Doors are a significant piece of furniture that performs not only a practical, but also a decorative function. That is why the combination of aesthetics and high performance is so important in these products. At the moment there is a wide variety of types of doors. They differ in composition, production technology and, as a result, durability.

In this article we will compare fairly popular products made using veneer and laminated film. Let's find out which is better: laminated or veneered doors?

What is better to choose: veneered or laminated doors

If you have to renovate your home, then you will have to change the doors accordingly.

Of course, finding a suitable product is not difficult, since the market can offer a wide selection of products in this segment. However, it is necessary to rely not only on the appearance of the product and compatibility with the basic design of the room, but also on the list of technical characteristics. The photo shows the most popular types - veneered and laminated specimens. Therefore, you first need to figure out which doors are better.

Comparative analysis of coatings. Reviews

Judging by the reviews, buyers prefer veneer or PVC construction. Moreover, the choice in favor of these options is made due to their strength, texture and appearance. As practitioners say: “the main thing is that the door does not look like a cardboard box covered with film.” There are different comments about lamination. Apparently, a lot depends on the manufacturer.

It is better to invite a professional installer to install the doors.

Attention! When selecting a door, experts advise paying attention to the components and inviting a professional installer. An excellent copy can be ruined by illiterate installation.

If we classify the doors we examined according to wear resistance, then the veneered structure will be in first place, PVC in second, laminate in third, and the last place will be occupied by the laminated version.

If you are choosing interior doors for a cottage or apartment, veneered panels will add charm and nobility to the interior. For an office, a rational option would be a door lined with PVC film.

Design differences

Laminated door in the nursery

Laminated door design

Let's start with laminated products. Judging by the name, it becomes obvious that laminate is used as the basis for production. It is not difficult to choose such a door to match the color of the interior, because the varnish used for painting has a sufficient number of color options.

Laminate is produced using high-quality materials and innovative technologies, so it is no worse than natural wood, and its service life is much longer. This is evidenced by reviews from customers who chose laminate products. Laminate structure:

As for veneer, this material is thin sheets of wood. When veneer is used in the production process, it is treated with special compounds, which will subsequently provide the product with moisture resistance. In the photo you can see how close the veneer is in appearance and texture to natural wood. A variety of colors will allow you to choose the right tone without any problems.

Advantages of laminated structures:

Flaws

Disadvantages of veneer

These are the main advantages and disadvantages of both types of products. So what will be the answer to the question - laminated or veneered doors: which is better? Oddly enough, there is no clear opinion. Veneered products are more suitable for connoisseurs of individuality, as well as adherents of natural materials. As for laminate, doors made using it will delight the owner with their ease of maintenance.

However, for those who want to save money, it is better to take a closer look at laminate, because the cost of a product made from this material is almost half that of its competitor.

But at a higher price, veneer doors can be easily restored if necessary, so the product will maintain a respectable appearance longer. But the damage that has occurred to the edge of the laminated door, alas, cannot be hidden.

Finally, laminate doors are similar to each other, which cannot be said about veneered products. Reviews about each of these materials are quite contradictory and depend not so much on technical characteristics as on the personal preferences of buyers.

Whatever you choose, be it veneered or laminated doors, the product, first of all, should please you and fit not only the interior, but also the size of your budget. When planning to make a purchase, take the time to consult with a professional to be confident in your choice.

Source

Doors with which finish is better: veneered, laminated or with PVC film

To determine which doors are better: veneered, laminated or PVC, we will compare these finishing materials according to a number of parameters. Each coating has its positive and negative sides. Even the most expensive coating is not without its drawbacks. In addition, in the kitchen, bathroom or living room, the requirements for doors are somewhat different. Also an important factor will be the budget that you can count on when planning such a purchase. The choice of these door finishing materials for comparison is due to their greatest popularity among consumers.

What is each type of door finish?

The main task facing any production is to reduce the cost of products while maintaining quality. Since the manufacture of doors often uses materials different from the original ones (if previously they were made from solid wood, now this is rather considered a luxury), the standards themselves have changed. It is clear that there cannot be a clear solution, for example, which is better - PVC doors or veneer, each coating has its own characteristics. First, consider each material and its constituent elements.

Veneered doors

Externally, doors made of this material are closest to classic solid wood structures - these models have the same surface pattern, similar performance properties, but their cost is much lower. This is explained by structural features, because veneer is a thin slice of wood, 0.2 to 5 mm thick, and it is glued to the outer part of the door surface.

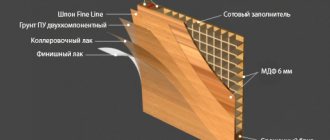

The interior is made either from solid wood of a less expensive type of wood, or from chipboard and MDF. Another option is a frame made of pine bars, the cavities in which are filled with cardboard honeycomb filler and sheathed with MDF sheets. This design has much less weight than solid wood models, but it is somewhat less durable.

The veneer layer is glued to the finished frame using vacuum hot pressing, which ensures the strength and durability of the fastening. For maximum preservation of appearance, finished doors are varnished - this emphasizes the grain of the wood and protects the veneer layer from ultraviolet radiation and mechanical influences.

As a result, veneered doors do not differ in appearance from those made from solid wood - to a non-professional, they will only be given away by the lower weight of the structure, but for interior models this is rather an advantage. Since such doors are made from various artificial materials, they are less sensitive to temperature changes, and the low cost compared to solid wood models makes this option one of the best purchasing solutions.

The general disadvantage of such door panels is inherent in all wooden models - without special treatment it is better not to install them in wet rooms. Also, it is better not to place veneered doors in a place where direct sunlight falls - despite the protective varnish, they can darken over time.

Laminated doors

This is one of the most economical options. Structurally, they consist of a wooden frame, lined with MDF panels, on which a laminated coating with the desired pattern or color is applied. The outside surface is covered with a protective layer. The internal cavities of the frame are filled with various fillers - mainly cardboard honeycombs, but chipboard and MDF can also be used.

The main advantage of such a door is its low cost and stable color - laminate manufacturing technology allows you to get the same color even in products from different batches.

The laminate is resistant to moisture, and the stacked door frame ensures no deformation due to temperature changes. Such models are lightweight, so they can be used for installation in any interior partitions.

Doors covered with eco-veneer

Eco-veneer is called environmentally friendly for the reason that it is chemically inert and does not contain chlorides - this is one of the criteria that can be used when deciding which is better - PVC doors or eco-veneer. In any case, there is nothing in common between “eco” and natural veneer except the surface texture. Some sellers take advantage of the external similarity and present eco-veneer as “the same veneer, only better,” arguing that it is not afraid of moisture.

In fact, only the internal parts of the frame are identical, and the outer covering is made of different materials. This does not mean the poor quality of such a coating - quite the contrary - this is a new word in the manufacture of doors, it’s just that if for some reason you need a completely natural wooden covering, then ekopchon will not work in this case.

Doors covered with PVC film

Unlike classic plastic doors, which are made entirely of PVC profiles, these models have a traditional wooden frame, which is coated with polyvinyl chloride.

The film application technology involves the use of special chambers into which the frame of the door leaf coated with synthetic glue is placed. A film is applied on top of the surface, which is then baked at high temperature - a diffusion process occurs, as a result of which the PVC becomes part of the surface of the door. This technology allows you to obtain matte or shiny surfaces of any color and texture.

PVC film can be applied to a frame made of solid wood, which is made from a single piece of wood or beams glued together. In this case, the solid wood is taken from inexpensive, usually coniferous, wood species.

The second option is doors in which the frame is made of beams. The voids are filled with cardboard honeycomb filler, and the top is covered with MDF panels, onto which PVC film is applied.

When choosing between veneered, laminated, eco-veneer or PVC film-coated doors, you need to take into account a large number of factors. Which ones to pay attention to first, and which ones can be ignored, depends on where and by whom such doors will be used.

Coating technology

Let's look at how such doors are made. Veneered doors consist of an MDF base and a wooden frame. A coating is applied on top that imitates solid wood, that is, veneer. To ensure that it is securely attached to the surface, special adhesives are used. To remove the slightest air bubbles, the workpiece is placed in a heat chamber, where the gluing process itself takes place under pressure at high temperatures.

Schematic cross-sectional representation of a veneered door

Laminated models are finished solely under the influence of temperature. In order to process the raised protrusions, you need to warm up the material well and press it under pressure against the door onto the adhesive base.

In both cases, the ends of the doors are covered by an edge. This can be a base material or a plastic strip. In order to understand which is better, it is important to check the quality of the edge gluing. It is also fixed using high temperature due to the presence of an adhesive base on the back side.

To protect the decorative coating, varnish is applied on top. Laminated models often have a similar treatment in advance. Veneer can be processed both in advance and on the finished product.

Door lamination occurs under the influence of temperature

Environmental friendliness

Practice shows that when deciding which interior doors to choose - laminated or veneered, PVC or eco-veneer, buyers do not pay as much attention to the issue of environmental friendliness as is commonly believed. But we will consider these questions.

Veneer . It is presented as an environmentally friendly and harmless material that can breathe. Some marketers add a third point here: the use of veneer reduces wood consumption. Questions arise immediately on all of the above points. Firstly, who will guarantee that varnish or glue was used during production, which will not emit fumes in the future. Secondly, a surface coated with varnish (and veneer is always coated with varnish) cannot possibly be breathable. Thirdly, we must understand that it is not the consumption of wood that is decreasing, but the amount of wood waste that is now used for production.

Laminate . Essentially, this is paper coated with a protective coating - if it is of high quality and not subject to fumes, then such a door will not be harmful to health.

Eco-veneer . According to the manufacturers, the material does not emit any fumes into the air, and accordingly, it will not release them to the outside if they begin to appear from the glue on the frame. It is difficult to say about the consumption of wood here, because its fibers are used in production.

PVC film . One of the components of this material is chloride, which is slowly but surely released into the air. The question remains whether this happens during the entire service life or for a certain time, but judging by the conclusion of the commissions on permission to use this material and the number of installed plastic windows and doors, basically this point remains without due attention. It is much more often mentioned that PVC is a completely artificial material, and wood is not used in its production.

In terms of environmental friendliness, veneer wins by a slight margin, but doors covered with eco-veneer and laminate with a high-quality coating are unlikely to be inferior to it. Here you also need to pay attention to what content the door leaf itself has. The best option in terms of environmental friendliness would be doors whose frame is made from an array of low-value species covered with veneer. If you choose between a frame made of chipboard and MDF, then the best option would be MDF, since it is a more environmentally friendly material.

How to choose eco-veneer doors - let's look at specific examples

Interior doors made of eco-veneer can be called leaders in the price segment up to 7,000 rubles. To prove this, let's look at what is in opposition:

- Natural veneer : undoubtedly, synthetics (in our case, semi-synthetics) will never be able to compete with natural material, and in this regard, natural veneer wins, but the price of such doors begins where the cost of eco-veneer models ends. It turns out that most of the natural veneered products remain “behind the scenes”;

- PVC : they have absolutely equal cost indicators. They are on the same level in terms of design options and types of structures. The difference lies in the characteristics of the finishing material: PVC is pure synthetics with a very controversial opinion regarding safety. Eco-veneer – half synthetic. The base is the same wood, albeit in the form of waste, plus a gluing polymer and a more gentle technology for gluing MDF;

- Laminated : with equal price indicators, they lag significantly behind in strength and design options;

- Inexpensive solid wood : in fact, the basis of eco-veneer doors is already solid pine. If it makes sense to compare eco-veneer models, it is only with pine products without a top coating: the former have much more possibilities for use, and the scope of application of the latter is often limited to country interiors, cottages, baths and saunas. At least in modern city apartments, pine is not installed without finishing. Other types of solid wood produce doors that cost more than 7,000 rubles, which means they do not fit into the comparison parameters we have established.

So, interior doors made of eco-veneer are truly leaders in the sector of inexpensive doors. Let's look at what they look like, what interiors they are suitable for, and what styles they go with.

Panel boards with a flat surface are the simplest and most inexpensive option

Their peculiarity lies precisely in the absence of those very features. Yes, yes, and such paintings have a right to exist - well, not everyone can be aesthetes and strive for sophistication - some lead a rather ascetic lifestyle and reject everything that is devoid of functionality.

The beauty of the panel door is in the texture of the eco-veneer. We have already said that with its help it is possible to recreate the structure of any tree, and it cannot look mediocre. The option is suitable for interiors in the style of modern classics, minimalism, partly loft, modern. These can be installed in any room by choosing the appropriate color. Perhaps you should abandon them in the hallway, since there is always not enough light here and doors with glass would be a more acceptable option.

Well, the commercial sphere includes offices, administrative buildings, doctors’ offices in clinics, various institutions and other buildings where practicality and low price are encouraged.

How to choose? These tips are universal and apply to all types of doors. Please pay attention to the following criteria:

- On style in the interior;

- On the colors in the room: usually doors are matched to the floor, baseboards, furniture, and accessories. Since our version does not have decorative elements, look for a match in color and texture;

- For fittings: metal handles will seem completely bad taste if furniture handles and picture frames are covered with gold plating or made to look like bronze.

Smooth with the addition of metal moldings

Such designs express the same rigor, but with a small addition. On the surface of the canvas there are thin metal moldings. They can be positioned vertically and horizontally. Common options:

- Dividing the canvas into several segments of the same width;

- Two horizontal moldings in the center. Two parallel lines at handle level;

- One vertical molding - from bottom to top, separating the first third of the canvas;

- One horizontal molding that serves as an extension of the door handle.

The colors of the moldings are matched to the color of the eco-veneer: metal inserts look good on dark and light surfaces. Golden decor is more suitable for canvases in brown-red-red colors. Their severity is appropriate in classic, Scandinavian interiors. In rooms in Provence and country style, they can also be used if the coating material has a strong woody pattern and is presented in a light palette of colors, for example, bleached oak.

Flat with flush-glued glass

All the following models already have a broader artistic meaning. Doors coated with eco-veneer often use glass, and different installation methods are used. Glass glued flush looks beautiful. This means that the glass surface and the MDF side panels are on the same level.

The model also comes in a wide range of colors. You can achieve the maximum design effect by choosing glass of a suitable color. White, pastel, brown doors are combined with light and black glass. To make a black door look spectacular, use a dark insert framed by light moldings, which give the structure a strict outline. Glass can be installed in a completely unexpected way - horizontally, vertically, on a large surface of the canvas, in the form of a narrow strip, one or several small inserts.

For interiors: classic, office. Match the color of the glass to other glass surfaces in the room.

Flat with aluminum edge

Externally, these are the same panel doors, models with moldings and flush glass, but they have one feature - the end part, which is adjacent to the frame and remains invisible, is made of aluminum. The structures benefit from strength because they are not afraid of strong impacts and abrasion during long-term use.

Models with aluminum ends, as a rule, last 5 years longer, especially if they are supplied in a factory version with hidden hinges. The fact that this is a new trend in the production of interior doors is evidenced by the improved design of the panels, which are covered with eco-veneer with vertical or horizontal arrangement of wood fibers, and the pattern is expressed so clearly that it has a 3D volumetric effect.

Such a door can be purchased in all the previously listed options - solid, with modlings, glass. Suitable for modern classic interiors, minimalism, modernism.

Moldings

Consist of two parts:

- Moldings – side load-bearing elements made of inexpensive solid wood and MDF;

- Inner glass insert.

They come with regular wooden or aluminum edges. The description of doors with flush glass insert fits these models. Doors with a large glazing area have a high light transmittance, so they are an acceptable option for installation in rooms where there are no windows - this is access to the ground floor, hallway, hall, bathroom.

Tsargovye - the most common models made of eco-veneer

Don't be fooled by the strange name of the design. You have, of course, already encountered such models many times. Externally, they are a frame with several vertical or horizontal inserts (tsargs). This creates a beautiful frame frame. The design, although elegant in appearance, actually has high rigidity, because the thickness of the inserts is greater than that of the panels. Strength is also ensured by their large number in a relatively small area.

By changing the size, location, colors of inserts, as well as using additional glass and moldings, you can get a huge number of interior door designs, for example:

- With cross inserts

- With vertical inserts

- With a combination of transverse and vertical inserts

- Imitation of classic paneled structures

- Glass and MDF inserts

Of course, in the category of side doors you can find absolutely any solution for use in modern and classic styles, for choosing a color in unison with the floor, furniture facades. With their help, you can regulate the amount of natural light, if you choose models with glass, or try to create a strict style of the study, if you take imitation panels and eco-veneer for oak, ash, wenge, mahogany.

All that remains is to learn how to choose the right fittings and opening method, we will talk about this further.

Strength and wear resistance

This is one of the main parameters that determines the service life of doors. Typically, manufacturers try to improve this indicator by introducing new technologies.

Veneer . The main protection for such doors is provided by a layer of varnish that covers them, but in any case, scratches and dents that may appear are quite difficult to repair or disguise.

Laminate . Originally designed as a floor covering, it is durable enough to resist cuts and dents. But inexpensive doors often use a material with a thin protective layer, which can be susceptible to abrasion.

Eco-veneer . Since it is created on the basis of polymer materials, the wear resistance of the surface treated with it is at a high level - it does not crack, is not susceptible to chipping or deformation. While natural veneer can change its appearance over time, eco-veneer will retain its original appearance for two to three decades. Unlike products made from natural wood, eco-veneer is not susceptible to cracking and fading from ultraviolet radiation.

PVC film . According to the technology, this material is literally baked on the surface, creating a durable coating. But when exposed to sharp objects, the film can easily be damaged. Subsequently, it may lag behind the base.

If you do not take into account the quality of the materials used, eco-veneer and laminate are clearly the leaders in this category.

What is important to know when purchasing

Good manufacturers of laminated doors take the final quality of their products very seriously. As a rule, they are produced on European equipment that meets all requirements, and only high-quality materials are used.

Despite all this, the buyer may still be faced with a low-quality, bad door. In order for the consumer to avoid such an unpleasant situation, he should know what he must obtain information about when purchasing.

So:

First, the buyer needs to find out what the door is covered with. A lot depends on the quality of the coating.

The only good thing about doors with this coating is their extremely low price. When showrooms offer customers the opportunity to purchase an unusually cheap interior door, they should expect it to have just such a coating, which means it makes no sense to demand special durability from it. Everything discussed in this article about laminate film refers to a coating called dual-chrome laminate. This polymer film is particularly durable, does not change color and is not scratched.

We advise you to study - How to accept an apartment in a new building and protect your interests

The doors are covered with it using a special technology, and therefore the film sticks securely and does not peel off over time. The most expensive and, very importantly, strong and durable material for covering doors is continuous pressing laminate or CPL plastic. This coating for laminating doors is particularly durable and wear-resistant. It is precisely because of this quality that doors with such a durable coating can be used in public places where their use is very far from gentle.

First of all, before purchasing, it is important to decide on the design. After all, it can be quite different. Look at the photo and choose

The instructions on the door should also be studied.

Pay attention to what humidity they can tolerate and how reliable it is. After that you can make a choice

Response to humidity and climate change

Here it is necessary to take into account not only the finishing, but also what the door frame is made of - an array of glued blocks of wood or chipboard and MDF. In the first case, the influence of humidity and temperature will be much more noticeable.

Veneer . In any case, it is not recommended to install such doors in rooms with high humidity. If the frame is made of solid wood, it will be susceptible to temperature changes.

Laminate . It tolerates moisture well, but if the outer layer is damaged it will begin to deteriorate.

Eco-veneer . The material is not susceptible to moisture and temperature changes. Such doors are recommended to be installed in the bathroom and toilet.

PVC film . Plastic does not absorb liquid at all and is not subject to deformation under the influence of temperature, so it can be installed not only in damp, but also in technical, unheated rooms. Under conditions of variable humidity and temperature, such doors will retain their shape unchanged.

In terms of this parameter, artificial materials win, and there is no particularly noticeable difference between them.

Which interior doors are more suitable for a bathroom?

The bathroom is a place of high humidity. If the room is small and the sink is installed close to the entrance, then the door bears a double load - from highly humidified air and water reaching the structure in a drip form.

Door coated with eco-veneer installed in the bathroom

2 relevant questions:

- How important is it to take this feature into account when choosing a door?

- Which interior doors are better for the bathroom because they are more resistant to moisture?

It is always worth remembering about high humidity and its ability to “kill” a structure in a short time, as long as there are manufacturers who like to save money, ignore the requirements of technology and put on sale, for example, paneled structures with a flat (not wrapped) edge. By thus creating “moisture bridges” on the door, the manufacturer minimized the moisture resistance of the product.

If we talk about doors of very high quality, then all are endowed with moisture resistance: PVC and eco-veneer - due to their polymer nature, and natural solid wood and veneer - thanks to a multi-layer varnish coating.

So, which doors are best to install in the bathroom:

- Material – PVC, eco-veneer, fine-line in excellent technological performance. Veneer and solid wood are acceptable if covered with high-quality varnish or enamel;

- Design – any, with wrapped edges;

- The design is suitable for the interior, similar to other doors opening into the room (bedroom, corridor).

To summarize the above, the choice of an interior door depends 90 percent on the operating conditions, and it leaves an imprint on the choice of material. The raw material from which the door is made is a direct indication for installing the door in a damp bathroom, luxurious living room, noisy children's room or quiet bedroom. Material plus design is already aesthetics and style, and if you add decor (reliefs, carvings, patina, brushing, etc.) to the two main indicators, then this is aesthetics, style and art - in a single bundle. In a high-end product, all criteria are implemented at the highest level - let's strive for this!

If you still have questions after reading, the specialists of the online store of interior doors “Into the House” are waiting for your requests!

These articles may also be of interest to you:

- What are drawer interior doors?

- Which interior doors to choose?

- Interior, decorative partitions and doors

- How can you protect the dressing room in the house?

Practicality and complexity of care

Veneer . Wooden doors often require special care, since chemically active cleaning agents are contraindicated for them. As a result, it is better not to install them in places with a lot of people traffic.

Laminate . They tolerate wet cleaning well, but since the laminate layer is usually quite thin, it is better not to use abrasive substances when cleaning it.

Eco-veneer . Manufacturers do not impose any restrictions on care products for doors covered with eco-veneer, but you should remember that they have a textured surface, so you should not use very rough cleaning products. They also tolerate the effects of detergents well.

PVC film . Surfaces coated with it can be washed with any cleaning products - other than that, they do not require any maintenance. The PVC surface has no pores, so it can be easily washed with detergents.

The easiest way to care for doors is with an external coating based on polyvinyl chloride - their dense surface prevents dirt from penetrating inside and it is easily washed off with any available means. However, on this same surface various traces of sweat and fat are most visible.

Design and appearance of the coating

None of the materials for the outer covering of the door leaves impose any significant restrictions on their design. Doors can be paneled, with glass, other decorative inserts, or with a pattern applied to its surface.

Veneer . The surface has a characteristic wood pattern - most often it is varnished, less often painted.

Laminate . The manufacturing technology makes it possible to apply any design to the surface, but buyers mainly choose solid colors “like wood”.

Eco-veneer . This is predominantly a design of monochromatic colors with a structure of the outer covering characteristic of wood. In addition to the fact that eco-veneer imitates a wood structure, its advantage is the ability to paint the surface in different colors during production and get, for example, blue wood. At the same time, the colors of different doors will be exactly the same.

PVC film . Manufacturing technology does not impose any restrictions on the colors and design of such doors, especially since it is possible to use relief embossing. Doors with PVC coating can be made very similar to solid or veneer structures, which allows them to be used together with such models in the same interior.

A special feature of coatings made from natural materials is the heterogeneity of their colors - the color tone of doors even from the same batch can vary slightly. At the same time, no coating can convey the beauty of natural wood except veneer and eco-veneer.

Door cost

Leadership in this category will be quite conditional, because doors with each type of external coating can be manufactured in different price categories - with different fillings and thickness of the coating itself.

Veneer . Natural materials have always been in price, especially since their scarcity is increasing over time - veneered doors, all other things being equal, will be the most expensive.

Laminate . The cost of a laminated door is cheaper than veneer and eco-veneer, but more expensive than doors with PVC coating.

Eco-veneer . Eco-veneer is in second place in cost, which is determined by the content of wood fibers in its base and recognized environmental friendliness. However, the cost of the final product for the buyer will be much lower than that of analogues made from natural wood.

PVC film . Relatively low price - these are one of the most inexpensive and accessible economy class doors.

Also, the type of door - folding, sliding or solid - will have a big impact on the cost. The first two options require additional fittings, the quality of which is subject to serious requirements.

Source

Comparison

The naturalness of the veneer and the artificial origin of the laminate lead to different performance qualities and different prices for the doors for which they are used. It is clear that artificial materials can be of any color and any texture. Here laminated doors have a huge advantage, since the range of offers is very wide. Veneer, like any natural material, has a rather limited range of textures (colors may vary due to the use of stains), but it benefits precisely from the fact that it is “natural”, that is, environmentally flawless, and this often plays a decisive role in the choice . Thus, veneered doors occupy a more prestigious market segment than laminated doors.

Laminate made from low-quality plastic can give off an unpleasant odor, which, however, goes away quite quickly. But spending several days inhaling harmful fumes is not a pleasant experience. True, sanitary rules and regulations regulating the quality of various coatings are becoming stricter, and such a situation is now unlikely. Laminated doors can be called a more affordable product, since they are on average cheaper than veneered ones.

Which doors are better - veneered or laminated?

Which doors are better - veneered or laminated?

When choosing both interior and exterior doors and wanting to save money, you will have to make a choice between veneered and laminated coating. However, there is no clear answer as to which of these materials is better. Here it is worth focusing on the parameters and operational characteristics that are priority for the customer - only in this case the choice will be justified.

Indeed, the main difference in the properties of doors made of these materials is the difference in their characteristics, so it is worth considering the pros and cons of each option.

Doors with veneer - characteristics, pros and cons

A veneered door is a panel of spliced solid wood covered with veneer. High-quality veneer is a thin cut of natural precious wood, which is glued onto a cheaper and, nevertheless, natural base. As a result, in terms of its parameters, such a door will be almost identical to a door made of expensive material, while the cost of veneered products is significantly lower. Natural veneer is durable, reliable and resistant to external influences. It is worth keeping in mind that natural veneer from different batches may differ in color, so when purchasing doors for a house in the same style, you should purchase them in one batch.

Let's evaluate the advantages of veneer, but it is worth keeping in mind that we are talking exclusively about high-quality products, in the manufacture of which all stages of the technological process were completed.

How to distinguish a quality design and expose a cheap option?

Experts advise that before paying for your purchase, pay attention to:

- manufacturing material. No chipboard, otherwise the door will quickly disappear into oblivion! MDF with filled honeycombs will last a long time;

- cladding Find out exactly what material is used for the coating and choose the one that suits your purposes;

- quality. Carefully examine the canvas and box. Scratches, swelling and peeling are a sign of an unscrupulous manufacturer.

- joints. A common joint defect is easy to detect before purchase. There should be no peeling of the coating at the ends of the door.

Laminated doors - advantages and disadvantages

A laminated door is a hollow structure, which is decorated on top with a layer of laminate with a pattern - it imitates the natural texture of wood. On top of this product is coated with several layers of varnish, which provides the necessary resistance to external influences.

The filler of such a door leaf can be either paper or wood - in high-quality models, the blocks of wood are located quite close to each other, while the cheap option implies a hollow space inside the leaf, which, for obvious reasons, is not capable of providing sound insulation.

The main advantage of laminated doors over veneered ones is their cost. However, for high-quality models the difference in price is small. If we compare the performance characteristics, it is worth noting the following advantages:

Let's note the disadvantages:

Features of laminated doors in operation and maintenance

An interior door is made from a frame made of natural wooden blocks and covered with decorative finishing. To choose which model to buy - laminated or veneered doors - you need to familiarize yourself with the main differences and purpose.

Doors decorated with artificial laminate are available in any color. Most often, their colors are imitation of different types of wood. On the outside they are coated with several layers of varnish, and on the inside they contain filler, which increases the strength of the laminate structure.

The choice of models is large; there are the following types of laminated products:

Choosing interior doors for a country house

If you do not take into account the aesthetic side of the issue, then it is better to choose interior doors for a country house in accordance with the atmosphere, and here it is specific, not always the same as the atmosphere in a city apartment. Having found out what this very specificity is, you can draw conclusions about which doors are suitable here.

Important criteria that can affect the condition of the structure:

- Material of walls, floor;

- Climatic conditions affecting humidity, temperature;

- Living conditions - permanent or seasonal.

The humidity in the premises and the temperature background depend on the first two parameters. They can change dramatically due to the operation of heating devices. You should be especially careful when choosing if you live in a wooden house, you have a low ground floor and humidity, especially in the off-season, reaches the maximum level - 98-99%. As soon as the heating system is activated, the rooms become dry. This period is considered critical for the door. Much depends on the correct choice and integrity of the manufacturer.

Veneered door installed in a country house

The second point is the frequency of residence. Everything is simpler here: if a house or cottage is used only in the warm season, then in winter there is a strong minus inside. Accordingly, the doors must withstand critical cold, and “correctly” respond to the thaw with the arrival of spring.

So, it turns out that an interior door in a country house should have at least three advantages:

- Do not react to high humidity;

- Remain insensitive to sudden changes in temperature and humidity;

- Feel good in sub-zero temperatures.

What interior doors are best installed in a country house? – Moisture-resistant, frost-resistant, reliable, very high quality build. Nothing handles moisture as effectively as polymers. Water has no chance to seep into the inner layers, which means doors made of PVC, eco-veneer and all types of artificial veneer are beyond competition.

Things are also good with frost resistance. PVC, for example, is used to cover entrance doors. The material feels great in the cold, does not fade under ultraviolet radiation, plus it has anti-vandal properties and cannot be damaged by sharp, cutting objects (within reasonable limits, of course).

Eco-veneer is the same polyurethane, and this polymer’s frost resistance reserve extends far beyond the temperature zero and reaches 30, or even minus 60 degrees.

Doors with eco-veneer finishing in a country house

Considering that not all houses have humidity and temperature that reach critical values, installing doors made of solid wood and natural veneer is a reasonable solution. The canvases and moldings are reliably protected by several layers of varnish; this, as well as pre-treatment with stains, primers, and wax, significantly increases the resistance to moisture. By species, oak, ash, and pine have the highest moisture resistance. Beech is not recommended, as this tree absorbs moisture strongly.

Features of veneered structures

Veneered door leaves are made from a natural wood frame, lined with a thin section of wood - veneer. When producing veneer sheets (thickness - from 0.1 to 10 mm), the texture and pattern of the material are preserved. The product is durable, impregnated with moisture-resistant solutions and covered with three layers of protective varnish.

Types of veneer for doors: