Insulating a balcony with your own hands, step-by-step instructions and photos, insulating loggias - external and internal.

During the cold season, many apartment owners in multi-storey residential buildings have problems using their balconies. Partly because for many people this area is not glazed or not properly insulated. A glazed and high-quality insulated balcony is an additional room in the apartment.

Insulating a balcony in a new building or in a purchased apartment will not be as difficult as it may seem initially. To do this, you need to purchase the necessary materials and draw up a plan for the sequence of work - proper insulation of the balcony. You will also receive answers to questions about how and with what to insulate the loggia.

How to insulate a loggia to keep it warm in winter.

The main distinguishing feature of loggias is their ability to become an extension of the living space. There are two methods by which you can properly insulate a loggia. This is to turn this area into a continuation of the living space and insulate the loggia as a separate room. To insulate the loggia and turn it into a living area, as an extension of the room, it is necessary to first glaze it. To do this, you need to contact one of the companies that installs PVC double-glazed windows on windows.

After this, they connect the living space and the loggia by dismantling a small piece of the wall and obtaining a passage in the form of a large arch. We must not forget about diverting the heating battery to the side. Then the floors are leveled, the expanded area is insulated and finished, and electric lighting devices are installed. Thus, the room turns into a full-fledged living space. A more complex option is to insulate the loggia, turning it into a separate living room.

This work should also begin with the installation of double-glazed windows; you can do such work yourself if you are a specialist in the installation of PVC glass blocks. If you do not have experience in such installation, then you need to learn practice from specialists involved in the sale and installation of plastic windows. After installing the double-glazed windows, you can proceed to insulating the loggia with your own hands, using step-by-step instructions:

- To do this, the area of the room is thoroughly cleaned of debris and dirt.

- Double-glazed windows and mechanisms are covered to prevent damage and all kinds of scratches.

- Next, you can begin arranging the ceiling; for this, a waterproofing cellophane film is fixed to the surface using an adhesive mass; you can also use a special primer paint.

- Then electrical wiring is made in special plastic hoses with points for sockets and lighting.

- After this, a regular lathing made of wood or special metal profiles is installed on the ceiling.

- Now you can install the ceiling structure. The most suitable materials for thermal insulation are sheets of foam or mineral wool. They are fixed in the sheathing, bringing out the wires for lighting fixtures, if any are provided.

- The final work with the ceiling is the installation of plasterboard sheets; you can also use plastic or wooden panels.

The final work with the ceiling is the installation of plasterboard sheets; you can also use plastic or wooden panels.

You should not forget about electrical sockets, the wiring of which must be brought to the surface. Next, we begin to improve the flooring. To do this, we place wooden logs on top of the previously laid insulating cellophane film and lay slabs of insulating material, then lay wooden boards or chipboards on top. At this point, the main work on finishing the insulated loggia can be considered completed.

Finally, linoleum or other finishing is laid on the floor surface.

We can say that the work carried out to insulate a loggia in a panel house is identical. The only additions at the initial stage are drilling holes at a slope towards the street to create ventilation under the surface of the insulation if polystyrene was used.

It is worth remembering that there is another technology for insulating a loggia in a panel house. Such work can be done by insulating the external loggia, but for this you will need to contact professional industrial climbers, and this is quite expensive.

How to insulate a balcony and loggias with your own hands step by step - instructions

It is possible to insulate balconies in various ways, but two options are considered the main ones. The first of them is external insulation of balconies; this method is considered quite labor-intensive. To carry out insulation work, you must contact a specialized construction company that has the appropriate equipment and an industrial mountaineering team.

For this reason, performing such work costs the apartment owner considerable expenses. The only advantage of such insulation of the balcony is the receipt of additional centimeters of residential territory.

Another and often used method is to internally insulate balconies yourself using carefully selected finishing materials. This improvement of the balcony area is carried out in several stages.

Usually they begin to carry out this work by drawing up a clear plan and purchasing the necessary materials for insulating the balcony, as well as closing the opening between the balcony and the room with cellophane film to prevent dust from entering the living space. Then this area is carefully cleared of various rubbish, and after that the old finishing materials are removed from the walls.

Next, they begin to seal the cracks, since their presence leads to considerable heat losses. Small cracks are sealed with moisture-resistant sealant; for larger recesses, polyurethane foam is most often used. Thanks to its use, the structure receives additional thermal insulation material.

To make it easier to insulate a balcony yourself, you need to level out all the unevenness on the surface of the wall, floor and ceiling using a diluted dry cement mixture. If the owner decides to install lighting fixtures in a room with hidden electrical wiring, he needs to cut through channels for the electrical wires, wire them and seal them. For external wiring, you can use plastic boxes.

Next, you can begin installing a waterproofing layer on the floor; for this it is best to use a polyethylene film, which is spread over the entire surface. In addition, such a film is also used on the surface of walls, fastening it with glue and sealing the joints on the ceiling, walls and floor with wide tape. After this, they begin to install flooring logs from wooden beams or metal profiles. Bars made of wood are best suited for these purposes, but not raw wood.

To prevent the formation of mold or mildew, wooden joists are coated with a primer. Then the openings between the wooden blocks, which are fixed to the floor surface, are sealed with insulation, for example: expanded clay, glass wool or mineral wool.

The rough finishing of the flooring is completed by installing chipboard sheets to the wooden joists, which are secured with self-tapping screws. After the rough finishing of the room, you can lay any finishing materials on the floor: linoleum, laminate, PVC tiles and others.

The insulation layer on the ceiling can be done in two ways, the first option is to attach the frame, and then the insulation and ceiling covering. Another finishing option does not include a frame.

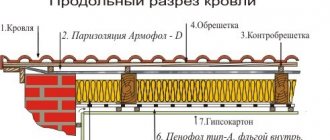

Taking into account the previously placed waterproofing film, a sheathing is installed on the ceiling. This lathing frame is made from beams or metal profiles, and then insulated with mineral wool or polystyrene foam. Next, they are finished using plastic or wooden panels or plasterboard sheets. The option with no sheathing is performed as follows.

The ceiling surface is cleaned of dirt and dust and primed. Then, sheets of insulation prepared for balconies or loggias are glued from a special adhesive solution; these can be sheets of penoplex; for better fixation, they are additionally secured with dowels. Next, you can finish the surface with any material that suits the apartment owner. For this purpose, ceiling material can be mounted around the perimeter of the ceiling on the walls.

Now we insulate the wall structure. The waterproofing layer has already been laid on the surface, then we install a sheathing of wooden beams or metal profiles, fill the space with insulating material, then we install sheets of plasterboard or plastic panels on the frame. You can use other finishing material that suits the homeowner.

Requirements for insulation, the better to insulate a balcony.

In order to choose the right quality insulation material for a balcony, you need to find out what characteristics it should have. First of all, it is increased strength, high water-repellent and fire-fighting properties. In addition, the insulated loggia must be an environmentally friendly product and fairly easy to install on the surface.

In order to choose the right quality insulation material for a balcony, you need to find out what characteristics it should have. First of all, it is increased strength, high water-repellent and fire-fighting properties. In addition, the insulated loggia must be an environmentally friendly product and fairly easy to install on the surface.

- Expanded clay is a fairly light and durable material, has high fire resistance and is durable. It also has disadvantages, low moisture-repellent properties, so it is used only for floors.

- Mineral wool - this product has good heat-insulating and sound-proofing qualities, has good fire-fighting properties and is environmentally friendly. When moisture gets in, its quality deteriorates.

- Polystyrene foam is easy to install, it is a fairly light and fragile material. Disadvantages: high fire hazard and insufficient strength.

- Extruded polystyrene foam is a fairly strong, moisture-resistant and durable product that is not difficult to install. Its cost is quite high.

- Liquid polyurethane foam has a high cost, has increased strength, durability and moisture resistance; it is easy to fill cavities and voids with special equipment.

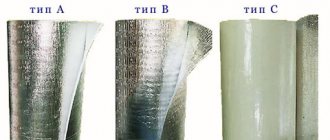

- Penofol has high moisture resistance and durability, good waterproofing and thermal insulation characteristics, but is rarely used as an independent material.

What exactly is best to use to insulate your loggia or your balcony depends on the choice of the home owner.

Where to begin

The loggia is freed from the old decoration - in the sequence ceiling-walls-floor. Loose and peeling coatings must be removed, after which the substrates are inspected for damage.

All enclosing structures will be insulated, so the bases do not need to be perfectly flat after removing the old finish, but cracks, potholes and furrows must be repaired.

Opened cracks on the floors must be presented to a professional (BTI engineer or a specialist from a third-party organization), who will give an opinion on their dynamics and determine the method of repair.

How to insulate a balcony in a panel house yourself.

Work on insulating a balcony in a panel multi-storey building should begin with glazing. Window designs are:

- plastic;

- tree;

- aluminum profile.

The most common and popular today for insulating a balcony and glazing a balcony are PVC windows; they retain heat well and are unpretentious in operation. To install them, it is best to contact a specialized company that installs such windows, and after installing them, begin to insulate the balcony in a panel house yourself.

We select insulation, clear the area of construction debris and various contaminants, and take the necessary measurements to purchase the material. After this stage, we arrange waterproofing from film and make internal lathing on the walls and ceiling from metal profiles or wooden beams. We install joists on the floor for covering.

After this, we insulate the room using mineral wool and lay chipboard on the floor, and finish the walls and ceiling using plastic or wooden panels, gypsum boards and other suitable finishing materials. It is important not to forget about electrical wiring; if the homeowner wants to make hidden wiring, he needs to do the wiring before starting work on insulating the balcony with his own hands.

If he intends to make it external, he will need to place special plastic boxes for these purposes at the final stage. After this, all that remains is to lay linoleum or other covering on the floor, and the finishing can be considered complete. When performing insulation work in a balcony room, the owner of the area needs to know the characteristics of various insulation materials before making his choice.

Thermal insulation materials used to insulate the loggia.

Insulation inside and outside loggias in recent years has been a fairly frequently performed finishing job. The reason is very simple, the desire of apartment owners to turn the territory into a separate living space and obtain additional living space. To keep it warm, apartment owners can use the following materials:

Mineral wool is a very commonly used insulation material for balconies and loggias. It has many positive features: easy installation, high thermal insulation and noise insulation characteristics, sufficient moisture resistance. This environmentally friendly product, which can be produced in sheets and in roll form, shows excellent results as insulation for loggias. The material has high fire resistance properties.

Polystyrene foam is a universal material with a homogeneous structure that is suitable for cold and unheated rooms. It has excellent moisture-repellent properties and excellent thermal insulation and noise insulation properties. Disadvantages include low fire performance.

Modern insulation material - penofol has high moisture resistance and durability, good waterproofing and thermal insulation properties, and is used quite rarely as an independent insulation material. It can also be used after drywall has been installed on the balcony.

Preparation for thermal insulation

Do-it-yourself insulation of the floor on the balcony begins with preparing the surface. It is necessary to inspect the balcony slab and assess its condition. It may require some minor repairs. But first it is necessary to strengthen the outer wall and install aluminum or plastic double-glazed windows.

If the balcony fencing is a lattice covered with lightweight fencing material, then it is recommended to line the outer wall with foam concrete blocks. When cantilevering the slab, it is necessary to coordinate these actions with the architecture department, since it may be necessary to strengthen the load-bearing capacity of the balcony. If you need to insulate the floor on the loggia, approval is not required.

Insulation of balconies and loggias with mineral wool

Insulating a room inside a balcony or loggia using mineral wool is quite often used. Such raw materials are produced in the form of plates and rolls. Work can be done both on flat walls and on non-standard surfaces.

The work includes cleaning the premises from various contaminants and debris.

Next, the cracks and joints are sealed using a solution based on a cement composition and polyurethane foam, a waterproofing film is installed, and electrical wiring is installed.

After this, a metal sheathing of U-shaped profiles is installed on the walls and ceiling, and wooden logs are laid on the floor. Now sheets of mineral wool insulation are installed in the sheathing structure, the walls and ceiling are finished with plasterboard sheets or panels, and chipboard is laid on the floor. After this, the final finishing of the room occurs.

Special dryers

All dryers are generally divided into ceiling, wall, floor and portable.

Modern ceiling dryers eliminate many inconveniences. For example, designs with a “lift” mechanism are ideal for balconies or bathrooms with high ceilings. They can be rope or metal, the main thing is that they make the hanging process much more convenient. You lower the dryer to a comfortable level, then hang the laundry and raise it again. There are lift-type dryer models that can also be attached to walls. This is especially convenient if the ceiling is suspended and no load can be placed on it.

Wall-mounted dryers are considered the most convenient, especially for a small bathroom. I found folding models to be an interesting and practical option: the same ropes, only invisible until the laundry is drying. A drum with ropes inside is hung on one wall, and fastenings on the other. When necessary, the ropes are pulled out of the drum, and after drying they are automatically returned. This method allows you to hang the entire structure lower, so as not to climb on a stool, and does not spoil the appearance of the balcony or bathroom. The device can withstand 6 to 12 kg of laundry depending on the model; it is best used for drying light laundry.

Accordion type dryers are very durable. They are attached to the wall and look neat and compact, and fold out for drying. Most often made of stainless steel or aluminum. However, due to their compactness, bed linen can only be dried folded, which increases the drying time. If the accordion is installed in a well-ventilated room, then this is not such a problem.

Wall-mounted dryers can also be folding, mounted in a cabinet or wall. This is a very compact option for a small bathroom. The strength of the structure depends on the strength of the fastening, but they are usually designed for light loads. I was visiting a house with such a dryer; the owners used it only for clothes, and dried bed linen by throwing it over the door. A strange option, but there was nothing else left.

A heated towel rail is also a wall-mounted drying method. Due to its temperature effect, it is even more effective, and also helps dry clothes on other fixtures in the bathroom by heating the air in the room.

A large niche is occupied by floor structures that can be placed in any room and removed after use. From my own experience, I can say that these are very convenient: they are stable, quite roomy (you can dry anything) and mobile. You can choose an option for different purposes and room sizes: small on wheels, vertical multi-tiered or classic horizontal.

Such dryers can even become a “feature” in the interior!

Portable dryers are most often the same folding option as floor dryers, but are placed on a bathtub or mounted on a door or radiator. I would recommend this option for temporary housing, when it is impossible to mount dryers into the wall, and there is not enough space in the rooms for a floor dryer.

Dryers are electric - this combines the efficiency of a heated towel rail with the functionality of a floor-standing option. Sometimes electric dryers are indistinguishable in appearance from a heated towel rail. Just plugged into an outlet.

Insulation with polystyrene foam and polystyrene foam

Insulation using polystyrene foam occurs quite often nowadays, although many new insulation materials have appeared in recent years. Polystyrene foam is an environmentally friendly product with high density and a long shelf life.

Expanded polystyrene is a product that is practically not exposed to moisture and is shaped like a slab. The composition of expanded polystyrene is an air mass consisting of many bubbles, enclosed in thin layers of polystyrene, with good vapor barrier properties.

Work traditionally begins with cleaning the room from various contaminants and debris. At the next stage, the cracks and joints are sealed using cement mortar and polyurethane foam.

Next, installation of waterproofing film, installation of electrical wiring. After this, a metal sheathing made of U-shaped profiles is mounted on the walls and ceiling, and wooden logs are placed on the floor.

Now sheets of foam plastic are placed in the sheathing structure, then the walls and ceiling are finished with panels or other finishing materials, and chipboard is laid on the floor, on top of which linoleum is laid.

Warm wall

By analogy with the floor, there are warm walls. It's really possible to make them. To do this, take the previously mentioned heating mats and attach them to the wall surface. When laying the products, you need to make sure that there are no kinks in the corners that could damage the electrical cable.

Bending at right angles is unacceptable. In addition, uneven laying of tile mixture with voids is not allowed. Subsequently, such a careless attitude to installation causes overheating - this method does not make the space safe for living.

In some cases, additional work is required, which is carried out in advance. Among them, it is worth highlighting the laying of the parapet and the creation of side wall structures. For this, materials made from ceramic brick or foam block are used.

Insulation of a balcony or loggia with penofol

Insulating a balcony room with penofol is a modern, but already well-proven technology. Penofol is foamed polyethylene having different thicknesses. Having a thickness of about one centimeter, penofol can replace up to 100 millimeters of mineral wool. The greater the thickness, the higher its cost.

Penofol is produced in rolls, it has a fairly long service life and is not fire hazardous. Insulating a balcony room is quite simple using penofol.

First of all, debris and dirt are removed, cracks are sealed, and electrical wiring is installed. Then penofol is fixed to the ceiling, floor and walls. After this, the sheathing structure is installed on the ceiling and walls, and wooden logs are laid on the floor.

Next, the structure is finished with panels, and laminate is laid on the floor. The work can be considered completed.

Insulation on the ceiling

Insulation with penoplex on the ceiling differs from the process of laying on walls only in the need for additional fastening of the slabs.

Umbrella dowels made of plastic are used that do not form cold bridges.

- If there is not enough distance from the rough ceiling to the opening window vents, the sheathing is fixed to the concrete, and insulation is inserted into the resulting cells.

- When metal profiles are used for drywall, strips of penoplex are placed inside the crossbars.

- In this case, the sheathing is fastened with a small gap from the concrete, which is then sealed with foam adhesive.

Leveling and insulating the floor on the loggia with a dry screed

In order to properly insulate a loggia, you must always remember about insulating the floor in the room. One of the high-quality materials serving for these purposes is dry floor screed. Doing the insulation of loggia floors yourself is not an easy, but doable task that the home owner can do.

First, he needs to clear the area of dust and debris, and also purchase the materials necessary for these purposes: plastic film, profiles, expanded clay, edge tape. Joints and cracks are sealed with polyurethane foam and cement mortar. These works begin with waterproofing; for these purposes, a film is used, and for waterproofing the sides along the perimeter of the floor, an edge tape is used.

Next, U-shaped profiles are laid out, with the wide side at the bottom. Expanded clay is poured to the required level and then the slabs are laid in special grooves, most often these are cement-bonded or gypsum-fiber sheets. Next, you need to seal the joints with a cement mixture. All work is carried out using a level and beacons.

The principle of dry screed construction and the necessary materials.

For dry screed, you can use fine slag or crushed stone; screening out crushed stone is best. As waterproofing, not only cellophane film is used, but also a film based on synthetic rubber or polypropylene foam, as well as a multilayer reinforced film coating. U-shaped metal profiles can be replaced with wooden beams used as joists.

All work must be carried out using the installation of special beacons; the alignment of metal profiles must be done using a horizontal level, which avoids significant distortions and slopes.

How to lay dry screed on a loggia.

The basis for laying a dry screed on a loggia is the method of making a base from any bulk material: coarse sand, expanded clay, fine crushed stone, crushed stone screenings. Also pay attention to the condition of the slab on the floor, the condition of the cracks and joints. The technological process of laying dry floor screed on a loggia includes a selection of high-quality construction tools and the selection of the necessary material. The work includes the following stages:

- All cracks and joints on the floor are sealed using polyurethane foam.

- A film for waterproofing is laid, it can be of different quality, but the main thing is that it goes onto the walls. Then an edge strip is laid along the perimeter of the base of the floor, connecting to the film.

- The necessary logs are installed using metal profiles. Work is carried out at a strictly measured horizontal level.

- Dry thermal insulation material, expanded clay or crushed stone screenings are backfilled. You can also use ready-made Knauf backfill for dry floor screed.

- The insulating layer is leveled using the “rule” and thermal insulation material is added to the places where it is missing.

- Gypsum fiber sheets are then laid in two layers with a slight offset to cover the joints on the bottom layer. Fixation is carried out using construction glue or PVA, as well as self-tapping screws.

- After this, the joints of the top layer are sealed and the flooring is laid.

All work can be done independently without the involvement of specialists within one working day, following the balcony insulation diagram, provided all materials and tools are available. The installation of such a screed provides the following advantages: quick completion of work, a slight increase in the load on the floor and a significant increase in thermal insulation.

Loggias or balconies in the apartment are used to store unnecessary things. These auxiliary areas of the apartment can be more usefully used as residential areas. To do this, the loggia must be structurally connected to the living space, room or kitchen.

And to make this space suitable for all-season living - insulate it. For a loggia, insulation is a kind of clothing that performs two main functions:

- reduction of heat loss and savings on home heating

- increasing the living space and comfort of those living in the apartment

The main methods of insulating a balcony are external and internal. External insulation of a balcony can only be done by throwing industrial climbers - installers - onto the balcony or using a tower. The method is expensive - the owner of the apartment will have to pay hourly fees for special equipment and the installation team. Insulating a loggia or balcony yourself is cheaper. It is enough to stock up on the necessary hand and power tools, building materials and installation skills.

A warm balcony can be completed and calculated by a special design and estimate organization in compliance with the requirements of building codes and regulations (SNiP). This project is needed to officially recognize the insulation of the loggia as a legal redevelopment. You will submit it to the district administration, then to the BTI for the preparation of a new technical plan.

Necessary tools and materials for insulating a loggia

Let's find out how to make a warm balcony with your own hands and how to properly perform external insulation of a balcony. To insulate the balcony yourself, before work, make sure you have the necessary set of tools for installation:

- A hammer drill and drills for it with a diameter of 6, 8, 10, 12 millimeters;

- Screwdriver, wood and metal drills with a diameter of 3 to 12 millimeters;

- Jigsaw plus wood/metal files;

- Grinder (angle grinder) with a working diameter of wheels of 125 millimeters, cutting wheels for metal and concrete;

- Laser or water construction level;

- Mounting level 50 centimeters long;

- Construction stapler;

- Gun for polyurethane foam;

- A stationery knife with blades 20 millimeters wide;

- Other hand tools: hammer, tape measure, screwdrivers, steel square, pencil, pliers, side cutters, wood saw, metal scissors.

Making a balcony warm will help nothing other than the correct choice of the main insulating material - insulation. The choice of insulation for a balcony is determined by thermal conductivity, price and fire-resistant properties. Thermal conductivity of insulating materials is the ability to transmit thermal energy. The lower the thermal conductivity, the less heat the insulation will release into the street from the apartment. Let's consider four types of insulation:

Expanded clay is a cheap bulk insulating material. Non-flammable Due to its properties, it can only be used for floors. When dry, it is unreliable; voids form between the granules, allowing cold air to pass through. To bind the granules into a homogeneous mass, they are poured with cement laitance - a liquid unsaturated concrete solution. Mineral wool is a lightweight fibrous material made from basalt or glass microfilaments. Its thermal conductivity is 0.070 W/m*K. Insulating the inside of a balcony with mineral wool, especially if it is used to insulate the loggia from the inside, is not a better option than from the outside. Over time, mineral wool becomes brittle and the scattered fibers turn into mineral dust, which can cause irritation to the respiratory tract. Cotton wool absorbs moisture, which can cause fungus. Foam plastic is the lightest and most inexpensive sheet insulation. Its base is foamed polystyrene foam granules. It stores heat well - conductivity 0.050 W/m*K. But when burned, it releases toxic substances that are hazardous to health. Penoplex is extruded polystyrene foam. Burns weakly, with attenuation. It has the lowest thermal conductivity - a 20 mm thick foam sheet is comparable to a 400 mm thick brick wall, 50 mm thick mineral wool and a 30 mm thick polystyrene foam sheet. If you choose how to insulate a loggia in a panel house from the inside, it is better to choose penoplex. Since it is possible to insulate a balcony from the outside only with material resistant to weather changes, the same penoplex is used for these purposes by installation teams. The result is a loggia that is dry and warm.

The materials for the sheathing will be:

- Wooden 40 - mm bars

- Wooden 40 - mm bars

- Galvanized straight hangers

Before installation and insulation work, it is important to stock up on fasteners of different calibers:

- To attach direct hangers to concrete panels or brick walls, you will need 6 x 60 mm dowel nails

- Liquid nails - a heavy-duty assembly adhesive that can reliably fasten foam or polystyrene boards to walls

- 10 mm staples for a construction stapler

- Dowels - mushrooms 8 x 200 - when using sheet insulation, the panels are attached directly to the wall

- Dowel - 8 x 100 nails. They fix the floor sheathing bars to the concrete base of the subfloor

Do-it-yourself insulation of loggias step-by-step instructions

The technology requires that the balcony be insulated by installing heat-resistant windows. The loggia in front of the insulation is a huge window opening. A warm loggia is a space covered with a PVC window made of a multi-chamber profile with low thermal conductivity, and internal reinforcement with a solid steel or aluminum pipe.

If the balcony is insulated from the outside, the window space must also be closed, because all insulating facade finishing materials are attached to the finished window.

General characteristics of loggia windows:

- 2-chamber (for the middle climate zone) or 3-chamber (for northern climate) double-glazed window

- 5-chamber profile

- reinforced reinforcement

Use only two- or three-chamber double-glazed windows with a thickness of at least 20 millimeters.

Step No. 1. Preparatory

Where to start with insulation? The balcony or loggia needs to be prepared - remove everything unnecessary. The workspace should be empty. To do this you need:

- Free the loggia from unnecessary things and furniture

- If necessary, dismantle the balcony railing if a floor-to-ceiling window will be installed

- Remove fragile and crumbling elements of plaster and screed, clean interpanel seams

- dismantle all unnecessary elements: bars, slats, subfloor, fences, clothes dryers, remove old dowels and screws from the walls

- Seal cracks, voids, and through holes. Smooth out surface damage on walls, floors, and ceilings. Materials for sealing cracks - cement mortar, gypsum plaster mixture. Treat places where the balcony slab-fence does not fit tightly to the floor/wall of the balcony with a weather-resistant sealant. For deep voids and foam, it is better to use a mounting gun - with its help you can regulate the pressure of the foam and get to the most inaccessible places. Foam is an excellent insulating material and will complement the overall insulation of the loggia.

- Plan the location of lamps and sockets, junction boxes, installation hatches for servicing hidden wiring

- Cover the doorway to the loggia with a covering film to prevent dust from flying into the apartment

Step No. 2. Insulating the floor

IMPORTANT: To ensure that both the floor and the ceiling are perfectly flat, you must set the level to zero. To do this, using a laser or water level, you need to mark a horizontal line around the perimeter of the balcony or loggia. From it, measure the top point of the floor sheathing and the bottom point of the rough ceiling. This is very important for insulating the loggia floor.

The floor insulation algorithm is as follows:

- Mark the location of the sheathing bars on the subfloor. The perimeter sheathing should retreat from the wall by the thickness of the insulation, 50 - 100 millimeters.

- Using a flat brush, treat the surface of the bars with a fire retardant - a liquid fire-resistant compound. The bars can be drilled straight through with a hammer drill with an 8 x 160 mm drill.

- Drive a dowel into the drilled holes - nails 8 x 100 millimeters, hammer until it stops. The sheathing parts are fastened together with self-tapping screws using wood 4.2 x 35 millimeters. Attach the bars to the floor with such a run-up that when laying penoplex or polystyrene foam between the sheet of insulating material and the sheathing there remains an installation gap of 1 centimeter.

- Sheets of polystyrene foam/penoplex can be glued to the subfloor with liquid nails. It will be more reliable to mount the sheets to the floor with polyethylene mushroom-shaped dowels. Fill the installation gaps with polyurethane foam. After hardening, cut off excess foam with a knife.

- Cover the insulation sheets with a vapor barrier membrane, which will remove moisture from the insulation.

- Mount sheets of plywood cut to the size of the loggia/balcony onto the sheathing using 35 mm long wood screws. The thickness of the subfloor sheets should not be less than 18 millimeters. It is possible to lay additional insulation with aluminum foil - penofol - under the plywood.

Step No. 3. Thermal insulation of walls

Mark with a building level the vertical lines for attaching direct hangers so that the distance between the future vertical elements of the sheathing is 10 - 15 millimeters greater than the width of the sheet of insulating material.

Direct hangers are attached to the concrete/brick through the mounting lugs of the dowel - 6 x 60 mm nails.

Fix the insulation sheets to the wall with dowels using fungi or liquid nails in the same way as to the floor. Fasten bars cut to size or cut pieces of steel profiles to straight hangers using 25 mm self-tapping screws.

Also secure a vapor barrier membrane or penofol with foil on top using a stapler. Tape the foam foam joints with aluminum tape.

Drill bars or steel profiles of the counter sheathing on top of the foam foam.

Sheathe the balcony along the sheathing with moisture-resistant plasterboard 12.5 millimeters thick.