Sealing cracks, seams and joints is a necessary measure, without which almost any repair or construction cannot be done. Most often, the problem is solved with the help of polyurethane foam, and the most important question that arises is what is the consumption of polyurethane foam per 1 meter of seam. We will understand what types of material are offered on the construction market, what affects consumption and how to calculate it correctly.

An indispensable method for sealing seams Source meiwurkje.nl

Why is it important to know the consumption per m2

Professional builders, taking into account a preliminary inspection of the site, can immediately draw up an estimate in which the customer will understand how much it will cost him to install the structure.

Having personally undertaken the manipulations, it is necessary to purchase a sufficient amount of materials so that the process does not stop halfway.

Weighty frames or plastic windows need to be thoroughly secured in a specific place, and if there is a shortage of mixture, the product will have to be pulled apart or secured manually for some time. Such additional tasks will complicate the work of the master, and will also bring a lot of inconvenience and waste of useful time.

Let's talk about brands

Among the manufacturers known on the market are Titan, Macroflex and Penosil. But this is not all...

Titan – the brand produces several types of MPs that differ in their specific focus and capabilities.

Along with conventional MPs, Titan's assortment includes foam with increased sound-proofing properties, with a fire-resistant filler (Titan Professional B1), as well as several types of multi-temperature MPs.

Macroflex. Russian manufacturer producing a full line of construction foam.

Household and professional MP, for different temperatures, with enhanced adhesive ability, with improved thermal insulation properties, etc.

Foamed. Wide range (about 20 types of MP). Personally, I have been using Penosil for several years. And I can only say good things about him. Excellent combination of price and quality…

Presented in two series: PENOSIL Gold, intended for professional builders, including fire-resistant and for different seasons, and a household series, PENOSIL Premium, whose element is used in major and local repairs.

How much polyurethane foam is needed in a can for one window?

If the preliminary measurements were taken correctly, and the walls after dismantling the old structure turned out to be of decent quality, then one container of the mixture per 0.75 liters. quite enough to install a window.

We should not forget about the thermal and sound characteristics of the room; the thickness of the seam created depends on these indicators. In panel houses, the concrete base rarely turns into dust, which cannot be said about private buildings.

At the time of dismantling the old structure, some parts of the opening often fall out; all craftsmen who have encountered repairs on adobe or self-leveling walls of a dilapidated type are aware of such excesses.

Potholes have to be leveled with polyurethane foam, which significantly increases the consumption of the polyurethane mixture.

Specifications

The construction market is saturated with aerosol sealants, which makes choosing the right material difficult. In any case, you should start by assessing the capabilities of polyurethane foam; technical specifications will help compare MPs from different manufacturers. The material is assessed according to the following parameters:

- Foam output volume. The characteristic is indicated on the cylinder and measured in liters. You should be aware that this value is true only under ideal conditions. In case of wind, non-ideal air humidity, the same temperature of the cylinder and air, the volume will be less (sometimes much).

A simple way to fix a wall defect Source yandex.net

- Adhesion (the ability to form a strong bond). MP is compatible with most building materials (concrete, metal, stone, brick, wood, PVC). Exceptions are silicone, polypropylene, Teflon, polyethylene, oily surfaces, ice.

- Foaming. Saturation of the initially liquid mass with gas at the moment of exit from the cylinder (boiling occurs due to high internal pressure). In poor quality foam, the bubbles aggregate into larger cavities, often on the surface; the foam itself settles. The problem lies in an unbalanced composition, for example, if there are not enough surfactants in the mixture. The correct porous structure makes the material stable in any conditions.

- Expansion (primary). Occurs during operation and lasts until the polymerization process in the foam itself is completed. Thanks to the expansion process, the seam is not completely filled during operation, and the material is consumed more efficiently. The foam distributes itself in the seam, taking up space and providing reliable fixation.

High-quality composition does not drain from vertical surfaces Source yandex.net

See also: Catalog of companies that specialize in finishing materials and related work

- Secondary (subsequent) expansion. After applying MP, a change in the volume of foam not intended by the manufacturer is possible, and this can be either shrinkage or expansion. The smaller it is, the better; There are cases when such an expansion broke wooden frames or bent the plastic of the window sill. The cause may be deficiencies in the foam or external factors (dirty surface, insufficient moisture, careless work).

- Viscosity. Viscosity refers to a certain concentration of the substance in the cylinder. If the air temperature becomes too low or high (beyond +5-+30°C), the viscosity is no longer stable. In this case, the MP does not form a solid mass, but begins to flow; there is no need to talk about quality.

Sealing the seams of the door frame Source chistodoma.com

What determines the consumption of polyurethane foam?

In some situations, standard tables that help determine the required volume of polyurethane foam to complete the started process do not contain the indicators that the master encounters.

Such deviations occur for a number of reasons, such as:

- Errors were made during preliminary window measurements.

- The quality of the frame is low.

- Installation is carried out by an inexperienced person.

Experienced builders can competently approach the implementation of the process, and at the time of removing the old structure, disrupt the integrity of the opening to a minimum; the presence of potholes in the partitions also determines the consumption of foam per 1 m of seam.

Types of polyurethane foam

When purchasing cylinders from the makroflex brand or any other manufacturer, it is important to clearly understand that the mixture is divided into 3 types, namely:

- The universal model is distinguished by fast polymerization, you can work at a temperature not lower than -10 degrees, there is no need to warm up the container.

- Winter foam allows you to apply a specialized solution to surfaces that have cooled down to -18 degrees.

- The summer sample is intended for heated surfaces up to +35 degrees.

Features of application

When choosing a manufacturer of mounting foam, the consumption per 1 m2 of which has yet to be calculated, you should understand that the following samples go on sale:

- Highly expanding.

- Medium expanding.

- Slightly expanding.

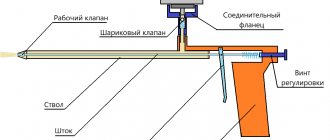

Before spraying the mixture, the container is first shaken for 15 seconds, after which the container is immersed in the gun and the solution is dosed by pressing the trigger.

To take advantage of the entire volume, it is necessary to strictly hold the container with the bottom up, and to achieve high-quality adhesion, the surface is moistened with water.

Depending on the expandability indicators, information can be clarified with the seller or in the product description; fill half the seam with the mixture, sometimes two-thirds of the space.

Consumption factors for polyurethane foam in m3

Approximate data when taking measurements often led to errors; the volume of foam that will be required to level the space between the wall and the structure directly depends on the accuracy of the measurements.

In addition, the type of base is taken into account; upon contact with a brick, the solution can increase to 1.1 times; if a profiled sheet is used, then the numbers increase: 1.1-1.6 times.

It is impossible not to mention aerated concrete, this material is capable of absorbing foam, the amount of costs for purchasing cans will increase. You must work with a pistol, otherwise you can waste a lot more material; it is difficult to dose the mixture correctly and economically through the embedded disposable tube.

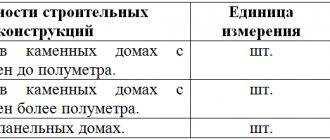

Foam consumption per 1 meter - table

By looking at the specific manual, anyone new to using polyurethane mortar will be able to find out the consumption depending on the width and depth of the seam. Products from the company Macroflex were used as a sample; this must be remembered.

Based on the data presented, it becomes clear that the table shows the consumption of polyurethane foam per 1 m of seam as follows: taking into account the same depth, as well as a width of 6 mm, one cylinder is enough for 8.3 m of seam.

When the indicators change upward, the distance that can be covered with one purchased container decreases.

Stop water and other suitable options

Different suppliers offer their own range of waterproofing products. For example, Tytan Professional STD, Tytan Euro-line GUN, Hauser W&D, Tytan Professional Lexy 20, Tytan Professional GUN, Makroflex 65 Standart, Makroflex PRO. However, in practice, only the last option can be used for waterproofing

The manufacturer indicates that the foam has an optimal number of open and closed cells, which is important for waterproofing materials

In addition, special attention must be paid to compounds intended for sealing. Soudal offers a wide selection of these products

The household and professional lines contain compounds for sealing when installing door and window frames, window sills, blinds, thresholds, steps, etc.

Reference. Sealing is the process of making surfaces and joints impervious to gases and liquids using special materials.

It is also possible to find special mounting foams for waterproofing on sale. The most famous is the two-component moisture-resistant foam “Stop Water”, which can withstand gas and liquid pressure up to 1 bar and is chemically neutral. The foam is intended for installing windows and doors in flood-prone areas, for eliminating leaks, sealing cables, fixing pipes, gluing concrete rings, etc. Does not support combustion, class - B2.

Despite the availability of a significant number of options for polyurethane foam for waterproofing, this solution is not optimal. In theory, foam can be used quite successfully as a waterproofing material. But in practice it is necessary to use alternative options. And there is a large selection of them on the market.

Calculation formula

Taking note of one effective example and substituting personally obtained measurements of the object, the master will be able to quickly calculate how much mixture will be needed to complete the work begun.

The formula looks like this: P = W * D, while the abbreviation “P” means consumption per 1 m.p., “W” is responsible for the width indicator, and “G” is the depth of the seam in mm.

As an example, it is worth giving a ready-made, solved example, the depth and width are the same - 10 mm, for 1 m.p. in such a situation you need 100 ml of polyurethane solution.

There are also triangular joints; in such cases, another formula is suitable, which looks like this: P = 0.5 * W * D; when applying the mixture, the tip is sometimes cut at an angle of 45 degrees.

Measurement accuracy

A common mistake that nullifies further “scientific” calculations of raw material consumption is careless or “by eye” measurements of the object being sprayed with polyurethane foam. Firstly, you need to use special measuring instruments - laser rangefinders, tape measures, level gauges. The more accurate the measurements, the smaller the final error. Secondly, when taking measurements, simple geometric calculations of areas are not enough; it is necessary to examine the object for the presence of voids, cracks, beams and complex construction units that are subject to foaming.

Let me give you a simple example: a hangar needs to be insulated along its entire contour; under the ceiling there is a rectangular beam of 20x40 cm, 12 m long. It would seem an insignificant nuance. Now let’s calculate that we have a relatively flat ceiling with two additional edges of 40 cm each and a length of 12 m - this is 9.6 additional square meters or about 24 kg of raw materials with a layer of 5 cm. Not to mention the complication of the surface, which gives additional overspending. What if there are several of these beams? Or is it not a beam, but a channel with an even larger surface area? All this must be taken into account and strictly considered.

Recommendations for economical consumption

Few beginners know what affects the magnification coefficient of a brick wall; the material is wetted before application, this is the only way to be sure of high-quality adhesion.

For each type of foam, the percentage of air humidity at the time of manipulation becomes an important indicator; the cost-effectiveness of consuming a specialized solution depends on these parameters.

In order not to be upset by the low yield of the mounting component, you should trust only time-tested brands and buy a product that has already received positive feedback from customers.

We calculate the optimal amount of material

Correctly calculating the amount of building materials that you will need to perform one or another type of construction and repair work is not an easy task. We all know that wallpaper, tiles, glue, and everything else is usually purchased with a certain reserve. But what about sealants? It would seem that there is no point in calculating the exact consumption of the sealing compound, since you can always go to a hardware store and buy the missing material. But there are times when it is better to calculate at least the approximate amount of sealant in advance. For example, you order a material of a certain color, which will be made to order for you (the so-called tinting of the sealant in the mass). In order not to make a mistake and not to buy too much, you should use some calculations and formulas.

What type of foam is best for foaming plastic windows?

When directly visiting the store, each consumer must make sure that the product is fresh, the expiration date is also indicated on the foam, and the indicators printed on the bottom of the container should be checked.

Popular brands today are:

- Soudal;

- Makroflex;

- Penosil;

- Wellfoam;

- Titan.

For the installation of plastic windows, one of the listed brands is suitable; on professional samples of the solution there are peculiar marks, 50, 65, 70, which indicate the volume of output of the polyurethane component.

Window-how

Manufacturers of plastic windows are developing their own technological solutions designed to facilitate the installation process and guarantee long service life of windows. An interesting option is offered, for example, by the Group’s specialists - special panels 9 mm thick, trimmed on one side with a hard PVC sheet 1 mm wide, and on the other with rigid polystyrene. The design provides good vapor barrier and eliminates undesirable effects associated with freezing of the junction of the window and the opening. Finishing with PVC sheets provides a modern appearance, easy maintenance and no operating costs, and the film protects the slopes during installation and finishing work in the room. Among other things, such a panel makes it possible to deliver the window on a turnkey basis on the day of installation, which is not possible when using “wet processes”. In the latter case, the installation of the window lasts at least two days. For comprehensive finishing of a window opening, we also offer decorative corners made from solid PVC sheet by extrusion, covering the joint between the slope and the wall.

Polyurethane foam is produced in several types, each of which has its own consumption

The average values shown on the packaging or the container itself may not be confirmed in practice. Professional samples of models were designed for a pistol; if you use a disposable tube, the result of efficiency will disappoint the master.

This type of mixture creates a tighter joint, secondary expansion is at a low level, this is exactly how it was intended by the manufacturer. With proper skill, a person can easily create a uniform layer, but without experience in performing manipulations, part of the polyurethane was often squeezed out.

The situation can be corrected by trimming the excess, but the consumption in this scenario will be greater. Do not forget about the types of compositions; highly expanding, moderately expanding and weakly expanding models work according to a specific scheme; the material’s belonging to the group must be indicated on the packaging.

Polyurethane foam: consumption per 1 sq. m.

Online calculators have become quite popular, allowing, after entering specific parameters, to immediately get an answer to the question of how much foam will need to be purchased for the upcoming work.

People who confidently use a personal computer will immediately understand what the essence of the program is, which cannot be said about some older individuals who poorly understand certain aspects of using technology.

In such a situation, the formula given above will become relevant, and if the standard width and depth have been identified, you can compare the characteristics with the table and find out the upcoming consumption per 1 sq. m.

Which foam to choose

In addition to the rating of the manufacturer whose products a person is interested in, it is important to pay attention to useful information regarding the composition, scope of application, degree of flammability of the mixture, as well as temperature conditions.

Only a thorough analysis of the cylinder and consultation with the seller will help you understand whether a specialized solution is suitable for a specific situation, building or weather conditions outside the window of the house.

Having understood all the intricacies of classifying mixtures, the risk of making a mistake at the stage of purchasing cylinders will be significantly reduced. Beginners will appreciate not only useful recommendations, but also detailed descriptions of each individual item from experts.

Compound

A high-quality mixture can be easily distinguished from an outright fake; to do this, just look at the list of substances on the inside of the can.

The list often includes:

- Prepolymers, polyol and isocyanate are the basis of the solution.

- Butane and propane perform a displacement function.

- To increase adhesion, all kinds of additives are introduced at the manufacturer's factory.

Each model of material for installation of structures has the listed components; the absence of one of them will indicate the low quality of the polyurethane mixture.

You can also find more complex compositions on the shelves; professionals call them two-component compositions, but such types of cylinders are rarely used for domestic purposes.