Polyurethane foam is used everywhere in a variety of jobs. It is necessary for filling the joints between the frame and the wall when installing doors and windows, when laying pipelines through holes in the walls and when connecting other communications. It is also used for sealing seams when laying thermal insulation materials based on mineral fiber, for gluing PPU insulation and in many other cases. Cylinders with material vary in format. Models are available for use with or without a pistol. What to do if you bought regular polyurethane foam without a gun, how to use it correctly in compliance with the technology and to obtain a high-quality result?

Main characteristics of polyurethane foam

Polyurethane foam is a stable chemical structure consisting of a liquid prepolymer dissolved in liquefied gases, having a low dead weight and high internal concentration. This is a universal tool that has a number of advantages:

- High-level thermal and sound insulation.

- Ability to hold different types of materials together.

- Convenience of installation work.

- Practical packaging that can be reused.

When the material expands during the hardening process, it becomes possible to qualitatively seal any joints and seams, even when applying foam without a gun.

Previously, cement mortars were used as an alternative, but the production of such materials requires serious labor. In addition, old materials are inferior to new ones in most operating parameters.

Polyurethane foam sealant: a little theory

How to work with sealant without a foam gun? Very simple. But first, let's talk a little about the main character of this article - foam. For what? And then, to understand the principle of operation of polyurethane foam. I think no one wants to ruin the substance and the home. It is so? Great. Then let's get started.

Story

The sealant was born thanks to the German chemist-technologist Otto Bayer. He invented the substance back in 1937. Or rather, he discovered polyurethane. And in 1970, specialists from an English company invented polyurethane foam sealant.

It has been tested and improved over the years. In 1980 it was used by construction workers in Sweden. The invention was to the liking of many maestros of architectural art, since it had a number of positive properties.

Today, of course, sealant is produced in many countries. For its production, exclusively innovative technologies are used.

Concept

Polyurethane foam or polyurethane foam sealant is a substance that consists of two components - polyols and methyl...ate (you'll break your tongue there). In addition, in the manufacturing process of the product, stabilizers, catalysts, a mixture of butane and propane, etc. are used.

How to use polyurethane foam without a gun at home

There are several ways to apply material to different surfaces without using a gun. The main thing is to take into account not only the operational properties, but also the scale of the planned activities. This is required by any construction work using a can of polyurethane foam without a gun.

What precautions should you remember when working with a cylinder of polyurethane foam at home?

When working with a can of polyurethane foam without a gun at home, you must follow basic safety rules. First of all, you need to take care of protecting your eyes, skin and respiratory tract. To do this, it would be a good idea to use special protective glasses and gloves during construction work.

In order to prevent a decrease in the yield of the material and a decrease in its further expansion during hardening, before starting work, the temperature of the foam in the cylinder should have an optimal value and be in the range from +20 to +30°C. You need to heat the construction foam to the required temperature at room temperature or by placing the balloon in warm water. Under no circumstances should a gas stove or other open flame sources be used for heating. Liquefied propylene gas, which is part of the foam, has flammable properties and is easily flammable.

When choosing polyurethane foam in a store, the buyer has the right to demand that the seller provide him with a certificate of conformity of the product. It is also worth paying attention to the expiration date of the purchased products.

Preparing the work surface for applying foam

The main thing is to provide maximum protection. If there is debris and dust on the work surface, they are completely removed. Large gaps can be pre-filled with small pieces of foam.

Any planes inside the surface to be treated require preliminary moistening. However, it is important to ensure that moisture does not drain from the surface. Excess moisture is also undesirable, including when using polyurethane foam with a tube.

Using polyurethane foam without a gun - step-by-step instructions

The workflow itself includes several stages. This instruction will show you how to use polyurethane foam without a gun.

- Wear gloves for protection.

- Prepare the surface to be worked on.

- Seal the gaps.

- Shake the professional spray can.

- The foaming area is sprayed with water; for this you can use a regular household sprinkler.

- Remove the cap from the cylinder.

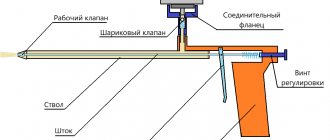

- A special tube is put on, which is included in the kit. The Zubr models are no exception.

- A tube, its edge, is brought to the area that needs to be filled. Then press the valve until the seam being treated is at least half filled. This is an important rule.

- The cylinder is positioned only with the bottom up; this is its main working position, including in the case of a tube and its use.

- After half an hour, you can visually inspect the area that has been treated.

- After a day, you are allowed to get rid of excess polyurethane foam; they are cut off with a stationery knife.

- It is imperative to carry out finishing work in the future, since the foam itself does not resist ultraviolet rays. You need to choose one of the modern types of cladding to make the installation process easier and faster.

Correct position of the foam container when working without using a gun

When using a cylinder without a gun, difficulties may arise in adjusting the flow of construction foam, so it would be a good idea to first test the intensity of the supply of the substance on the rough material.

Is it possible to reuse an already opened cylinder without a gun?

The possibility of reusing construction foam without guns is not excluded. To do this you need to take several steps. The tube is carefully bent, then this place is fixed with tape or tape. The valve is pressed to maintain the pressure reading.

If the substance used is stored for more than 5-6 months, acetone will be needed. After removing the tube from the cylinder, it must be thoroughly treated with the specified solvent. It wouldn't hurt to clean the valve itself. The procedure is repeated 2-3 times to achieve better results. A separate question is how to replace construction foam guns.

Classification

In order not to feel like a “blonde” while “shopping”, you should study the varieties of the substance.

Release:

- professional (for a pistol);

- household (with a tube nozzle).

- B1 – off;

- B2 – lights up, but goes out;

- B3 – lit.

- winter – used at outside temperatures of -20/+35°C;

- summer – used at +5–35°С;

- winter-spring-summer-autumn – used at -10/+35°C.

- reusable – reusable;

- disposable – used once (the remainder is thrown away).

So, we’ve sorted out the types of the main character of the article.

Which one is better? Well, to each his own. For example, for large volumes, specialists use professional two-component polyurethane foam, which is distinguished by its all-season, non-flammable and reusable properties. For those interested, here is an article about sprayed thermal insulation. But we, as non-professionals, can use a household option with flammability class B1, intended for one-time use.

Disadvantages of applying construction foam without a gun

If the work is done with just a tube, many people have doubts about the need to purchase a professional construction tool. But this seems to be a problem only at first glance. Professionals still advise not to abandon the use of special devices.

- Fast action regardless of the amount of work. For example, to process a two-meter seam, 10-30 seconds will be enough. In turn, the work of applying polyurethane foam without a gun takes at least 15 minutes.

- Accuracy. The gun has a very narrow nozzle and supports adjustable settings. Therefore, you can fill even the smallest gaps, which is simply necessary in some situations. The foamed surface is then difficult to distinguish from other areas. This rule applies equally to walls and floors.

- Foam consumption is very small, since the materials are supplied in doses. In the case of a tube or cylinder, you cannot do without overspending.

Polyurethane foam with a tube is great if you only have to do one-time work on a small area. Otherwise, it is better to replace it with another device. It is also necessary to take into account that installing a tube on a cylinder is not always possible.

As an option, you can use special mini-cylinders with a volume of 250-500 ml. The main thing is to purchase them in sufficient quantities in advance. It is not recommended to use the remainder of the material; in this case, the professional foam remaining inside the small-volume cylinder is disposed of along with it.

As for the pistol itself, it also has its drawbacks. For example, after use, the tool requires cleaning (see in more detail “How to clean a foam gun?”). They produce special care compositions that act in just a few seconds. Usually the manufacturer additionally writes in the instructions about how to handle the device. Tubes often remain an independent invention.

Acetone at home easily replaces special liquids, and anyone can keep it at home. When working, the composition must be poured into the nozzle of the tool, and then completely clean it using a wire or cleaning rod. All actions must be performed as carefully as possible, otherwise delicate structural elements may be damaged.

Additional Tips

There are several recommendations for those who are interested in using polyurethane foam; the videos will also help you understand this issue.

- The water sprayer and knife are prepared in advance in order to later get rid of the excess that was squeezed out along with the rest of the mass.

- If foam appears in unnecessary places, it is removed using a soft sponge with acetone. These are standard terms of use.

- With economical consumption, it becomes easier to avoid material costs. The applied mixture can also be stored for quite a long time.

- After applying foam at home and in other objects, the surface is treated after a maximum of 4 hours. After 7-8 hours it will be more difficult to cut the material as everything will have completely hardened.

- The work must be carried out in a respirator; it will protect human organs from foreign substances getting inside. Gloves and goggles are also recommended.

- There is no need to wait until the color of the polyurethane foam darkens while using it. This means the beginning of a reaction to ultraviolet light.

- Polyurethane foam cannot be used near open fire, cylinders cannot be stored where the sun constantly shines. The sealant contains substances that can be flammable.

- When applied to a dirty surface, you can also encounter problems. It is better to use a vacuum cleaner first, and at the same time clean the floors.

- Too strong temperature fluctuations can disrupt the structure of the composition.

It is important to use the material wisely depending on the time of year and temperature.

Application area

The sealant has eclipsed many of its predecessors - plaster, mineral wool tapes, cement, bitumen, etc., which is no wonder.

It is used for:

- installation of door and window blocks;

- fastening insulation, waterproofing, sound insulation;

- filling cracks and crevices formed during repairs;

- filling voids that appeared during construction;

- performing facing works;

- filling holes, cracks, cracks in interior items.

The substance has a wide range of applications. Because of this, it will definitely not be forgotten, somewhere on a dusty shelf in the garage or closet.