A correctly selected window seal performs several functions at once: eliminates drafts and noise, reduces heat loss, and prevents the penetration of moisture from the street.

Even modern plastic windows eventually need to install a new seal.

Self-adhesive sealing strips are easy to install on windows yourself.

About insulation

The microclimate of the room depends on the windows. Due to uninsulated windows, the glass fogs up, cracks and fungus appear on the slopes, and there is always a draft and street noise. To effectively insulate windows, it is necessary to determine the reasons for low thermal insulation.

Most often they are the following:

Wooden windows

First of all, insulation is required for old window structures for the following reasons:

- Previously, glass was secured to the frame with special putty. Over time, it dries out and becomes stained;

- the frames dry out, so cracks and gaps appear between the glazing bead and the glass;

- the sashes are deformed and are not held tightly to the frame.

Plastic windows

It is mistakenly believed that such windows are quite airtight and therefore do not need insulation. Unfortunately, after a few years the seal collapses, and insulation is indispensable.

There are other reasons why it is necessary to deal with plastic windows:

- violation of window installation technology;

- distortion of the window structure due to shrinkage of the house;

- factory defect of window design;

- mechanical damage to structural elements.

Reasons for blowing

It is not enough to just insulate the frames. It is necessary to identify the place that has become a conductor of cold. The most common causes of leakage are:

- windowsill;

- slope;

- sashes and frame;

- glass.

Bridges and gaps often form at the bottom of the window sill, which may not be noticed. Insulation materials on slopes deteriorate or are missing altogether. The wood of frames and sashes may be subject to shrinkage and subsidence. Due to the movement of the soil, cracks form under the building. In places where the glass is adjacent to the frames, drafts may occur. The putty only lasts a few seasons, so it needs to be renewed periodically.

Due to gaps in window frames, significant heat loss can occur

It is difficult to identify places of blowing visually, so their presence is checked in several ways. A wet hand or a lit candle is brought to the window. Wet skin is very sensitive and will immediately feel the slightest air currents, and the flame will fluctuate under the influence of a draft. Windows in good condition need to be insulated around the perimeter, but for heavily damaged structures, all cold bridges must be removed.

You will see how to properly insulate wooden window frames in this video:

Materials you can use

We will look at different options so that you can understand both how to insulate plastic windows and how to insulate wooden frames. These are different types of structures, and working with them can be very different.

I'll start with the simplest solutions, at the beginning of each section it will indicate what type of windows the technology is used for, so that you learn only what suits you.

Option 1 - cotton wool and paper

This is the cheapest insulation for window frames, which is used on wooden structures. The technology involves working indoors, since paper and cotton wool are not intended for outdoor use.

As for recommendations for carrying out work, they are as follows:

It is better to purchase the option, as in the photo - in the form of a roll; such cotton wool is much easier to separate and stuff into the cracks.

The main disadvantage is that with constant changes in temperature and humidity, the tape can come off.

Don't use regular tape! Although it holds better, if it is torn off it can remove the paint from the frames,

The work is carried out with any suitable tool, it can be a small spatula, a screwdriver or something else.

After drying, the paper will stick well to the frame. To remove it in the spring, you just need to wet the surface.

In the spring, the tape is simply carefully separated from the frames; usually this process does not cause difficulties.

Option 2 - special insulation tape

There are two main options here:

- Thermal tape made of polyethylene foam. It resembles a regular tape, but unlike it, it is made of foamed polymer, which retains heat well and does not require additional sealing of the cracks with cotton wool. Sold in rolls of 10 meters and has a width of 50 mm;

- Self-adhesive foam tape. This option can be used both for cracks in the frame and for joints by gluing the material to the open sash. Foam rubber has good thermal insulation properties, so it retains heat well.

As for the application, everything is very simple:

- Self-adhesive insulation is simply glued in the right place. If there is a gap around the perimeter, then the foam rubber can be pushed into it with a spatula. It is important to close all places through which heat is lost and press the material tightly to the surface;

The tape must be pressed tightly to the surface

- The sashes are insulated with foam tape by gluing it around the perimeter. The material can be placed both on the frame and on the sash - wherever is more convenient for you. The protective layer is removed from the tape and it is pressed tightly along the entire length of the joint.

Foam rubber compresses well, so it is often used for frame and sash joints

Option 3 - rubber seal

Can be used on both wooden and plastic structures. Its main purpose is to seal the joint between the sashes and the frame. Thanks to this, heat loss through this part of the structure is reduced tenfold.

If you are figuring out how to insulate wooden windows for the winter, then you will need a universal option that can have different widths. The thickness of the rubber bands is selected for a specific structure, so that after closing the sash the joint is tight.

The seal is simply glued around the perimeter of the frame

As for the rubber tape for plastic windows, it is selected depending on the brand of profile used. Just tell the store what brand your windows are from, and they will give you the right seal.

For plastic windows, special rubber seals with a special profile are produced

Please note that for reliability in plastic systems, the elastic can be glued to both the frame and the sash.

Option 4 - putty or silicone

If the first option can only be used on wooden structures, then the second is suitable for both wood and plastic. The following can be noted here:

- The putty can be used both inside and outside. This is a special composition that is sold in hardware stores and is specifically designed for sealing the joints of glass and frame. Applying the putty is very simple: roll the compound into a thin sausage, which you press against the edge of the window frame, and then form an inclined surface so that moisture drains from the joint;

The putty is easy to use

- Silicone can be used for both plastic and wooden windows. In the first case, it will be used to seal the junctions of ebbs or cracks around the perimeter, and in the second, beads can be glued to the silicone. This will make the connection airtight and prevent the glass from rattling. You can apply the composition to the gap between the bead and the glass if you did not do everything right away.

Silicone does not allow air and moisture to pass through

Option 5 - insulation of slopes

Now let's figure out how to insulate slopes from the outside and from the inside. As for interior work, foam plastic is most often glued around the perimeter, and the surface is covered with plasterboard or plastic. Separate reviews have been written on how to properly carry out this type of work; we will not discuss it here.

As for external insulation, there can be two options:

- If the frame is located inside the slope, then it is enough to seal the joint with foam and putty on the outer part to protect the insulation;

Foam fills all voids at narrow joints

- Let's figure out how to insulate the slopes of plastic windows from the outside. The instructions for carrying out the work look like this: first, foam sheets of suitable width are glued around the perimeter; they should extend slightly onto the frame around the entire perimeter. Then the slope is reinforced with mesh and plastered, with paint or a decorative coating applied on top.

Polyfoam is excellent for external insulation of slopes

Vapor barrier device

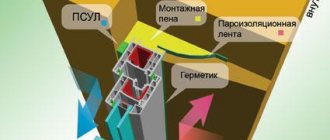

There are three layers:

- From the inside - thermal protection prevents heat loss from the room to the street

- The middle load-bearing insulating layer provides thermal insulation and sound insulation. These problems are solved by polyurethane foam or other porous material. It is rational to include vapor barrier self-adhesive tapes in this inner layer if the window unit is installed in wet rooms - kitchens, baths or showers

- The outer layer waterproofs the joint and protects against the penetration of cold street air

Vapor barrier tapes are available with a one-sided adhesive layer and double-sided. A one-sided sticker is used if the film is mounted on the side surface of the window frame. Double-sided tape gives an advantage in choosing fasteners: on the frame or in the window opening. According to climatic versions, tapes are also produced in two types - for areas with low winter temperatures - a winter version of the tape, and for areas where temperatures do not fall below +5⁰С - a summer version.

The base for the adhesive layers of the tapes is butyl rubber or metal.

Main types of vapor barrier tapes:

- PSUL, or pre-compressed sealing tape, is used for finishing and vapor barrier of external joints, ensuring a tight connection between the window frame and the external wall. The base material is butyl rubber; the thickness and elasticity of the tapes provide good insulation.

- BC - vapor barrier tapes for sealing joints for dry finishing of slopes - made of plastic or plasterboard. sizing with BC tapes reduces the risk of condensation.

- VM - vapor barrier tapes attached to the window frame, with an overlap, in order to improve the thermal insulation of joints.

- GPL is a polyethylene foam tape, laminated on one side, with metal strips and an adhesive layer over the entire width.

In addition to the main layer of non-crosslinked polyethylene foam, which is 2 mm thick and is waterproofing, the GPL tape has a second layer - both vapor barrier and protective. The thickness of the outer layer is only 20 microns, the material is polypropylene.

GPL tapes are used for all types of door and window blocks as universal ones. They combine two tasks - waterproofing and vapor barrier. The structure of foamed polyethylene is elastic and closed-porous, so the material does not absorb moisture and its hygroscopicity is almost zero. The tapes are flexible and suitable for installation on uneven surfaces. Metal lamination and the quality of the main polymer (polypropylene as a protective layer) determine chemical resistance in both acidic and alkaline environments, and as a result, good durability of GPL tapes.

They produce GPL tapes in standard width sizes of window and door units, width 9; 12; 15; and 20 cm, in rolls of 15 m.

Features of installation of vapor barrier tapes

- The minimum temperature for installing tapes is +10⁰С

- The tapes are applied to the prepared surface - complete cleaning of all contaminants, dust removal and degreasing. Preparation is vital for the vapor barrier to work properly.

- Marking lines for attaching vapor barrier tapes. Determine the position of the frame in the opening without fixing, mark the lines for sticking the tapes, then remove the frame and install the tape according to the markings

- Protective paper strips are removed from the tapes immediately before the final installation of the frames

- After gluing the tapes, the joint is filled with foam

- The tapes under the window sills are installed last

- If wet plaster is planned over the vapor barrier tape, then the outer side of the tape must ensure adhesion to the solution. From the range of vapor barrier tapes it is possible to choose a material with the desired properties

- Glue the tapes along the perimeter of the frames without breaks, in continuous stripes. There is no need to overlap or overlap the tapes; at joints, adhesives recommended by the manufacturers or tape are used

The issue of the need for vapor barrier of windows is decided by each owner, based on the specific operating conditions of the windows. Budget options for installing tape are absolutely excluded. But many experts believe that vapor barrier of windows is by no means a reinsurance, but a real opportunity to increase the service life of window systems and improve the indoor microclimate, and saving in this case is not an entirely correct approach.

Types of insulating tapes

The widespread use of tapes for insulating windows is explained by a number of reasons:

- no annual replacement required;

- insulation is carried out in a short time on our own;

- there is no dirt when pasting, since no water is used;

- no traces of adhesive remain on the frame;

- there is no diffusion of the adhesive layer with the frame paint.

But this method of insulation also has disadvantages:

- after gluing, you cannot open the window sashes;

- Poor-quality or poorly glued tape lags behind the frame in small areas.

Construction stores offer two types of tapes, which differ in the installation method.

Pasting

Foam tape with adhesive backing

Tapes of this type have a wide grip. The adhesive composition is applied during manufacturing (self-adhesive type) or during installation work.

To create self-adhesive tape, polyvinyl chloride, rubber and polyethylene foam (foam rubber) are used.

Due to the plasticity of these materials, the tape is easily compressed to the size of the gap. To ensure that the insulation does not stand out against the background of the window, dyes are added: black, brown, white.

Typically the packaging will indicate the size of the gap that the tape will cover. Popular options with sizes 3 - 7 mm.

Foam rubber tapes were the first to be used. Their popularity is explained by a number of advantages:

- high compression ratio;

- the frame does not collapse in places of insulation;

- low cost;

- high protection efficiency.

Such tapes have negative qualities:

- insufficient efficiency for large gaps;

- short service life. Effective during one winter season;

- in cheap models, the adhesive tape does not stick well;

- low resistance to water.

It is more convenient to use self-adhesive tapes on foam rubber for insulation.

They stay on the window longer and regulate the degree of pressing of the sashes.

Sealing

D - shaped tubular seal with adhesive base

Tapes of this type have a hollow tubular shape, which is why heat is retained. The materials chosen are rubber and polyvinyl chloride.

On one side of the tape there is a groove hook or an adhesive coating with paper protection.

It is believed that the groove is more resistant to mechanical stress.

The following qualities are considered advantages:

- gaps up to 0.7 cm are blocked;

- withstands any temperature changes;

- It is possible to choose a color to match the color of the frame;

- the use of the window is not limited;

- affordable price.

But most of the disadvantages relate to adhesive tapes:

- not suitable for all window designs;

- when temperature changes, the adhesive layer is destroyed;

- with frequent deformations, peeling occurs in the glued places;

- The foam tape quickly gets wet and dust sticks to it. For this reason, frequent replacements are carried out.

Tubular seals are checked annually. If necessary, individual fragments are replaced.

Characteristics of insulation

Before using insulation for windows, you need to get acquainted with them, find out their advantages, identify disadvantages, and divide them into types. This section will help you gain useful knowledge about this type of window seals.

Types of seals

The most common are self-adhesive tapes made of rubber and foam rubber. Self-adhesive window insulation can be easily fixed with your own hands by simply removing the protective film from the side where the adhesive is applied. The shelf life is no more than 3 years, after which the foam wears out and the rubber loses its shape.

Self-adhesive rubber tape - suitable not only for windows, but also for doors and hatches

- Another type of insulation is tapes that do not have an adhesive base. To fix it, you need to purchase a special glue (silicone sealant is suitable), which is applied directly to the window frame. The price of such tapes is significantly lower than all other types.

- Groove seals are suitable for plastic and wooden windows, which are manufactured using modern technologies. The insulation is a tubular cord made of silicone or thermoplastic elastomer. The peculiarity of the products is their long service life, about 15-17 years.

Sectional view of groove seal

Benefits of use

- Simple and convenient installation on any surface. You don't need any special tools or any skills for this process, a little instruction before use and your windows will no longer create drafts.

- Visually, window insulation is almost invisible. They can be matched directly to the color of the window: white, gray, brown and many others.

- The seal does not create unnecessary problems when closing the window; it is quite elastic. At the same time, air permeability in the room increases, which has a beneficial effect on both people and indoor plants.

- It is worth noting the resistance to low temperatures. The temperature range at which insulation for window frames does not lose its working properties is quite large: from + 45 to – 50 degrees.

Flaws

Short service life. Every few years you will have to replace the old seal with a new one, spending not only money but also time on this. Low wear resistance. Foam products begin to crumble over time, while rubber products lose their original shape. The need for preparatory work. This is because the adhesive is unlikely to adhere to dirty or uneven surfaces.

Therefore, it is very important to degrease and remove all irregularities from the window frame.

Your protection from the cold: why do you need thermal tape?

In houses and apartments where plastic windows have not yet replaced worn-out wooden frames, they prepare for the approaching frosts as if they were going to fight a serious opponent - after all, in winter, any crack becomes a source of constant drafts, simultaneously drawing heat out of the room. Even the best heating systems are not able to deal with such leaks and “heat the street”, so window covering has become a real autumn tradition. And only with the advent of thermal tape on the market, the situation noticeably changed for the better.

Until recently, various folk methods were used, such as wet newspaper twisted into a flagellum, rags for caulking cracks, foam rubber, paper strips on kefir, and the like. A more advanced and convenient option is masking tape, or crepe, but, firstly, by itself it is not capable of providing the proper level of thermal insulation (the cracks still need to be additionally caulked or filled with insulation). Secondly, the masking tape either does not hold well (if the room has high humidity - for example, in the kitchen), or holds so tightly that in the spring it has to be removed from the window frames along with the paint.

Thermal tape or thermal tape is a modern replacement for the usual masking tape, many times superior to it in its quality characteristics. First of all, thermal tape is both an adhesive tape and an insulation material, that is, when sealing cracks with it, you do not need to take any additional measures, laying, caulking, and so on. A standard strip width of 50 mm is enough to reliably seal a gap of up to 1 cm, but if the gap is larger, the thermal tape can be glued in two strips, overlapping.

Heat tape is not afraid of moisture and is resistant to chemically active substances, so it is used in any room, including in the kitchen, where ordinary masking tape (not to mention popular alternatives) begins to lose its properties soon after pasting due to high humidity. lag behind and let cold air into the room. Moreover, the thermal tape can even be washed! In addition to thermal insulation, this material provides a certain degree of waterproofing of the room, and also increases its sound insulation. The adhesive composition applied on one side of the thermal tape, coupled with its elasticity, allows you to reliably attach the thermal tape to any materials (after cleaning them from contaminants, if necessary). At the same time, the heat tape can be easily removed from the surfaces to be pasted without tearing off the paint coating. If you do not intend to remove the thermal tape, it will successfully serve for more than one season - the durability of this material is 5 years.

Sometimes a buyer has a reasonable question: how light, thin, translucent strips of thermal tape can serve as high-quality protection from Russian frosts. However, it must be taken into account that thermal tape is made from polyethylene foam, one of the most effective and environmentally friendly thermal insulation materials. If we compare polyethylene foam with conventional insulators, then with a thickness of 1 cm, this material retains heat in the same way as 4.5 cm of wood or 15 cm of brickwork; mineral wool gives a similar effect with a thickness of 1.5 cm, expanded polystyrene - with a thickness of 1.2 cm. In addition, thermal tape can be used in a wide range of temperatures: from -50°C to +70°C, the only condition is to carry out any work with it at a temperature of +1°C (for greater efficiency, temperatures from +10°C are recommended).

Thermal tape is confidently gaining popularity today and is quite capable of soon becoming a leader in its market segment, since useful qualities combined with an affordable price make it the optimal material option for protection from winter cold.

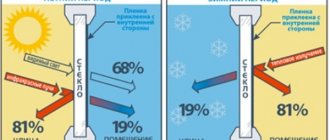

How to avoid the appearance of fungus on slopes

For example, there is a wall made of aerated concrete. There is no insulation of the facade. The temperature outside the house is minus, and the temperature inside is positive. Let’s say it’s 26°C outside and + 20°C indoors. Window installed.

In this design, a window (even a high-quality one with several cameras and energy efficient) is a cold bridge. Those. where the window is installed, the thermal contour of the wall is weakened, and the effective thickness of the aerated concrete (which affects the thermal resistance of the entire structure) is actually reduced, and the slope freezes. This can be visualized like this:

Because of this, part of the slope with the window frame ends up in the so-called zone. dew point. This in turn leads to condensation in this place.

The problem is aggravated by the fact that the slope is not covered with vapor-permeable material. Warm water vapor contained in the air of a living space tends to escape and easily penetrates into cold slopes, and conditions for moisture condensation are created in the structure. The slopes become waterlogged and mold and mildew appear on them.

Insulation for windows - 5 options for materials and features of their use

Window insulation tape - how to avoid drafts and increase energy savings

Surely, you remember that window insulation tape was used several decades ago. Now that new types of windows made of metal-plastic have appeared, it would seem that the need for such material has disappeared. However, it is not.

The tape is still in demand because it:

- avoids heat loss;

- helps avoid drafts.

By the way, in past years, materials for window insulation were still not as accessible as they are now.

Not everyone was able to purchase the tape, and therefore had to use more accessible means:

- cotton wool;

- rolled newspapers;

- gauze, etc.

How to insulate

There are many different materials that you can use for . Let's look at some of them.

Sealing gaskets

Experts say that for windows these are special tubular profiles (they are also called sealing gaskets). They come in different sizes and are made of different materials. The most practical option is foam pads, rubber and polyethylene foam. All of these can be found at any construction market.

We cover the windows with newspapers

This is an old but proven method. We roll each newspaper into a tube, the width of which should be slightly larger than the distance between the window sashes. Then place the resulting rolls vertically close to each other and close the windows. If the room will not be ventilated in winter, then all small cracks can be plugged with tow, foam strips or cotton wool.

Textile

You can also cover the windows with strips of white fabric. It is first moistened with hot water, wrung out, and then thickly lathered with soap. If the cracks are very wide, the window insulation tape is applied in several layers. On the windows, the white fabric is practically invisible, the soap solution serves as an excellent insulator, and with the onset of spring, this entire structure can be easily removed if it is wetted with water. But in winter, due to temperature changes, the fabric may peel off, so everything will have to be redone.

Foam rubber

You can also use foam insulation or cotton wool. First, we fill all the cracks with foam rubber material, then glue them with strips of fabric on top. Strips 4-5 cm wide can be cut from an old sheet. Instead of glue, regular soap is used here too. Instead of fabric, you can use paper, but by the end of winter it will turn yellow and will not look aesthetically pleasing.

Paraffin

You can also insulate using paraffin. Take an ordinary paraffin candle and melt it in a water bath. Hot paraffin is poured into a syringe and injected into the cracks. Once frozen, paraffin becomes a reliable barrier to the cold.

Features of preparing windows for insulation

Preparing a window for insulation with tape is almost no different from preparation for other insulation materials. At the same time, there are some peculiarities.

The main stages are as follows:

- Everything is removed from the windowsill. The blinds are removed from the window.

- The frames are washed with soapy water and then dried. The tape requires a dry and grease-free surface.

- The glass is carefully inspected. Wooden windows may have cracked glass. They must be replaced as they are a source of heat loss.

- Grooves are prepared for the sealing tape. They should not contain old tape, dirt or paint.

- Before starting work, they determine the places where cold air comes from the street. They are insulated first. Weak points are the sashes, slopes, and window sills.

Installation of double doors

A good way to insulate your home is to install a double entry door. Due to the formation of an air space separating the room from the street, heat is retained. The disadvantage of this design is the reduction in space.

A threshold is set for the indoor unit. Insulation is additionally laid on the slopes between the doors. There are designs where two doors are hinged on one deep frame.

When insulating entrance doors, you must remember that moisture affects the canvas from the street side. Treatment with impregnation, painting with paint or varnish will help protect against dampness as much as possible. Drying oil creates good waterproofing.

There are a number of rules by which entrance and interior doors are installed. When installing them in accordance with GOST, there are many options for how to seal the gap, which must be present. The gap ensures unhindered opening and closing of the canvas, even if it swells or is slightly distorted.

Clearance standards for a standard door

Insulation with adhesive tape

The insulation technology is not very complicated. First of all, it is necessary to follow the sequence of work.

Plastic windows

Insulation is carried out in the following sequence:

- pre-removed old insulation is used, firstly, to purchase similar material, and secondly, to pre-cut the old material to size.

- gluing begins from the top of the window. As you progress, the protective layer is removed in small sections, and the tape is pressed tightly.

More details in our video:

1. The pasted tape should not have many tears.

2. In the corners the tape is not cut, but wrapped.

Wooden windows

For these windows, in addition to adhesive tape, thin foam rubber is often used. The work is performed in the following sequence:

- strips of foam rubber are cut along the window opening;

- cut foam rubber is placed between the frames;

- The tape is cut to the size of the window;

- The tape is applied with a sticky layer to the foam rubber and smoothed with a napkin.

This insulation will last up to three years. But it’s better to do it as shown in the video:

When is the use of film justified?

Manufacturers of thermal insulating films for windows recommend using them for gluing to the glass of windows, houses, and apartments in the autumn-winter period, that is, from October to March. During this period, protecting windows from heat leakage is justified. The sun's rays that tend to enter the room have almost no heat, so the reflection of the UV part of the solar spectrum is not significant. The film is completely transparent and does not tint the windows. Infrared (warm) rays that come from heating devices are reflected from the windows back into the room, retaining heat.

The effectiveness of the film depends on the method of gluing it to the glass.

Films come in the following types:

- Heat shrink. They have the ability to stretch when they are heated with a warm air stream. Since the film is glued to double-sided tape, it plays the role of additional glass, enhancing the thermal insulation properties of the double-glazed window.

- A film that is glued to glass using a soap mixture.

- Self-adhesive film.

Energy-saving film is available in various colors: bronze, gold, blue, silver. Therefore, it is easy to match it to the interior of the room.

How to glue thermal tape on windows. How to insulate old wooden windows for the winter

Personally, I encountered the problem of window insulation when I rented an apartment. In summer and early autumn the apartment was comfortable, but when severe frosts began, the old wooden windows began to feel cold. The main source of cold was the cracks at the bottom of the window - between the frame and the window sill.

The method that will be discussed below will help to cope with the problem temporarily, which is, in principle, suitable when the apartment is not yours or you are just planning renovations.

To insulate windows, we need a special material - thermal tape.

This is a very common and inexpensive material. The average retail price of a roll (length - 10 m, width 50 mm) is approximately 30 rubles. One roll is enough to insulate a standard kitchen window in a Khrushchev-era apartment building. That is, for a two-room apartment you will need 3-4 rolls, which in total will be 90-120 rubles.

The thermal tape is self-adhesive, that is, an adhesive composition is already applied to its surface, which is a big plus. It is also worth noting that the glued heat tape holds securely, but if necessary, it can be easily removed without damaging the paintwork or leaving marks. This material, useful for the home, is made of polyethylene foam, which has excellent thermal insulation properties.

It is recommended to carry out work on window insulation at temperatures above +10 o C, this will ensure reliable adhesion of the adhesive composition of the material to the surface of the window frame, slopes and window sill.

Take a roll of thermal tape and glue the window around the perimeter, as well as between the sashes

Smooth the glued area with your hand, cut off the excess with a construction knife or scissors. The entire process of insulating windows is very simple and takes a minimum of your time. Comfort and warmth to your home!

What to do if water is leaking from the crack?

A more global and radical solution to the problem is needed for water leaks during rain.

First you need to remove the outer slope. In most cases, the surface of the mounting foam underneath does not have insulation and has already turned into dust. In this case, the sequence of actions is as follows:

- all ancient polyurethane foam is removed;

- if necessary, additional supporting blocks are installed;

- a vapor barrier tape PSUL or PBA is installed in the resulting groove;

- the place under the frame is foamed with polyurethane foam;

- the sealing layer is sealed with insulating tape;

- low tide is set.

If the ebb is attached with screws to the outer surface of the frame, then additional sealing is recommended. Before installation, silicone is applied to the contact surfaces.

It must be emphasized that the approach to window repair should be optimal. Before starting work, you should realistically assess the scale of the work and your strengths.

It may well be that calling in the services of experts could be cheaper than an unsophisticated and very large-scale repair.

Also watch the video below for useful tips on how to remove a gap in a plastic window with your own hands.

I have the same thing in a rented apartment, but the gaps are quite huge and there are leaks. Is it possible to contact window installers and get repairs at a low cost if the windows were installed in 2014?

This is absolutely the installer’s fault; most likely, during installation they were careless in installing the window sill. In the end, there was such a defect in the work. You can naturally use silicone or PVC glue, but this will not fundamentally solve the problem. You need to remove the low tide and remove all the dirt (dust), then foam this place, return the low tide to its place and also foam under the low tide.

We have a similar problem in our apartment. In winter and spring, puddles always appear on the windowsills and mold or mildew appears. It's scary that this problem keeps popping up. It is necessary to test these methods, and what can help us!?

After reading this delightful article, did you find out how to seal the gap between the window and the sill?

I will definitely recommend reading it to my friends and acquaintances.

Subtleties of choice: manufacturers and prices

When choosing a self-adhesive tape, you should pay attention to the profile and material from which the insulation is made. For cracks with a width of 1-3 mm, profile C or E is suitable, for 3-5 mm - P and V, for 3-7 mm - B and O.

Important: shelf life plays a big role in insulation materials, since the glue dries out over time.

The modern range of insulation products includes many manufacturers:

- rubber insulation, which can be found in any store - from 160 rubles for 5 meters;

- Ultima - Polish foam rubber seals, price from 220 rubles per 12 m;

Penosil - two-component insulation made of EPDM rubber, price from 600 rubles;

- "Penofol" - foil-coated polyethylene foam, price from 108 rubles per m 2.

But you can find out how and where you can use liquid insulation in Polinor cylinders by reading the contents of this article.

It will also be interesting to learn about what kind of insulation to put under linoleum and how to do it correctly.

But what is the price of insulation for a warm water floor and which one should be used, this information will help you understand.

Which floor insulation under screed is the best to use and how to use it correctly, you can read in this article.

But what is the price of foil insulation for the floor and where should such a building material be used, this information will help you understand.

What it is: description

The main materials from which insulation is made are rubber, PVC, foam rubber and polyethylene foam. An adhesive composition, protected with special paper, is applied to one side of the insulating tape. When applying insulation, the paper is removed.

Insulation materials are supplied in the form of cut strips, combined into reels, or in the form of formatted rolls.

Rubber

They are distinguished by the lowest price among analogues. They retain heat effectively and are attached using glue or a stapler. One of the disadvantages is poor resistance to moisture: when water gets on the rubber, the material quickly peels off.

If you buy rubber insulation, then the softest one. Rigid models do not adhere well to the window and allow heat to pass through.

Polyvinyl chloride

Reliable and environmentally friendly insulation, which has good frost resistance and resistance to deformation.

When choosing, it is important to pay attention to the rigidity of the product: overly hard models will not adhere well to the surface. Service life is 2-3 years

Foam rubber

Safe to use and reliable insulation. In addition to thermal insulation, they provide good protection from extraneous sounds. Foam insulation is supplied in the form of strips. The advantages of such seals include low cost and provision of air flow for the room.

However, in terms of thermal insulation, foam rubber is significantly inferior to PVC and polyethylene foam, plus it peels off from the surface quite quickly.

Figure: the shelf life of foam rubber is 1-2 years.

Polyethylene foam

They are bundles made of foamed polyethylene. They retain heat perfectly, provide sound insulation and even protect against moisture on the balcony. The most expensive insulation materials among those presented. Service life – 3-5 years.

Benefits and Features

The advantages and technical characteristics of self-adhesive insulation include:

- Frost resistance. Depending on the material from which the insulation is made, its thermal conductivity coefficient varies. However, for all of them it is at a high level: after application, the tape will maximally limit the contact of the room with the environment and prevent the appearance of drafts and cold bridges.

- Versatility. The insulation is suitable for cracks up to 7 mm wide.

- Reliability. The material is not afraid of temperature changes, moisture, and chemical influences.

- High-quality sound insulation. Most types of insulation can not only protect the room from frost, but also from extraneous sounds.

- Environmentally friendly. The materials do not come into contact with the environment or react with chemicals. Insulation materials are absolutely safe for human health.

- Convenience. Once applied, the insulation will not interfere with closing and opening windows. And the installation process itself will not require the help of specialists: the owner of the house will be able to insulate the window on his own.

- Low cost. Compared to other methods, self-adhesive insulation has an optimal combination of price and quality.

- Variety of colors. Among them are white, black, dark brown, which allows you to choose the material to match the windows, ensuring a harmonious appearance of the finished structure.

- Fire safety. The materials from which insulation is made are low-flammable and difficult to ignite.

The video shows self-adhesive foam insulation for windows:

One of the disadvantages of insulation is its fragility - the material is enough for one or two seasons. And also that the tape is not suitable for insulating plastic windows or loggias with double-glazed windows.

But this article will help you understand how to use foam insulation for windows and how to do it correctly.

But what self-adhesive insulation for metal doors is and how it is used correctly can be understood by watching the video in this article.

Basic methods of insulating window frames

There are various means for insulating windows, the distinctive characteristic of which is not only the price, but the following indicators:

Do-it-yourself window insulation

Let's consider several different options, with a detailed description of each type of insulation. Detailed instructions will also be given on how to secure this or that type of material with your own hands. This will allow you to choose the best option for you.

Cotton wool and tape

There is a special tape for insulating windows, which is simply glued to the frame, covering the cracks.

If you can't buy it, you can use:

This method is quite economical. To implement it, you need to caulk the cracks with cotton wool, using a thin, sharp object with which you can tightly push the cotton wool, and seal it on top with ordinary tape.

As mentioned above, this is an economical method, but this is, in fact, the only positive characteristic.

There are also several negative aspects.

- fragility

- low aesthetics;

- poor efficiency, especially in severe frosts.

Based on foam rubber

The second most popular is foam rubber for insulating windows, the price of which is also not high, but it:

- easy to stick;

- quite effective;

- It is equally suitable for both wooden and plastic windows.

This adhesive-based material is relatively aesthetically pleasing and is guaranteed to last for one season.

Advice. However, this material is not recommended for use if the humidity level in your area is high.

Because foam rubber has the negative property of absorbing moisture, which subsequently leads to the base peeling off.

Modern and airtight

Recently, insulating windows with silicone sealant has become increasingly popular.

It is especially effective if you have:

- wooden frames;

- large or even huge gaps in frames.

Application of silicone sealant

Silicone-based sealant is relatively inexpensive.

It must be applied exactly to the gap:

- between the frame and the box;

- between frame and glass;

- between the box and the wall.

The main, undoubted advantage of this material is its high tightness. It really protects from the wind, but there is a problem - if it is applied into the gap between the frame and the box, it will be extremely difficult to clean the surface of this material.

High quality putty

Another good sealant for insulating windows is window putty. This method of insulation was used a couple of decades ago. The putty is similar to hard, rigid plasticine, but if you squish it a little in your hands, it becomes more pliable, making it easy to apply into crevices.

Advice. With any option for insulating window frames, you must first wash their surface and let it dry.

After the frames are completely dry, the surface is degreased. To do this, you need to wipe it with alcohol and let it dry again. This will subsequently allow the insulation to adhere to the surface and last as long as possible and effectively resist cold wind and frost.

The putty is applied as follows:

- Having softened it, apply it to the cracks;

- if they are too big, try pushing the putty inside a little;

- After hardening, the putty will become not only strong, but also dense.

This material has many positive characteristics:

- quite economical;

- one block, the price of which is low, is enough for one large frame;

- does not absorb and even repels moisture.

The only visible drawback is that it takes a relatively long time to apply the insulation.

Rubber based insulation

The modern method of insulation is a special rubberized insulation.

According to consumer reviews, this method:

Naturally, its price is slightly higher than other materials, but it is worth it.

Insulation is divided into several main categories, each of which has a specific letter index:

- category “E” - thickness from two to three and a half millimeters and is optimal for insulating plastic windows for the winter;

- category “D” is a denser material, the thickness of which ranges from three and a half to eight millimeters, and therefore it is ideal for wooden frames and boxes;

- category “P” - thickness reaches from three to five and a half millimeters, it is optimal for both wooden and plastic frames.

The material does not absorb moisture, and is also effective even in severe, severe frosts, when the air temperature drops to minus forty.

Thermal reflective film

Experts say that windows can only be insulated by replacing them with vacuum double-glazed windows. It is guaranteed to last for more than forty years, but it is quite expensive to install. It is much more practical to install a special heat-reflecting film in the space between the glass.

Before installing it, check the frames and make sure that all the glass is held tightly. If you notice that they are loose in some places, treat the cracks that have appeared between the glass and the frame with silicone sealant. Ideally, you should use a sealant that dries clear. Reinforce the corners of old frames with metal corners.

Useful tips

When working with tape, insulation, tape for sealing windows for the winter, you must follow these useful recommendations:

- If you need to cover one window, then on average it takes 5 meters of tape, so it is not advisable to buy a whole roll.

- The material will not last long on a poorly prepared surface.

- It is better to choose the tone of the strip to match the color of the window frame.

- High-quality masking tape will not leave marks on the surface.

- If the window glass is damaged, it should be replaced before insulation, as it will serve as a source of drafts.