The article will discuss what isover insulation is, how it is produced, what technical characteristics it has, what disadvantages the products of the French concern “Saint-Gobain” have, what types of presented material are most popular in our domestic market. Photos and videos will reveal the nuances of installing slabs and rolls.

Packed isover slabs Source emupauto.ru

How it is made

So, what is Isover insulation? The characteristics of any insulating material depend primarily on how accurately the required technologies are followed during its production. Isover insulation is manufactured as follows:

- Quartz sand, cullet, limestone, soda ash and other minerals are thoroughly mixed in advance.

The resulting mixture melts at a temperature of 1300 degrees. until a homogeneous fluid plastic mass is obtained. In a special installation, this liquid glass is fed from a great height into a bowl rotating at high speed, the walls of which have small holes. Under the influence of centrifugal force, the hot mass is squeezed out in the form of long thin threads. The fibers are mixed with yellow polymer glue. The resulting sticky mass is fed into a special oven, where it is rolled between steel shafts and blown with hot air. As a result, the glue sets and the layer itself is leveled. The finished glass wool is fed into circulation saws to be cut into slabs of the required size.

Material Specifications

With an optimal price/quality ratio, thermal insulation has the following technical characteristics:

It should be clarified that these are average indicators. Insulation is available in a wide range, so density and thermal conductivity may vary.

| № | Name | Dimensions | Thermal conductivity | Weight | Volume (pack/m2/m3) |

| 1 | Isobox Extralight | 1200mm*600mm*50mm | 0.038 W/(m*K) | ~ 4.8 kg/pack | 8 pcs/pack 5.76 m2/0.288 m3 |

| 2 | Isover Classic Plus | 1170mm*610mm*50mm | 0.039 W/(m*K) | ~ 6.5 kg/pack | 14 pcs/pack 10 m2/0.5 m3 |

| 3 | Izover Classic TWIN-50 | 6150mm*1220mm*50mm | 0.041 W/(m*K) | ~10 kg/pack | 2 pcs/pack 15 m2/0.75 m3 |

| 4 | Izover Frame P-34 | 1170mm*619mm*50mm | 0.034 W/(m*K) | ~7.61 kg/pack | 16 pcs/pack 11.42 m2/0.571 m3 |

Table 1

| Material | Density, kg/m3 | Dry thermal conductivity coefficient λ, W/(m oC) | Calculated thermal conductivity coefficients in wet condition* | |

| λA,W/(m oC) | λB,W/(m oC) | |||

| Concrete | ||||

| Reinforced concrete | 2500 | 1,69 | 1,92 | 2,04 |

| Aerated concrete | 300 | 0,07 | 0,08 | 0,09 |

| 400 | 0,10 | 0,11 | 0,12 | |

| 500 | 0,12 | 0,14 | 0,15 | |

| 600 | 0,14 | 0,17 | 0,18 | |

| 700 | 0,17 | 0,20 | 0,21 | |

| Brickwork | ||||

| Ordinary clay on cement-sand mortar | 1800 | 0,56 | 0,70 | 0,81 |

| Silicate on cement-sand mortar | 1600 | 0,70 | 0,76 | 0,87 |

| Ceramic hollow core with a density of 1400 kg/m3 (gross) on cement-sand mortar | 1600 | 0,47 | 0,58 | 0,64 |

| Ceramic hollow core with a density of 1000 kg/m3 (gross) on cement-sand mortar | 1200 | 0,35 | 0,47 | 0,52 |

| Silicate eleven-hollow on cement-sand mortar | 1500 | 0,64 | 0,70 | 0,81 |

| Silicate fourteen-hollow on cement-sand mortar | 1400 | 0,52 | 0,64 | 0,76 |

| Tree | ||||

| Pine and spruce across the grain | 500 | 0,09 | 0,14 | 0,18 |

| Pine and spruce along the grain | 500 | 0,18 | 0,29 | 0,35 |

| Oak across the grain | 700 | 0,10 | 0,18 | 0,23 |

| Oak along the grain | 700 | 0,23 | 0,35 | 0,41 |

| Insulation | ||||

| Stone wool | 130-145 | 0,038 | 0,040 | 0,042 |

| Expanded polystyrene | 15-25 | 0,039 | 0,041 | 0,042 |

| Extruded polystyrene foam | 25-35 | 0,030 | 0,031 | 0,032 |

*λA or λB is taken into account depending on the city of construction (see table 2).

Installation features

The frame for Izover can be assembled from either a wooden plank or a metal profile. The distance between the individual elements of the sheathing should be slightly less than the width of the insulation boards. This allows you to install them by surprise.

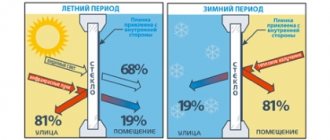

Of course, “Izover”, the technical characteristics of which we have described, when used as a heat or sound insulator, must be protected from moisture. In order to prevent it from getting wet, steam and waterproofing films are used. When assembling a pie of walls or roofing, in this case a certain order of installation of materials is observed. The vapor barrier is installed on the interior side. Due to temperature differences, the humidity in rooms and attics is usually higher than outside. Therefore, condensation forms on the walls and ceiling. Using a vapor barrier prevents it from getting on the insulation. A waterproofing film is installed outside. It protects Izover from getting wet during rain or melting snow.

Additional fasteners when installing slabs, as already mentioned, are not used. They are only necessary when installing the material on the ceiling. In order to completely prevent their loss, in this case special dowels called “fungi” are used.

Since the material is capable, albeit in small quantities, of releasing substances harmful to human health, when installing it from inside the premises, you should carefully monitor the tightness of all finishing seams.

Safety

The safety of stone wool for health is evidenced by its natural origin , production method and the conclusion based on the results of product testing and audit of the enterprise . It is no coincidence that professional builders use mineral insulation in the construction or reconstruction of even children's, medical and sports institutions . ISOVER stone wool creates a comfortable temperature in the building of the Federal Center for Cardiovascular Surgery (Chelyabinsk), in an emergency hospital (Kazan), in many kindergartens in Moscow, St. Petersburg and other Russian cities. This material is chosen when it is important to use a safe product with a positive experience of use, the quality of which can be trusted. Fire safety Mineral wool belongs to the group of non-combustible materials. Therefore, it does not burn, does not spread fire and does not emit harmful substances not only when in contact with an open fire, but also simply when heated.

Environmentally friendly and harmless

Fiberglass materials of this type are absolutely harmless to human health and life. During their operation, no harmful substances are released. Finnish scientists have been checking this fact for half a century. No danger was detected - this verdict was repeatedly made by specialists from the Institute of Cancer Problems.

Rules for working with stone wool

Manufacturers of stone wool recommend installing stone wool in accordance with the rules for working with any building material, i.e. wearing gloves and a respirator.

Insulation weight

If we compare Izover with other heat insulators in terms of weight, it will turn out to be much lighter than the others. Therefore, in those buildings whose walls are made of not very durable materials or excessive load is unacceptable, the use of Izover will be an excellent way out.

Description and Application

The presented material has many advantages and disadvantages of mineral wool. And this is not surprising, since their properties are quite similar. It is produced in the form of slabs, which can be either rigid or semi-rigid. There is also the opportunity to buy Izover in the form of rolls and mats. They are used in the arrangement of the roof and facades of the house, ceilings, walls and floors.

Izover is based on glass fibers, the length of which reaches 100-150 microns and the thickness of 4-5 microns. It is these parameters that allow the Izover heat insulator to obtain high levels of elasticity and resistance to loads.

In the photo Izover insulation

Using wool of different densities for insulation

The choice of insulation according to the indicator under consideration depends on the place of its use. It is not always necessary to overpay in order to get the desired result. Most often, the facade, walls, roof and floor are insulated. These are the options that are worth considering.

Facade

When selecting insulation for a facade, you need to pay attention to the mass and density of mineral wool. For most buildings, weighting is very undesirable. It is also worth paying attention to the possibility of subsequent finishing, because this indicator is also influenced by

So:

It is also worth paying attention to the possibility of subsequent finishing, because this indicator also affects this. So:

- If the facade is equipped with a ventilated one, then a sufficient density is 45-100 kg m³. Here the cotton wool is laid into the sheathing and there will be virtually no stress. The main tasks for this type are to maintain its shape and not sag under its own weight, and the indicated indicator is enough for this.

- If the facade is to be plastered over insulation, then the density should be above 100 kg m³, optimally from 145 to 165. This will allow the use of any types of plaster mixtures, including bark beetle, barenkom and even mosaics. Since this mineral wool will have to withstand heavy loads during installation, it must be securely fastened; for this, a system with dowels is used in combination with adhesive fastening.

Wall insulation

In this case, the selection is made based on ease of installation, that is, the density should be at least 30-45 kg m³. In this case, you need to insulate from the inside; MDF boards or drywall should be screwed onto the material on top. In order to mount such mineral wool, you need a lathing; rolls or sheets are placed in it.

Roof

Since roof insulation work is carried out at heights, the main criteria when selecting mineral wool are light weight and ease of use. Material with a density of 30-35 kg m³ can be pleased with these qualities. Its sound and heat insulation properties will be excellent, and at the same time light weight. Installation can be carried out using two methods:

- Using a construction stapler.

- In the lathing with a vapor barrier closure.

In both the first and second cases, it is necessary to cover the insulation with finishing material on top.

The selection of mineral wool in this case depends on the type of floor finishing. So, if these are sheet materials, for example solid boards, laminate, etc., then a density of more than 30-45 kg m³ is not needed. After all, there will be no pressure on the cotton wool; it is placed between the lags.

But now manufacturers offer material with an indicator of 200-220 kg m³; such wool can be mounted on the base and filled with cement screed on top. Of course, the price of such material is quite high, but the ease of handling is the greatest possible.

Characteristics and scope

The material is produced in slabs and rolls and is characterized by high thermal efficiency, elasticity, density and light weight.

Refers to non-combustible materials. The main competitors in the mineral insulation market are Ursa, Izovol, Rockwool, Parok, Knauf. Isover mineral wool has a wide range of applications in general construction work. For industrial work, the Izover company produces insulation under the Isotek brand.

Isover is used for the following types of work:

- thermal insulation and sound protection of external walls;

- roof insulation;

- ventilated facade systems, multi-layer walls;

- for sound insulation of internal partitions;

- in industry - for insulation of pipelines, ventilation, etc.

Isover, like other insulation, has its advantages and disadvantages.

The advantages of Izover include:

- Ease of transportation and storage - the manufacturer compresses the insulation 5-6 times when packaging it. Izover restores its shape 100%.

- Product lines with different technical characteristics are intended for different areas of construction. For example, Isover Sound Protection or Isover Pitched Roof.

- High elasticity. The insulation is superior to other mineral wool in this indicator, thanks to the special TEL technology with which it is produced.

- High energy efficiency - 5 cm of mineral wool is equal in thermal conductivity to 1 m of brickwork.

- Refers to non-combustible materials. The use of mineral wool for thermal insulation of a house does not increase its fire hazard class.

- Noise protection. Due to the fact that there is air between the fibers of the insulation, it does not transmit sounds well.

- The warranty period declared by the manufacturer is 50 years.

- Resistant to biological and chemical influences.

- Light weight – 28-60 kg/m3.

- Convenient to work. To insulate the surface, you just need to roll out the roll.

- Does not shrink during use.

- Environmentally friendly material. Holder of the EcoMaterial Absolute eco-label and ISO 14001:2004 international environmental management certificate.

- Heat resistant.

- High density and rigidity, which allows you to install insulation without additional fasteners.

The disadvantages of Izover include:

- The soft structure of wool limits its scope of application.

- Absorbs moisture well. A ventilation gap is required during installation. If this is not done, the cotton wool can become saturated with moisture and lose its technical characteristics, and even freeze completely in winter.

Approximate price of popular brands on the Russian market

Manufacturer Saint-Gobain supplies the domestic market with a wide range of products based on two types of mineral wool - fiberglass and mountain basalt, the latter is more expensive due to its higher environmental friendliness, causing less harm to health during installation and operation.

Prices for slabs and rolls differ among different suppliers of goods; the cost of one package is usually indicated; the average price for some types is:

- 60 rubles per 1 m2 of glass wool slab or roll 50 mm thick (Warm House), the cost of a product with a thickness of 100 mm is 2 times higher;

- 85 rubles per 1 m2 of 50 mm thick basalt wool slab (Warm Roof, Warm Walls, Quiet House series);

- 125 rubles 1 m2 for quartz thermal insulation with a foil vapor barrier in one roll, intended for insulation of saunas and baths (Warm Sauna).

Price list for some brands

Effective solutions for thermal insulation using ISOVER

Application of Izover, its specifics and varieties

It is known that approximately forty percent of heat loss occurs through the wall partitions of a building, so insulating “weak spots” with high-quality material, subject to and following all installation rules, is a guarantee of heat preservation in the house. As a result, spending on more expensive and reliable insulation will provide further savings on heating all rooms during the cold season.

The manufacturing company invites customers to choose the most suitable insulation among several types, which can be divided depending on the area of application.

Areas of application of Izover thermal insulation:

- roofs and ceilings;

- external walls;

- internal, interior partitions.

Further types of Izover products...

Izover KL-34

This type of Izover product consists of slabs, the thickness of which can be 5 or 10 centimeters. It is suitable for insulating any planes - vertical, horizontal, inclined. Due to the tight fit on the frame, the use of additional fasteners is not required. KL-34 slabs are often used to insulate ventilated facades.

Izover KL-37

A soft fiberglass based insulation that is designed to work in buildings where the insulation is not heavily stressed. Interestingly, the packaged material is subjected to additional compression by 2 times - this helps reduce the overall volume, thereby slightly reducing delivery costs. Like the previous type of Izover insulation, KL-37 does not require additional fasteners. However, it should be remembered that during installation it is necessary to comply with the condition - to strive for the tightest possible fit of the slabs to the surface.

Izover KT-37

It is used for insulation of attics, roofs, as well as interfloor ceilings. The main difference from KL-37 is that it is a roll material. The remaining characteristics, recommendations for operation and installation are the same.

Izover KT-40

It is supplied in rolls and, unlike other Izover products, this type of material consists of two layers, each of which is 5 centimeters thick. KT-40 will be an ideal option if installation is carried out in a wooden or metal frame, where the distance between the posts is 60 centimeters.

Isover STYROFOAM 300A

Produced in the form of slabs with extruded polystyrene foam. This material requires the use of fasteners. Thanks to the special composition of STYROFOAM 300A boards, the heat and moisture protection indicators are higher than those of many similar products. This type of Izover insulation has found its application in the thermal insulation of walls, floors and flat roofs. It is allowed to apply a layer of plaster directly on top of the slabs.

Isover VENTITERM

Insulation based on mineral wool with basalt fibers. The versatility of this material is due to the fact that installation can be carried out both with and without fasteners. Professionals have long found use for this insulation in insulating water supply systems and ventilation pipes.

Izover Pitched roof

Izover Pitched Roofing has been specially developed to protect the roof. This type of insulation not only allows you to retain heat, but also, thanks to its ability to absorb sounds from the outside, creates an atmosphere of peace and quiet. Positive properties also include the non-flammability of the material and good vapor permeability. It must be remembered that the pitch of the rafter system must correspond to the dimensions of the insulation boards.

Izover Soundproofing

Izover Sound Protection mats and slabs are designed specifically to minimize the possibility of penetration of extraneous noise from the outside. Installation can be carried out in internal partitions or suspended ceilings.

Isover Sauna

Insulation Izover Sauna. In addition to the fact that this material has all the qualities of high-quality insulation, Izover Sauna also creates a barrier to steam, making it ideal for installation in baths, saunas and rooms with high humidity. The material is mats with a thickness of 5 or 10 centimeters and is supplied in rolls.

To make it easier to search and select the right product, the manufacturer of thermal insulation materials Izover has developed and presented a line of products indicating the purpose and area of application right in the title:

- Izover Warm home.

- Izover Warm roof.

- Izover Warm walls.

- Izover Quiet House.

Brand history

The rights to the brand belong to the Saint-Gobain company from France. Its main office is located in Paris, and its founding date is 1665. It appeared at the direction of Louis XIV and produced glass and mirrors. The name Isover insulation is formed from the words “glass” and “insulation”. In our country, the company's products were initially known under the Uteplyaev brand.

Initial Izover products in Russia

Over more than 350 years of history, Saint-Gobain has grown into an international industrial group represented in 67 countries and employing over 170 thousand employees. Sales in 2015 amounted to 39.6 billion euros.

Soundproofing Izover “Quiet House”: The company is included in the following ratings:

- The hundred largest industrial enterprises according to Forbes.

- Top 100 innovative organizations in the construction sector.

- Best Employer - 2016

Experience and the latest technologies have made the company a world leader in creating a comfortable living space. The main activities of Saint-Gobain are:

- Innovative technologies in the field of high-tech products in the production of ordinary and special glass.

- Building materials represented by ISOVER, ISOTEC, ISOROC brands in insulation; GYPROC in gypsum solutions; WEBER dry mixes; ECOPHON for acoustic ceilings and panels; in siding and tiles - CERTAINTEED; RAM pipes

- Distribution activities in the field of building materials.

Saint Gobain Campaign:

The company's products have been known on the Russian market for more than 20 years. Ten years ago, a plant was opened in the Moscow region (Egoryevsk), and since 2011 in Chelyabinsk, the Minvata company began producing stone fiber insulation. All products have international environmental certificates and comply not only with internal corporate standards, but also EN 13162—ISO 9001.

Isover characteristics

Of course, before choosing this material for insulating a house, you should find out what specific properties it has. There are several types of Isover insulator. In terms of characteristics, they all differ slightly. Materials of this brand are produced with different density and thermal conductivity.

Isover Classic insulation, for example, has the following characteristics:

| Coef. thermal conductivity | At 25 gr. — 0.041 W/mK At 10 g. — 0.038 W/mK |

| Density | About 15 kg/m3 |

| Fire resistance | NG |

| Water absorption | per day no more than 0.08 kg/m |

| Width | 1220 mm |

| Length | 6150 mm |

| Thickness | 50 mm |

This type of Isover insulation is currently the most popular. Other types of insulators of this brand also have good qualities.

“Isover” is supplied, the characteristics of which, therefore, allow us to judge it as a truly effective insulation material, in slabs and mats that are easy to install.

Types of mineral wool Izover

Isover does not produce universal mineral wool. There are such classification principles by which varieties are determined:

- Light thermal insulation consists of mats and slabs that are suitable for treating the walls of brick and wooden houses, as well as for roof insulation. They are not used for finishing foundations and floors.

- General building insulation. This category includes soft slabs for frame structures and medium-hard, rolled mats, mats with foil on one side.

- Special purpose mineral wool. This group includes materials for pitched roofs, which have absolute non-flammability, increased hydrophobic properties and good vapor permeability.

Main characteristics and features of Izover fiberglass insulation

Izover insulation is a durable, elastic material that is highly resistant to significant loads. The production of this type of product takes place using modern, patented TEL technology. Fiberglass is used as the main component.

There are several main characteristics of Izover insulation:

Coefficient of thermal conductivity. The indicated value is – 0.038 W/(m*K) (in the International System of Units (SI), thermal conductivity is measured in watts per meter kelvin). Thanks to such a low value, the fiberglass that is part of the Izover insulation does an excellent job of retaining air and retaining heat.

Soundproofing properties. The air gap that forms between the glass fibers allows for maximum noise protection.

Flammability of the material. The entire line of Izover thermal insulation materials has passed a special test. Products with a density of less than 30 kg/m³ belong to the NG class - non-combustible building materials (flammability tests were carried out in accordance with GOST 30244–94). It follows from this that the use of Izover insulation for thermal insulation of a private house or large industrial building is completely safe.

Moisture resistance and vapor permeability. These parameters are very important, because the ability to withstand moisture determines how well the material will perform its main functions. When the air in the room is humid (and for residential buildings and normal human well-being, this figure should be at least 40%), the fiberglass that is part of the Izover thermal insulation boards/rolls may slightly deteriorate its heat-shielding properties. To prevent this from happening, it is necessary to leave a small distance between the wall and the insulation during installation (about 2 cm). Since fiberglass can quickly “give up” excess moisture, this air layer will help avoid its accumulation in the material.

It should also be mentioned that the insulation contains water-repellent additives that have water-repellent properties.

Life time. Building a house is a complex, long and painstaking process that requires maximum attention to the quality of construction products. Since insulation is one of those materials whose replacement is quite labor-intensive and involves considerable material costs, you should study not only the characteristics of thermal protection, but also the service life. There are examples of half a century of using Izover materials without any loss of thermal insulation properties.

Environmental Safety. Izover products are environmentally friendly thermal insulation materials, the safety of which for human health has been proven and documented. On the official website of the manufacturer, anyone can freely study the environmental product declaration EPD (Environment product declaration). In addition, Izover products will never harbor insects or mold.

Weight. Izover insulation has less weight than many other similar materials from other manufacturers. This characteristic allows the use of Izover in rolls or slabs in those buildings where it is necessary to reduce the load on walls and other floors.

Product release form. The manufacturer offers the consumer various options for release forms - rolled material or slabs with different hardnesses. In addition, Izover insulation can be single-layer, with a thickness of 5 to 10 cm, or two-layer, with a thickness of at least 5 cm for each layer.

Standard dimensions for slabs: 1 meter wide, 1 meter long. However, at the request of the customer, it is possible to change these parameters.

Standard dimensions of Izover roll insulation: 1.2 meters wide, 7–14 meters long. Total area from 16 to 20 m². After opening the package, you must wait a few minutes for the material to straighten on its own and completely.

Brand history

The rights to the brand belong to the Saint-Gobain company from France. Its main office is located in Paris, and its founding date is 1665. It appeared at the direction of Louis XIV and produced glass and mirrors. The name Isover insulation is formed from the words “glass” and “insulation”. In our country, the company's products were initially known under the Uteplyaev brand.

Initial Izover products in Russia

Over more than 350 years of history, Saint-Gobain has grown into an international industrial group, represented in 67 countries and employing over 170 thousand employees. Sales in 2015 amounted to 39.6 billion euros. The company is included in the following ratings:

- The hundred largest industrial enterprises according to Forbes.

- Top 100 innovative organizations in the construction sector.

- Best Employer - 2016

Experience and the latest technologies have made the company a world leader in creating a comfortable living space. The main activities of Saint-Gobain are:

- Innovative technologies in the field of high-tech products in the production of ordinary and special glass.

- Building materials represented by ISOVER, ISOTEC, ISOROC brands in insulation; GYPROC in gypsum solutions; WEBER dry mixes; ECOPHON for acoustic ceilings and panels; in siding and tiles - CERTAINTEED; RAM pipes

- Distribution activities in the field of building materials.

Saint Gobain Campaign:

The company's products have been known on the Russian market for more than 20 years. Ten years ago, a plant was opened in the Moscow region (Egoryevsk), and since 2011 in Chelyabinsk, the Minvata company began producing stone fiber insulation. All products have international environmental certificates and comply not only with internal corporate standards, but also EN 13162—ISO 9001.

Stamps

Isover's lines of thermal insulating products include several dozen items and are designed to solve specific problems. They all differ in delivery form, thickness, density and size.

For general construction work

Izover Profi.

A universal material with increased elasticity. Provides the highest level of thermal protection among the brand's retail materials. Supplied in rolls, plate thickness – 50, 100 and 150 mm. Does not require additional fasteners during installation; can be installed by surprise. Received positive reviews from builders.

Used for insulation and sound protection:

- external walls inside and outside the house;

- pitched roofs;

- interfloor ceilings;

- frame walls;

- internal partitions;

- ventilated facades.

Classic.

Supplied in rolls, material thickness – 50 mm. Can be installed by surprise. Application area:

- insulation of suspended ceilings;

- interfloor ceilings - the material lies between the joists;

- attic spaces.

Isover Classic stove. The shape of mineral wool is slab. Size – 610*1170 mm, thickness 50 and 100 mm. Packaging 5 and 10 m2.

Application area:

- insulation of frame walls;

- insulation of walls from the inside;

- insulation of ventilated facades.

Isover kl 34. Release form – slab with a thickness of 5 and 10 cm. Does not require additional fasteners during installation.

Application area:

- ventilated facades;

- frame walls.

Isover kl 37. Release form – plate. It is used for insulation and sound protection of roofs and interfloor ceilings.

Isover kt 40. Two-layer roll material. Thickness – 10 cm, each layer is 5 cm. Used for insulation of horizontal planes.

Isover Sauna. Supplied in rolls, mat thickness 50 and 100 mm. The main feature is the presence of a vapor barrier layer. Suitable for rooms with high humidity. Refers to moderately flammable materials. It is used for insulation of walls, floors and ceilings in baths and saunas.

Izover Uteplyaev. Universal mineral wool, available only for Siberia and the Far East.

Special solutions

The Izover product line includes special insulation materials with characteristics optimized for solving specific problems.

- Isover Pitched Roof. Has increased moisture resistance.

- SoundProtection. Provides a high level of noise protection.

- Frame P32. Designed for insulation of frame houses. Provides savings on heating costs of up to 25% compared to the basic product.

- Frame M40-Al. Min wool with one-sided aluminum coating. Designed for wet rooms, can be used without additional finishing.

- Izover Plaster Facade. The material is of high density and has low vapor permeability.

- Vent Facade Top and Vent Facade Bottom. They are used for two-layer insulation systems for ventilated facades.

- Floating Floor. Designed for insulation and sound insulation of floors. Has increased elasticity and density. It is made using tongue-and-groove technology.

- Isover OL-P. Special solution for flat roofs. Has ventilated grooves to remove moisture. Made using tongue-and-groove technology, which increases the tightness of the mineral wool layer.

Types of ISOVER insulation

The manufacturer does not produce universal material. Considering the high technology of the production process, Isover can be manufactured for:

- Light thermal insulation. TEL technology is used in production. Slabs and mats are produced. Can be used as insulation for the walls of a wooden or brick house, for insulating roofs, but should not be used for insulating foundations and floors

- General building insulation. There are also several varieties: - soft slabs made of fiberglass for frame structures, - roll mats are used without fasteners, - mats, one side of which has a foil base, - slabs of medium hardness

- Special products. We are talking about ISOVER for pitched roofs. This material has high hydrophobic characteristics, it does not burn and has a high level of vapor permeability

The ISOVER markings for civil engineering are as follows:

- KL – slabs

- KT – mats

- OL-E – special hardness mats

- The numbers indicate the thermal conductivity class

Application of ISOVER

The scope of ISOVER is very diverse. It can be used to insulate roofs, attics, building facades, interiors, suspended ceilings, floors, basements and foundations.

- ISOVER KT40 is recommended for use when insulating ceilings and floors. This is a material consisting of two layers that can be easily separated. Installation of horizontal surfaces does not require additional fastening

- ISOVER STYROFOAM 300A is a tile material that requires mandatory fastening when installed on vertical surfaces. Can also be used successfully on horizontal surfaces

- ISOVER KL 34, ISOVER KL 37 – slabs that are sold in compressed rolls. The material is used as insulation for walls inside the apartment, for insulation of internal partitions, for thermal insulation of ceilings and attics.

Do you need another insulation? We also advise you to learn more about the use of insulation with foil. Cheaper, but no less good option. Didn't find any suitable options? Find out more about the technical characteristics of Knauf insulation in this article. Perhaps this material will suit you better.

How to insulate walls and floors with Izover?

You need to work with this material in the same way as with any other insulation. The main thing to know is that high-quality insulation is a multi-layer cake. And then there will be a positive result when the order of composing the layers of this pie is observed.

Wall insulation

In order to mount Izover on the wall, it is necessary to make a lath. These can be wooden planks or metal. Then you will need to attach drywall to them.

The technique for performing the work may be as follows:

- The walls need to be primed

- Attach the heat-reflecting sheet. This should only be done for walls that border the street.

- Make a vertical sheathing. This can be a full-fledged frame, but it can also be ordinary wooden planks. The step between the slats should be made according to the ISOVER width

- Lay sheets of insulation, gluing them to the wall

- Attaching the moisture-repellent film

- Now you need to fill the horizontal strips

Ceiling insulation

It is necessary to insulate the ceiling using practically the same technology as the walls. The only difficulty is that you have to mount it above your head.

Disadvantages of ISOVER

Even modern materials cannot be absolutely perfect. But regarding ISOVER, it can be said that its two shortcomings can be completely mitigated.

- ISOVER – prickles and causes irritation. This can be avoided by wearing gloves.

- ISOVER is afraid of moisture and under its influence it loses all its positive qualities. This means that the material cannot be used outside (except for those types that have additional protection in the form of foil layers)

ISOVER cost

Rolled standard ISOVER, which is used for insulating walls and ceilings, has a square area of 20 m2.

The thicker the sheet, the better the technical characteristics of the isover insulation, the price is correspondingly higher. Thus, ISOVER KT 40 has a thermal conductivity class of forty, a sheet thickness of 10 cm, is classified as non-combustible material and costs 750 rubles.

ISOVER sheet, which can be used for pitched roofing, has dimensions of 100 / 1170 / 610 millimeters. The packaging area is from 14 to 17 m2 depending on the thickness of the sheet. The cost is about 800 rubles.

Density of mineral wool thermal insulation

The density of mineral wool insulation largely determines its intended purpose and is one of its main performance characteristics. Its value is influenced by the thickness and number of fibers in the structure (the percentage of foreign impurities is usually not taken into account), as a result, the higher it is, the more expensive the building material is. The insulation is produced in the form of soft mats and hard slabs with a density from 11 to 400 kg/m3; the choice of a specific brand depends on the degree of load of the structures and the construction budget.

- What parameters is density related to?

- How to choose insulation for various structures?

- Price of different brands

What does density affect?

For any insulation, the rule is true: the lighter it is, the better, but this cannot definitely be said about mineral wool. Its low thermal conductivity is indeed due to the presence of air between the threads, but when a certain minimum is reached, it ceases to retain heat. In practice, the density of mineral and basalt wool affects its weight and cost, and is also directly or indirectly related to other characteristics: thermal conductivity, noise absorption, load-bearing capacity and ease of installation.

1. Thermal insulation.

This insulation uses the properties of weightless air with a thermal conductivity coefficient of no higher than 0.026 W/m·K. Thanks to the combination of fibers with different directions, manufacturers managed to achieve a similar value of 0.036 for light and soft boards, 0.032 for semi-rigid boards and 0.04-0.046 for dense and cylindrical products (which is more than good for non-flammable insulation). But when a certain mass is reached, the fibers stop retaining air and thermal conductivity deteriorates. The worst protection is observed for loose insulation with a density of up to 30 kg/m3 with a disordered fiber direction - 0.05 W/m K.

2. Noise absorption.

Materials with low air permeability are good acoustic insulators. Therefore, dense and rigid slabs absorb sound in any case (even if this is not their main purpose). But they weigh a lot and are not always suitable for internal soundproofing of rooms; for this purpose it is better to buy specialized brands: glass wool with long and thin threads or basalt with randomly twisted fibers. Rockwool, Izover and other brands have such series; their insulation density is in the range of 45-60 kg/m3.

3. Load-bearing capacity.

Regardless of the design, overly lightweight materials are not used when installing in areas subject to high loads. This is due to the risk of deformation or creasing, low compressive and bending strength. In such cases, high-density insulation materials (at least 150 kg/m3) are clearly required. If there are supporting structures (frame, joists, reliable sheathing), the use of lightweight grades is allowed and encouraged; insulating abilities come to the fore.

4. Laying nuances.

There is a clear connection between density and ease of handling of the material. Lightweight soft insulation can be placed without problems in the inter-lag space of roofing systems (non-used surfaces) when laid from above, but installing them from the ceiling is a more than complicated process. The vertical placement of rolled grades is a little easier, but due to the risk of fibers sliding down, it is better to purchase compacted wall insulation. The most convenient option is considered to be semi-rigid slabs with slightly springy edges (up to 60 kg/m3) or high-density mineral wool.

Scope of application of fiberglass products

“Isover” is considered a universal insulation material, therefore it is suitable for the following work:

| The product's name | We recommend using it together with | |||||

| Classic | Classic Stove | Pro | Sauna | vapor barrier | hydro-moisture barrier | |

| Insulation of pitched roofs | fits | fits | we recommend | — | Yes | Yes |

| Insulation of external walls under cladding or brick | fits | we recommend | we recommend | — | Yes | |

| Insulation of walls from the inside | fits | we recommend | we recommend | — | Yes | |

| Insulation of frame walls | fits | we recommend | we recommend | — | Yes | Yes |

| Soundproofing of partitions | fits | we recommend | we recommend | — | ||

| Insulation of attic floors | fits | fits | we recommend | — | Yes | |

| Insulating the ceiling above the basement | fits | fits | we recommend | — | Yes | |

| Soundproofing floors using joists | fits | fits | we recommend | — | ||

| Soundproofing of suspended ceilings | fits | fits | — | — | ||

| Insulation + vapor barrier of internal walls and ceilings | — | — | — | Yes |