How to tighten the fittings of plastic windows so that it does not blow

The tightness of the sash rebate to the frame is determined by the eccentrics, which engage with the strikers. Installers leave them in the neutral position by default. But with the onset of cold weather or strong gusty winds, such pressure is not always enough. You have to install it yourself.

There are pins on the side that need to be adjusted to achieve the desired result. They have three provisions:

- Neutral. Installed at the manufacturing plant. The mark (dot or tick) is located along the vertical axis.

- Winter. The mark on the trunnion is turned towards the rubber. This position provides maximum pressure.

- Summer. The point or mark faces the street. This way the pressure is loosened for the summer season, which increases the service life of the sealing rubber bands.

The trunnions are turned using a No. 4 hex key, an asterisk or a screwdriver. There are several of them around the entire perimeter. The exact quantity depends on the size of the sash.

Instagram @regulirovka_okon

Neutral position

Instagram @regulirovka_okon

Position

Instagram @regulirovka_okon

Position

When a house shrinks or structural elements sag over time, you may encounter misalignment of parts relative to each other. Eliminate it by adjusting the hinges. We'll show you more details on how to do this correctly in the video.

How to eliminate blowing from under the glazing bead

The problem is rare and is a manufacturing defect. Therefore, if the warranty has not yet passed, contact the installers. There may be several defects.

Usually the glazing bead simply does not match the dimensions. If its length is less than necessary, cracks will form at the corners at the joint. When the glazing bead turns out to be longer, after installation it does not fit well and bulges. A defect may appear during operation. A pressure bar installed with excessive tension snaps off due to thermal expansion.

In both cases, the bead must be replaced. You buy a new clamp strip from a window company and cut it to size. It is easy to cut down at an angle using a hacksaw and a miter box. It is useless to shorten an old long rail. Most often it is already deformed. And if not, carefully trimming it a couple of millimeters turns out to be very difficult.

Main reasons

PVC structures with closed doors should not let air in from the street. Manufacturers promise users perfect tightness throughout the service life. If it starts to blow from a plastic window, then it is necessary to determine the culprit of heat loss in the room.

Incorrectly set mode is the main problem with drafts from glass blocks. The designs provide 3 adjustment options that need to be changed in different seasons. After installation, the default position is “Standard”. If there was a service during the warm season, the specialist could reset the plastic window to its summer state. There is a separate position in the buildings for winter.

Reasons for blowing through the structure Source severdv.ru

In designs, the problem arises from a manufacturing defect. Low-quality plastic has low resistance to temperature changes. PVC deforms or cracks in cold weather. The defect often appears in new windows, although it also happens several years after installation. If stored improperly in a warehouse, even a good profile may lose its tightness, which will cause blowing.

Drafts often occur when low-quality fittings and seals are used. If manufacturers have saved on components, then even an expensive plastic window will blow. If the rubber bands are heavily soiled, the tightness of the profile is compromised and microcracks appear. Cold air penetrates into the room without problems.

Source of cold air in the window Source folksland.net

It starts to blow from a plastic window if there are installation errors. If the installation is carried out in violation of the technology, then it will leak through the glass block. Deviation from the norm occurs when:

- incorrect profile location;

- poor-quality insulation of slopes;

- poor installation of the window sill.

If a plastic window does not meet climate standards, it will definitely be cold. A single-chamber profile is suitable for mild winters; it can withstand a maximum of -10 C. At -15 C, a two-chamber model is needed; at -30 C, a three-chamber model is needed. Professionals recommend choosing glass blocks that are suitable for the weather of the region.

What to do if a plastic window is blowing from below from under the sash

If the adjustments described above did not resolve the problem, it means that the rubber seal is worn out. In this case, you can see the following defects: rubbing, jamming, loss of elasticity. We select new tires according to the sample or type of profile system. We change in the following sequence:

- Use the handle to open the door.

- In the corner we pry up the seal and tighten it around the perimeter until we reach the top loop.

- We move the sash to the “ventilation” position.

- We take out the remaining part of the sealing rubber.

- Carefully clean and wash the installation groove.

- We place the beginning of the new rubber at the top in the middle. We completely go around the perimeter with a single contour. It is important to avoid excessive tension at the corners.

- At the junction we cut the rubber without excessive tension or overlap.

- Pull out both ends of the elastic. Apply a drop of Moment glue to their lower parts and install them back.

Be sure to change the second sealing contour, which is located on the frame. The principle of operation remains the same.

The described method is suitable for tilt and turn opening. To repair conventional pivot windows, you must first remove the sash.

What tools and materials are needed for adjustment?

The choice of a set of tools to eliminate blowing from the hinges of a PVC window depends on the design of the window. In the case where the clamping mechanism is located on the hinge side, the adjustment procedure can be performed with a simple screwdriver on hand. The “tongue” helps to set the level of pressing of the sash; the more it is extended, the more tightly the sash will fit.

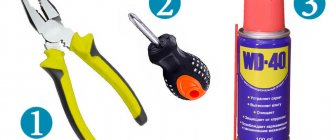

In other cases, the performer will need a set of the following tools:

- 4 mm hex wrench or “four”, hereinafter referred to as an adjustment wrench;

- regular pliers;

- wrench;

- a regular screwdriver.

In order to extend the “tongue” on the windows with the left hinges, the adjustment key is rotated counterclockwise, and on the right - clockwise.

How to get rid of a draft from under the windowsill

Cold air can come directly from under the window sill board or from the junction of the lower frame profile with the window sill. Both defects indicate irregularities in the construction of the foam seam. In new buildings, installers save foam by filling large gaps with construction waste.

The most correct solution is to dismantle the window sill and reinstall it with careful foaming of the seam. In this case, it is necessary to break the lower part of the slopes and restore them after repair. Therefore, this method is rarely used. To avoid the least damage, we carry out the work in the following order:

- We break the plaster layer under the window sill to a height of 5-10 cm.

- We clean the mounting foam and construction debris from the seam. We leave only the support bars on which the window sill board rests.

- Carefully foam the seam to its full depth.

- After hardening, we restore the plaster and wallpaper.

Foam expands as it hardens. To prevent the window sill from lifting up, we place something heavy on it.

If work is carried out at sub-zero temperatures, you need to use special frost-resistant polyurethane foam.

This method is only suitable for shallow window sill depths. If it is more than 20-25 cm, it is very difficult to reach the frame installation plane. In some cases, the defect can be eliminated from the street side.

- Doors and partitions

How to insulate a balcony door made of wood and plastic: instructions for each type

Defective window design

If a metal-plastic window was created by an unknown company, it is likely that errors were made during production. In this situation, it can come through from anywhere: the frame, the connections between the frame and the glass unit, the profile, and so on.

The fittings in the window structure are responsible for the operation of the entire mechanism as a whole. If any of its elements break, the window will not function correctly, and as a result, the fittings may cause drafts.

What to do when a plastic window blows from the hinge side

If a tight fit of the sealing rubbers is ensured, the only possible defect is damage to the slopes. There are practically no blows in plastered junctions. Therefore, we will tell you how to repair prefabricated slopes made of sandwich panels. First we dismantle them:

- We remove the outer framing corners or profiles.

- Using a long knife or wood hacksaw, cut the foam seam around the perimeter.

- We remove the panels.

- We clean the remaining foam from the wall and plastic.

After dismantling, we see the quality of the installation of the window unit itself. We evaluate it visually and establish the points through which cold air enters the apartment. We remove the old foam from them and foam the joints again.

A draft may appear due to the formation of cracks in the wall under the plastic panels. If you find them, the damaged areas need to be expanded, primed and sealed with plaster.

After sealing the problem areas, we restore the slopes.

The problem may lie not only in the interior, but also in the exterior decoration. In urban development, the outer slope is formed by a quarter in reinforced concrete panels or brickwork. But between the wall and the PVC window profile there is always a foam expansion joint.

The most common mistake is improper sealing. The installers do not cover the foam, leaving it in direct sunlight. Over time, it collapses and crumbles. Fixing a damaged junction unit is simple:

- Using a knife or spatula, remove the insulation from the gap.

- Re-foam the seam.

- After the composition has completely dried, cut off its protruding parts.

- We close the gap with a stripping or plaster it.

These were the main faults that you can fix yourself. You have learned how to adjust plastic windows so that it does not blow and you can now repair them if minor defects appear. Let's give a few more recommendations that will help keep your home warm.

- Window

Do-it-yourself replacement of double-glazed windows in plastic windows: 7 answers to the main questions and instructions

Prevention recommendations

Windows are taken for granted by many: however, they require regular maintenance.

- The washing up. Wash sashes, frames, slopes on the front and back sides at least 2 times a year.

- Adjustment. Due to a large number of operations, the fittings become loose and begin to blow, so they need to be tightened. Call a professional at least once a year.

- Replacement of worn parts. Seals, hinges and other elements may break - do not delay updating them.

The only thing more important than prevention is proper installation: trust window replacement only to trusted companies that guarantee their work. Do not skimp on fittings and components, then they will be reliable, last a long time and will not blow.

How to make an additional camera on a double-glazed window

Modern two-chamber systems reliably protect the house from any frost. The energy efficiency of older frames lags far behind. Eliminating this shortcoming requires a complete replacement of the glazing, which is very expensive. A budget solution to the problem is a special thermal film. It is installed on the PVC profile in the following sequence:

- Wash the glass and frame thoroughly.

- We glue double-sided tape along the perimeter around the glazing beads in a single outline.

- Remove the top protective strip from the tape and glue the film.

- Cut off the excess with a utility knife.

- We heat the material until the folds are completely smoothed out.

Thermal film creates an additional sealed chamber that accumulates heat and reduces thermal conductivity. It retains light transmission and remains virtually invisible.

- Window

How to adjust plastic windows for the winter: detailed instructions

How to insulate PVC windows yourself

If all measures to eliminate drafts have not brought the desired result, you should try to insulate the window structure yourself.

- First, you need to remove dust and other contaminants from the glass unit and frame. Particular attention should be paid to the seal, since foreign accumulations on it lead to premature loss of rubber elasticity and a decrease in the tightness of the structure as a whole.

- Treating areas with an increased likelihood of drafts with silicone sealant will help minimize the penetration of cold air from outside and retain heat inside the room.

- For larger gaps, a special sealing cord is better.

- The energy-saving properties of a double-glazed window can be slightly increased with the help of insulating film. The film is applied from the inside, and the result, according to manufacturers, is comparable to installing additional glass.

Of course, all the methods described above will not be effective in every case. Using film and sealant, it is unlikely that it will be possible to make budget models the same as high-quality multi-chamber structures. Sometimes getting rid of drafts and increasing the level of comfort in a room is only possible by completely replacing the window unit with a more airtight, warmer and soundproof one.

Subscribe

Ways to solve the problem

To eliminate the problem of blowing out a slope with your own hands, a home craftsman, if he has tools and consumables, must fulfill the requirements of the technological map:

- The slope framing element is removed from its seat to determine the blowing problem.

- If the slope is made of plaster and paint, it may require partial destruction, since there may be pores or cracks inside the material.

If there is worn foam, the material is cut out from the seam.- The resulting cavity is cleaned of dust and dirt by blowing with compressed air under pressure.

- If necessary, the technician tightens or reinstalls the screws on the mounting plates that secure the frame.

- The cavity between the frame and the slope is filled with polyurethane foam, after which it is necessary to wait time for it to harden.

- Excess foam is removed with a knife after hardening.

- The cavity is protected with sealant using a mounting gun.

- After polymerization of the substance, a foil hydro-vapor barrier tape must be glued along the entire length of the joint to prevent blowing, moisture and fumes from entering the seam.

- Upon completion of the restoration work, it is necessary to re-assemble the slope structure - the finished framing elements are fixed with adhesive compounds, mechanically, or a layer of plaster and paint is applied to the end of the opening.

Advice. If refinishing involves wet processes, such work should begin only after polymerization of the sealing agents used in the repair of the window structure.

When is a simple repair not enough?

In some situations, simply repairing the window sill board and sealing the seam may not help , since more serious intervention in the building structures is required:

- If there is insufficient insulation in the outer wall, it is necessary to install additional insulating material on the facade of the building. In old apartment buildings, such work is carried out as part of a major overhaul by local authorities.

- In case of insufficient power of heating devices, they must be replaced, since the heat input must ensure heating of the entire volume of the room.

- If there are cold bridges or cracks in the wall structure, it is necessary to carry out finishing or restoration work after a detailed examination of the structure.

Note! If the owner of a residential or public premises decides to carry out a complete renovation of his property, experts advise using all of the listed methods simultaneously.

With a combined approach, maximum energy efficiency of the space being used is achieved, and external structures almost completely eliminate heat loss.

Free consultation:

Consultant:

Telegram:

WhatsApp:

E-mail: E-mail address is protected from spambots. Javascript must be enabled in your browser to view the address.

Check out

Blowing through a plastic window, how to fix it?

After-sales service is a set of measures that allows you not only to eliminate air leaks and cracks in your window, but also to prevent their occurrence in the future.

It includes:

- consultation and free visit of a specialist;

- diagnostics of the condition of window structures;

- adjustment, cleaning, lubrication of fittings, prevention of sagging;

- replacement of window seals and sealing.

Service cost 1860 rubles/leaf

taking into account all materials and work (the amount includes the replacement of 8 m/p. sealing seal for 170 rubles + adjustment and lubrication of locks).

FAQ

❓ Why is it blowing from plastic windows? I don’t know what to do?

The causes of the problem are always different, see the most common ones here. Our technician will conduct an inspection, determine the causes and eliminate the breakdowns.