Just 20 years ago, wooden windows were installed in brick houses. Today, practically all residential and non-residential buildings have plastic analogues. They provide warmth and comfort in the room and last longer. Therefore, many owners of country houses replace old wooden windows with new PVC systems. It is important to understand how plastic windows are installed in a brick house. This will allow you to save money by performing the installation yourself, or supervise the work of the craftsmen.

Advantages of replacing wooden windows with plastic ones

It is useful to know the pros and cons of PVC systems. Then it will be easier to understand whether it is worth installing them. Those who choose plastic windows for a brick house do not regret their decision.

Below are the reasons for installing plastic windows instead of wooden ones:

- Plastic windows are supplied ready-made. This simplifies their installation.

- Quick installation. Carried out during the day.

- Reasonable price.

- There is no need to further process the frame. Wooden structures have to be repainted every year and coated with special compounds that protect them from moisture and pests.

- Wide selection of colors.

- Perfectly flat surface.

- Easy to care for. PVC construction is easy to clean.

- Reducing noise levels from the street.

- Excellent thermal insulation due to the tight fit of the sashes to the frame and the multi-chamber system.

- They serve for several decades.

Among the disadvantages of PVC windows, the following should be highlighted:

- They are unable to maintain optimal moisture conditions in the room, creating a greenhouse effect. This disadvantage can be eliminated by regular ventilation.

- Plastic cannot be repaired. Scratches and other damage cannot be removed. A wooden frame can be updated by sanding or repainting.

- High expansion coefficient of polyvinyl chloride profile.

Removing old windows

Dismantling old sashes

The next step will, of course, be dismantling the old window . Using a crowbar, we remove all the sashes, remove the old ebb and pull out the window sill, having previously destroyed the bottom of the internal side slopes. Then, using a hacksaw, we cut the impost and dismantle it. Then we saw the bottom part of the window frame and, using a crowbar, carefully pull the window frame out of the opening. We clean the window opening from tow, cotton wool and dust, thoroughly, while wetting the surface of the window opening to avoid dusting the entire room.

Now, everything is ready to install the metal-plastic window.

Features of installing plastic windows in a brick house

Brick houses, like buildings made of other materials, have a number of characteristic features. Such buildings are distinguished by small window openings. The height of a standard double-leaf window does not exceed 160 cm, and the width is 125-140 cm. Therefore, if you want to install a larger structure, you will have to further expand the opening.

To properly install a PVC window in a brick house, you must consider the following:

- The walls of brick buildings are quite wide. The window sill must be made of the appropriate size. Its width usually exceeds 40 cm.

- There are voids in the brick. The material is heterogeneous. Therefore, it is necessary to use large fasteners to ensure reliable fixation of the system. It is recommended to increase the number of attachment points and select a suitable installation method.

- The width of the internal slopes is significant. It is larger than that of economical panel houses. After dismantling the old wooden window structures, it increases by another 10-20 cm. In general, the size of the slopes can reach 50 cm.

To install a plastic double-glazed window in a brick building, you need to spend more effort and time than in the case of similar work in a panel-type house. However, the installation of such structures in brick buildings is fully justified. Indeed, in combination with massive walls, PVC systems perfectly retain heat and ensure silence.

Possible difficulties and errors

When installing window units on their own, beginners often make a number of mistakes that lead to negative consequences. To avoid such problems, experts recommend adhering to the following rules:

- The frame is skewed when installed in the opening - the mortar flows on the horizontal and vertical planes should be knocked down even at the stage of taking measurements.

- Self-tapping screws for fixing steel plates fall into the cracks of the brick - the length of the fasteners should be selected in such a way that, if possible, the fixation is carried out in the joints of the masonry.

- When foaming the installation gap, too much material is wasted - the width of the seam should not exceed 20 - 25 mm. If there is too much of a gap, the end of the opening must be plastered.

- Poor adhesion of self-adhesive tape to the profile and masonry - all contact surfaces must be dust-free and treated with a degreaser.

- After fixing, the window structure swings in the opening - it is necessary to add anchor plates at least every 400 mm on each side of the frame.

If these recommendations are followed, the window unit in a brick opening will be used for at least the warranty period stated by the manufacturer, without the need for repair or replacement.

Is it possible to install plastic windows with your own hands in a brick house?

Many owners of country houses wonder whether it is possible to install plastic windows with their own hands in a brick house. Companies that manufacture PVC structures offer their sale with installation. As part of the promotions, installation is carried out free of charge. But most often you have to pay for such a service. In order to save money, you can install plastic double-glazed windows in a brick house with your own hands. To do this you need:

- Have repair skills.

- Know the design features of PVC products.

- Have enough free time (it is advisable to set aside a day for work).

- Have the necessary tools and skills to work with them.

- Proceed according to the instructions.

- Be extremely careful.

Methods of fastening a PVC window system

Before installing a plastic window, you need to decide on the method of fastening the structure. There are several popular options for fixing the profile system - using an anchor, plate or dowel. To choose the appropriate method, you need to know the features of each fastening method.

Anchor dowel

When installing a plastic window yourself is done in a panel or brick house, the walls of which do not have a layer of insulating material, any of the options for fixing the PVC structure can be used. Using an anchor is considered a reliable method. The sleeve of this fastener expands the sleeve when the screw is tightened. Therefore, the anchor dowel is securely fixed in the wall.

The disadvantage of using an anchor is the inability to dismantle it. Therefore, before starting work, it is necessary to carry out thorough preparation, including leveling the profile system. Otherwise, correcting errors will be very expensive.

To apply the anchor dowel, a through hole is created in the frame. This can lead to depressurization of the cameras in the profile. As a result, there will be a violation of the temperature balance inside the profile system.

The use of anchors requires certain professional skills from the work performer. If there is an error, gaps may appear or the fastening element will interfere with closing the sash. If all the work is done correctly, the window system will not sag and vibration will be eliminated even under strong wind loads.

Mounting plate

This fastening option must be used if the installation is carried out in a building with walls made of foam blocks, aerated concrete or reinforced concrete panels with insulating layers. After all, these are porous materials. The anchors will not hold securely in them.

Using plate elements is the simplest method of fixation, but it is not a 100% reliable method. However, it is used most often. It allows you to avoid depressurization of the profile system. The disadvantages of this method of fastening also include the possibility of the PVC window shaking. After all, the plates are fixed at one end to the profile with self-tapping screws, and are not twisted with it through through holes into a single structure. The other side of the fasteners is screwed to the wall using not an anchor, but a screw and a plastic dowel.

Nog

This type of fastener is an ordinary screw. It is used in the same way as an anchor. However, the dowel can always be unscrewed if necessary.

Technology for installing plastic windows in a brick house

Correct installation of plastic windows in a brick house is very important. The operation and durability of the PVC system depends on this. Therefore, it is necessary to follow a special technology. It can be of two types: with and without unpacking.

Installation technology without unpacking is used most often when doing the work yourself. After all, then you don’t have to disassemble the window structure. The point is that the whole system is inserted into the prepared window opening. Fixation is carried out using special fasteners. They are pre-installed on the window frame at the fastening points with the PVC system. It is important to carefully check all planes with a building level. Installation technology without unpacking is not suitable for very large windows (more than 2x2 m) and high-rise buildings.

When installing using the unpacking technology, the PVC structure is disassembled into parts. Remove the glazing beads and opening sashes, and remove the double-glazed windows from the frame. After this, the window is leveled with glazing beads and fixed in the opening. Then the glass unit, sashes and glazing beads are put in place. This installation option is associated with a number of risks:

- Mechanical damage to glazing beads (scratching, chipping).

- Constant fogging of windows during operation.

- Incorrect assembly of the system, due to which it will not work correctly.

- Broken glass pane.

In general, the technology is easier. You can implement it alone. But it is time-consuming and requires knowledge of the design of the PVC system.

Assembling the installed window

The frame installed in the opening and foamed around the perimeter must be assembled.

Double-glazed windows are inserted into blind, non-opening parts. To glaze (fasten) an installed double-glazed window, you will need a medium-sized plexiglass hammer. The beads are cut at an angle of 45° and inserted into the frame around the perimeter of the glass unit with some force. In order for the glazing bead to finally snap into place, it must be lightly knocked down with a hammer. If the window unit being installed has opening sashes, it is necessary to hang them on their hinges. This task is not difficult to cope with, since modern window fittings are very easy to use. But putting the sash in place is not enough. You should check its functionality and, if necessary, adjust it in the hinge part using a special adjusting key.

To check how accurately a plastic window is level, you need to open the sash. If it does not slam shut or open wider by inertia, it means the block is installed correctly.

Step-by-step instructions for installing a PVC system in a brick wall

The correct operation of the mechanism and the durability of the system depend on how correctly the plastic double-glazed window is installed in a brick wall. In order for everything to be done correctly, you need to follow the instructions.

The correct installation of plastic windows in a brick house is carried out as follows:

- Tools are being prepared.

- Measurements are being taken.

- A window opening is made in the wall if necessary.

- The PVC structure is installed using the selected technology.

Rules and requirements for installation according to GOST

The installation of windows and the requirements for this process are regulated by several documents. For example, GOST 30971-2012 specifies permissible deviations in assembly joints , as well as what characteristics they should have.

An addition to this document is GOST R52749-2007, since it describes the characteristics for seams that are reinforced with self-expanding vapor-tight tape.

The resistance of the seam to deformation should be 15%, water resistance - 600 Pa, and thermal resistance 3 m2 * ° C / W (characteristics of a unit with the first class of protection). 2nd and 3rd order seams have higher performance .

SNiP 02/23/2003 specifies the protection standards that a window must have for good thermal insulation and long-term operation. It recommends using a profile with 2-3 chambers for regions with average temperature conditions, and 4-6 for Siberian frosts.

GOST R56926-2016 regulates the distances between the frame and the window opening, if observed, the translucent structure will not fall out of the building without severe destruction of the walls.

This document also indicates the permissible deviation of the window structure during installation of 2° (up to 2 mm/m and less than 3 mm over the entire length of the profile). The depth of the window in the opening depends on the presence of a quarter. Most often, the profile is installed 1/3 or 2/3 from the outside of the house.

Features of taking measurements

To create an opening for a plastic double-glazed window, you need to calculate its dimensions. To do this, you need to measure the PVC structure. The opening should be a few centimeters higher and wider so that the system can be leveled. A two-centimeter seam on each side is filled with polyurethane foam.

If you plan to install it in a finished opening, then you need to clean it of construction foam and other sealants. Next measure the width and height. Subtract 4 cm from each indicator. You will get the dimensions of the window, which must be made to order.

How is installation done?

The spacers necessary to adjust and fix the required gap are inserted into the opening. The profile is aligned in the opening using a level and the specified spacers - for this, the wedges move horizontally and vertically. After leveling, you need to mark the points in the wall where the fasteners will be located. The profile is removed, holes are made in the wall using a suitable tool.

Then it returns to the selected and adjusted position, and the fasteners only slightly secure it (it is not turned completely), the alignment accuracy is checked, the bolts are finally screwed in (the amount of protrusion of the bolt cap is no more than 1 mm). When the frame is fixed, the sashes/glazed windows are inserted, the entire structure is checked, adjusted and adjusted.

After completing the main installation, all that remains is to install the plastic slopes and window sill. Before installation, all surfaces used must be leveled and clean. To cut and fit slopes and plastic window sills, you will need a power tool.

First, the upper horizontal is mounted, it is recessed deep, and the space is filled with polyurethane foam (a little, since after hardening it can damage the loose structure of the slope). The second step is to install the vertical slopes (it is important to use a level), and then the lower one. All elements must be properly joined so that there are no gaps between them. After installation, the corners are closed with special corners.

How to cut a hole in a brick wall

You can install a PVC system in a finished window opening. But, if you need to make an additional window, then you will have to cut a hole for it. This must be done carefully to avoid collapsing or cracking the brick wall. Initially, it is necessary to apply markings to the surface according to the calculations performed.

Cut out the window opening using a hammer drill. You need to knock out a hole in the shape of the letter “T”. Be sure to insert a metal crossbar to hold the top brickwork. After this, the wall is disassembled, starting from the bottom up. Protruding bricks are cut down with a grinder. The created opening is reinforced with corners and channels.

Service

It comes down to just two simple steps:

- In spring and autumn, move the pressure rollers from winter to summer position and back. If you leave them in the winter position for the summer, the compressed seal may lose its tightness when it gets cold;

- Lubricate the rubber seal with castor oil twice a year. It will prevent the rubber from losing elasticity and cracking. The oil can be found in any pharmacy.

Castor oil. Ask at any pharmacy.

How to install a plastic window correctly

When the opening is prepared, you can install a PVC system into it. You can do this in one of two ways. In the first case, special metal plates are used. They are secured with small self-tapping screws with a press washer on the sides of the window frame. Two such elements are installed on each side. About 30 cm are retreated from below and above. For wide windows, two additional plates are attached to the top. If the width of the system is less than a meter, then fix one plate at the top of the opening. After this, install the frame on the wedges and level it. They are attached with plates to the opening using dowel nails and a hammer drill.

You can also fix the PVC system with concrete screws. In such a case, a frame is drilled in the middle from the bottom and top of the glass unit and sash. Initially, this is done with a metal drill. After drilling the frame, take a concrete drill. With its help, a neat recess is made in the wall. In a similar way, holes are drilled on the sides at two points located with an indentation of approximately 30 cm from the bottom and top. Next, a concrete screw is driven or screwed flush into the frame and wall to secure the structure. The fastener head should not interfere with the PVC system opening and closing. Then the sashes and double-glazed windows are put in place.

At the end of the installation of the plastic double-glazed window, the gaps between the frame and the opening are sealed with polyurethane foam. In this case, the PVC system must be closed. The foam dries in about 12 hours. Then you can install the window sill and ebb.

Materials needed to complete the work

Before starting installation work, it is necessary to prepare the following materials:

- Wedges that are inserted for the correct installation of windows.

- Sealant.

- Polyurethane foam.

- A water vapor barrier material that is required for joint protection from moisture.

- Anchor bolts.

By the way, wedges are used in the installation process for more precise installation of plastic profiles. Without such materials it is much more difficult to do this. Polyurethane foam is an insulating material that will fill the space between the frame and the wall. When choosing foam, it is necessary to take into account that it must correspond to the temperature level, and work will be carried out at it. If you buy a material that is intended for use in the summer, its use may result in a poor quality insulation layer being created. Even during the work, the use of a self-expanding sealing tape is required. This material is glued along the window perimeter from the outside, and after that its expansion begins. The sealant is used to fill the space between the window sill and the slopes.

Possible mistakes when installing plastic windows in a brick house

If the PVC system is inserted incorrectly, this can lead to heat leakage and rapid destruction of the window frame. Most often, those who decide to install a plastic window themselves make the following mistakes:

- They do the calculations incorrectly. If the opening is larger than necessary, the gap can be filled with foam, but it will look sloppy. If the opening is smaller than necessary, then the insulation layer will not fit.

- Poorly clean the surface before sealing the joints. Due to the remnants of the old sealant, dust and debris, the polyurethane foam does not bond well with the substrate.

- The frame is positioned too close to the slope or trim. This makes it difficult to carry out a good seal. If these areas are plastered, then due to thermal expansion of the plastic frame, cracks and crevices will soon appear. Moisture will penetrate through them. This will help dampen the insulation layer of the brick wall.

- The distance between the slopes and the frame is too large. This leads to excessive load on anchors, dowels and displacement and deformation of the plastic structure.

- The drainage hole is blocked. This helps to reduce the tightness of the PVC system and destroy the frame.

- The window sill strip is not installed. This causes water to seep under the window frame. Because of this, the wall becomes wet and the dowels become corroded.

- The structure is poorly fixed. This contributes to a change in the position of the system under the influence of external factors, causing difficulties in closing and opening the valves.

It is possible to correct errors at the stage of making them. Therefore, it is important to carry out the installation carefully. And it’s better not to do them at all. To do this, you need to follow a number of expert advice:

- Watch videos in which professionals and home craftsmen tell you how to properly insert PVC windows into brick walls. They focus on complex, problematic issues and provide useful recommendations. There are many such videos on the Internet.

- Consult with the company’s specialists for the production of PVC systems regarding the design features and nuances of its installation.

- Make a step-by-step plan for completing the work and follow it. This will allow for quick and correct installation.

- Insert and fix the PVC structure together with an assistant. Then the work will be faster and easier, and mistakes will be avoided.

Installing the window sill and slopes

The installation of wooden windows, like plastic ones, cannot be considered complete if the window sill is not installed. The window sill board snaps into place and is attached to the stand profile. If, during dismantling, voids are identified under the window, you can fill them with insulation, for example, rolled or tiled, and then install a window sill. To finalize the opening, you need to understand how to properly install the slopes. They can be plastered or assembled from sandwich panels made of expanded polystyrene foam. With the latter option, the panels are cut to size locally, taking into account the geometry of each slope. A U-shaped plastic profile, otherwise called a starting profile, is screwed to the frame close to the slopes. A panel is inserted into it. The voids foam. Foam is a polyurethane foam sealant that, due to its properties, requires a certain amount of time to fully expand and harden. Typically from 1 to 24 hours. Where they adjoin the wall, the sandwich panels are covered with a decorative profile, most often F-shaped.

The junctions of the slopes and the frame to the window sill are sealed with sealant.

Dark brick house with white windows: photo

You can insert a double-glazed window with a white, cream, brown, gray frame. The color must be chosen taking into account the design of the rooms and the color of the brick from which the house is made, the type of exterior decoration. Then it will be possible to give the building a complete, beautiful look. Houses made of dark brick with white window frames look especially attractive and elegant. To see this, you should look at the photos below:

Thus, you can install plastic double-glazed windows in a brick house yourself. But in order to carry out proper installation, you need to take into account a number of important nuances, follow the recommendations of specialists, and act carefully and consistently. If you have doubts that you will be able to install the PVC system yourself, then it is better to turn to professionals for help. It is advisable to order installation from the company that manufactured the plastic structure. This will be cheaper and the warranty on the product will remain intact.

Did you like the article? Tell your friends:

Choice

What should you pay attention to when ordering windows?

Plastic, wood, aluminum

With a limited project budget, our clear choice is metal-plastic windows . Why are wood and aluminum bad? Here are the arguments against them:

- Modern wooden windows with hermetic seals and double-glazed windows cost at least one and a half times more than plastic ones. When precious wood is used to make frames, the price gap reaches three or more times. Please note - with the same or worse performance properties as plastic (resistance to mechanical stress, cleaning agents, fluctuations in humidity and temperature);

Modern wooden window: stylish, but very expensive.

- Cold aluminum frames are a good solution for an unheated loggia; in a living room, each frame will become a bridge of cold: it will contribute to heat leaks and become covered with frost on especially cold days. Insulated frames with plastic inserts again cost significantly more than metal-plastic ones. At the same time, their only real advantage compared to PVC is their slightly greater rigidity, which will simply be unclaimed during everyday use.

The structure of the frames of a warm aluminum window.

What to expect from plastic?

- Service life of at least 50 years. During this time, the windows may only require replacement of the seal;

- Resistance to operating temperatures in the range from -60 to +60 C, allowing windows to perform their functions in any climate zone;

- Resistant to any chemical and biological influences. PVC is inert towards acids, alkalis and mold . Unlike wood, by the way;

- High-quality thermal insulation (of course, how much this property depends on the profile).

Germany, Russia, China

Most manufacturers of finished windows position German Rehau and KBE profiles as elite solutions that provide new windows with a lot of wonderful properties.

Window profiles produced by the German company Rehau.

In practice, the only real difference between German, Russian and Chinese profiles presented on the domestic market is the slightly greater rigidity of German products under bending load due to the greater wall thickness of the metal core.

Hint: the rigidity of the window frame is in demand when the window area is large and there are large wind loads. And that is very limited. I have a panoramic attic glazing 2.7 meters high and 5 meters wide, assembled on an inexpensive Chinese Hauteck profile; The windows can withstand strong winter winds without any incidents.

Thanks to affordable prices and decent quality, Chinese profiles are in great demand in our country.

Service life, UV resistance and other characteristics important to the owner do not differ at all. At the same time, the price of a German profile is at least 30% higher than the cost of domestic products.

The conclusions, I think, are obvious: when ordering a window, you should not chase the name of the profile manufacturer. But it is worth paying attention to the number of isolated chambers in its structure. The more there are, the better the frames will protect the apartment from the cold.

However: the brand is very important when choosing accessories. I advise you to opt for a set from Siegenia-Aubi, Maco, Roto or Winkhaus. It is these manufacturers who guarantee the high wear resistance of the fittings elements coupled with the thoughtfulness of its design.

Siegenia-Aubi fittings: the best of the best.

Energy saving, light protection, noise insulation

The choice of double-glazed window affects the performance of the window to the greatest extent. It determines how warm the apartment will be in winter and whether the window will cause extreme heat in summer.

I will allow myself to conduct a small educational program on the properties and functions

Thanks to affordable prices and decent quality, Chinese profiles are in great demand in our country.

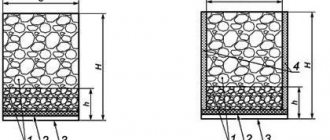

Number of cameras

The chamber is the gap between the glazing threads. Each chamber is sealed. The more chambers in a double-glazed window, the better thermal insulation it provides: additional glass limits convection, which transfers heat between the outer and inner surfaces of the package.

In warm regions of the country (Crimea, Krasnodar Territory, Stavropol Region), windows with single-chamber double-glazed windows are most in demand. Areas with colder winters (center of the country, Siberia, Far East) require the installation of double-glazed windows. Finally, in Yakutia and Chukotka, three-chamber windows (with four glazing threads) are used along with them.

Window with three-chamber double-glazed windows.

An important point: the more chambers in a double-glazed window, the heavier it is. Increased weight means more load on the profile and fittings, which often leads to sagging window sashes.

Energy saving glass

The so-called energy-saving double-glazed window differs from the usual one in the presence of one or (less often) two energy-saving glasses. Thanks to a multilayer metal coating (usually consisting of titanium oxide and silver) applied to one side of the glass, it reflects most of the infrared radiation, transmitting light in the visible part of the spectrum.

What is the result?

- In summer, glass prevents excessive heating of the room by direct sunlight;

- In winter, when the temperature in the room is higher than outside, it reflects IR rays towards the interior, preventing heat loss.

This is how energy-saving double-glazed windows work.

I will give some useful and interesting facts related to energy-saving glass.

- Heat loss through a single-chamber energy-saving package is 40% lower than through a conventional two-chamber package;

The photo shows panoramic windows with single-chamber energy-saving double-glazed windows in the attic of my house.

- Energy-saving glass is produced with hard and soft coating. The second type of glass (i-glass) is more advanced because it retains more thermal radiation with greater light transmittance in the visible spectrum (90% versus 70). The downside of its advantages is the instability of the spraying: it is always deployed inside the sealed glass unit, since it is easily damaged when washing windows;

- Installing a second i-glass into a double-glazed window improves its thermal characteristics by only 2-3 percent;

- A two-chamber window with two i-glasses is the most effective for protection against heat loss. Its heat transfer resistance approximately corresponds to this characteristic of 70 cm thick brickwork.

To make sure that your double-glazed windows are equipped with energy-saving glass, light a match or lighter and look at the reflection of the light. I-glass reflects flames with slight color distortion.

A simple test to determine the type of glass.

Filling the chambers

The chambers between the glasses can be filled not only with air, but also with inert gas (most often, relatively inexpensive argon is used as filling). Why is this necessary?

The fact is that a chamber filled with argon conducts heat worse due to two features of the gas:

- Less thermal conductivity compared to air;

- Higher viscosity , and, therefore, lower speed of convection currents that transfer heat between the glasses.

Thanks to filling with inert gas, the heat transfer resistance of the energy-saving package increases by 10-12%. With conventional glass, argon is less effective - it improves the thermal characteristics of the package by only 4-5%.

Inert gases reduce heat transfer by convection.

There is some bad news:

- The buyer does not have the opportunity to check what the glass chambers are filled with. He will have to rely entirely on the integrity of the seller;

- Argon is gradually filtered through the sealant around the perimeter of the glass unit. On average, about 2% of gas is lost per year.

Light-protective glasses

They are distinguished by reduced translucency to 30-70 percent. Translucency is limited by a metal coating with a structure reminiscent of energy-saving. This type of glass is typically used in large, south-facing windows and is often combined with i-glass in a single glass unit.

Several types of light-protective glass.

Noise protection

Noise protection is provided by the special structure of the glass unit: it is assembled from glass of different thicknesses, separated by spacer frames of variable width. Thanks to this structure, the package absorbs noise in the widest possible sound spectrum.

Installation of noise-proof double-glazed windows.

Number and location of sashes

The maximum width of the sash should not exceed 80 centimeters. After some time, a wider opening sash will inevitably sag under its own weight and begin to rub against the frame.

An excessively wide sash will sag over time under its own weight.

If the window width is more than 160 cm, it is better to make it three-leaf, with the opening sash placed between two blind ones. As an option, you can make the two outer doors open, and the central one closed.

What is this instruction related to?

Remember: windows have to be washed periodically, both inside and outside. It is desirable that you can reach any point of the blind sash without much effort and without exposing yourself to the risk of falling out of the window.

A caveat: of course, for cleaning you can remove and replace the double-glazed window. However, doing this several times a year, you will agree, is quite tedious.

Removing the glass unit of a plastic window.

Functionality

When ordering windows, you should pay attention to some additional functions of the fittings.

The ability to not only turn the sash on its hinges, but also tilt it towards you is a definite plus. The transom mode allows you to ventilate the room even in the heaviest rain. In addition, a tilted window will not allow your cat to go out for a walk at low tide (a rather dangerous walk, I dare say).

When turning the handle, the sash should be pressed against the frame by several rollers, and not just by the central lock. Otherwise, the window will not be airtight: there will always be small gaps at the top and bottom of the sash.

It is desirable that the pressure rollers be eccentric, with “summer - winter” positions. Rotating the roller or its bushing by 180 degrees will increase or decrease the pressing force of the sash, compensating for changes in the linear dimensions of the seal due to temperature fluctuations.

Turning the roller adjusts the pressing force of the sash.

Finally, I highly recommend choosing fittings with a micro-ventilation system. This is the name given to the ability to turn the handle to fix the sash ajar, with a gap of several millimeters between it and the frame. Micro-ventilation will provide the room with fresh air without cold drafts.

How to install correctly: choosing an installation method

There are two different methods: with and without unpacking (disassembling) the window. When unpacking, holes are drilled through the frame and anchors are driven through them into the wall. This method is more complicated, but the fastening is more reliable.

This is an anchor bolt installation. There are three of them on each side.

When installing without unpacking, metal plates are attached to the outside of the frame, and then they are attached to the walls. This is naturally faster, but the fastening is very unreliable: under significant wind loads, the frame will warp or it will sag.

This is the fastener most often used by installers. In my opinion, they look unconvincing

If you really don’t want to disassemble the window, you can mount it on a plate, but use not narrow and thin ones, but thick and wide ones, which are often used when installing a rafter system.

In principle, small windows installed on mounting plates, provided there are no significant wind loads, can stand normally. If you live in a region with strong winds, and they blow mainly through your windows, if the apartment is located in a high-rise building, in these cases installation with unpacking is necessary.

Below, watch an emotional and intelligible video that explains why it is better to use anchors.

Installation of a mosquito net is described in this article.