Hello, dear friends! I propose to talk about the insulation of plastic windows, which can be done outside and inside. Sometimes this is a dire need because the plastic bag, i.e. the window, does not retain heat properly and is also ventilated.

Even if the window is new, this is not a guarantee that a draft will not appear, and the sash will not cause heat to escape from the house. This results in increased heating costs and the inability to stay warm in winter.

Experience shows that the most common places for heat loss are glazing beads, rubber seals, fittings, and the perimeter of the window frame. That is, areas where the double-glazed window comes into contact with the wall, window sill, and slope.

Causes of heat loss

The main places for blowing are: glass unit holders, rubber seal, places under the hinges and handle, around the perimeter of the frame.

There can be several reasons for cold air entering a room. The most common problem arises from improper installation of double-glazed windows, namely ignorance and non-compliance with window installation technology. Negligent attitude of the installation team towards work, poor sealing of cracks, failure to seal installation seams with sealing tape. And if the external slopes of the windows are not finished in a timely manner, then after a period of time, environmental influences will destroy the polyurethane foam.

Saving on construction foam, insulation, not using protective thermal insulation, using low-quality components during the assembly process - all these are the reasons for the necessary insulation work.

The situation of building shrinkage is relevant for those living in new buildings or a wooden house, because... this can lead to distortion of the frame. Another important reason is improper window care. Many people neglect primitive window cleaning. So, about 2 times a year, the window seal needs to be washed and lubricated with glycerin so that over time it does not begin to crack, which will naturally facilitate the transmission of heat.

Cold may enter the room if the clamping flaps are loosened. This can be solved by adjusting the fittings.

How to protect windows on the first floor without bars. How to protect windows from burglary without installing bars

The window opening is a favorite loophole for experienced thieves. To avoid possible theft, windows should be secured against tampering. This is especially true for owners of private houses and those who live on the first floors of apartment buildings.

How to protect windows from burglary?

If problems almost never arise with entrance doors, then with windows the situation is completely different. Grilles installed in window openings are reliable, but from an aesthetic point of view they are completely unattractive. But few people know that there are other ways to protect windows from burglary.

It is very difficult to hack a securely protected window, and in some cases it is completely impossible. So, in addition to installing simple metal grilles, there are other methods of protection.

Use of windows equipped with security mechanisms

Some manufacturers of plastic windows offer ready-made solutions for their clients:

- Windows with security level WK1. They are distinguished by the presence of mechanisms that make their locking more reliable. For example, if a thief tries to enter a room through a window using ordinary tools, he will not succeed. The mechanism securely holds the bar from the outside;

- Windows with security level WK2. They use more advanced window mechanisms. For example, a thief will definitely not be able to open a window with a chisel. It will take a long time to hack. In addition, it is guaranteed to cause noise and attract attention;

- Windows with security level WK3. The most reliable window protection. It is distinguished by the presence of additional locking pins. A thief will not be able to open the window even if he uses a crowbar to do this.

Installation of anti-burglary fittings and security hinges

To enter a house through a window, thieves in most cases press down one of the window sashes. Using anti-burglary fittings will prevent this from happening. The fittings are a plate made of durable metal. It will reliably protect the window handle from drilling.

It is also recommended to use safety hinges and a locking pin. These devices prevent intruders from pressing the window sash. In addition, you do not need to hire specialists to install them. You can do everything yourself.

Remember, any fittings can be easily replaced with anti-burglary ones. Standard windows can be easily converted into secure ones. Therefore, if you have not yet taken care of your own safety and the safety of your property, now is the time to do so.

Features of insulation of window slopes

Thermal insulation of external window slopes affects the comfort of living in the house, because... maintains an optimal and correct microclimate throughout the year. The procedure does not require the involvement of specialists or professional equipment. You can implement it yourself using available tools.

Since there are seams between the window frame and the wall, they are usually filled with foam to prevent drafts. This substance has good thermal insulation parameters, but can be destroyed by moisture. Boxes that do not have additional lining are not sufficiently protected from negative factors. If there is no insulation, the joints will be exposed to water, so over time the fasteners will begin to wear out and the window will sag.

After the structure shrinks, voids appear between the opening and the frame, which provokes freezing and the formation of cold bridges.

Insulated windows do not accumulate condensation inside the building, and therefore prevent the appearance of mold in residential areas.

Window putty

Paper or window putty is an affordable and quick method. To work you will need old newspapers or paper, water and two parts of crushed chalk or part of clay.

Grind the newspapers, mix the components and as a result you get a viscous, plastic mass that can be used to seal any, even the smallest and narrowest, cracks and gaps. For aesthetics, the putty is covered with decorative elements on top.

You can buy ready-made construction putty. This is a rather labor-intensive process, since before starting it is necessary to remove the old putty, then apply new material, level it, if necessary, close it with a bead and paint.

After the procedure, the window can be easily cleaned of putty. In addition, the product does not absorb moisture. However, the effect will only last for one season. In addition, the putty prevents the window frames from opening. Therefore, with the onset of warm weather, the product is removed and the windows are thoroughly washed. Before next winter, to prevent the wind, you will have to seal the frames again.

How to determine where a draft is coming from a window

Even if there is one defect in the window structure, this will lead to drafts. To find out which direction it is blowing from, you can use the following methods:

- Run your hand around the perimeter of the window and check where there is a draft.

- Using a lighter, evaluate where the intensity of the flame changes.

You can also place a sheet of paper in an open window and then close the sash. Next, you should pull the tip of the sheet: if it comes out easily, the seal is not pressed well enough.

Other window sealing products

The sealant will be a real salvation if there is strong wind from the windows. The sealant is applied to the areas where the glass meets the frame. Window frames must be washed, degreased, and then carefully applied. To make the seam as airtight and aesthetically pleasing as possible, squeeze out the compound with even pressure and distribution; Paraffin is used to insulate wooden frames. The product only eliminates blowing through the pores of the wood. For the procedure, melt the paraffin and glue the surface of the valves with the mixture. This is a budget but labor-intensive method. In addition, it does not eliminate drafts around the perimeter of the glass and frame; Thermal-saving film is a popular and affordable material for covering windows. It not only covers the areas where the glass and frame meet, but also reflects the resulting heat. This increases the thermal insulation of the room and reduces heat loss by 75%

It is important to glue the material correctly, without folds or air bubbles. You can easily apply the film yourself, but it is quite expensive; Oddly enough, washing the window glass and thick long curtains will help to insulate the windows

Clean double-glazed windows allow sunlight to pass through as efficiently as possible, which will heat the room. And thick and long curtains will retain heat inside the room; Electric heating of windows and double-glazed windows is another modern and expensive way to reduce heat loss. In the first case, a heating cable is installed around the window. In addition, you can install ready-made double-glazed windows with heated glass, which will be heated from the inside.

Adjusting the clamping mechanism

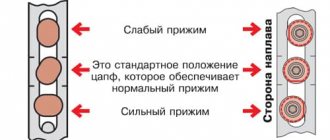

During operation, the window is exposed to mechanical and climatic factors. As a result, loss of sealing rubber volume may occur. What causes air to get inside the house. To solve this issue, it is not at all necessary to resort to replacing the gasket, unless, of course, it is completely in unusable condition. You just need to adjust the clamping mechanism.

To begin, find the protruding cylinder - the axle - in the cut places of the metal plug. Then move the hooks to the required position or adjust the trunnions. To change the position of the hooks, loosen the bolts. When moving to the street side, the pressure increases, and in the opposite direction decreases.

Blowing from a plastic window, find and eliminate

Where can it blow from plastic windows?

To understand why it blows from a PVC window, you need to inspect the components, and for this you need to know the design principle of the window unit.

Construction of a window unit - main elements Construction of a plastic window and door - list of elements

The most common places for blowing:

- window glazing bead (glass unit holder);

- rubber compressor;

- window fittings (for example, blowing from under the hinges, into the handle);

- the perimeter of the window frame - the junction of the slopes, window sill, walls.

How to determine where it is blowing from a plastic window?

The presence of a defect in one of the components of the window unit leads to blowing from plastic windows. There are three ways to determine the exact location of heat loss from metal-plastic windows:

tactile hand. To identify a gap, just run your palm over the surface of the window block;

lighter. The search procedure is similar to the previous one, but the light is more sensitive to drafts and can detect even the weakest blowing.

paper. An ordinary sheet of paper is pressed against the window (put into the open window and clamped by completely closing the sash), if you pull the corner of the sheet and it easily pulls out, then the seal is not pressed enough (this may indicate that the window is operating in summer mode, the old seal is in this mode does not press well to the frame).

Why does it blow from plastic windows - reasons for heat loss

installation error. This is the most common reason associated with ignorance or non-compliance with the correct technology for installing a plastic window. 15 years ago, this service was so in demand that everyone who had at least some idea about installing window units became installers. Naturally, few people installed PVC windows according to GOST;

window distortion due to shrinkage of the house. A pressing problem for residents of new buildings and wooden houses;

an attempt to save money. One of the weighty arguments in competition is always price, especially during an economic crisis. The price reduction often occurred at the expense of quality: saving on foam, on insulation, ignoring the need to protect the heat insulator, using low-quality components when assembling windows - all this over time led to the fact that the consumer is forced to change or additionally insulate PVC windows;

physical wear of window components, in particular sealing rubber bands, or weakening of the pressing force of the sashes;

violation of the operating rules for plastic windows, which include the need to wash the window seal and treat it with glycerin. This care prevents the seal from losing its elasticity and cracking.

What to do if it's blowing from a plastic window

Of course, eliminate the source of the draft. From a practical point of view, there are two simple options - call a specialist to repair and adjust (expensive) windows or do it yourself (cheap).

The desire to seal all the cracks yourself using improvised means is nullified because: firstly, it is not aesthetically pleasing, and secondly, there are no guarantees.

When is it advisable to hire professionals:

The plastic window was recently installed. The installer company is responsible to the consumer for the reliable operation of the windows (if the warranty covers this period);

the window opening is located at a considerable height (in a multi-story building). It is better to entrust any high-altitude work to professionals (industrial mountaineering services). If the window is located on the second floor or higher, the work will be associated with increased risk;

if there is a manufacturing defect. For example, obvious manufacturing or installation defects that appeared during the warranty period;

if necessary, replace parts. It is better to install “original” fittings if it is necessary to replace individual elements of the window unit;

work is carried out in winter. Knowledge of installation technology and how to insulate plastic windows for the winter allows installers to complete the work quickly, without significantly cooling the living space.

However, often, the cost of hiring specialists is equal to the cost of installing a new window, and this fact makes it more profitable to do the insulation work yourself.

How do you determine where it's blowing from?

Even if there is only one defect, there will be blowing from the window. You can determine where this is coming from in one of three ways:

- Run your hand along the perimeter of the window block;

- A lighter. Just like with a hand, in the place of a draft the light will change;

- Place a regular sheet of paper in the open window and close the sash. If, when you pull the tip of the sheet, it easily pulls out, this will indicate poor pressure on the seal.

How to check windows for ventilation and tightness

Visually or using tactile sensations, it is quite difficult to determine the place where the tightness is broken.

Thus, in winter, blowing can often be confused with cold glasses (“cold background”), so to determine possible problems it is better to use one of the following methods:

- A lit candle will help you determine from inside the room where the air is blowing from. You need to bring it close to the window and walk around the perimeter. If the flame burns evenly, then everything is in order in this area. The rapid fluctuation of the flame indicates air currents entering the room from the street.

- If you run a damp palm along the contours of the valves, you will feel a sharp chill in the places where the air is blown. It can blow from under the sash or at the junction of the frame and the slope, and cold can also be felt inside the plastic frame.

- You can hold a piece of paper between the closed window sashes and tug it a little. If the paper is easily removed, or the window does not close tightly, then you cannot do without replacing the seal or adjusting the clamping mechanism.

- A piece of chalk will also help you find places where the seal is not pressed tightly. To do this, you need to paint the rubber parts with it, then close and open the window and inspect the frame. If there are places where it is not painted, then the opening is blown through here.

- You can try to press a little on the closed doors; if the noise from the street becomes noticeably quieter, then it is blowing from the doors.

How to insulate a window for the winter with your own hands

All measures to insulate a double-glazed window must be carried out before the onset of the cold period. Because materials such as dry mix and sealant should be used only at certain temperatures, as they may lose their properties. Air humidity should be optimal, there should be no draft. Insulation must be done simultaneously from the outside and inside.

Materials used Various materials and methods can be used here. Such as :

- Construction foam. It is the best means for window insulation. As it expands, all voids are filled. But the foam must be protected from direct UV rays and temperature fluctuations.

- Using mineral wool. It has good thermal insulation properties.

- Polystyrene foam or polystyrene foam for insulation of slopes.

Note: Rigid insulation is used in cases where the installation seam is no wider than three millimeters. In others it is better to use mineral wool.

Silicone sealant is used when processing plastic parts of windows to eliminate blows. Using dry mixtures, slopes on the street side are insulated. Construction tape is used instead of sealant or on top of it.

External insulation

External insulation work includes insulation of the slope and ebb on the street side. If insulation of the outer slope has not been done previously, then all actions will be useless. After time, the window will still be blown out, in addition, the inner wall may become damp and moldy. Caulking the external cracks will not lead to anything, because the plaster and foam will gradually become unusable.

Summary

As you can see, plastic windows also require insulation. If, after calculating the cost of time, effort and money, it becomes obvious that you can earn a large sum during self-insulation, then it is better to hire specialists who will do everything themselves. When working to insulate a window, you must be extremely careful and follow safety rules, especially if the window is not on the first floor.

Recommended Posts

Beautiful tulle for the kitchen + photo

Dormer window on the attic roof

Repair and insulation of old wooden windows

How to attach blinds to plastic windows + video

Soft windows for gazebos and terraces

Curtain and cornice - what's the difference?

Why is it necessary to insulate slopes?

Often, after replacing windows, they are limited to only decorative finishing of the slopes, which is wrong and can lead to problems in the near future, because:

- The seams between the wall and the glass unit are filled with polyurethane foam. But this material is not sufficiently resistant to high humidity, ultraviolet radiation and low temperatures. Very quickly, unprotected polyurethane foam will begin to deteriorate under the influence of weather conditions, which will lead to heat loss through voids in the seams.

- Numerous cracks on untreated surfaces of slopes are a common cause of heat leakage from a room.

- Moisture can accumulate in the voids between the wall and decorative panels, which means condensation may form.

Insulation of window slopes with penoplex. How to CORRECTLY make warm slopes

How to properly finish window (door) slopes. This advice applies primarily to old housing stock, that is, not insulated on the outside. When replacing windows (doors), the question arises of how to make slopes.

Now everywhere and in everything there is a very fashionable trend - “quick and cheap”. Personally, I don’t understand this, as they said “only cats will be born quickly” and also “cheap fish makes cheap fish.”

Where did this come from - PVC slopes? It's simple. Window installers came, quickly replaced them, and they don’t want to go to the apartment for a few more days, working several hours a day, because no one wants to pay for good quality. And the people who ordered such work don’t want to “spread the dirt for a long time” and everyone needs to finish it quickly and sit down to watch TV.

So, if you don’t agree with the sayings and think that slopes can be covered simply with plastic crap panels, then don’t read this topic, don’t waste your time. For those who want something “just like themselves”, good and durable, I’ll tell you further: If the house (cottage) is new and the outside is well insulated, such slopes can be made - it certainly won’t be worse, but there is no need to insulate them as such. Why do you need to insulate slopes at all? Everything is very simple. In winter, the wall around the windows on the slopes freezes faster than in the thickness itself, since around the window there is the shortest path for frost. The dew point at an internal room temperature of 21 degrees is 11.62 degrees Celsius. Therefore, during the winter the slopes can become moistened, the frost penetrates inside even faster... this all takes a very long time to explain (Building Thermal Physics), in short - on the slopes a temperature of less than 11 degrees forms and condensation begins to form in this place. The more it falls, the more the slope gets wet. The more it gets wet, the more frost penetrates the slopes inside.

As a result, the finish of the slopes deteriorates, and if they do not dry out for some reason, mold will already form in the high humidity.

To prevent mold, it is necessary to reduce the humidity to normal.

This is achieved in two ways - to prevent moisture from condensing and accumulating, and secondly, if the material gets wet, it must be dried. The second option is not suitable for finishing, as it falls apart. Therefore, it is necessary to prevent moisture from forming!

By gluing foam plastic to the slopes, we limit the penetration of moisture from the room into the wall. In addition, we shift the dew point in this case in the wall closer to the street. And inside the wall there are already slightly different condensation processes.

Gluing and finishing of slopes should be done only with cement mixtures specifically designed for gluing and creating a base layer on foam plastic.

The base layer can be further finished using any painting method. It’s better, more practical and more common to paint.

In Germany, the use of gypsum mixtures on external walls (including their interior decoration), as well as in wet rooms (swimming pools, bathrooms, toilets) is prohibited.

This has its own clear and scientific justification. Another video is currently being filmed about this (subscribe to YouTube and you’ll see). The video will also be posted online.

Here in the picture you can see the temperature distribution in uninsulated window slopes with conventional plaster. The arrow points to the area where the temperature lines are already below the dew point.

Here is a thermogram with insulated slopes only 2 cm thick. You can see how the temperature gradient has changed and the temperature lines with temperatures critical for water condensation have shifted inside the wall and closer to the street.

The results of conventional plastered slopes are mold and damage to the finish.

B Enjoy watching. Learn! Don't be lazy to do it well and for a long time!

Ready to answer constructive questions.

Insulation of window slopes from the street

The entire process of insulating windows from the outside consists of the following steps:

- Preparatory work;

- Cleaning slopes from dirt and foam residues;

- Applying a primer to the surface;

- Installing insulation with glue;

- Sealing cracks with glue;

- Arrangement of corners;

- Installation of polymer mesh;

- Plastering.

Important: When installing insulation, it must be laid so that it partially covers the window frame, and the installation seam is completely closed.

First you need to cut off all the remaining foam. The slopes are treated with an antibacterial primer mixture. Tiles equal to the size of the slope are cut from penoplex. They are smeared with assembly adhesive and pressed to the surface. Here you can use dowels. The corner is installed. A fiberglass mesh is placed on the tile over the applied adhesive. You need to give it time and apply glue on top again. Upon completion of the insulation work, water-based paint must be applied to the surface.

Important: Paint is applied only after the glue has completely dried.

Thanks to external insulation of windows, condensation does not form.

Insulation of ebbs To insulate ebbs of plastic windows, you need to fill all the cracks with heat-insulating material and foam them. To prevent water from getting on the insulating material, a metal strip should be installed on top of the flashing. The angle of its installation should be more than five degrees, and the horizontal edge should extend twenty to thirty millimeters beyond the facade, while the side edges should be turned up. The places where the plank is adjacent to the surface must be covered with a hermetic mixture.

Insulating windows from the inside Work on insulating a window unit from the inside of a house may include: replacing a worn rubber seal, adjusting fittings, sealing joints, replacing a double-glazed window with an energy-saving one, insulating it with film. The role of the rubber seal is quite significant, it ensures the tightness of the window. So it is extremely important to regularly inspect the seal and properly care for it. Sealing of joints is carried out by applying sealant to the blow-out areas. Today on the building materials market there is a huge selection of sealing compounds of different types - for different wall materials, for different temperature conditions, etc.

Additional methods of window insulation These methods include primitive window washing. After all, if the glass is dirty, then it does not fully transmit the sun's rays. You can use thick fabric for curtains, which will also help retain heat inside the building.

For insulation, it is possible to use available materials - foam rubber, soaked paper, window tape, etc. Energy heating of a window or double-glazed window can also be arranged. To do this, a heating cable is placed around the perimeter of the window, and a special conductive film is placed on the glass.

Using heat-saving film Insulating film for windows helps keep the house warm. To create the desired effect, you first need to properly prepare the surface. The tools we need are a hair dryer, scissors, and a knife. The surface is cleaned of dirt, the glass is well rubbed. Double-sided tape is glued around the perimeter of the glass box. The film is separated using a stationery knife, cut to the required size and pasted onto tape. The film is blasted with warm air from a hair dryer. If small swellings form, they will need to be burst with the tip of a knife. This is perhaps the most economical method of insulating plastic windows. In any case, for a high-quality result you need the right integrated approach.

Window repair: do it yourself or invite specialists?

When planning the insulation of plastic windows for the winter, you should soberly assess your strengths, and for this you need to know what work you can do yourself, and what it is better to entrust to specialists.

Insulation of plastic windows: what you can do yourself

- replace seals;

- seal the joints;

- adjust the shutters;

- insulate slopes.

Insulation of plastic windows: when to call a specialist

- replacement of accessories;

- glass unit replacement;

- insulation of windows from the outside.

What materials are suitable for thermal insulation?

In order for all the activities carried out to have a positive result, it is necessary to select the right materials. The following is used as a heat insulator for slopes:

- Mineral wool (basalt, slag or glass wool).

- Styrofoam.

- Extruded polystyrene foam.

- Polyurethane foam.

- Sandwich panels.

- Fiberglass, one side of which is covered with a layer of foil.

In the process of selecting the required material, the dimensions of the window opening and the places where the insulation will be installed are taken into account. Mineral wool, for example, performs its functions with a thickness of at least 10 cm, which is not always convenient for insulating a window from the outside.

In addition, cotton insulation requires the use of a water barrier on both sides. This is due to the fact that after getting wet the material loses its insulating properties.

An affordable and popular option is to use polystyrene foam and extruded polystyrene foam (penoplex). Moreover, the latter material is preferable because it has a higher density with a smaller thickness. It is important to protect the polymer insulation from the sun in a timely manner. When exposed to ultraviolet light, foam becomes brittle.

If polyurethane foam was used during the installation process, then there is no hope for complete thermal insulation. Of course, if the voids are densely filled, some of the heat will still be retained in the room, but if the house is located in a region with low winter temperatures, then you will have to take care of additional insulation.

A good option that solves two problems at once would be sandwich panels. The top layer is a decorative material, the bottom layer is insulation. At the same time, it is possible to choose an option for your home if the facade is already lined, but the slopes had to be insulated later. In addition, some creators of such panels offer options with different insulation materials.

A new option for insulating slopes is fiberglass with a foil base. It is difficult to install such material with your own hands, so you need to take the help of professionals. But you will be 100% sure of the result. The insulator perfectly protects against moisture and penetration of cold air currents.

Additional measures

See also

Street stairs in front of the house and to the attic: what are they?

In addition to external insulation, also do not forget to insulate the window sill and make slopes from the inside.

It is important to understand that heat does not always escape, but cold enters through the cracks around the perimeter of the glass unit. In some cases, the window itself is to blame.

Both new and old plastic windows have several weak points. Namely:

- clamping elements;

- glazing beads;

- seal.

The glazing bead holds the glass unit itself. If it moves away a little, then heat can escape through the gaps formed, and cold can also enter. In this case, you will have to secure the glazing bead, or replace it if the element can no longer fit tightly to the glass unit.

The situation with clamping elements is similar. They don't close the window tightly enough. A test using a piece of paper will be a great help here. The clamps can usually be adjusted. You will need special cams and some tools.

Seals can also sometimes cause windows to not perform their functions effectively enough. The best option is to remove the old seals and replace them with new ones.

Sequence of work on internal thermal insulation

Those who want to get a positive result from insulating slopes need to be prepared for the fact that the process is carried out both outside and inside. Both options for carrying out work have features and a certain sequence of execution. Therefore, we will consider each of them separately.

The internal slope is insulated according to the following plan:

- Leave the new window for several days so that it is well fixed in one place.

- Inspect the foamed space. If there are gaps, add foam and leave until completely hardened.

- Trim off excess areas.

- Treat the surface of the slope with an antibacterial primer composition. The solution will help resist the growth of mold and mildew, and will also increase adhesion for subsequent stages.

- Level the slope using plaster. A flat surface will make a good base for tightly fixing the insulation.

- The plastered and dried base is again covered with antibacterial primer, for the same reasons.

- Glue the insulation. To do this, use liquid nails or glue suitable for the selected material.

- The corner is covered with a plastic or metal corner and plastered together with the total area of the slope; a reinforcing mesh must be used. Fiberglass will make the plaster layer strong and reliable.

After this, they begin decorating. Painting, tiling, or another option chosen by the home owner will do.

How to protect plastic windows from being opened from the outside. European protection of plastic windows

The now common windows made of PVC profiles first appeared in Western countries. For this reason, it will still be useful for manufacturers of domestic plastic window structures to look at how their Western competitors are solving the problem of structural safety. The countries of the European Union have long been systematically addressing issues of life safety for each of their citizens at all levels of life. This program to some extent also concerns the production technology of plastic windows. For this purpose, European manufacturers even studied the actions of burglars. Based on the results of these observations, methods were subsequently put forward to strengthen and protect the home from invasion by outsiders. One of the proposals in this direction was to equip window systems with additional security mechanisms so that the sashes are not as easy to break into as in a conventional design.

With all this, the installation of anti-burglary equipment should not be detrimental to the operation of the window locking system. In any case, a professional window installer knows that at the last stage of the work he will need to adjust the operation of the fittings. When the fittings are adjusted, the window sashes open smoothly and without problems and close just as easily.

It should also be noted that in European countries, anti-burglary equipment is now installed on windows during the construction of new houses. That is, in fact, these elements have already been transferred to the category of basic ones. Experts believe that an anti-vandal and anti-burglary system should be installed at least in the corners of window structures. Additional fittings must be installed in accordance with European standards for loads allowed for plastic windows. This is necessary in order to eliminate the possibility of deformation of the entire structure. In Germany, which is considered the world's main supplier of plastic window structures, a similar standard was also adopted, called DIN V ENV 1627–1630. He assumes that each new window should be equipped with a whole set of fittings corresponding to the degree of protection of the structure. Each product protection class has its own set of accessories, differing not only in quality, but also in their effectiveness. It is possible to determine the protection class corresponding to a particular window only after conducting an appropriate examination. During its implementation, specialists study and take into account various methods and tools used by professional burglars (usually screwdrivers and master keys of various configurations). However, during a practical test of the burglary resistance class of a window structure, specialists use a special key, with which they try to open the window in the corner area and remove the frame. The adopted standards also provide for procedures that require the window to be resistant to dynamic and static loads, as well as to manual break-ins.

Sequence of work on external thermal insulation

The outer slope also needs to be insulated, and this process should be taken seriously. Material that is laid outdoors is constantly exposed to destructive factors such as:

- Atmospheric moisture.

- Negative air temperature.

- Ultraviolet radiation.

- Exposure to wind.

- Insects, rodents and birds love to make their nests out of insulation materials.

Therefore, unprotected material quickly becomes unusable. Insulation of external slopes is carried out according to the following points:

- Remove excess polyurethane foam.

- Cover the slope with soil with an antibacterial composition.

- If there are large differences, the surface is plastered. Select plaster for external use.

- Once again they resort to priming. The composition will protect against fungus and mold, and will also increase adhesion with the following materials. Don't skip this step.

- Start with insulation. For external treatment of slopes, a denser material is chosen, for example, penoplex. It is glued to an exterior adhesive suitable for polymer materials.

- For greater reliability, the heat insulator is fixed to the slope with dowels with a wide head. It is not necessary to do this indoors, since there is no exposure to gusts of wind.

- The corners of the slopes are covered with corner elements. They will make the edging more neat and attractive. In addition, making a beautiful corner will be much easier.

- The insulation is covered with plaster with mandatory reinforcement. If you do not use a mesh, during the first year of operation the layer may crack and crumble.

After the layer has dried, decorative finishing is performed. Sheathing materials are used only those that can withstand external load.

Preparatory work

First of all, it is necessary to find out whether the windows allow heat to pass through and in what place.

The following signs may indicate that the seal is broken:

- drafts;

- clearly audible noise from the street;

- the appearance of condensation on the inside of the window.

To find the problem area, you can use an ordinary match. The flame will flicker in the place where air from the street passes into the room.

Before you start insulating plastic windows with your own hands, you need to determine when their warranty period expires. Information about this can be found in the contract for the purchase and installation of window equipment. If it was installed very recently and the warranty period has not expired, then all defects, including those associated with a violation of the window seal, must be eliminated by the manufacturer at its own expense. But after self-repair, the warranty automatically ends and in the future all problems will have to be fixed independently.

If the windows were installed quite recently and the warranty period for them has not expired, then defects associated with the violation of the tightness of the windows should most likely be corrected by the manufacturer (specify this in your contract)

If the windows are no longer new, and the warranty period has long expired, you can safely begin to improve them. Doing the work yourself will help you save not only on paying for the services of a master, but also on utility bills.

It is best to insulate plastic windows before the onset of cold weather. By preparing your home for winter in advance, you will save more heat. Many jobs will be much easier to complete, since some types of building materials cannot be used at low temperatures.

Before proceeding directly with insulation, you should wash the windows, frames, window sills and slopes from the inside and outside. This is necessary for high-quality repairs: various materials will not adhere well to dirty surfaces. In addition, washing itself increases the thermal insulation of windows. A clean window allows light to pass through, but has poor permeability to infrared rays, which transmit heat. When dirty, on the contrary, the glass begins to give off heat more strongly.

Tips for insulating plastic windows with your own hands and step-by-step instructions are presented below.

Thermal insulation of slopes on doors

The area around the entrance doors also allows heat to escape to the outside, and if you do not create a barrier, cold air will enter the house without restriction. The process of insulating door slopes is not at all different from the same work around the window. Therefore, everything is done according to the same plan:

- Cleaning the surface of excess polyurethane foam or old decorative coating.

- Application of deep penetration primer.

- Plastering if necessary.

- Primer treatment.

- Installation of insulation - fixation with an adhesive solution and several dowels with a wide head.

- Application of primer to improve adhesion.

- Installation of corner elements.

- Fastening the reinforcing mesh with the same glue.

- Plastering insulation.

- Rubbing the dried layer.

- Decorative facing of the slope.

When is thermal insulation necessary?

The Russian proverb “prepare your sleigh in the summer” is a direct answer to this question. Of course, you need to take care of window insulation in advance, even during the warm season. Although many people prefer to wait until it’s completely hot; As a result, many difficulties arise, especially if the insulation is carried out outside, and it is already very cold outside.

Modern insulation materials often cannot withstand low temperatures. In addition, working in winter with open windows will not add joy to residents.

But this information will help you understand what shutters on windows in a country house might look like.

Insulate plastic windows in advance. If you don't have the basic skills to do it yourself, hire a qualified professional to save you from heat leaks in the future.

Maybe

Exterior works

To more reliably protect the room from heat loss, it is necessary to insulate the window slopes from the outside as well. The best material for these purposes is penoplex. You will also need a special sealant for exterior use. In a private house, you can do the work yourself, but in a multi-story house it is better to use the services of professionals.

The technological sequence of operations is as follows:

- Clean the surfaces of external slopes from dust, dirt, paint residues, finishing and building materials.

- Level with cement mortar and allow the layer to dry.

- Cut the insulation into pieces of the required size.

- Coat the sheets with glue and install them on the slopes. Additionally secure in several places with dowels.

- Mount the corners. Do not neglect this stage. As a result, you will receive not only insulated, but also smooth slopes.

- Treat the front surface of the penoplex with special glue and secure the reinforcing mesh.

- Level with putty.

- After drying, apply water-based paint or other finishing materials.

The issue of slope insulation should not be ignored. The microclimate in the house and the size of the electricity bills depend on how well and timely this is done. Moreover, the whole process can be carried out independently.

How to cover windows with toilet paper. How to glue windows with soap for the winter

We glue windows with soap

Man has always thought about improving living conditions and the comfort of his home. This has always been the case at all times. Strong winds and harsh winters leave little choice, forcing residents to seal their windows and insulate their homes. Of course, at the current stage of development of the construction industry there are many modern technologies for sealing windows and further retaining heat. Also, no one has canceled expensive plastic windows, which can forever solve the issue of saving heat in your apartment.

But not every family can afford to buy modern windows, and they are simply accustomed to gluing windows with soap for the winter the old fashioned way

Or in some other old and proven way, it doesn’t matter. There are a large number of old and quite effective methods for sealing windows that remain relevant to this day.

We will discuss the most famous and widely used, affordable method of sealing windows using strips of paper or fabric and simple laundry soap.

Eliminating shortcomings

The primary task before starting window covering is the following.

There are more convenient pasting methods

It is necessary to carefully examine all potentially dangerous places from where cold air can pass into the room. Determine how you want to insulate your windows. Then you need to purchase materials and available tools, if necessary. One of the simplest and most affordable methods of insulation is to cover windows with soap for the winter. This is the most popular and beloved method that our grandmothers and mothers used in those years when there was no talk of other innovations. The work, in principle, did not require much physical effort and consisted of several stages:

- Carefully seal all detected cracks with rags or cotton wool using a knife;

- cut strips of paper;

- soak the pieces of paper in soapy water and carefully stick them on the window frames.

The main advantage of this method is that the white paper or fabric is not noticeable and does not interfere with the aesthetic appearance of the window.

The soap itself simultaneously serves as an adhesive and sealant, and also does not allow cold or wind to pass through. Also, already cut paper or fabric strips can be used several times without losing the quality of window insulation. The disadvantage of this budget method is that if there is a sharp change in temperature, the paper may peel off. When the warm season approaches, strips of paper or fabric can be easily and without much physical effort peeled off by simply moistening them with warm water. Typically, this very affordable and effective method is used to cover old wooden windows. In addition, instead of cotton wool, you can use other materials that are available on the farm. https://www.youtube.com/watch?v=diWmEA1RPlI

Last few tips

Before the cold weather, every person begins to think about such an important

question: how to save heat and insulate windows? This issue is all the more relevant and acute given the increasing prices for energy resources. It is known that poorly laminated windows do not retain even half the heat. Now there are modern insulating materials that allow you to effectively cover windows and contribute to impressive heat retention. But with such a variety of means, the choice always remains only with the person, which method of insulating windows, modern or old-fashioned, to choose.

Do-it-yourself insulation of slopes of plastic windows

If problems arise with the functionality of the existing structure, dismantling is performed. Preparations for work begin with the choice of insulation. After this, you can begin the operation.

The procedure is performed in several ways.

Method No. 1

If the slope has unevenness or is located at an angle, materials with high elasticity are used. Experts recommend mineral wool.

The technology includes the following actions:

- the remaining foam is cut off and the resulting cut is carefully sealed;

- A guide profile is attached to the edge of the frame. Its task is to fix the installed panels;

- A wooden strip is mounted on the outer edge of the window opening. She secures the panels. If the window opening is smooth, there are no irregularities or protrusions, the rail does not need to be installed;

- the surface is treated with a putty mixture. After drying, you need to go over it with a primer and an antibacterial solution;

- While the surface is drying, it is necessary to prepare the insulation. When using mineral wool, you need to remember to wear protective gloves. This material is hazardous to health;

- a panel is prepared, which fits into the initial profile. Between these elements there is a void into which the insulation is placed. The space is completely filled.

This method is considered the simplest. Users who do not have deep knowledge in the field of construction can cope with it.

Method No. 2

Several materials are used for insulation in a brick house. They will create maximum thermal insulation. Instead of insulation, a combination of mineral wool and foil is used. Finishing is done with three-layer sandwich panels.

The procedure is performed sequentially:

- preparatory work. It is worth eliminating defects and getting rid of cracks. All joints are treated with sealant;

- Profiles for panels are installed around the perimeter of the window. After this, you need to fix the wooden slats. They will serve as a guiding element. Foil with steam and heat insulating properties is applied to the slats;

- The sandwich panel is cut into pieces of the required size. They are superimposed on the main profile;

- free space appears between the slats and the foil. It must be filled with mineral wool.

The final step will be securing the panels. They are pressed tightly against a wooden block and secured with glue or dowels. After performing this operation, the corner is puttied. You need to wait until it dries. Then a plastic corner is mounted on it.

Process

- Clean the surface with a rag;

- We pass with a thin layer of primer;

- We install a profile located closer to the frame and on the outer part of the slope;

- We seal the seams between the frame and the wall with foam;

- We measure and cut foam sheets of the required size;

- Apply glue to polystyrene foam or mounting foam on the wall;

We wrote separately about whether it is worth attaching polystyrene foam to polyurethane foam.

- Carefully apply the foam sheet to the wall;

- We foam the seams on the inside of the profile.

This procedure will make it possible to avoid cold bridges, which will become the self-tapping screws screwed into the profile.

- Apply a layer of primer to cover small seams between the profile and the foam;

- Using self-tapping screws, we attach pre-cut sheets of drywall to the profiles.

The insulation of slopes with foam plastic can be considered complete. We move to the street.

How to insulate the window sill of a plastic window

Under the windowsill you can often feel the movement of cold air. If a crack is visible, it needs to be foamed. It will be good if you attach a piece of plastic under it and fill the void inside with polyurethane foam or polystyrene foam. Stages for insulating a window sill:

- Remove the window sill.

- The wall on which it was located should be thoroughly cleaned of dirt and dust, after which all cracks and problem areas will be visible.

- Cracks can be closed with polyurethane foam.

- When the foam hardens, cut off the excess with a knife.

- Prime the entire surface.

- Apply sealant to all joints and corners.

- Plaster.

- Place the window sill in place.

Useful tips

Knowledge of some of the subtleties that experts share will allow you to do the insulation of the slopes of plastic windows with your own hands more efficiently. As a result, the windows will not be damaged by the environment and will last a long time.

It is worth considering these recommendations:

- Polystyrene foam tends to expand in heat. When attaching it, it is not recommended to use a large amount of glue. Otherwise, it will quickly crack and lose its thermal insulation capabilities.

- To extend the service life of the insulation, outdoor work should be carried out only in dry times and in warm weather.

- The use of thermal liners will significantly improve heat retention in the room and protect against moisture penetration.

- When installing insulation on slopes, it is recommended to treat all wide cracks and joints with silicone sealant.

Internal insulation of windows

The process of how to insulate windows with your own hands also includes the interior finishing of some components. These include:

- internal slopes;

- insulation;

- windowsill.

Insulation will require special patience and care.

Internal slopes

The process of how to insulate the slopes of plastic windows from the inside is very similar to what was described above. Internal slopes require careful processing to achieve a pleasant appearance. It must match the chosen interior. The first step is to cut off the protruding foam, and also add it in those places where cracks have formed. The old finishing that was near the old windows is completely removed. The surface of the slopes is treated with a deep penetration primer and left until completely dry. The next step is to install drywall, plastic panels or putty and plaster.

Note! After finishing, the slopes can be painted using water-based paint or finished with decorative plaster, which is better than using plastic panels.

Windowsill

The window sill is an integral part of the window. For plastic windows, PVC window sills are used, which can be of various sizes and designs. But the correct installation must unite them. First of all, you need to find out where the heat loss is going. The gap can be between the window and the window sill, as well as the window sill and the concrete part. In the first case, it is necessary to seal the gap with sealant. For a white profile, you can purchase white sealant, and for other colors, transparent is perfect if the required color is not available.

If it blows from under the window sill, then certain mistakes were made during its installation. In cases where complete dismantling of the window sill is impossible, there is an option using foam to try to blow out problem areas. After the procedure, it is advisable to place something heavy on the windowsill so that the foam does not deform it and lift it up. If you have the opportunity to remove the window sill, you can additionally foam the junction of the window and the wall. A small layer of insulation is also placed under the window sill.

Advice! Insulation can be done using a special film. The process of such insulation is shown in the video below.

Insulation

In some cases, it may be necessary to replace the insulation on the window sash and frame. In plastic windows, replacing insulation is a simple matter. The use of adhesives is not required here. The rubber base is fixed in special grooves that are located on the plastic profile. The old insulation is disposed of. To make it easier to insert the insulation into the grooves of the sash or frame, it can be slightly moistened with soapy water. It is worth remembering that it must be laid in one contour. To do this, it is important to measure everything correctly and make a small reserve. It is better to opt for black insulation, which is also made of PVC. Insulation materials painted in a different color have a less durable structure, which leads to their rapid wear. In some cases, it is necessary to replace the rubber seal that holds the glass unit in place. To do this, you need to remove the retaining strips and the glass unit itself. The junction points are cleaned of dust and other dirt, after which the insulation is installed and the glass unit is installed.

Advice! Before replacing the insulation on the window, you need to try to adjust it or switch it to winter mode. The illustration below shows how this can be done.

Expert recommendations

The insulation procedure is characterized by its peculiarities. Knowing the subtleties, you can avoid many problems. To ensure the highest quality work, adhere to the following rules:

- If there is no insulation of the required size, you can use separate pieces. They are placed tightly to each other.

- Ideal adhesion can be achieved through a combination of glue and reinforcing mesh.

- Preparatory work includes getting rid of cracks and defects. If the hole is larger than 3 mm, sealant must be used.

- Of all insulation materials, extruded polystyrene foam has the maximum thermal insulation function. This will be a plus when performing outdoor work.

- You need to choose thermal insulation based on the dimensions of the gaps. If the free space exceeds 4 cm, use polystyrene foam or polystyrene foam. If the gap is 2-3 cm - fiberglass, less than 2 cm - polyurethane foam, mineral wool.

You cannot take foam with a density of less than 30 kg/cubic meter. m. If you prefer mineral wool, the density should exceed 75 kg/cu.m. m. Otherwise, the insulation will not withstand the load and will quickly become unusable.

Sources

- https://domsdelat.ru/okna_i_dveri/uteplenie-okon-snaruzhi-svoimi-rukami-prichiny-poteri-tepla-metody-utepleniya-otlivov-i-otkosov-instrukciya.html

- https://ebtim.com/montazh/uteplenie-otkosov-okon-snaruzhi.html

- https://balkon4life.ru/osteklenie/okna/tyoplye-otkosy/.html

- https://1pofasadu.ru/uteplenie/otkosov-snaruzhi-svoimi-rukami.html

- https://uteplix.com/obyekty/okna/uteplenie-otkosov.html

- https://okna-dom.net/utepleniye-otkosov-plastikovykh-okon/

- https://vdome.club/remont/okna-dveri/teplye-otkosy-dlya-plastikovyh-okon-kak-sdelat-svoimi-rukami.html

Insulation of metal-plastic windows

Before insulating metal-plastic windows, you should carefully study the cause of the leakage and try to eliminate the problem. Any plastic window is a combination of important elements: PVC profile, double-glazed windows, fittings and seals. The slopes act as the frame of this window block. The problem may lie in each of the listed components, which can cause drafts and heat loss.

Insulation of slopes

The reason for window leaks is often incorrect and poor-quality finishing of the slopes. You should insulate double-glazed windows when you feel a slight chill that seeps from the cracks between the frame and the window slope.

Experts recommend that if plastic windows are installed in a new building, they should be dismantled followed by high-quality installation, since during operation the house may shrink or the installation of double-glazed windows was carried out with violations of technology. If the problems are minor and dismantling was avoided, then insulation should be done in any case.

A wide variety of materials can serve as insulation: plasterboard insulation boards, mineral wool, polyurethane foam, construction foam, basalt fiber, silicone. The technology is simple - the insulation is fixed to the surface of the opening, which covers the installation seam and part of the window frame. Drywall is installed on top of the insulation, which is treated with putty. The use of extruded polystyrene foam makes it possible to do without drywall. Insulation sheets are processed using plaster mesh, sand-cement mixture and finishing putty.

Adjusting glass unit fittings

During operation, walls and windows undergo shrinkage, which leads to a slight, but important for tightness, misalignment of the sashes. Unadjusted fittings affect the operation of the sashes, and their adjustment will affect the efficiency of double-glazed windows

The density of the sash is adjusted using eccentrics, which are responsible for the tightness of the sash. Rotating the eccentric clockwise will provide tighter pressure, which in turn will reduce the penetration of cold air. The eccentric is provided with a mark that can be directed towards the street, which indicates a weakened clamp, or towards the seal, indicating optimal clamping to the frame.

There is also the opportunity to learn how to insulate a plastic window using a clamping mechanism located on the hinge side. A hexagon is used for adjustment. If the tongue of the clamping mechanism is extended, then the window is pressed firmly against the frame. Pressure adjustment occurs when the hexagon is rotated counterclockwise for a window with hinges on the left, and clockwise with hinges on the right.

If the tongue located on the sash is pushed in strongly, this means that the sash is pressed tightly against the frame. Rotating the hexagon counterclockwise (with the hinges on the right) will allow the tongue to extend.

Replacing the seal

Insulating plastic windows by replacing the seal is an effective and expedient method, since this preventive action will increase the performance characteristics of window structures. Condensation, ice, draft - all these are indicators of wear on the seal.

Experience shows that before insulating metal-plastic windows, it is necessary to decide on the type of sealant and its composition. A rubber band with a tubular or shaped cross-section must reliably withstand humidity, heat, frost, and chemical attack. This task is best accomplished with synthetic rubber, which is characterized by exceptional wear resistance and can guarantee 10 to 15 years of service.

https://youtube.com/watch?v=ggx3YTcZqUo

To replace the seal, you will need rubber scissors, glue, and a solid sealing cord. At the initial stage, it is necessary to remove the worn-out rubber cord; usually it can be removed easily, without much effort. The profile grooves should be thoroughly cleaned from dirt with a soft cloth. Lubricate the corner areas of the frame with glue to securely attach the seal. Carefully insert a new seal into the grooves, where it is imperative to use a single piece for the entire opening. The compactor is laid without tension or compression. The corner joint of the system is filled with glue, and the remaining rubber cord is cut off with scissors.

It is worth remembering that insulating metal-plastic windows is a complex procedure, which, if performed correctly and carefully, will certainly lead to the desired results.

Causes of drafts

You should also have basic information about the causes of drafts. Having basic knowledge, you can avoid such unpleasant situations in the future.

- Making mistakes during window installation. One of the most common problems associated with the low qualifications of the installer. If a draft occurs immediately after installation, then you need to contact this installation company again and demand that the defects be corrected. If you install plastic windows yourself, you need to check the correct installation and correct any errors.

- Shrinkage of the soil under the house and, as a result, skewing of windows. A rare problem that occurs among residents of new houses.

- Poor quality materials and manufacturing defects. An attempt to save on the price of double-glazed windows can cause poor window sealing, but even owners of expensive windows are not insured against defective parts. If the terms of purchase allow, take advantage of the opportunity to return the entire set or only the defective parts.

- Physical wear and tear on the locking parts of the window and seal. A very common problem for window owners who have been using them for a long time without replacing them.

- Violation of the rules of use and care. Over time, the sealant may lose its properties. To prevent this from happening prematurely, it is necessary to wash it and treat it with emollients. For example, glycerin.

If you evaluate in detail all the causes of drafts and heat leaks, you can divide them into two categories based on the possibility of eliminating them - with the help of window installation specialists and solving problems yourself.

It is best to use the services of professionals to solve the following problems:

- If problems with the window are identified during the warranty period. At this time, the installer company bears full responsibility for its operation. Independent intervention in the design features may result in denial of further warranty service.

- External work at height is required. In such conditions, the likelihood of injury greatly increases, and it is better to entrust such work to professional workers.

- Detection of manufacturing defects during the warranty period.

- Replacement of some structural parts, requiring certain tools and skills to work with them.

If the work is done from the inside, then most of it can be done independently.

Tools and consumables

Depending on the type of insulation chosen, the following materials and consumables may be required :

- drill or hammer drill;

- Master OK;

- putty knife;

- chisel;

- hammer;

- self-tapping screws;

- mushroom dowels;

- thermal insulation adhesive;

- silicone sealant;

- construction knife;

- roulette;

- marker;

- building level;

- vapor barrier film;

- sandpaper;

- concrete solution;

- plaster;

- antiseptics;

- individual protection means;

- construction tape;

- fiberglass reinforcing mesh;

- plastic (PVC) corners and plugs.

How to change the seal

Special rubber bands are used as a seal on plastic double-glazed windows, improving sound and thermal insulation. They are available in different quality on sale. Rubber bands marked EPDM optimally combine affordable price and good quality, which is why they are most often purchased. Products with the VMQ brand are of high quality, but are too expensive. There is no need to buy TPE sealant, as it quickly deteriorates when exposed to weather.

Important!

There is also a seal with an adhesive layer on sale, which is attached to the window using the principle of adhesive tape. It is not a complete replacement for a conventional seal, so it is not advisable to buy it.

Seal replacement procedure:

- The seal that has served its useful life is removed by prying it by the middle. The freed space in the grooves is thoroughly washed with laundry soap or other detergent. Then thoroughly dry and degrease with alcohol.

- To make the fit tighter, the corners of the profile are glued with construction adhesive, PVA or silicone. After applying the composition, wait until it dries completely.

- After this, the rubber seal is prepared for installation. If material marked EPDM is used, it is measured along the length of the perimeter of the opening, since it bends easily. The remaining materials are cut to the length of the side of the opening with a small margin.

- Then the elastic is inserted into the grooves, being careful not to deform the material. It is more convenient to do this operation together using improvised tools.

To extend its service life, the rubber band should be washed and coated with silicone grease several times a year. After five years of operation, the seal is replaced with a new one.

When is it necessary?

Most often, insulation of PVC windows may be required when :

- During installation of the frame, uncovered gaps or unclosed mounting foam formed between it and the opening. If it is not insulated, it will begin to absorb moisture or dry out.

- It is necessary to protect the window frame from external influences at the joints with the opening so that water does not get into them, and also to avoid the formation of blow-out spots or cold bridges. Also, temperature changes at fastening points can lead to their destruction and subsidence of the frame.

- After the window shrinks, empty spaces appear through which the cold will pass.

- It is necessary to shift the dew point so that condensation does not form on the window, which causes dampness, mold or mildew to appear.

- It is necessary to improve the appearance of the window opening from the outside.

It is always recommended to do insulation, as this greatly reduces heat loss, but in some cases this procedure is difficult to carry out or it is not necessary :

- In wooden houses, insulation of slopes is most often carried out using wooden panels that cover the seams, since the use of insulation can negatively affect the window opening.

- If the quarter is made of brick (a special protrusion that covers the top and sides of the opening from moisture), then insulating the slope may be difficult or simply not necessary.

- If the joints are plastered and there is no heat loss, then treating the slopes from the outside can lead to the opposite effect, that is, the room will be too hot, and the dew point will also shift, which will cause mold to appear.

Cover with film

If you have done all possible types of work, but the room is still cold, you will have to use an extreme method - cover the window with film. Yes, it's ugly. But it’s better not very beautiful, but warm. This method is usually used for windows facing the backyard. We take a thick transparent plastic film, stretch it from the outside onto the window, securing it with strips from the street. Not the most aesthetically pleasing window insulation, but effective.

Ugly? But it's warm...

Why does this method work? Because an additional insulating layer of air is created between the film and the outer glass. This is the first point. The second is this. Since the film is usually nailed to the walls, it turns out that cold air does not penetrate to the frame.

Energy saving film

The same effect - an additional insulating layer - also works in the case of the recently advertised insulation of window glass using film. As you know, any room loses heat through walls, windows, roof, floor. Windows account for up to 40% of heat loss. Previously, this problem was solved by installing additional winter frames. Heat-saving film is essentially a modern substitute for such a frame. Thin double-sided tape is attached to the window frame, and a film is glued to the tape. How smooth is not the point. It needs to be heated with a hairdryer (a regular one, not a hair dryer), after which it will level out and be unnoticeable.

Special energy-saving films are sold

This simple method allows you to raise the room temperature by several degrees. The same film will prevent overheating in the summer - prevent the sun's rays from passing through the glass. The only disadvantage of this method is the inhumane price. A square meter of film costs from 350 rubles, plus you will need double-sided tape.

Is this energy efficient film different from regular film? It's hard to say until comparative tests have been carried out. Will anything change if you cover the window with regular plastic film? Hardly. The advantage of this film is that it is crystal transparent and, after heating, is invisible on the window. So this is a relatively inexpensive and easy way to raise the temperature in the room without ruining the view from the window.

Cheaper way

Almost the same effect can be achieved if you stick packaging film with air bubbles on the inside of the glass. Of course, using this film we lose transparency, but the price is not so high. The film is generally very easy to install. We moisten a piece of film cut to the size of the glass with water (from a spray bottle). Water is applied to the smooth side. We spray it on the glass. We lay the film, align it, press it, straighten it with our hands. That's it, the film is glued.

You can do it easier - stick bubble wrap on the inside of the glass

It can last for months. It can be removed without any problems - they pulled the edge and it all came off. The same piece can be used for several years, since nothing happens to it. This is a simple method that makes insulating wooden windows more effective.