Penofol insulation is a modern, effective thermal insulation material that provides excellent reflective thermal, sound, and vapor insulation. It consists of foamed polyethylene and thin foil (20 microns). The thickness, structure and density of polyethylene varies depending on the modification. We will look into which Penofol to choose and which side to attach the insulation in in our article.

Important: Brand polyethylene foam can be used as the main and additional insulating material.

Operating temperature range - from -60°C to +100°C. The thermal reflection coefficient of this insulation is 95-97%, which indicates its phenomenal efficiency. Why Penofol can sometimes become covered with moisture, we wrote an article here. Now let's talk about the features of fastening polyethylene foam insulation.

Scope and installation features of reflective insulation

Thermal insulation with a metallized layer is manufactured in accordance with all hygienic standards and is a low-flammability material.

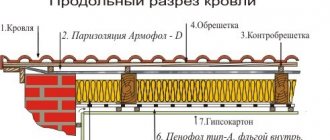

Thanks to its small size, it does not cause problems during transportation and installation. The rolls are easy to cut, and for fastening you only need a construction stapler and special tape. Reflective insulation effectively reduces the heat loss of a building when combined with the main insulation. Installation of the canvas with lavsan film provides protection from steam and moisture. Its use as part of a roofing pie is possible outside and from the attic. Insulation of the roof under the roof covering is carried out while eliminating noise and protecting against moisture penetration. The canvas is attached to the sheathing with a stapler, the joints are taped with tape. The reflective layer is directed upward. The finished insulation is covered with a counter batten for the finishing coating.

When attaching insulation, it is necessary to provide an air gap of at least 20 mm between the insulation and the outer cladding. Reflective ability, resistance to moisture and high temperature allow the material to be used when finishing baths and saunas. When insulating a balcony, polyethylene foam with lavsan is the best choice. A thin layer of insulation does not take up the space of a small room, while it performs the function of vapor and waterproofing and does not require the creation of additional layers.

Low water absorption and thermal conductivity, immunity to temperature changes and most chemicals, and long service life have made insulation a popular material for insulating air ducts, water mains, refrigeration units and equipment. It is used inside and outside buildings and protects structures from changes in temperature.

Installation of insulation with lavsan is suitable for surfaces of any configuration. It is effective in low-rise construction and in the construction of frame houses. Be sure to fasten the panels end-to-end, excluding overlap.

The joints are sealed with a special type of tape consisting of foil with an adhesive layer or a composite of aluminum and polyethylene. The connecting element has strength, the ability to reflect ultraviolet and infrared radiation, and moisture resistance. Its service life is equal to the service life of the reflective insulation.

The use of insulation with lavsan allows you to reduce heating costs and ensure energy savings.

Advantages and disadvantages

The main function of this multilayer material is to protect a certain structure or space from various environmental influences. This non-combustible building material has many advantages.

- Versatility. Penofol is used not only to preserve heat and protect against moisture. It has high vapor and sound insulation, allowing you to reduce the use of a large number of different films. The product can be used both indoors and outdoors, as it is not at all afraid of moisture.

- Subtlety of the material. The thickness of penofol is several times smaller than many similar insulation materials. When installed even in the tiniest room, you don’t have to worry about reducing the living space.

- Wide choose. The material is presented on the market in a wide range of types. Therefore, it is easy to choose exactly the one that is needed for the current job and taking into account specific conditions.

- Quality level. The material is made using the most modern technologies, which allows reducing heat loss to only 4%. In winter, a room decorated with penofol will be warm, and in summer it will be cool.

- Easy to install. The material, produced in rolls, is light and flexible. This allows a person with no experience in the construction industry to cope with work even in the most difficult areas. This building material, unlike old insulation materials, does not require the construction of a frame. It can be glued directly to the rough wall, and can be cut with ordinary scissors.

- Environmentally friendly. Unlike mineral wool, you can work with penofol even with bare hands, as it does not cause any irritation to the skin. This insulation can be safely used even for installation in kindergartens and schools.

- Practically does not burn. It can be described as highly flammable.

- No parasites. This insulation does not serve as food or home for rodents or insects.

- Easy transportation. The weight of one roll of penofol is so small that you can easily carry it in your hands all the way from the hardware store to your home. The material is difficult to deform or break.

- Radiation protection. It is perhaps the only insulating material that can reflect radiation exposure. This effect is achieved by aluminum foil and is necessary for some industrial facilities.

Unfortunately, with all its positive properties, penofol also has some disadvantages. Due to the soft surface of the material, finishing with plaster is impossible, since it simply does not stick to it and is easy to break. Installing such insulation with metal brackets will compromise its integrity and may reduce its thermal and waterproofing characteristics. It is necessary to either purchase it on a self-adhesive basis, or put it on a special composition, which is purchased separately.

What is Penofol

Penofol is a practical and inexpensive insulation made of non-crosslinked polyethylene foam with aluminum foil applied on one or both sides of the material. Gas-filled cells are sealed and closed, which provides high compressive strength, but does not interfere with the bending of the material. The cell size is usually from 0.5 to 2 mm.

Instead of aluminum foil, lavsan is also used, a polymer material with good reflectivity in the infrared frequency range of electromagnetic waves.

The insulation stands out from the rest due to its affordable price and simple installation method, however, due to thickness limitations, it is used in a fairly narrow number of cases where it is only necessary to supplement the existing enclosing structures, increasing the overall resistance to heat loss.

Penofol has found its main area of application in air conditioning and thermal insulation systems, where the bulk of the heat is transferred using infrared radiation.

Three types of penofol are produced:

- Type A - with one-sided foiling;

- Type B – with double-sided foil;

- Type C – foil on one side and self-adhesive surface on the other side.

The choice of a suitable option is determined by the direction of propagation of the target thermal radiation. For example, one-sided penofol, when installed on the wall of a living space, when the foil surface is facing inward, protects against heat loss from inside the house to the outside. This means the house will be warmer in winter.

Double-sided penofol can not only prevent heat loss from the house to the street, but also the flow of heat from outside. So it will be warm in winter and not hot in summer, since the heat from the walls irradiated by sunlight will not overheat the air inside the room.

How to attach

The basis for penofol is polyethylene, which, unfortunately, has very weak adhesion to construction adhesive solutions.

Mechanical methods are used for fastening: self-tapping screws with a press washer, stapler brackets, clamping strips, fixation under the sheathing. When laying on a horizontal surface under a screed, fastening is not necessary at all.

All joints and fastening points where the material has been stitched through are sealed with special tape made from thick aluminum foil or a polymer base coated with aluminum. This will restore the tightness of the insulation layer and give additional strength to the insulation.

Foil self-adhesive

As an additional fastening, double-sided tape can be used along the edges of the penofol strip.

However, manufacturers provide an even better option. The self-adhesive surface of foam foam “type C” makes installation on any clean, prepared surface extremely simple. One side of the material is completely covered with an adhesive composition with the same properties as regular tape, covered with a protective film.

If you need to glue a small screen, for example, to the wall behind a battery, where it is inconvenient to mount it in other ways, then self-adhesive penofol is the best practical solution.

It is enough to prepare the surface, clean, degrease and, if necessary , prime it so that it does not accumulate dust.

Technical characteristics and types of penofol

There are several types of foil penofol, which differ from each other in characteristics. Accordingly, letter markings are placed on different models, which make it possible to distinguish different models of penofol. The following types are available on the market:

- A. Marking with this letter indicates that the material is covered with aluminum foil on only one side. As a rule, the material is combined with other insulation materials (styrodur or polystyrene foam).

- B. The marking indicates that there is a foil coating on both sides. Can be used for standalone use.

- C. Self-adhesive penofol. It has a self-adhesive coating in the form of moisture-resistant contact adhesive. Can be used without the use of mounting hardware or tools.

- ALP. Polyethylene is applied to the aluminum coating. This type of penofol is also called laminated. Often used in agriculture or in places with slightly aggressive environments.

- R, M. One-sided foil coating, while the penofol itself has a relief structure.

- SuperNet. The word comes from the English word "network". It follows from this that this type of penofol is used for insulation of utility networks and communications.

- AIR. This foil penofol is used in special air exhaust structures.

Let's take a closer look at foil penofol: technical characteristics will present only the three most popular types - A, B and C:

Double-sided foil penofol in action

- Can be used in temperatures ranging from -60 to 100 degrees Celsius;

- Thermal reflection - within 95-97%;

- The operational amount of moisture in the material according to SNiP 2-3-79 is from 2 to 10%;

- The thickness of the material is from 3 to 5, as well as 8 or 10 mm.

- The specific heat capacity of all three types of material is J/kg.

Advantages and disadvantages

Advantages of foil foam with an adhesive layer:

- small thickness. Can be used in rooms with limited space;

- high rates of heat, noise, vibration and vapor barrier. Can be used at sites where other types of insulation are ineffective;

- radiation protection. Able to reflect beta radiation, suitable for insulation in technogenically unfavorable areas;

- ease of installation. Laying the material requires a minimum of time, tools and labor;

- strength and density. Resistant to damage and physical impact, does not deform even under high load;

- durability. Does not rot, does not mold, is immune to pests, does not change physical and chemical characteristics over time;

- aesthetics. Has an attractive appearance and does not require additional finishing;

- low price compared to other types of insulation.

Disadvantages of penofol:

- excessive softness. When exposed to sharp objects, it is easily pierced and torn;

- doesn't hold its shape well. In most cases it is used in combination with other heat insulators;

- instability of the aluminum layer. Treatment with solutions or paints can destroy the foil;

- fire hazard. If it comes into contact with faulty wiring, it will cause a short circuit.

According to the fire safety certificate, foil penofol is a material with low flammability and low flammability, but during combustion it produces high smoke levels.

Would you use self-adhesive foam foam as insulation for your home?

Yes

No

Stages of finishing walls with penofol

Penofol, in addition to its heat-insulating properties, helps preserve the space of the room, since its layer is much thinner in thickness than similar insulation materials.

To insulate walls and internal partitions, all three types of insulation are used. To prevent the accumulation of moisture on the foam foil, create a space with air ventilation with a thickness of 2 cm.

Penofol is mounted on the wall surface if it has an adhesive layer. The material with foil on both sides is attached with a ventilated gap on both sides of the layer.

To do this, a frame made of lath is attached, an insulator is placed on it, nailed to the tree with nails, staplers or drilled with screws. To create a second air gap, another slatted frame is made, and plasterboard, sheets of plywood or chipboard are mounted on it.

The insulation strips are joined end to end; the best option is to cut the seams for a tighter fit. The seams are protected from unfolding and drafts with aluminum tape.

External thermal insulation of walls is carried out with penofol, if further finishing of the facade is planned with hinged ventilated systems made of plastic, siding and other finishing.

Penofol: general characteristics

Penofol is a material for heat, sound and vapor insulation, foil-clad polyethylene foam of the class of reflective insulation. This combined material consists of polished aluminum foil 20 microns thick and a base of foamed polyethylene of different densities, structures and thicknesses (from 2 to 10 mm). Aluminum foil is polished to such an extent that it reflects heat and prevents it from escaping from the room. Its reflection coefficient is at least 97%. You can compare this foil with conventional construction foil, which has a coefficient of 50-70%.

Penofol does not absorb moisture, does not require the installation of additional vapor barrier, and its properties are not affected in any way by the temperature and humidity conditions of the premises. The sound absorption of penofol is no less than 32 dB, and it protects from both structural and acoustic noise.

Penofol is produced in rolls. This thin, light, flexible material is very convenient and easy to install.

All of the listed properties make penofol a unique material that allows you to create comprehensive insulation of a residential building, bathhouse or sauna, as well as administrative and industrial buildings, warehouses, shops, and refrigerators.

Types of penofol

Foil penofol is traditionally produced in three main modifications:

- type A

– one-sided foiling; application – insulation of roofs, walls, engineering systems from the inside; - type B

– double-sided foil; Application – insulation of internal partitions and interfloor ceilings; - type C

– one-sided foil and self-adhesive layer; Application – for cases where it is technically difficult to use other brands.

In addition, today there are many other types of penofol: with perforation, internal reinforcement, the use of other types of foil, etc.

Main technical characteristics of penofol

In accordance with the Technical Assessment (FTS Gosstroy of Russia) TO No. 0457-01, the following technical characteristics of penofol can be named:

- Can be used at temperatures from -60°C to +100°C.

- The coefficient of thermal reflection of the surface is not less than 95%.

- The thermal conductivity coefficient at a temperature of 20°C is not more than 0.039 W/m.

- Water absorption by volume is no more than 0.35-0.7%.

- Dynamic modulus of elasticity under load 2 KPa – 0.26-0.39 MPa,

- 5 Kpa – 0.77-0.72 MPa.

- Relative compression under a load of 2 Kpa – 0.09-0.03 units,

- 5 KPa – 0.20-0.12 units.

Composition and principle of operation of the material

Penofol insulation is obtained by foaming polyethylene with propane-butane or approved phenols in an extruder at high pressure.

The gas expands, a bubble is formed, which cools sharply and hardens at the exit from the nozzle.

The result is a material with a porous closed cell. By adjusting the pressure and temperature of the mixture in the extruder, a material of different porosity, thickness and density is obtained.

A layer of polished aluminum foil is applied on top of the polyethylene, whose heat reflection coefficient reaches 95-97%. If, in addition to thermal insulation, the material is used for waterproofing, two layers of foil are applied to the surface of the polyethylene film using the heat welding method.

Main characteristics of foil penofol

Nowadays a lot of materials are produced under the PENOFOL brand. Perhaps it is worth listing those that are most in demand. Among them we can highlight the classic Penofol, covered with aluminum foil on only one side. This Penofol is type “A”. Penofol, which is foiled on both sides, is type “B”. Penofol of both these types is quite dense and also resistant to physical stress.

Penofol type C belongs to the category of self-adhesive materials. In it, a polished aluminum coating is applied to a layer of foamed polyethylene on one side, and on the other, a layer of moisture-resistant glue and a film that prevents the adhesion of materials. This type of insulation is used where regular Penofol is not suitable or is too expensive, because no additional devices are needed to attach it.

There is also Penofol, which has perforation. It can also be single-sided or double-sided and was produced not so long ago, and is used for thermal insulation of facades from the outside. Perforation allows moisture to escape from the material. In other words, walls insulated with such material can “breathe”.

Penofol thickness. The thicker the insulation, the more expensive it is. As for thickness, its standard sizes are: 10, 8, 5, 4 and 3 millimeters. You can understand that centimeter-thick material with a double layer of foil will be the most expensive. By the way, it not only stores heat better than anyone else, but also protects well from noise. In terms of optimal price-quality ratio, Penofol with a thickness of 0.5 centimeters came out on top.

Heat conductivity. Since this insulation is combined, combining heat reflection and absorption, it is difficult to compare it with traditional heat insulators. Penofol insulation helps reduce convection due to the polyethylene foam layer, and the foil layer on the outside can reflect up to 97% of heat rays. The result is comprehensive insulation.

Laying penofol on the floor in the steam room

Vapor permeability and sound absorption

Penofol almost does not absorb moisture, and it does not matter what humidity the air has indoors and outdoors. This does not depend on the change of season and temperature conditions.

This distinguishes this insulation from most modern heat insulators. There is no need to lay a vapor barrier film when using Penofol. After all, its vapor permeability coefficient does not even reach 0.001 milligrams per meter-hour-Pascal. We can say that this insulation is an excellent barrier to fumes.

Service life and safety. One of the cleanest materials in terms of ecology is polyethylene foam. Therefore, it is this that underlies Penofol. By the way, in terms of durability (200 years) this substance can be given the highest score. At the same time, you will be able to protect yourself from the harmful effects of electromagnetic radiation. They can be reduced by two or even ten times.

What is the name of foil with insulation: introduction to penofol

Foil penofol is a registered brand. It is represented by a multilayer material that belongs to the class of reflective thermal insulation. The name of insulation with foil is derived from two words: “foam” - from expanded polystyrene and “foul” - from foil.

Penofol consists of foil and expanded polystyrene foam

Its main purpose is to protect building structures from wind loads, moisture, steam, and condensation. Penofol is a universal material that combines the qualities of heat, sound, steam and moisture insulation. The basis of such a heat insulator is polyethylene foam with closed pores, which are 95% filled with air, thereby eliminating heat transfer. This polymer layer can be of different thickness, structure and density.

Polyethylene is covered on one or both sides with aluminum foil, which is pre-polished to achieve maximum reflectance. The material is applied by heat welding, which ensures reliable adhesion of the foil to the polyethylene.

Important! As a result of using foil foam, it is possible to reduce the cost of heating rooms in winter, and in summer, slow down the heating of the house.

Scope of application

Reflective thermal insulation is applicable to all surfaces without dirt and dust, suitable for complex structures with corners, bends and differences. Insulating walls from the outside can achieve maximum effect by creating an air gap of 20 mm on the foil side.

The material is effective for multi-story and single-story frame houses, and it will increase the resistance of the walls without increasing their volume. Installation is carried out end-to-end without overlaps, and the seams are taped with foil tape.

Application from inside

If you want to insulate the room from the inside, then there are two options. The first option is to make 2 air gaps between the external wall and the material, between the insulation and the cladding (for example, drywall). In this case, TIM with double foil is used.

The second option is to create one gap between the external wall and the insulation, for which material foiled on one side is used. The foil is turned indoors.

Roof insulation

Reflective TIMs mounted on the roof provide not only thermal but also vapor insulation. The under-roof space is also protected from moisture.

Reflective film is especially effective when insulating the ceiling of a bathhouse.

Piping and ventilation

Pipes require insulation with double-sided foil. If the pipes have a diameter less than 159 mm, then there is no need to create an air gap between the TIM and the pipe. If the pipes have a larger diameter, then a gap is required. The air gap is arranged as follows:

- The first option is to attach rings made of foil film to the pipe with a distance of 300-400 mm from each other. And on top of the rings the pipe is wrapped with insulation;

- the second option is to lay wooden blocks with a cross-section of 10 by 10 mm or 20 by 20 mm along the pipe, after which insulation is wrapped on top of them.

3 Characteristics of the insulator - what makes it popular?

Foil penofol is considered a universal insulation material, the advantages of which are provided by its excellent technical characteristics. It can be used for thermal insulation of various building structures in residential and non-residential premises, inside and outside buildings. The most important parameters of a heat insulator include the following properties:

- 1. Thickness. One of the most important advantages of penofol is its small thickness, which is much smaller than other insulation materials. The standard thickness of such thermal insulation does not exceed 10 mm. The thickness of penofol directly affects its cost. For internal insulation, it is best to use material 5-6 mm thick.

- 2. Thermal conductivity. It is very difficult to calculate the thermal conductivity of a combined insulation material, so foam foam is usually referred to as its heat transfer resistance. For material foil-coated on both sides with a thickness of about 5 mm, this figure is 1.23 m2/C/watt. To ensure the same heat transfer resistance using mineral wool, you will need to install an insulating layer about 80 mm thick.

- 3. Moisture resistance. The material does not absorb moisture, its moisture absorption ranges from 0.35 to 0.7% per m3.

- 4. Sound insulation. Correct installation of penofol ensures high-quality noise insulation of rooms - up to 32 decibels. To increase the level of sound insulation, before installing insulation, it is necessary to seal the seams of building structures.

- 5. Vapor permeability. The vapor permeability coefficient of penofol is 0.001 mg/m/h/Pa. Thus, this insulation can be installed without first installing a vapor barrier layer.

The popularity of the heat insulator is determined not only by its technical characteristics, but also by its resistance to various external influences. This material can be used at temperatures from -60 to +100 °C, withstands the effects of almost any chemicals, and is environmentally safe for humans. Manufacturers assure that penofol can serve for 200 years, but it is not yet possible to verify the reality of such statements, since the material has been widely used relatively recently.

Can be installed without first installing a vapor barrier layer

Insulation is a highly flammable material and does not support combustion. It is fireproof, so it can be used in different buildings and premises. When burning, it releases water and carbon dioxide; if there is not enough oxygen in the surrounding space, it can release carbon monoxide. However, it is characterized by medium rigidity, bending and compressive strength ranges from 44 to 74 kg/m3. Thanks to these technical characteristics, penofol is used almost everywhere today. It perfectly protects rooms from low temperatures, from cold bridges and reduces the load on the heating systems installed in the rooms.

We advise you to study - Arbolite blocks - disadvantages, advantages and characteristics

We insulate the house with penofol

Let's consider how to properly use this material when insulating various elements of a building.

Roof insulation

The roof should be properly arranged in such a way that moisture cannot penetrate into the constituent elements either from above in the form of precipitation or from below in the form of water vapor. In the event of moisture penetration, natural ventilation must be present in the roof structure, through which moisture must be removed from the room.

Creating a vapor barrier is a necessary measure, because the humidity level in any room is quite high. This is influenced by both the person himself (breathing), and indoor plants, the process of cooking, etc. And the warmer the room, the higher the humidity.

In this regard, in addition to vapor and waterproofing barriers, the roof structure provides 2 ventilation layers:

- Between the roof and waterproofing. This layer is intended for ventilation of the roofing material.

- Between thermal insulation and waterproofing, providing the necessary air exchange over the insulation.

Insulated roof “in section”.

Naturally, when installing penofol sheets, you may not consider using other insulation, but experts recommend adhering to a combined approach, which we will consider.

Instructions for carrying out work:

- From the inside, we stuff sheathing bars onto the rafters. The insulation will be attached to them. The fastening step is 20-30 cm.

- We chose mineral wool as the main insulation. From the outside, we lay the slabs tightly on the sheathing, avoiding through holes. If holes appear, seal them with foam.

- Now you should begin installing the waterproofing. For these purposes we use foam sheets. We nail it to the rafters from the outside. There should be a gap of 5 cm between penofol and mineral wool, which is needed for ventilation.

- We create ventilation for the roof on top of the waterproofing. To do this, we fill bars with a cross section of 25 by 50 cm along the rafters.

- On top of the beams we fill planks across the rafters to create a full-fledged sheathing on which the roofing material will be laid.

Roof insulation - view from the inside.

- The next stage is vapor barrier, which prevents water vapor from entering the insulation layer. We again use penofol as a vapor barrier. From the inside we nail the sheets to the rafter system.

- A sheathing of slats should be placed on top of the vapor barrier. It is on them that the internal cladding will be attached: plywood, plasterboard, lining, etc.

Wall insulation

The walls are insulated with this material both outside and inside.

If we talk about external insulation, the technology here is identical to creating ventilated facades using other heat insulators. The only difference is that penofol is stuffed on top of the slats, as mentioned above.

We insulate the wall with penofol.

Most often, this insulation is used specifically for internal wall insulation, since the economic efficiency will thus be significantly higher, and besides, the work can be carried out at any time of the year. For internal insulation, you can use penofol as the main thermal insulator, laying it in one or two layers.

Just install insulation

The use of penofol is extensive. To install insulation with a foil layer, it is necessary to perform a number of preparatory operations, depending on the type of work and the material that will be insulated.

The use of penofol in a wooden house as insulation is the most common. For high-quality gluing, it is necessary to pre-treat the surface with a grinding machine.

Penofol is attached to penoplex using polymer glue, which is applied to a denser surface.

A misconception is that penofol is attached to a soft surface using staples or an industrial stapler. This will compromise the integrity of the coating and the material will lose its insulating properties.

It will be easier to glue isolon to metal if you use self-adhesive insulation. However, a simple way would be to press the insulation onto the metal surface with rigid foam boards.

The main thing is to follow the basic rules for installing penofol: do not use it in flooring under a concrete screed, do not stitch or fasten with wire, do not use a stapler, do not glue joints with adhesive tape.

For high-quality installation, overlap one sheet onto another, accurately measure the required length to save material, and always lay out the insulation in a thin layer, without forming an “accordion.” For the highest quality organization of butt joints, use special adhesive foil.

Basic rules for installing penofol

If you are planning to lay foil penofol on a balcony or loggia, follow these rules:

- A small distance for ventilation, about 1-2 cm, should be maintained between the structural elements and the penofol itself. This is done in order to avoid the appearance of moisture.

- The material should only be laid with the foil surface inward, towards the heat source. You can secure the material either using mounting tape or a stapler. You can also use C-class penofol so as not to use additional fasteners.

- The sheets must be joined end-to-end to achieve the same thermal reflectance. If the balcony or loggia is not sufficiently insulated, it is recommended to lay the material with an overlap, the width of which is 10 cm.

As a conclusion, we note: by choosing foil penofol to insulate a balcony or loggia, the master will not only achieve a high-quality result, but will also be able to significantly save on additional insulation, auxiliary and installation equipment.

And now we bring to your attention a video in which we compare foil penofol and its characteristics with other similar materials.

Video: Penofol and its analogues

The construction of any facility is impossible without the use of thermal insulation materials. With their help, resource costs for heating are reduced. One of the popular solutions is foil penofol. It is chosen for its excellent characteristics. The installation procedure for the material does not contain any difficult aspects. Even a beginner can easily handle this work. Compared to other solutions, it costs significantly less. The result is high-quality and inexpensive insulation of premises.

Application of foil penofol

The scope of use of the material is very wide and is becoming larger every year. Most often used for the following purposes:

- Hydro- and thermal insulation work in baths, saunas;

- Roofing work, roof insulation;

- Protection of utilities, boilers and heating tanks;

- Insulation of refrigerators and cold rooms;

- Insulation of floors, ceilings and walls on balconies and loggias, as well as their vapor barrier.

https://youtube.com/watch?v=lJpeX_rfMxM

Foil insulation is also used in the insulation of ventilation ducts and air conditioning systems, for insulating special equipment, when creating temporary structures, etc.

Technical characteristics, dimensions and weight of the insulation roll

- Large range of temperature parameters: from -60° to +100°.

- The reflective effect reaches 97%.

- Thickness from 3 to 10 mm. There is penofol 40 mm thick, designed for use in northern regions.

- Water absorption% - from 0.7 to 0.35.

- Ultimate compressive strength, MPa - 0.035.

- Vapor permeability - 0.001 mg/mchPa.

- Thermal conductivity from 0.037 to 0.052 W/ms.

| Name | type A | type B | type C | AIR | 2000 type A | 2000 type B | 2000 type C | type AL-P | Super NET |

| Application temperature, °C | -60 to +100 | ||||||||

| Thermal reflection coefficient of the surface, %, not less | 97 | ||||||||

| Surface optical reflection coefficient, %, not less | 90 | — | |||||||

| Thermal conductivity coefficient, λ, at 20 °C, no more than W/m °C | |||||||||

| dry | 0,037-0,038 | 0,048-0,049 | 0,042 | ||||||

| - under operating conditions A | 0,037-0,038 | 0,049-0,050 | 0,043 | ||||||

| - under operating conditions B | 0,037-0,038 | 0,050 | 0,043 | ||||||

| Heat absorption coefficient (with a period of 24 hours), s, W/m °C | 0,45-0,51 | 0,44-0,48 | |||||||

| Vapor permeability coefficient, no more than, mg/mh Pa | 0,001 | ||||||||

| *Heat transfer resistance, R (depending on thickness), m2 °C/W | 1,14-1,36 | — | 1,07-1,26 | 1,3-1,5 | |||||

| Dynamic modulus of elasticity, Units, MPa | |||||||||

| under load 2 kPa | 0,26-0,39 | 0,26-0,40 | |||||||

| under load 5 kPa | 0,72-0,77 | ||||||||

| Relative compression, units | |||||||||

| under load 2 kPa | 0,03-0,9 | 0,04-0,10 | |||||||

| under load 5 kPa | 0,12-0,20 | 0,13-0,23 | |||||||

| Reduced impact noise level reduction index, dB | 20 | ||||||||

| Specific heat capacity, C, kJ/kg °C | 1,95 | 1,95-2,00 | |||||||

| Calculated mass ratio of moisture in the material, w, under operating conditions, %: | |||||||||

| A | 2 | ||||||||

| B | 10 | 2-5 | |||||||

| Flammability group | G1 |

Dimensions and weight

| Material type | Thickness, (mm) | Width, (mm) | Length, (m) | Area, (sq. m) |

| A, B | 3-5 | 1200 | 30 | 36 |

| A, B | 8, 10 | 1200 | 15 | 18 |

| A.L.P. | 3 | 580 | 15 | 17,4 |

| Name | Type | Roll thickness, mm | Net roll weight, kg | Gross roll weight, kg | Roll diameter, m | Roll height, mm | Roll length, lm | Roll area, m2 | Approximate roll volume, m3 |

| PENOFOL 2000 | A | 3 | 4,8 | 5,1 | 0,42 | 1200 | 30 | 36 | 0,212 |

| PENOFOL 2000 Economy | A | 3 | 8,0 | 8,3 | 0,49 | 1200 | 50 | 60 | 0,288 |

| PENOFOL 2000 | A | 4 | 5,8 | 6,1 | 0,48 | 1200 | 30 | 36 | 0,276 |

| PENOFOL 2000 | A | 5 | 6,8 | 7,1 | 0,53 | 1200 | 30 | 36 | 0,337 |

| PENOFOL 2000 | A | 8 | 4,9 | 5,2 | 0,48 | 1200 | 15 | 18 | 0,276 |

| PENOFOL 2000 | A | 10 | 5,9 | 6,2 | 0,53 | 1200 | 15 | 18 | 0,337 |

| PENOFOL 2000 | A | 13 | 7,5 | 7,8 | 0,60 | 1200 | 15 | 18 | 0,432 |

| PENOFOL 2000 | A | 15 | 8,5 | 8,8 | 0,65 | 1200 | 15 | 18 | 0,507 |

| PENOFOL 2000 | A | 20 | 7,3 | 7,6 | 0,61 | 1200 | 10 | 12 | 0,447 |

| PENOFOL 2000 | IN | 3 | 6,6 | 6,9 | 0,42 | 1200 | 30 | 36 | 0,212 |

| PENOFOL 2000 | IN | 4 | 7,6 | 7,9 | 0,48 | 1200 | 30 | 36 | 0,276 |

| PENOFOL 2000 | IN | 5 | 8,6 | 8,9 | 0,53 | 1200 | 30 | 36 | 0,337 |

| PENOFOL 2000 | IN | 8 | 5,8 | 6,1 | 0,48 | 1200 | 15 | 18 | 0,276 |

| PENOFOL 2000 | IN | 10 | 6,8 | 7,1 | 0,53 | 1200 | 15 | 18 | 0,337 |

| PENOFOL 2000 | IN | 13 | 8,4 | 8,7 | 0,60 | 1200 | 15 | 18 | 0,432 |

| PENOFOL 2000 | IN | 15 | 9,4 | 9,7 | 0,65 | 1200 | 15 | 18 | 0,507 |

| PENOFOL 2000 | IN | 20 | 7,9 | 8,2 | 0,61 | 1200 | 10 | 12 | 0,447 |

| PENOFOL 2000 | WITH | 3 | 3,8 | 4,0 | 0,42 | 600 | 30 | 18 | 0,106 |

| PENOFOL 2000 | WITH | 4 | 4,3 | 4,5 | 0,49 | 600 | 30 | 18 | 0,144 |

| PENOFOL 2000 | WITH | 5 | 4,8 | 5,0 | 0,53 | 600 | 30 | 18 | 0,169 |

| PENOFOL 2000 | WITH | 8 | 3,5 | 3,4 | 0,48 | 600 | 15 | 9 | 0,138 |

| PENOFOL 2000 | WITH | 10 | 3,6 | 3,9 | 0,53 | 600 | 15 | 9 | 0,169 |

| PENOFOL 2000 | WITH | 13 | 4,4 | 4,7 | 0,60 | 600 | 15 | 9 | 0,216 |

| PENOFOL 2000 | WITH | 15 | 4,9 | 5,3 | 0,65 | 600 | 15 | 9 | 0,254 |

| PENOFOL 2000 | WITH | 20 | 4,1 | 4,4 | 0,61 | 600 | 10 | 6 | 0,223 |

| PENOFOL | WITH | 3 | 4,2 | 4,5 | 0,42 | 600 | 30 | 18 | 0,106 |

| PENOFOL | WITH | 4 | 4,8 | 5,1 | 0,48 | 600 | 30 | 18 | 0,138 |

| PENOFOL | WITH | 5 | 5,5 | 5,8 | 0,53 | 600 | 30 | 18 | 0,169 |

| PENOFOL | WITH | 8 | 3,5 | 3,8 | 0,48 | 600 | 15 | 9 | 0,138 |

| PENOFOL | WITH | 10 | 4,0 | 4,3 | 0,53 | 600 | 15 | 9 | 0,169 |

| Penofol Super NET | A | 6 | 6,4 | 0,62 | 1200 | 15 | 18 | 0,461 | |

| Penofol Super NET | IN | 7 | 7,4 | 0,62 | 1200 | 15 | 18 | 0,461 | |

| Penofol Super NET | WITH | 7,8 | 8,2 | 0,62 | 1200 | 15 | 18 | 0,461 |

Table of main technical properties

| Options | Type – A | Type – B | Type – C |

| Applicable at a temperature of 0 C | from – 60 to +100 | ||

| Surface thermal reflection coefficient, % | 95 – 97 | ||

| Thermal conductivity coefficient, dry, at 20° C, no more. | 0,037 – 0,049 | 0,038 – 0,051 | 0,038 – 0,051 |

| Water absorption by volume,% | 0,7 | 0,6 | 0,35 |

| Vapor permeability, mg/m h Pa | 0,001 | ||

| Ultimate compressive strength, MPa | 0,035 | ||

Application

The universal material isoline has found application in construction and everyday life. You can use it to create heat, noise and vapor insulation for a room, regardless of the type of building.

Isoline is popular:

- When used in floors

- When insulating an attic

- When used on a sloped roof

- For thermal insulation of walls

- For insulating internal partitions

- For thermal insulation of floors

- For thermal insulation of external load-bearing walls

- For use in “warm floors”

- For insulation of basements

How to use isoline?

The excellent characteristics of isoline make it possible to work with it in residential, industrial and administrative premises.

Before using the material, it is necessary to prepare the working surface: clean it from dust and dirt, degrease it.

It is important to attach the isoline to a fairly soft and flat surface; this can be done in the following ways:

- using a stapler, screws or slats;

- using glue or aqua spray;

- using double-sided tape - in case of attachment to complex, ribbed and curved surfaces.

The instructions describe the sequence in which isoline is used. It is applied “joint to joint”, with an overlap of about 5-10 cm. The joints are fastened with glue or tape, in some cases welded with an industrial hair dryer.

When making insulation, it is important to be extremely careful: do not cut or damage the surface of the material. If there is a violation of the integral structure, it is necessary to correct this defect, for example, using a patch

What glue should I use Penofol?

Penofol is mounted using glue. Fastening with nails and screws is used mainly for fixing type B sheets to walls. At the same time, the places of fastenings and joints are additionally taped with tape or strips of polyethylene foam, since violation of the integrity of the coating negatively affects the heat-insulating properties.

Attention! When installing one-sided Penofol, you should attach it with the foil side out. The glue is applied to the side without foil.

The correct adhesive for installing Penofol is important, but even more important is a properly prepared surface. Any surface must be leveled, all defects (gaps, cracks) eliminated, and debris removed. Manufacturers offer a specialized adhesive composition for polyethylene foam, but a universal adhesive, liquid nails, double-sided tape, or a layer of polyurethane foam will also work. The main thing when choosing an adhesive composition is to take into account the specifics of the specific surface to which the insulating material is attached. When choosing an adhesive, operating conditions should also be taken into account. For interior spaces it is important:

- Permit for indoor use;

- Complete absence of toxicity;

- High resistance to adhesion;

- Temperature range: from -60°C to +100°C.

For use in outdoor installation, the resistance of the adhesive mixture to water vapor and liquids is important.