Eco-friendly, efficient, durable, for all types of structures - these are the insulation materials produced by the Isover company in recognizable yellow packaging. Like the price range, the range of its insulating materials is quite wide. Under the Isover brand they produce insulation based on quartz and basalt for various types of facades, ceilings, roofs, and partitions. The right product can be found for both private housing construction and serial construction.

Installation features

When working with the material, you must use gloves.

When working with Izover material, remember - this is glass wool. Despite the application of additional protective coatings to the surface of certain types, the spread of glass dust cannot be ruled out. Contact with skin will cause only temporary irritation, but contact with eyes or respiratory tract will be a serious problem. Therefore, the use of gloves, masks, respirators, and safety glasses when working with mineral wool is mandatory.

Laying Isover stone wool is a simple, quick and almost waste-free procedure. Installation between the joists inside the interfloor ceiling is carried out without the use of additional means of fixation. Sloped roof structures also usually do not require the use of dowels or strings. Vertical installation of rolls can cause some difficulties, so it is not advisable. The slabs are installed in partitions between profiles or sheathing bars, mounted so that the insulation fits as tightly as possible. As a rule, the width between the posts equal to the width of the slab minus 1 cm is quite sufficient. Installation of facade samples is carried out using disc-shaped dowels or special glue.

Stamps

Isover's lines of thermal insulating products include several dozen items and are designed to solve specific problems. They all differ in delivery form, thickness, density and size.

Please note: since all brands have the same base, they are interchangeable.

For general construction work

Izover Profi. A universal material with increased elasticity. Provides the highest level of thermal protection among the brand's retail materials.

Supplied in rolls, plate thickness – 50, 100 and 150 mm. Does not require additional fasteners during installation; can be installed by surprise. Received positive reviews from builders.

Used for insulation and sound protection:

- external walls inside and outside the house;

- pitched roofs;

- interfloor ceilings;

- frame walls;

- internal partitions;

- ventilated facades.

Classic. Supplied in rolls, material thickness – 50 mm. Can be installed by surprise.

Application area:

- insulation of suspended ceilings;

- interfloor ceilings - the material lies between the joists;

- attic spaces.

Isover Classic stove. The shape of mineral wool is slab. Size – 610*1170 mm, thickness 50 and 100 mm. Packaging 5 and 10 m2.

Application area:

- insulation of frame walls;

- insulation of walls from the inside;

- insulation of ventilated facades.

Isover kl 34. Release form – slab with a thickness of 5 and 10 cm. Does not require additional fasteners during installation.

Application area:

- ventilated facades;

- frame walls.

Isover kl 37. Release form – plate. It is used for insulation and sound protection of roofs and interfloor ceilings.

Isover kt 40. Two-layer roll material. Thickness – 10 cm, each layer is 5 cm. Used for insulation of horizontal planes.

Isover Sauna. Supplied in rolls, mat thickness 50 and 100 mm. The main feature is the presence of a vapor barrier layer. Suitable for rooms with high humidity. Refers to moderately flammable materials. It is used for insulation of walls, floors and ceilings in baths and saunas.

Izover Uteplyaev. Universal mineral wool, available only for Siberia and the Far East.

Special solutions

- Isover Pitched Roof. Has increased moisture resistance.

- SoundProtection. Provides a high level of noise protection.

- Frame P32. Designed for insulation of frame houses. Provides savings on heating costs of up to 25% compared to the basic product.

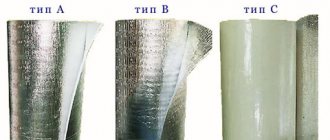

- Frame M40-Al. Min wool with one-sided aluminum coating. Designed for wet rooms, can be used without additional finishing.

- Izover Plaster Facade. The material is of high density and has low vapor permeability.

- Vent Facade Top and Vent Facade Bottom. They are used for two-layer insulation systems for ventilated facades.

- Floating Floor. Designed for insulation and sound insulation of floors. Has increased elasticity and density. It is made using tongue-and-groove technology.

- Isover OL-P. Special solution for flat roofs. Has ventilated grooves to remove moisture. Made using tongue-and-groove technology, which increases the tightness of the mineral wool layer.

Video description

The video shows the technology of insulating the walls of a frame house with isover:

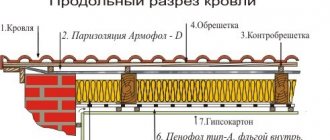

Technology for installing isover on the side of the building facade

The sheathing is constructed in increments of a centimeter narrower than the width of the insulation. The slabs are laid inside, and a counter-lattice is attached on top. It should provide an air gap. A waterproof and windproof membrane is attached to it. And the finishing decorative trim (siding or lining) is already attached to it.

Soundproofing technique using isover

To soundproof the lower surfaces, floating floor technology is used. It helps reduce indoor noise levels by 50%. It is called so because the materials used for finishing do not come into close contact with the side walls. Therefore, noise waves are not transmitted to them.

Technology for laying floating floors Source sk.decorexpro.com

To build such a structure, a layer of vapor barrier is first spread on a reinforced concrete base, then an isover is laid on it. Waterproofing material is spread on top. The top of such a cake can be filled with concrete screed or covered with gypsum sheets. Even before starting work, damper tape must be glued to the walls along the entire perimeter of the floor. It will ensure the formation of a technological gap that will not allow noise to move across the floors. The width of the tape should exceed the thickness of the screed by 2-3 cm.

Insulation release form

There are also single-layer and two-layer Izover. In the first case, the thickness reaches 5–10 centimeters. The two-layer material does not differ too much in thickness, since here the dimensions of one layer are about 5 centimeters. The slabs can be about a meter in size, or more precisely, this is the standard that can most often be found on the construction market, but there are exceptions when ordering insulation on websites or from dealers.

One roll of Izover insulation is about 16–20 square meters, that is, quite large in size. The roll width reaches 1.2 meters, while its length can vary from 7 to 14 meters. It goes without saying that the technical characteristics will differ slightly depending on the choice of material size.

Best answers

Elena:

You named different brands. We need to look at the insulation. If the humidity is high (or at risk). then foam plastic (plain or extruded) is better. If there is no moisture, then cotton wool is more environmentally friendly. At normal humidity, all modern insulation materials have approximately the same heat transfer resistance coefficient.

Special opinion:

insulation is better in mats than in rolls. their other parameters are almost the same.

Andrey Denisov:

there is also penoizol

Alexei:

read - what they are made of, the smelliest ones are those with phenol-containing fiber.

Marina Alskaya:

The difference is in cost and durability of materials. But no matter what you choose, installing insulation from any of these companies is equally difficult. If the walls are insulated, then waterproofing is also necessary.

Ecowool-Voronezh:

Manufacturer. Each manufacturer has materials of different prices and different densities, some have “eco-friendly”, some have “soundproofing”, which is basically the same thing. They differ in features and density. There are different densities for different applications. The higher the density, the colder it is. Everyone is afraid of moisture - a vapor barrier is required. The thermal resistance coefficient for all is indicated for absolutely dry material.

HUMAN:

I used Rockwool to insulate the house... a house according to Norwegian technology with autonomous heating... permanent residence... cool in summer, warm in winter within 22 degrees... 100mm of insulation in terms of thermal conductivity is equal to 300mm of timber...

Brand history

The rights to the brand belong to the Saint-Gobain company from France. Its main office is located in Paris, and its founding date is 1665. It appeared at the direction of Louis XIV and produced glass and mirrors. The name Isover insulation is formed from the words “glass” and “insulation”. In our country, the company's products were initially known under the Uteplyaev brand.

Initial Izover products in Russia

Over more than 350 years of history, Saint-Gobain has grown into an international industrial group, represented in 67 countries and employing over 170 thousand employees. Sales in 2015 amounted to 39.6 billion euros. The company is included in the following ratings:

- The hundred largest industrial enterprises according to Forbes.

- Top 100 innovative organizations in the construction sector.

- Best Employer - 2016

Experience and the latest technologies have made the company a world leader in creating a comfortable living space. The main activities of Saint-Gobain are:

- Innovative technologies in the field of high-tech products in the production of ordinary and special glass.

- Building materials represented by ISOVER, ISOTEC, ISOROC brands in insulation; GYPROC in gypsum solutions; WEBER dry mixes; ECOPHON for acoustic ceilings and panels; in siding and tiles - CERTAINTEED; RAM pipes

- Distribution activities in the field of building materials.

Saint Gobain Campaign:

The company's products have been known on the Russian market for more than 20 years. Ten years ago, a plant was opened in the Moscow region (Egoryevsk), and since 2011 in Chelyabinsk, the Minvata company began producing stone fiber insulation. All products have international environmental certificates and comply not only with internal corporate standards, but also EN 13162—ISO 9001.

Key insulation indicators

Isover is an insulation material that is made from fiberglass of the best quality using a special technology. It is in many ways similar in its properties to mineral wool. Available in:

- rigid and semi-rigid slabs;

- rolls and mats.

The latter are used in the arrangement of building facades, ceilings and for roof insulation. The basis for Izover is glass fibers. Their indicators:

- length varies from 100 to 150 microns;

- thickness is 4 to 5 microns.

Due to the above parameters, the insulation is characterized by resistance to various types of loads and elasticity.

Thermal conductivity indicators

The thermal conductivity coefficient is not so high and is only 0.041 watts per meter per Kelvin. Moreover, this value does not change upward over time, as happens with some other heat insulators. Thus, glass fibers are able to conserve heat and retain air.

Sound insulation parameters

Fiberglass material has good performance in terms of protection from external noise. This is due to the fact that there is an air gap between the layers of material. It is she who is responsible for delaying extraneous sounds. Silence in the room where Izover was applied was ensured.

Prone to fire

Any thermal insulation materials whose density reaches 30 kg per cubic meter and are called Isover are classified as non-flammable. This is their definition, in accordance with GOST standards. This insulation can be used in any home, including residential ones. Izover's characteristics allow this to be done. Its use is considered safe both for insulating a one-story cottage and a high-rise building.

Rigid and semi-rigid modifications, equipped with a coating of Tyvek film, fiberglass or aluminum foil, are considered low-flammable. There are some restrictions for such insulation, but there are relatively few of them. Accordingly, they can be used almost everywhere. The main requirement concerns strict compliance with fire safety standards in the building, which form the basis of SNiP.

Vapor permeability of Izover

For most modern thermal insulators, resistance to moisture is the main disadvantage. Most of them cope with their functions, as long as the air in the room is dry. Once it gets wet, even fiberglass can retain heat less well. But Izover is good because it is able to both quickly absorb moisture and quickly release it back.

For this rule to always work and under any conditions, it is necessary to leave a gap between the insulation and the wall, the diameter of which would be at least 2 cm. It is necessary for optimal ventilation. If you forget about this point, then the thermal insulation characteristics of Izover will begin to decrease as moisture accumulates. Its vapor permeability varies from 0.50 to 0.55 mg/mchPa. If the insulation receives 1% moisture, then the thermal insulation performance will drop by 10%.

Duration of service

Isover is an insulation material for which service life is one of the key indicators. Even if it is able to retain heat for a long time, it can last no more than a year. It all depends on the specific product. Insulating a building requires a lot of effort and time. Yes, and this requires a lot of work.

Fortunately, Izover is an exception to the rule. By using it to cover the floor and walls, you can forget for a long time about the need to re-install it. There are examples when it was possible to use a heat insulator for several decades in such a way that all its indicators remained unchanged.

The so-called water repellents included in Izover have water-repellent properties. In addition, insects and other pests do not settle in this insulation, since they simply do not like such a habitat. Even mold does not attack fiberglass insulation.

https://youtube.com/watch?v=PVDsrv-vC-g

Environmental performance and safety

Izover can boast not only of its technical characteristics. Any fiberglass materials of this type are considered harmful to human health. It does not include any toxic compounds. Finnish scientists spent a long time checking the parameters of the material and came to the conclusion that its use, even over a long period of time, does not negatively affect people’s quality of life.

Product weight

Isover is much lighter than other heat insulators. That is why in those structures where the walls are not made of the most durable materials or the excessive load is unacceptable, it becomes a way out.

The lineup

Like any building material, isover insulation is available on the market in several types. Each of them is designed for specific building structures:

Isover product line

- “Sound protection” is intended for finishing partitions and walls.

- For frame construction, insulation of the “ Framework ” model is used.

- “Profi” is used for insulating attics and pitched roofs. This is high quality insulation. Profi is offered on the market in rolls of thickness 50, 100 and 150 mm.

- The classic is widely used. He can insulate floors, joists, attic floors and other complex objects. Although Classic is a roll material, it can be used to cover huge areas at a time. Usually two layers of 50 mm are laid in a roll. So you can safely divide it or use it as is.

- Classic Plus . This heat insulator is used to insulate the external and internal surfaces of walls. Has high thermal insulation characteristics. A magnificent example.

Important . Many models are classified as “interchangeable”. That is, one is freely replaced by another. In this regard, Pro and Classic Plus are universal insulation materials.

The sound protection model has increasingly become used in rooms where there is a need to reduce the penetration of noise from the outside. Sound protection is two in one. Therefore, for those who no longer want to hear their neighbors’ steps overhead, it is recommended to install Izover Sound Protection under suspended or suspended ceiling structures.

Fiberglass construction wool from a Finnish manufacturer is today a leader in the “thermal insulation” category. Excellent quality characteristics plus an affordable price for the mass consumer. This is enough to achieve the excellent qualities of a 100% insulated house.

Mineral wool insulation Isover (Izover) Venti 100

- Length(mm):1200mm

- Width(mm):600mm

- Density (kg/m3):82 kg/m3

- Packed area: 2.16 m2

792 RUR

Mineral wool insulation Isover (Izover) Venti 150

- Length(mm):1200mm

- Width(mm):600mm

- Density (kg/m3):82 kg/m3

- Packed area: 1.44 m2

775 RUR

Mineral wool insulation Isover (Izover) Light 100

- Length(mm):1200mm

- Width(mm):600mm

- Density (kg/m3):38 kg/m3

- Packed area: 2.88 m2

563 RUR

Mineral wool insulation Isover (Izover) Optimal 100

- Length(mm):1200mm

- Width(mm):600mm

- Density (kg/m3):34 kg/m3

- Packed area: 2.88 m2

117 RUR

Mineral wool insulation Isover (Izover) Optimal 50

- Length(mm):1200mm

- Width(mm):600mm

- Density (kg/m3):34 kg/m3

- Packed area: 5.76 m2

363 RUR

Mineral wool insulation Isover (Izover) Venti 30

- Length(mm):1200mm

- Width(mm):600mm

- Density (kg/m3):103 kg/m3

- Packed area: 5.76 m2

692 RUR

Mineral wool insulation Isover (Izover) Venti 50

- Length(mm):1200mm

- Width(mm):600mm

- Density (kg/m3):85 kg/m3

- Packed area: 4.32 m2

792 RUR

Mineral wool insulation Isover (Izover) Light 50

- Length(mm):1200mm

- Width(mm):600mm

- Density (kg/m3):38 kg/m3

- Packed area: 5.76 m2

563 RUR

Mineral wool insulation Isover (Izover) Facade 100

- Length(mm):1200mm

- Width(mm):600mm

- Density (kg/m3):145 kg/m3

- Packed area: 1.44 m2

854 RUR

Against the backdrop of many proposals for new insulating materials, mineral wool “Isover plaster facade” and other types of “Isover” remain recognized classics. Fiberglass is processed using a special patented technology to produce insulating materials with strictly specified properties. If high adhesion to adhesives is required for external wall insulation, we recommend using “Isover façade”.

In addition to chemical resistance to plaster mixtures, this type of material has a zero ignition rate. According to the area of application, Izover is divided into the following types:

- For light thermal insulation;

- For general building insulation;

- For special purposes;

- Lightweight insulation.

Almost weightless Izover mineral wool slabs eliminate the load on the base. The slabs are used in the reconstruction and construction of residential buildings and industrial facilities. This is a well-proven insulation of floors, roofs, walls, attics, and ceilings between floors. The slabs are available in optimal sizes. Thanks to this, 20% less time is spent on installation. Our company’s specialists will tell you what is best for you to buy - “Isover Facade” or other products of this brand.

General building insulation.

Izover fiberglass rolls are mounted without fastenings and fit tightly to the base. They have proven themselves to be excellent for thermal insulation of partitions, walls, floors and more. You can buy Izover stone wool with aluminum film for vapor barrier.

In the production of mineral wool of this class, particularly enhanced moisture resistance and fire safety properties are imparted. Insulation is widely used for arranging pitched roofs of houses, insulating floors, insulating water pipes and ventilation pipes. To protect against external airborne noise, “Isover sound protection” is used. The level of protection is confirmed by acoustic tests.

Material Specifications

With an optimal price/quality ratio, thermal insulation has the following technical characteristics:

- High thermal conductivity: 0.033-0.037 W/mK.

- Flammability class NG: does not ignite and does not support combustion.

- Wide operating temperature range: withstands heat up to 6,000 degrees without deformation.

- Density: about 15 kg/m2.

- Moisture absorption: 0.08 kg/m per day.

It should be clarified that these are average indicators. Insulation is available in a wide range, so density and thermal conductivity may vary.

| № | Name | Dimensions | Thermal conductivity | Weight | Volume (pack/m2/m3) |

| 1 | Isobox Extralight | 1200mm*600mm*50mm | 0.038 W/(m*K) | ~ 4.8 kg/pack | 8 pcs/pack 5.76 m2/0.288 m3 |

| 2 | Isover Classic Plus | 1170mm*610mm*50mm | 0.039 W/(m*K) | ~ 6.5 kg/pack | 14 pcs/pack 10 m2/0.5 m3 |

| 3 | Izover Classic TWIN-50 | 6150mm*1220mm *50mm | 0.041 W/(m*K) | ~10 kg/pack | 2 pcs/pack 15 m2/0.75 m3 |

| 4 | Izover Frame P-34 | 1170mm*619mm*50mm | 0.034 W/(m*K) | ~7.61 kg/pack | 16 pcs/pack 11.42 m2/0.571 m3 |

Minwata Rockwool

The main feature of the laboratory production of Rockwool mineral wool is that it is identical to natural conditions during a volcanic eruption.

This effect has a positive effect on the quality of the building material - the arrangement of the fibers is chaotic, due to which the following properties are achieved:

- combustion resistance

- at temperatures up to 1000 C they do not even melt, - excellent thermal insulation properties

- up to 0.046 W/m K. - vapor tightness

- not affected by water

- high sound insulation

- increased resistance to mechanical stress.

The Rockwool brand has become widespread among construction companies and private consumers in the domestic market due to its perfect fire safety, good hygroscopicity and sound insulation and relatively low cost. Prices from different suppliers may vary widely, because... Some sellers offer immediate installation work and delivery to the site.

There are also different types of this insulating material, for example, the price of Rockwool Light Butts starts at 1,873 rubles for 1000x600x50mm slabs, and some facade varieties of mineral wool can reach 7,000 rubles for the same volume.

Brand history

The rights to the brand belong to the Saint-Gobain company from France. Its main office is located in Paris, and its founding date is 1665. It appeared at the direction of Louis XIV and produced glass and mirrors. The name Isover insulation is formed from the words “glass” and “insulation”. In our country, the company's products were initially known under the Uteplyaev brand.

Initial Izover products in Russia

Over more than 350 years of history, Saint-Gobain has grown into an international industrial group represented in 67 countries and employing over 170 thousand employees. Sales in 2015 amounted to 39.6 billion euros.

Soundproofing Izover “Quiet House”: The company is included in the following ratings:

- The hundred largest industrial enterprises according to Forbes.

- Top 100 innovative organizations in the construction sector.

- Best Employer - 2016

Experience and the latest technologies have made the company a world leader in creating a comfortable living space. The main activities of Saint-Gobain are:

- Innovative technologies in the field of high-tech products in the production of ordinary and special glass.

- Building materials represented by ISOVER, ISOTEC, ISOROC brands in insulation; GYPROC in gypsum solutions; WEBER dry mixes; ECOPHON for acoustic ceilings and panels; in siding and tiles - CERTAINTEED; RAM pipes

- Distribution activities in the field of building materials.

Saint Gobain Campaign:

The company's products have been known on the Russian market for more than 20 years. Ten years ago, a plant was opened in the Moscow region (Egoryevsk), and since 2011 in Chelyabinsk, the Minvata company began producing stone fiber insulation. All products have international environmental certificates and comply not only with internal corporate standards, but also EN 13162—ISO 9001.

Types of thermal insulation

All materials produced under the Isover brand differ from each other in functional purpose and physical properties. Industrial and household categories of insulation are supplied separately. There are several of the most popular varieties of products from Saint-Gobain.

Types of thermal insulation Izover:

Minvata Izover KL 34

This is a mineral plate 5 or 10 centimeters thick. It is used in frame construction and does not require additional fastening with dowels. These products are characterized by high elasticity, which maximizes the scope of application.

The insulation is packaged in a bag. After opening, it instantly takes on its original appearance and is ready for installation. Another advantage of this modification is low shrinkage. Among the technical characteristics it should be noted:

- Thermal conductivity – 0.034 W/μ.

- Vapor permeability – 0.53 mg/mchPa.

- Nominal compression at 2 thousand Pa – 60%.

- Return to normal state – 98%.

Thermal insulation of walls and floors:

Pitched roof

This modification is intended for use as roof insulation. Available in the form of mats measuring 117x61 centimeters and 5-10 cm thick. It is almost one hundred percent hydrophobic. This is its main advantage over its competitors - the ability to use it in conditions of high humidity without loss of properties.

This type of Izover product is characterized by the following indicators:

- Thermal conductivity - 0.035 W/mK.

- Steam conductivity - 0.55 mg/mchPa.

- Absorbency with partial immersion - 0.08 kg/m² in 25 hours.

- A density of 15 kg/m³ is combined with sufficient return and deformation properties.

The advantages of the material make it number 1 in the Russian markets.

Non-combustible thermal insulation for pitched roofs Izover is sold in packages with an area of 14.72 m² and a weight of 10.8 kg.

Product category KT37

This insulation is available in rolls 630 cm long, 60 cm wide and 50 or 100 millimeters thick. Double compression packaging allows for convenient and economical transportation of the material to the construction site. If the volume of insulation in the package is 0.16 cubic meters, then after opening it increases to 0.71 m³. The scope of its application is the insulation of concrete, brick, and wooden buildings from the inside. It is not prohibited to install floors and interfloor ceilings as thermal protection.

Due to the density of 15 kg/m³, it is not recommended to use KT37 in structures with high mechanical loads. Thermal conductivity of 37 W/μ is sufficient to create an effective coating even in one layer. In this, Isover competes with Rockwool Wired Mat 80 slabs. However, the roll form of the product allows you to insulate large areas much faster with the help of a non-combustible product from Saint-Gobain.

Roof insulation:

Material indexed KT40

It is classified as wall insulation. Isover KT40 is supplied in rolls and is intended for frame, brick houses and for insulating free building cavities. The roller, which is 10 cm thick, can be easily divided in half thanks to its two-layer structure. Its remaining dimensions are: 7 meters in length and 61 cm in width. Covered area - 17.8 m².

Izover roll insulation: Its thermal insulation properties are slightly worse than those of other Izover materials - 0.04 W/mk. However, high vapor permeability (0.5 Mg/mPa) makes it possible to effectively insulate buildings made from any raw material with its help. To improve moisture absorption, which amounts to 15% of the weight of the product, it is recommended to install additional waterproofing. GOST 30225 classifies KT40 as non-combustible thermal insulation.

Basalt mass

Russian factories, in addition to fiberglass slabs, produce materials in the form of stone wool. Similar varieties have the following differences:

- Higher cost.

- More durable, stronger and denser than traditional mineral wool.

- Less elasticity. Packages are larger, increasing the cost of storage and transportation.

- High moisture and heat resistance.

Basalt insulation is more expensive, but of the highest quality.

Classification of basalt insulation:

- Optimal - for pitched roofs in the form of sound and thermal protection.

- Light - for frame house construction.

- Acoustic - for sound insulation.

- Floor - from impact noise.

- Ruf V, Ruf N - for flat roofing.

- Plaster and Facade-Master are designed for facades under plaster.

- Venti - with improved vapor permeability.

- The standard applies to multi-layer brickwork.

Testing basalt wool for combustion:

Characteristics of Izover insulation

Let's look at what this heat insulator is. First of all, the quality of any thermal insulation material depends on the accuracy of adherence to manufacturing technology at each stage of production. The production of Izover is carried out in several stages, each of which is carefully controlled.

Provided that all technological standards are observed during manufacturing, Izover insulation has the following basic qualities:

Thermal conductivity

For Isover, the thermal conductivity coefficient is 0.041 watts per meter per Kelvin. In addition to the fact that this value is more than acceptable, it is noteworthy that it practically does not increase over the entire service life of the insulation. This is due to the fact that strong fiberglass is less susceptible to destruction and reliably retains air.

Soundproofing

Using Izover as a soundproofing material can effectively protect a room from extraneous noise and sounds. Like all fiberglass insulators, Izover perfectly retains air inside, which destroys sound waves, and taking into account specially developed modifications, the sound insulation of rooms treated with insulation meets all existing standards.

Flammability

Thermal insulating materials with a density of up to 30 kg US3 and called Isover are not considered flammable. This is how they are designated by special GOST 30244-94, which assigns them the abbreviation NG. Thus, the use of Izover insulation from the point of view of fire safety is absolutely safe both for industrial construction and for private households.

As for Izover sheet insulation, according to the technical characteristics, the above GOST defines them as slightly flammable. This definition suggests that such insulation can be used in industrial and civil construction, for insulation and sound insulation of most buildings and structures, with the exception of objects with a high fire hazard.

Vapor permeability

The ability to maintain heat and sound insulation parameters in conditions of high humidity is characterized by the vapor permeability of the insulation. For Isover, this coefficient is 0.5-0.55, which means that with an increase in its humidity by 1%, the thermal insulation parameters can decrease by 10-12%. However, this significant drawback is characteristic of all such materials and, subject to all technological measures, it can be avoided. With proper ventilation and waterproofing, Izover will fully cope with its responsibilities.

Life time

Proper installation of heat insulation is a labor-intensive and expensive undertaking, so the service life of the insulation is very important. Due to the high mechanical strength of fiberglass, Izover is able to maintain its configuration unchanged for quite a long time

This allows the insulation to retain air, and therefore heat. With the correct ventilation and waterproofing system, the service life of Izover will be 40 years or more.

Environmentally friendly and harmless

In terms of environmental safety, Izover has all possible safety certificates. Materials made using a similar technology have undergone repeated tests and the result has always remained unchanged: Izover insulation, the properties of which are given above, does not pose any danger to humans.

Weight

In terms of its weight characteristics, Izover compares favorably with its closest competitors. Its low specific gravity and high thermal insulation make it possible to successfully use it for insulation and sound insulation of non-load-bearing structures, and also significantly simplifies installation.

Release form and dimensions

To meet all the needs of the construction market, insulation can be produced as:

1. Roll type;

2. Insulation boards;

3. According to individual sizes.

The thickness of Izover insulation in one layer is 50-100mm.

The standard roll width is 1200mm, and the length can vary from 7 to 14m.

The slabs have a size of 1000x1000mm, except where otherwise specified.

Other Various Options

- Average density 13kg/m3;

- The tightness of contact with the insulated surface strongly depends on the configuration of the object.

To summarize all of the above, it can be noted that using Izover, the main characteristics of which we discussed above, is economically feasible. In addition, laying this insulation, as a rule, does not require special skills, which also allows you to save money and insulate your home yourself.

How it is made

So, what is Isover insulation? The characteristics of any insulating material depend primarily on how accurately the required technologies are followed during its production. Isover insulation is manufactured as follows:

Quartz sand, cullet, limestone, soda ash and other minerals are thoroughly mixed in advance.

The resulting mixture melts at a temperature of 1300 degrees. until a homogeneous fluid plastic mass is obtained. In a special installation, this liquid glass is fed from a great height into a bowl rotating at high speed, the walls of which have small holes. Under the influence of centrifugal force, the hot mass is squeezed out in the form of long thin threads. The fibers are mixed with yellow polymer glue. The resulting sticky mass is fed into a special oven, where it is rolled between steel shafts and blown with hot air. As a result, the glue sets and the layer itself is leveled. The finished glass wool is fed into circulation saws to be cut into slabs of the required size.

Types of isover insulation

Isover insulation has nine popular varieties:

- Isover KL34 – slabs 5 or 10 centimeters thick, suitable for any surface;

- Isover KL37 – slabs are produced in pressed packages;

- Isover KT37 – roll material;

- Isover KT40 – two-layer mats; .

- Isover STYROFOAM 300A – solid boards with the addition of extruded polystyrene foam;

- Isover VENTITERM – slabs treated with a water repellent;

- Isover “Pitched roof” – used for roof insulation;

- Isover “Ventfacade” – two-layer facade slabs;

- Isover “Sound Protection” – available in the form of plates and rolls, used for sound insulation.

Many types of insulation can be interchanged with each other.

Application of isover insulation

Izover is used for insulation of internal and external walls, roofs, floors of residential, public and industrial buildings. It is also used to minimize noise in wall, ceiling and floor structures.

Isover KL34 is used for any surfaces: horizontal, vertical, with any angle of inclination. To install the slabs, a frame is used in which the isover is mounted, and no additional fastenings are needed.

Isover KL37 is used for interfloor slabs, walls and roof slopes. Available in the form of pressed slabs and packaged. This type of insulation must be pressed tightly against the working surface; installation does not require additional fasteners.

Isover KT37 is produced in roll form, used mainly for horizontal surfaces, but can be used for internal walls and partitions and roof insulation. The material does not require additional fastenings; it must be pressed tightly to the surface.

Isover KT40 is a two-layer roll material used for horizontal surfaces. During installation it does not require additional fastenings.

Isover STYROFOAM 300A has improved thermal insulation and moisture resistance properties thanks to additives in the form of extruded polystyrene foam. The material is produced in the form of rigid slabs and requires additional fastenings. Depending on the base, the slabs are fastened with: plastic dowels, special mastics based on cold bitumen, or polyurethane foam glue.

Isover VENTITERM is produced in the form of dense slabs and is used for external insulation of facades, ventilation and water supply pipes, for sound and thermal insulation of ventilated facades.

Isover VENTITERM PLUS is available in slabs with the same dimensions as Isover VENTITERM. The main difference is the improved helicopter protection properties, due to the fact that on one side these plates are covered with special fiberglass.

Isover “Pitched roofing” is used for structures with changes in humidity conditions. It is also a good sound and heat insulator, used in any climatic conditions. It is used for pitched roofing and soundproofing of internal walls and partitions. The dimensions of the Isover “Pitched Roof” slab are 610x1170 with a thickness of 100 mm.

Isover “Ventfacade” is available in the form of slabs of different sizes, with a thickness of 50, 100, 150 mm. Consists of two layers, but can be used as a single layer material. Thanks to its elasticity and elasticity, it fits tightly to the base and does not require additional fastenings.

Isover “Sound Protection” is produced in the form of slabs with dimensions 610×1170 and a thickness of 50 mm. This material reduces noise levels and is used for sound insulation of roofs, facade walls, internal walls and partitions. Can be used in any climatic conditions.

Isover “Sauna” The product is intended for insulation of walls and ceiling structures of saunas and baths

from the inside.

The foil product is also good for insulating

other damp areas. ISOVER SAUNA also works as an effective heat insulator.

Isover “ Optimal”

– stone wool slabs for frame structures. The product is recommended for thermal insulation of the roof, walls, and floors of the house.

Isover “Facade- Master”

is a high-tech facade insulation for low-rise and private construction.

Isover “ Classic”

Used in lightly loaded horizontal structures.

Isover “ Pro”

, judging by the characteristics and reviews, is the most durable material in this line.

Isover “Ruf N” is a non-flammable basalt insulation. Made from stone fiber with the addition of a synthetic binder. High-density material can withstand significant loads. It is used as a bottom layer when insulating flat roofs in private housing construction.

Isover Venti

a special product for insulation systems for ventilated facades.

Advantages and disadvantages

Among the advantages of building materials, the following factors are worth noting:

- High-quality thermal insulation. Izover is used in particular for facade insulation, which allows significant savings on heating a house in the winter.

- Resistance to extreme temperatures.

- Fire safety. Mineral wool does not burn, so it is used for insulating multi-story buildings, where the spread of fire would have very serious consequences, as well as for roofs and attic floors, the structure of which consists of wooden elements.

- Resistance to mechanical and chemical influences.

- Tensile strength and no compressive deformation.

- Excellent sound insulation allows the products to be used in plasterboard partitions.

- Resistance to the negative effects of rodents.

- Easy to install.

These technical characteristics of Izover insulation speak in favor of its use in a variety of areas of construction.

However, this material has its drawbacks. During installation, it is necessary to use a full set of personal protective equipment: goggles, gloves, a respirator, long-sleeved clothing that completely covers the body.

Even if it is very hot outside, you cannot neglect the above remedies, because the fibers cause irritation and itching when they come into contact with the skin.

If the insulation is moistened by 1%, its thermal insulation properties deteriorate by 10%. Therefore, when using the material on the roof and attic, it is necessary to carry out waterproofing work, because getting wet will lead to a loss of thermal insulation properties. And when installing slabs on the facade of a building, it must be immediately covered with mesh or plastered to avoid moisture due to precipitation.

Varieties

Thanks to its excellent characteristics, Izover insulation has found wide application in various areas for exterior and interior decoration of the house. Insulation will be indispensable for insulating floors, walls, attics or attics. Compared to other insulation materials, Isover is much cheaper, which adds to its popularity.

Izover insulation is divided into several varieties, each of which is designed to fulfill its role.

Isover "Classic Stove"

A slab version of insulation is designed for thermal insulation of the following places:

- Insulation of the building facade.

- Creation of a heat or sound insulating partition.

- Thermal insulation of suspended ceiling.

Plate

Product release is carried out with the following indicators:

- A slab copy marked 50/E/K, produced in 14 pieces in one package. When laid, the products occupy 10 m2 of usable space. The packaging volume is 0.5 m3.

- Marking 100/E/K indicates the thickness of one sheet is 100 millimeters. One package contains 7 sheets, which can be used to insulate 5 m2 of cold surface. Available in container volumes of 0.5 m3.

Isover "Classic Twin 50"

Rolled varieties of heat-insulating material are used to cover large areas. Thus, it is possible to reduce the number of joining seams.

Applicable:

- As external insulation of facade walls.

- As a heat-insulating material for the roofing part of the house - attic or attic.

Available:

- In rolls. One package includes 2 strips, each 6150-8200 millimeters. The covering area of one roll is 15-20 square meters. Standard insulation thickness is 50 millimeters.

- Construction stores offer another type of product, “Classic Twin Promo 80”. The difference lies in the thickness of the product - 80 millimeters, and the coverage area - 18 m2.

Isover “Warm Home”

Recommended for use:

- Insulation of floors whose design includes logs.

- Thermal insulation of floor slabs.

Warm house

Two different types are produced:

- 2 strips per roll, 50 mm thick. The standard width is 1220 millimeters. Length 5490 millimeters. Covered surface area – 13.4 m2. The volume of the finished package is 0.67 m3.

- The difference between this type of product is the length of the strips - 7000 millimeters, and the correspondingly changed coverage area - 17.1 m2. These indicators could not affect the packaging volume - 0.85 m2.

When unfolding the rolls, their total thickness is 100 mm, which allows the use of 50 and 100 mm insulation of walls or floors.

Isover “Warm Roof”

Recommended places of use:

- Attic rooms.

- Insulation of pitched roofs.

Insulation of the following places is also possible:

- Lag floor construction.

- Walls with lined lathing.

The packaging is available in two types. The first one has dimensions of 50 x 1220 x 5000 mm, where the covered area is 12.2 m2, and the packaging volume is 0.61 m3.

Isover "Sauna"

Analyzing the name of the thermal insulation material, it becomes clear that it is intended for rooms with high humidity:

- Floor with logs.

- Walls with assembled frame.

- Ceilings.

One type of packaging with dimensions 50x1200x12500 mm. Covered area – 15 m2. The volume of packaged products is 0.75 m3.

The vapor barrier layer is a foil coating fixed to the outside of the insulation. It is used mainly for rooms with a large area, since one strip can cover a length of 12.5 meters. This advantage reduces the appearance of cold bridges.

Isover "Warm House Stove"

The main place of insulation is the floor structure. Using a thickness of 100 millimeters allows the use of thermal insulation material:

- Facade wall insulation.

- Internal thermal insulation.

- Frame partitions.

Warm House Stove

Produced:

- One package includes 14 mats of 50x610x1170 millimeters. Covered area – 10 m2. The volume of packaged products is 0.5 m3.

- One package including 7 mats – 100x610x1170 millimeters. Coverage area – 5 m2. The volume of packaged products is the same.

Isover “Warm Walls”

Thermal insulating product, recommended:

- External insulation of the building.

- Installation of thermal insulation for external finishing.

- Interior decoration.

The product is similar to the “Warm House” slabs and has two types of packaging.

Glass wool NEMAN

The products of the Belarusian glass factory meet the highest requirements. NEMAN glass wool has excellent thermal insulation and sound insulation properties, is not fire hazardous and is durable. The raw materials for production are domestic products.

Sevenfold compression of the material reduces transport costs.

Glass wool is produced in roll form. This facilitates the work on thermal insulation of pipelines and insulation of industrial installations.

Neman glass wool is mainly used for insulating pitched roofs, installing suspended ventilated facades and suspended ceilings. It is possible to use glass wool when carrying out thermal insulation work both outside and inside the building.

The topic of modern thermal insulation materials, both imported and domestically produced, continues to interest readers, because thanks to these materials it is possible not only to reduce home heating costs, but also to significantly reduce the cost of building construction. A leading specialist advises.