If plastic windows begin to show through after several years of high-quality use, then the reason may be the wear of the seal. Therefore, various fittings and rubber seals require special attention and care. Often, to eliminate the penetration of moisture and cold, it is necessary to replace the seal for plastic windows. So, let's look at what types of seals there are and how to replace it so as not to disrupt the normal air circulation in the room.

Sealing materials are available in various configurations

Why do you need a seal for plastic windows?

Double-glazed windows for windows are a sealed and energy-efficient element of the functional arrangement of a room. A special sealing rubber is used where the sashes meet the frame. This element protects the room from dust, noise and cold air entering from the street.

During installation, it is important to ensure a tight fit of the material

Elastic bands for plastic windows look like cords made of elastic materials. When deformed, such material is compressed. When the thickness of the cord changes, the tightness of the sashes decreases.

Window seals perform the following functions:

- protect from noise coming from outside;

- prevent dust from getting inside. Installing gaskets will improve the overall level of cleanliness in the rooms;

- promotes high-quality thermal insulation. Seals allow you to retain heat and even reduce heating costs;

- provide protection from moisture. Rubber material does not allow water to pass through;

- comfortable operating conditions for window structures and increased service life.

The seal occupies a specific place in the frame structure

For your information! Even windows with built-in gaskets will need replacement after some time. It is recommended to reinstall after 5–6 years of operation.

Lubrication rules

In order for any seal to serve its allotted service life, before use and periodically during operation of the PVC window, it must be lubricated with a certain type of lubricant. The type of lubrication and frequency of work are determined by the manufacturer of the window unit. Strict implementation of its recommendations will protect rubber products from premature drying, temperature fluctuations and the harmful effects of moisture.

As a rule, the manufacturer recommends the following types of lubricant for window seals:

- Universal silicone, average price from 400 rubles. per package. It is important to pay attention to the areas of application: rubber, silicone or other type of sealant.

- Universal lubricant WD-40 is not only suitable for the main seals, but also does not destroy the frame material, and is also suitable for preventive treatment of moving fittings, average price from 500 rubles. per package.

In addition, in everyday practice, users often use traditional methods of lubricating seals, for example, glycerin. You cannot count on the duration of such protection, due to the fact that it is quickly washed off with water when washing windows or in the rain.

When lubricating seals, you should absolutely not use the following improvised means :

- vegetable and butter, as well as margarine;

- various cleaning gels for dishes, tiles or shoes.

The technology for applying lubricant is quite simple; it is applied to a clean and dry surface of the seal with a clean rag, at a positive air temperature.

More information here.

When is it necessary to replace the seal in a plastic window?

Now let's figure out how to find out that the seal on plastic windows needs to be replaced. In fact, it is not always necessary to carry out repairs after 5–7 years of service life of rubber gaskets. With proper care, heat-insulating gaskets can last more than 10 years.

If replacement is necessary, the old seal can be easily removed

The need for replacement can be determined by the following signs:

- the appearance of microcracks on the surface of the seal;

- thinning of the elastic and flattening;

- drafts in the room;

- the occurrence of street noise;

- condensation on the profile;

- freezing of windows around the perimeter of the sashes.

Elastic material for PVC

How to check the closing tightness

Now let's find out how to check the tightness of the shutters. Most often, a thermal imager is used for these purposes, which allows you to find cold places.

The following methods will also help:

- light a match or candle near the window. If the light begins to fluctuate, this indicates a violation of the tightness;

- open the window and put a sheet of paper. Close the flap and remove the tab. With a dense structure this cannot be done;

- with very poor sealing, a draft will be felt even with your hand leaning against it.

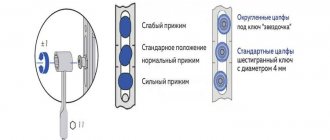

If the density is insufficient, the sashes can be adjusted

Stand profile

It is made of the same material as the window profile and is attached to the bottom of the window frame. It is used when installation of ebb or window sill is required. The stand profile adds 3 cm to the overall height of the window structure. This is important to take into account when taking measurements.

The substitution profile is used for installation of ebb and window sills

The use of a stand profile helps to protect the junction of the lower part of the window and the wall, eliminating thermal bridges and the appearance of condensation.

EPDM and TPE seals

EPDM or ethylene propylene rubber is a high quality material. One of the main advantages of this material is its resistance to ozone influence. With proper care, such material can last more than 15 years.

EPDM is made from ethylene propylene diene material. This is a soft gasket with a pipe profile. The seal is placed between the sash and the frame.

TPE (thermoplastic elastomer) retains all its characteristics in all weather conditions. The material perfectly tolerates sub-zero temperatures and fits tightly to the profile. The gasket is not subject to deformation under loads.

EPDM sealing material

Foam (Q-Lon, Shlegel)

Recently, German-made sealing tape Shlegel Q-Lon (“Schlegel Pendant”) went on sale. It consists of a polyurethane foam base in a polyethylene film shell, additionally reinforced with fiberglass thread or a polypropylene core.

Advantages:

- durability, recovery ability, rapid restoration of shape after compression;

- resistance to weather conditions, ultraviolet radiation, ozone;

- operating temperature range – from -60 ˚С to +70 ˚С;

- choice of colors, color fastness;

- good sound and heat insulation;

- no need to lubricate or maintain.

Flaws:

- the slightest damage to the shell leads to failure: the foam absorbs water, swells and freezes;

- increased load on window fittings; after installation, the hinges need to be adjusted;

- high cost, expensive installation.

Types of seals by type of installation

Sealing gaskets are also classified depending on the installation option. The following varieties are worth noting:

- self-adhesive window seal is equipped with an adhesive layer, which allows you to install the product yourself;

- sealants mounted on glue do not have a finished layer;

- grooved ones are used for wooden windows and are used to increase operating characteristics.

Self-adhesive tape

When choosing self-adhesive products, you need to pay attention to the expiration date. Since expired materials quickly peel off from surfaces.

Customer Reviews

The information that manufacturers provide about their products is intended to show the products from the best side. It is not profitable to provide information about the shortcomings or weak qualities of the seal, since this will immediately affect sales volumes. Therefore, it is much more useful to consider user reviews. This is the most reliable and truthful information because it comes from uninterested people. They have neither material nor reputational benefits. Let's look at some of them.

Marking of polymer, rubber and silicone seals for plastic windows

There are three main types of markings:

- KBE - teeth come in modified (presence of a stiffener) and unmodified design;

- Rehau is distinguished by single teeth of a slightly curved shape;

- Veka – the tooth is located at right angles to the base.

Sealing strip options

Replacing the seal in a plastic window with your own hands

The procedure for replacing seals on plastic windows with your own hands consists of two stages: preparation and installation work. Before installation, you need to prepare the place. First you need to remove the sash. To do this, the protective covers are removed from the hinges, and the pin is knocked out from the top canopy.

Installation of new material

Preparatory work includes:

- dismantling the old gasket using a narrow spatula;

- the surface is cleaned of dirt, dust and remnants of old material.

Installation depends on the types of rubber bands fastened. You can see how the installation is done correctly in the table.

| Photo | Description of work |

| To replace the sealing gasket, you will need a sealant, instant adhesive, which should be gel-based. You also need to prepare a rag, an ear stick, a stationery knife, scissors and wire cutters. | |

| First you need to remove the old seal. It is recommended to pull the tape out from the corner area. | |

| After this, the entire seal can be easily removed. | |

| Then you need to remove the rubber gasket from under the loop. To do this, the sash should be opened at an angle. You need to open it 10 mm and pull the bottom edge. | |

| Remaining material can be removed with a knife. You need to walk along the contour with a rag to clean the surface. Dirt in the groove can be removed with an ear stick. | |

| One end of the new seal should be inserted between the sash and the hinge. | |

| We stretch the piece to the middle of the sash. | |

| The sealing material must be pressed down. In this case, the lock must be placed in the groove. | |

| We stretch the seal around the entire perimeter. The rubber needs to be glued at the joint. | |

| The ends should be aligned to form a right angle. The excess needs to be cut off. | |

| Glue is distributed onto the two ends of the tape, but not onto the blades, but onto the lock area. | |

| The ends are inserted into the groove and pulled together. The elements need to be pressed for a few seconds. |

There are different options for replacing the sealing material. If you don’t know how to change the seal on plastic windows, then some methods can be seen in the video below:

Installing and replacing seals in wooden windows

For windows in wooden frames, the following sealing options are used:

- Silicone gasket is an elastic material that is used in the food industry and for medical purposes. This material comes in two types. Liquid silicone is distributed over the surface using a special gun. Rubber silicone is made in the form of flat strips;

- self-adhesive sealant is a tape of various configurations.

Installing a sealing tape in a wooden groove

When choosing a material, you should not choose thick gaskets, since windows or doors may not close.

What it is?

The seal, which is popularly called rubber band or window cord, is a specialized rubber product produced in the form of a tape with a relief/spongy cross-section.

It is fixed into specialized recesses of the PVC profile. It must have characteristics in accordance with GOST requirements :

resistance to significant temperature changes;- moisture, noise and heat protection.

Seals vary in shape, load-bearing capacity, color and base material from which they are made.

Large serious manufacturers have designed a unique type of seal for their PVC profile in terms of materials, shape and characteristics to ensure the highest possible operating parameters of the window. It can take various forms :

- tubular;

- single- and multi-petalled.

Therefore, when choosing a replacement seal, the user must know its name, brand and geometric characteristics.

The most popular manufacturers of rubber seals

Various manufacturers offer seals for plastic windows. The price also depends on this factor.

Rehau

One of the first manufacturers of gaskets was Rehau . It offers products made from thermoplastic elastomer and ethylene propylene rubber.

Products from this manufacturer have the following advantages:

- can be used over a wide range of temperatures;

- tight pressure along the entire perimeter of the glass unit;

- resistance to mechanical stress, ultraviolet radiation and high humidity;

- the material can last for many years.

The cost of products depends on the specific configuration and material of manufacture.

Rehau products

Veka

Veka , which have been on the market for more than forty years, are popular The company offers sealing material for glass and window sash.

It is worth highlighting the following advantages of the product:

- resistance to deformation and durability;

- resistance to humidity, severe frost and temperature fluctuations;

- increased level of sound insulation and thermal insulation.

Rubber sealing tape

KBE

This company produces double-glazed windows and accessories for them. The advantage of the product is that the gaskets fit tightly into the groove. The product must be rolled in using a special tool. The products are made from high quality rubber. Seals are ideal for improving the performance of windows made from different materials.

Universal gray material

Russian manufacturers

You can also purchase more budget options from domestic manufacturers. Obninskgazpolymer offer suitable products of good quality .

Important! When choosing such products, it is worth considering that seals from Russian companies may not be suitable for foreign-made double-glazed windows.

If you have double-glazed windows installed from a well-known manufacturer, then you should not save, but it is better to purchase fittings for plastic windows from the same company.

Domestic seal for window profiles

Rubber

This category of seals includes samples such as EPDM and vulcanized rubber. Such models are among the most common, they withstand mechanical stress well, are slightly susceptible to deformation, are quite elastic and resistant to shock and stretching. Also among the advantages are inertness to ultraviolet radiation and temperature changes. Even a deep minus or plus does not in any way affect the quality characteristics of the material. Disadvantages include high cost, as well as the ability of rubber, due to its origin, to color light plastic surfaces. The service life of this type of product can reach 10 years. As for domestic examples of seals made of EPDM and vulcanized rubber, Russian analogues are made from raw materials supplied by European and Asian countries, which directly affects the final cost of the products. All attempts to optimize production, as well as to use not pure material, but with impurities, end with a decrease in the performance properties of the sealant. Such products can dry out and quickly become unusable with intensive use of the window structure.

Seal gasket care - basic rules

Regardless of the choice of gasket option, certain maintenance is recommended to improve service life. Here's what to do:

- washing . Sealing products should be wiped with a sponge or cloth soaked in LOC or Edelweiss. Silicone seals require cleaning much less frequently than other options;

- lubricant _ It is recommended to use solutions containing silicone. Vaseline or any oil is not suitable for lubrication;

- removing dirt . It is necessary to clean dirt from under the seals. This can only be done with a soft object, since using a screwdriver or knife will reduce service life.

Cleaning profile elements

To care for fittings and gaskets, you need to use special sprays.

For your information! Cleaning should be done no more than twice a year. You can also take advantage of cleaning offers from various specialized companies.

Related article:

How to adjust plastic windows yourself? In a separate publication you can find detailed instructions on how to adjust windows in different situations.

How to choose and buy retail seals for plastic windows: prices

When choosing suitable products, it is recommended to calculate the total cost of replacing the seal in plastic windows. The cost of some product options is shown in the table.

| Photo | Products | Peculiarities | Average price, rub. |

| Schlegel Q Lon | PVC profile. Black color. | 60 | |

| Self-adhesive seal 8mm*4mm*18m | Material – polyethylene foam. | 60 | |

| Sealant "SibrTech" Basic | Self-adhesive tape based on polyethylene. | 37 | |

| Sealant for Veka Elementis profile | Black color. Suitable for frame and glass unit. | 4315 for 400 meters | |

| Rehau seal | Suitable for frame and sash. Black color. | 8202 for 500 meters |

Review by Vluan, Yekaterinburg: Polisan S seal for windows and doors, heat and sound insulating self-adhesive - A wonderful sound insulating seal.

Advantages: Excellent double-sided self-adhesive foam strips.

Disadvantages: Ten meters is not enough for me.

Self-adhesive “Polisan S” Reliable heat and sound insulating seal. I have problems in my house - there is a large crack running across the floor and the floorboards are coming away from the wall blocks...

More details on Otzovik:

Review by Ursulusa: Sealant for windows and doors Aviora - A high-quality sealant, but with special features.

Pros: good quality material

Disadvantages: does not always reliably protect from the wind if mounted as recommended by the manufacturer

In a sense, we were lucky - plastic windows and balcony glazing were installed in the house several years ago during a general large-scale renovation. They looked very good, so we didn’t change them during the renovation of our apartment. But, as it turned out, free is rarely good...

More details on Otzovik:

Requirements

Choosing the optimal price-quality ratio of self-adhesive insulation is not easy. Good material should :

- be strong but flexible;

- after compression, quickly return to its original shape;

- have a good adhesive coating;

- have a width, profile and color suitable for the given window openings.

A high-quality sealing profiled tape fits tightly into the groove of the window block, leaving no voids or protruding.

For wooden frames, self-adhesive foam rubber or polyethylene tapes of simple shape are suitable. For plastic structures, it is better to choose rubber or silicone models.