the trigger until the liquid becomes completely clear (this indicates that the hardened sealant has been dissolved).

- The canister with the cleaning mixture must then be removed and the trigger mechanism pressed again. If the trigger moves jerkily, this will indicate insufficient cleaning. Therefore, all manipulations must be repeated.

Precautions when working with cleaning products

Respirator Source FFP1 with valve. Photo by Leroy Merlin

Cleaners contain various chemical compounds, so safety regulations must be followed:

- carry out work in ventilated areas;

- use gloves, goggles and other personal protective equipment;

- during storage, the cylinder should not be exposed to ultraviolet rays;

- It is prohibited to store and use aerosol cans at high ambient temperatures;

- If a cleaner that is not intended for cleaning foam from hands comes into contact with the skin, the area must be thoroughly rinsed with water and treated with a hypoallergenic cream;

- If the cleaner gets into your eyes, rinse them thoroughly with water and consult a doctor.

DIY cleaner

To save money, you can resort to making your own cleaner. The effectiveness of such substances is lower. They are not recommended for washing the gun and removing foam from ceramic and plastic bases. But in all other situations this option has the right to life. To make the product you will need:

- acetone and other organic solvents, acetone can be replaced with liquid Cosmofen;

- means for pumping compressed air;

- metal container with lid and sprayer.

Slightly soluble cleaner Cosmofen 10 1 l. Photo by Leroy Merlin

The sequence of actions is as follows:

- the components are placed in a prepared container, which is filled 2/3;

- the container is closed with a lid;

- Finally, compressed air is pumped into the container, an electric pump is used for this;

- Before using a homemade cleaner, the container must be shaken.