TechnoNIKOL Carbon Eco can be used for roof insulation.

Technonikol extruded polystyrene foam is one of the highest quality and most popular foam plastics produced for insulation of construction sites in Russia. I will tell you everything about the characteristics, features and properties of this material.

Best qualities

Distinctive features of TechnoNIKOL extruded polystyrene foam are:

- low thermal conductivity;

- almost zero moisture absorption;

- environmental cleanliness;

- resistance to compression and deformation;

- life time.

Each parameter is important for understanding the effectiveness and breadth of use of polystyrene foam.

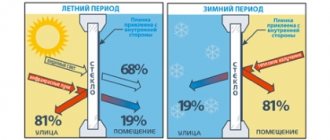

Low thermal conductivity is ensured by the presence of sealed volumes in the material with a gaseous environment inside.

Extremely low moisture absorption is achieved due to the tightness of the internal volumes of the insulator slab. Water can only fill the outermost granules damaged when cutting the material. Thermal insulation without cutting has an indicator equal to zero.

The material is absolutely safe during installation and operation. Expanded polystyrene has a certificate of compliance with environmental safety requirements. The styling technician can work without protective equipment. The installed polystyrene foam heat insulator does not emit harmful substances into the atmosphere.

Created under pressure, the material has increased mechanical strength. This quality allows it to be used for insulating horizontal surfaces with laying screed.

The chemical basis of the heat insulator is extremely stable and stable over time, which allows the finished product to maintain its operational properties in terms of insulation quality for a long time. The material is not destroyed under the influence of electric magnetic fields.

Application area

TechnoNIKOL extruded polystyrene foam has gained its popularity due to the fact that it has a fairly wide range of uses. It is used in both industrial and domestic construction. Using this material, you can thermally insulate a facade, including one designed under a wet screed.

Other surfaces that will be subject to load-bearing loads during operation can also be insulated using TechnoNIKOL products. This includes both straight and sloping roofs. With the help of this insulation, a cold attic space at home can be turned into a comfortable attic floor that can be used all year round. The thickness for effective insulation will be an order of magnitude smaller compared to the thickness of foam plastic or mineral wool. This is explained by the fact that the described insulation has an insignificant thermal conductivity coefficient, this value is 0.028 W/μ.

Thus, TechnoNIKOL extruded polystyrene foam is suitable for thermal insulation of premises for any purpose, where saving free space is an important requirement. Here you should highlight verandas, balconies, small rooms or loggias.

Insulation in numbers

General technical characteristics of expanded polystyrene are expressed in the following figures:

- specific thermal conductivity is in the range from 0.032 to 0.036 W/mK;

- vapor permeability in the region of 0.01 mg/m h Pa;

- density varies from 26 to 35 kg/m3;

- water absorption is 0.2% of the immersed volume;

- elasticity is 17 MPa;

- bending strength – 0.35 MPa;

- deformation of 10% during compression occurs under a load of 200 - 400 kPa;

- flammability class G4 (highly flammable);

- operating temperature from – 70 to + 75 °C;

- service life – 50 years.

EPPS - what is it?

EPS is a type of foam made using a slightly different method.

Polystyrene foam (or expanded polystyrene) acquires a cellular structure due to the fact that the plastic raw material foams. To obtain EPS, polystyrene foam granules are used, mixed with reagents, and subsequently the mass is extruded - that is, pressed through molding nozzles. The output is a more uniform and dense slab of a given shape.

Universal heat insulator

Technonikol xps extruded polystyrene foam fully realizes its improved thermal insulation characteristics when insulating balconies, loggias and floors, dachas and private households. Due to the large range of insulation materials produced for these purposes, it was given its own trade name - TechnoNIKOL Technoplex.

Expanded polystyrene TechnoNIKOL xps 30 is available in various modifications in terms of density, strength and thickness.

TechnoNIKOL xps 30 200 standard type is used mainly for insulating unloaded vertical surfaces of interior spaces. With a density of Technonikol xps 30 200 type standard of 30 kg/m3, it can withstand a load of 200 kPa. The dimensions of the Technonikol xps 30 200 standard plate are 1200x600 mm.

To insulate loaded surfaces, professional builders use TechnoNIKOL xps 30 250 standard type. This material can withstand 25% more compression load. TechnoNIKOL xps 30 250 standard type is available in thicknesses of 20, 30, 40, 50 mm. The 20mm sheet does not have an L-shaped edge. It is recommended to use Technonikol xps 30 250 standard for thermal insulation of external load-bearing structures.

Another representative of this brand is TechnoNIKOL xps 35, characterized primarily by the maximum possible density of 35 kg/m3. This gives it a maximum mechanical strength of 300 kPa and the ability to be used for insulating floors under concrete screed.

To secure sheets to a vertical surface, it is best to use polystyrene foam glue.

Minuses

Despite all the advantages of the unique insulation, it is necessary to pay attention to its disadvantages. Caution should be exercised when XPS comes into contact with certain types of varnish, acetone or drying oil. These substances can not only damage the surface of the insulator, but also completely dissolve it.

Also, the insulation is easily susceptible to the influence of products obtained through the distillation of petroleum and the influence of some alcohols. That is why you should pay special attention to the composition of the adhesive mixtures with which you plan to attach the insulator. It is important that they do not contain ethyl acetate, petroleum toluene, coal tar or its derivatives.

During prolonged use in air, extruded polystyrene foam undergoes oxidation, although modern industry is gradually reducing all negative aspects to a minimum.

We insulate professionally

To insulate the zero level of a building, foundation and roof in use, a professional material with increased resistance to compression is required. A product line with the Prof extension has been developed and is being produced: TechnoNIKOL carbon prof polystyrene foam. It is used by professional builders.

TechnoNIKOL carbon prof 300 has the lowest thermal conductivity threshold and can withstand a load of 3 kg/cm2 at a density of 30 kg/m3. The most convenient to use are carbon prof 300 slabs 1180x580x50 mm.

Expanded polystyrene TechnoNIKOL carbon prof 400 belongs to the same category. With similar characteristics, it compresses by 10% under a load of 4 kg/cm2. To obtain such a load, it is necessary to fill the slab with concrete 1.25 m thick. TechnoNIKOL carbon prof 400 has an internal density of up to 36 kg/m3.

XPS carbon prof does not absorb water and provides a certain degree of waterproofing of building structures.

Marking

Foamed polystyrene foam is marked according to GOST and European standards.

According to GOST, the marking must contain the following data:

- Product name

- Manufacturer's name or trademark and address

- Work shift, date of manufacture, workshop of the manufacturer

- Fire safety class

- Thermal resistance

- Thermal conductivity

- Nominal thickness

- Marking code

- Type of cladding or covering, if any

- Length and width

- Number of products in the package and their total area, if necessary

European standards for marking XPS are outlined in document EN 13164:2001 . However, different manufacturers have their own designations for the main characteristics. For example, material under the Penoplex brand has the following markings:

- Type indication – 30, 35, 45

- Designation of grooved surface

- Specifying the selected quarter

- Slab thickness in mm

This marking looks like this: 35GS-30.

We insulate environmentally

The use of nanocarbon admixtures for the production of insulation made it possible to obtain TechnoNIKOL carbon eco sp. The certificate of environmental compliance issued by TechnoNIKOL carbon eco sp allows its use for insulation work in residential buildings, healthcare facilities, preschool and school education. The addition of fire retardants to the starting material TechnoNIKOL carbon eco sp significantly reduces the level of fire hazard xps carbon eco. When insulating the walls of buildings, xps TechnoNIKOL carbon eco 1180x580x50 mm slabs are most popular.

Release form

XPS is produced in the form of slabs, substrates and decorative elements.

The slabs have dimensions of 600x1200 and 600x2400 mm. Some manufacturers produce slabs with a width of 600 and 580 mm. Their thickness ranges from 20 to 100 mm. They are supplied to stores in packages. The number of slabs in a package varies and depends on their thickness. Thus, 50 mm thick EPS is sold in packs of 8 pieces, 100 mm thick - 4 pieces.

In addition to slabs, the material is produced in the form of a base for flooring. There is a substrate for parquet, laminate and linoleum. Also, various decorative elements that are made from gypsum can be made from expanded polystyrene. At the same time, the appearance of the products is practically no different from plaster.

We insulate and protect

The unreasonable use of flat roofs can be corrected by using TechnoNIKOL carbon prof slope polystyrene foam. Using these slabs you can create a roof slope of 1.7, 3.4 and 8.3%. TechnoNIKOL carbon prof slope additional slabs placed in a separate position can significantly speed up the insulation of surfaces adjacent to ventilation shafts and skylights. The installation of TechnoNIKOL carbon prof slope makes it possible to change the direction of flow of rain and melt water without additional costs.

Characteristics of Technonikol brand polystyrene foam for solving industrial problems

Expanded polystyrene "Technonikol" is also produced for industrial purposes. One of the varieties is PROF, which is used for thermal insulation of office buildings, roofs of shopping and warehouse complexes. PROF SLOPE is a series consisting of five slabs, the sizes of which allow you to assemble structures of various shapes. This also includes those that have a certain slope.

SOLID is successfully used in the process of laying railway tracks and routes, as it is able to withstand high loads and serve for a long time, while it is not susceptible to destruction and rotting. The manufacturer offers for sale SAND, which is designed for construction using sandwich panels.

The qualitative characteristics of the material for industrial use differ from the properties of insulation for solving household problems, but the cost of the former is twice as high. You can buy it for an average of 6,000 Russian rubles per cubic meter

We insulate reliably

To insulate road objects, areas of territories, heavily loaded roofs and buried foundations, it is necessary to use TechnoNIKOL xps carbon solid polystyrene foam. Solid materials provide a strong and rigid foundation under (above) engineering structures, preventing soil freezing and displacement of laid coatings. The production of the following brands has been launched: TechnoNIKOL carbon solid 500, 700, 1000. With the same characteristics, they are distinguished by maintaining integrity under load in kPa, reflected in the number of the name. A good result with such indicators is guaranteed.

Negative reviews

Technonikol expanded polystyrene, the technical characteristics of which must be clarified before purchasing this type of thermal insulation, also has some disadvantages. According to buyers, it is toxic because when burned it releases substances hazardous to human health. Home craftsmen emphasize that polystyrene foam ignites quite easily when exposed to flame, and also requires the mandatory use of special glue during installation work.

Tips for choosing

To ensure that the quality of insulation with TechnoNIKOL extruded heat insulator meets the necessary requirements, it is worth taking note of several recommendations.

It is necessary to pay attention to the markings. It indicates the purpose of each material. The purchase should be made in a trusted store with positive customer reviews. You can scroll through the comments of professional construction experts in advance

In addition to the advantages, they usually indicate the disadvantages of a particular material.

The material is selected taking into account a special calculation. This will allow you to buy the right quantity. The formula is quite simple: the height of the walls is multiplied by the perimeter of the walls, then multiplied by the thickness, and then multiplied by the mark indicated by the manufacturer on the cubic meter marking. With a wall height of 3 m, a perimeter of 24 m, an insulation thickness of 5 cm (0.05 m) and a packaging volume of 0.36 m3, the result is:

- 3 x 24 = 72 (m2);

- 72 x 0.05 = 3.6 (m3);

- 3.6/0.36 = 10 (packs).

You will learn more about TechnoNIKOL Carbon products in the following video.

Installation subtleties

Insulation using technoplex is not a complicated procedure that requires special skills and knowledge. Such work can be performed by anyone, even those not familiar with the basics of finishing work. The slabs are glued or fixed with plastic dowels, which greatly simplifies the installation process. However, for high-quality wall insulation, experts recommend following the following rules:

- The insulation is laid only on a flat surface. Therefore, before starting work, it is necessary to knock off all mortar protrusions from the walls.

- To ensure that the row lies evenly, it is recommended to mark the starting line on the wall using a laser level. Further slabs will be placed more simply - the technoplex is characterized by ideal geometry.

- The first slab must be aligned strictly along the marked line, and a through hole for the dowel must be drilled in the center. Having achieved absolute symmetry, the corners are also fixed with fasteners.

- The seams between the insulation elements can be filled with silicone sealant.

- Before finishing the walls, the insulation is covered with a reinforcing fiberglass mesh and a layer of plaster.