The door for interior openings should fit harmoniously into the interior. And also perform functions for separating rooms. It is very common to want a room to remain closed but not locked. An ordinary magnetic latch copes with this task very well. It holds the sash tightly in the closed position, preventing it from swinging open due to drafts. And when you press the door handle, it easily allows it to open. Installing a magnetic lock is not difficult. To install a mechanism in an interior door, you do not need to be a professional locksmith. It is enough to have experience working with tools, including electric ones.

Door magnetic latches: types, advantages and disadvantages

We are talking about magnetic door latches for interior doors, and not about locks for exterior doors. This is important because they are designed differently. So, magnetic latches work due to the magnetic field generated by a permanent magnet. As you know, metal is attracted to magnets. This is how the magnetic latch works: there is a magnet and a metal plate. They are fixed on the jamb and at the end of the door leaf. When the doors are closed, they come closer, they are attracted. This is how magnetic latches are triggered, but they come in different types - active and passive.

Magnetic handles are comfortable and make little noise

Passive magnetic door latches

Everyone knows furniture magnets for fixing doors - these are passive magnetic latches. In the simplest version - for furniture - they are one or two magnet plates in a small plastic case. This housing is mounted on furniture in the right place. The second part - a metal plate - is attached to the doors. We close the doors, the magnet attracts the plate and holds it. Due to this they do not open.

Passive magnetic latches for furniture and interior doors

This type of furniture magnets is familiar to everyone, and the principle of operation is clear. There is an option for magnetic latches for sliding doors. They are placed in closets. In this case, the handles are made mortise so that they do not interfere with moving them.

Magnetic latches for sliding wardrobes

There are the same passive magnetic latches in larger sizes. They can already be used for interior and balcony doors. The same ones, but in a different design, are sometimes installed on entrance doors, but not as a lock, but rather as a closer. This is especially true for glass doors, on which it is problematic to install conventional door closers.

If we talk about the advantages of passive magnetic latches, they are obvious:

- Easy installation. Both parts are simply screwed to the jamb and door leaf opposite each other. This completes the installation. It is very rarely necessary to deepen them.

- Very low noise level. You can only hear a click when the leaf hits the door frame. But this sound is much quieter than the sound from a spring-loaded bolt.

- There is no mechanics, only the interaction of magnet and metal.

- Low price. Furniture options generally cost pennies, but for balconies and interiors the price ranges from $20 and above.

Magnetic lock for a metal-plastic balcony door

Passive magnetic latches are an excellent solution for plastic and metal-plastic balcony doors. We all face the need to go out onto the balcony or loggia. In this case, the locking mechanism handle is installed only indoors. If they are installed outside, it is only an ordinary handle, by which the sash can be pulled. Usually it is only possible to cover it, and in winter the cold is desperately drawn from under the door. This is where the magnetic latch comes in handy. It pulls and holds the door in the closed position.

Active with bolt

For interior doors, the passive version of the magnetic latch is not very convenient. Still, we are accustomed to the door leaf being fixed in a locked state. And fixation due to attraction is not very reliable. Even a draft can open the doors. Therefore, they came up with another type of magnetic latches - with a bolt.

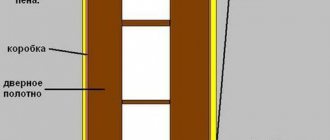

When a magnetic lock is installed on an interior door, a magnet is inserted into the jamb, and a plate with a bolt (retractable latch, tongue) is cut into the door. When the leaf is open, the latch is pulled inside the door leaf. The doors close and the latch moves closer to the magnet. Under the influence of the force of the magnet, the crossbar jumps out, falls into the groove, is attracted by the magnet and remains there. This is how the door leaf is fixed in the closed state.

A latch with magnetic fixation is not very different in principle from a spring bolt

When the magnetic lock needs to be opened, press the handle, forcefully move the bolt, and open the doors. Since the magnet does not attract the bolt, it remains pulled inward even after the handle is released. This is how a magnetic latch with a bolt works.

If we talk about active type latches, there are fewer advantages. Installation is standard. The parts cut into the frame and sash. The cost of a normal magnetic lock is quite high. The real advantages remain:

- Quieter operation. They are far from silent, as is often said in advertising, but quieter than spring bolts. True, if the bolt is made of plastic, then such a spring latch is almost silent.

- Long service life. The exact figure depends on the manufacturer, but since there are no rubbing parts, there is no particular wear either. Special magnetic plastic, reinforced with fiberglass, can withstand up to 200,000 operating cycles (open/close) without changes in performance properties.

And as always, how well a magnetic latch will work depends on its quality. Don't buy the cheapest ones. Some may work well, but there is no guarantee that you will get a good one.

Self-installation of locks in 2 options

We’ve decided on the locking models, now let’s talk about how to install them yourself in interior doors. But first, let's look at the tool, since in both cases the set is the same.

Minimum set of tools

To install a lock on an interior door, you don’t need many tools, plus all the tools are relatively inexpensive; often every home craftsman has such a set.

- Electric drill;

- Screwdriver or set of screwdrivers;

- A pair of chisels with a sting of 10 mm and 20 mm;

- Tape measure and pencil;

- Knife;

- Hammer;

- A 23 mm drill bit for wood, or better yet a set of 10 – 25 mm drill bits;

- A wood bit with a diameter of 50 mm and an adapter for an electric drill for this bit.

Option number 1. Install a light latch

We begin installation, as usual, with markings. The distance from the bottom edge of the door leaf to the core of the lock according to the rules is 950 mm. In office buildings, it is advisable to adhere to it so that the fireman does not get nervous, but at home it can be placed at any height.

Often on such latches the distance from the side edge of the blade to the center of the mechanism is 60 mm. But it is better to clarify this parameter in the instructions for the mechanism, because the insertion depth may differ in different models.

Now, using a square or the same tape measure, we transfer the side mark to the center of the end of the door leaf and make a mark.

To drill a strictly horizontal, even hole on an already installed door, it is advisable to firmly fix the leaf. The easiest way is to insert a couple of wedges on both sides between the floor and the canvas. Then insert a feather drill (23 mm) into the drill and drill a horizontal hole along the length of the mechanism.

Be careful, the slightest misalignment to the right or left can cause the drill to come out from the side and irrevocably damage the blade.

To cut a hole on the front of the canvas we will need a wood crown. Insert it into the drill and start drilling according to the markings. But at first the hole is not drilled all the way through, but only until the moment when the central drill of the crown comes out from the back side. After that, pull out the crown and do the same on the back side.

The moment of drilling the blade with a crown on both sides is very important; if you try to go through the entire blade on one side, then when it comes out, the crown can seriously damage the back side of the blade.

Now you need to insert the lock into the end hole and outline the perimeter of the lock plate. Make sure that the bar is in a strictly vertical position.

The stock for the lock's end plate is cut out using a chisel. Be careful not to go too deep, often 1 - 1.5 mm is enough. If you accidentally choose a groove that is too deep, you can place a piece of cardboard or paper under the bottom.

To firmly secure the mechanism, it must be inserted into the hole and secured with two self-tapping screws. Self-tapping screws will fit much better if you first mark the entry points with an awl or drill holes with a thin drill.

In principle, the installation of the lock is completed. Now all you have to do is insert the handle into the mechanism. Disassembling the handle for the lock model shown in the photo is in the instructions and video in this article, but such locks are good because most handle models fit them; the range of such models, selection rules and installation are shown in detail with photos and videos “here” " .

Option No. 2. Put a permanent lock

We will not repeat the marking technique for this type of lock again, since any locks on interior doors are installed at the same height. But it is highly undesirable to install permanent locks hanging, so you will need to remove the door leaf from the awnings, then install and secure it with the end up.

Unlike a simple latch, a capital lock has a rather large mechanism. We will select the groove for it using the same feather drill; to do this, you need to mark the center line at the end of the blade. Then we select a feather drill according to the thickness of the lock and drill a series of holes to the depth of the lock.

Next, take a couple of chisels and carefully cut out all the excess. The work is quite monotonous and without experience it can take up to an hour. Slowly, the sidewalls are trimmed with a wide chisel, and chips are selected with a narrow chisel.

When the hole is completely selected, all we have to do is select the stock for the lock face plate. The sampling technology is identical and we have already talked about it above. Next, screw the lock, insert the handles into it and mount the decorative trims.

A few words about installing the strike plate

The technique for installing the strike plate for a small latch and a major lock is no different. If you have mastered the insertion of the lock into the canvas, then installing the strike plate on the lock will not cause you any difficulties.

Related article: How to change the lock on a metal door yourself

First, a hole is marked on the loot and drilled for the lock tongue. Then we apply the counter strip to the loot and trace it around the perimeter. Now all that remains is to cut out the stock under the bar with a chisel and screw it on with self-tapping screws.

Types of magnetic locks

Magnetic latches can be of different designs:

- Only with a handle.

- Latch with handle and lock.

- With pen and magnetic card.

All these latches are of the mortise type.

The option is simply with a handle - for those cases when there is no need to lock the room. The handle is only needed for opening - to move the bolt away from the magnet. They also pull on it when the door leaf is opened or closed. It can be round or oblong, regular or not quite shaped.

For those cases when the doors need to be locked, there are models with a lock and a magnetic card. The latch is a stop that, by turning a small handle, jams the bolt. Until the lock is moved to its original position, no one will be able to open the doors.

Mortise magnetic latch with handle for easiest installation

The magnetic door latch with a card has a more complex device. When the doors are closed, the crossbar is located in the opposite part. In this case, the outer handle is blocked by a special device. The blocking can only be removed with a specially programmed card. The inner handle works as usual. Such locks are installed in hotels. They are unlikely to be needed for a house or apartment.

Installing a magnetic locking mechanism

In order to install a magnetic lock, you do not need to have any specific knowledge. The entire installation process is similar to the principle of installing a conventional mechanical device. All magnetic locks for interior doors can be divided into:

Overhead devices are famous for the simplest installation, because with this installation method there is no need to drill holes for the locking device. The Palladium 100-M, AGB Mediana Polaris, Apecs 5300-MC locks are distinguished by their simplicity of design and the absence of hinged elements. The entire mechanism installation process can be divided into the following stages:

- The location for installing the lock is marked on the horizontal or vertical part of the door frame.

- The location on the door leaf is determined for the counter plate by applying appropriate markings.

- A stencil is glued, the required number of holes and their diameter are determined from it, after which the counter plate is installed.

- The mounting plate is installed and the operation of the locking mechanism is checked.

Installing an electromagnetic lock has its own nuances, but in general requires a similar approach. The whole difficulty of installing an electromagnetic mechanism lies in connecting the electrical cables and laying them.

Magnetic locks AGB (Italy) - quality at an affordable price

Practicing craftsmen have many complaints about Chinese-made magnetic locks - often the magnetic latch simply does not work. To avoid getting into trouble, you should not skimp on accessories. The products of the Italian company AGB enjoy a good reputation, as evidenced by numerous positive reviews.

For marketing purposes, the term “smart magnetic lock” was introduced.

A smart magnetic lock that overcomes the most difficult climatic conditions. Created using innovative materials to ensure the lock operates even in extreme weather conditions (humidity, dust, chemicals).

Polaris 2XT is a smart magnetic lock from AGB.

The face plate is made of stainless steel. On request, the lock is available with a rectangular face plate. Polaris 2XT features quiet closing and precise mechanical connections that give a pleasant smooth handle and key turning feel.

Centro - magnetic lock with deadbolt

The adjustable Easy-Fix XT magnetic striker makes installation easy and the clamp system secures the insert into the striker

How to embed a lock into an interior door - 2 installation options for the home craftsman

Have you ordered the installation of interior doors, but for some reason did not install locks on them? Don't worry, you can do this kind of work yourself. Next, we will show you step by step how to embed a lock into an interior door, but since locks are different, you will learn how to correctly embed a lock in 2 options, with your own hands and with a minimum set of available tools.

How to repair a door handle and lock mechanism?

If the lock was installed in compliance with all the rules, then during operation it will serve for a long time and properly. But over time, wear and tear becomes more and more severe, the door handle mechanism and locking mechanism become unusable, and the door stops opening/closing normally.

You can notice the poor condition of the locking mechanism by the following signs:

- jamming of the lock mechanism;

- poor fit of the tongue into the groove, its constant getting stuck;

- the door starts to close/open poorly;

- When the door is closed, sagging occurs, and subsequently the locking mechanism completely fails to fit into the desired joint.

Adjusting the lock is easy. To work, you will need a screwdriver and consumables such as wood or rubber gaskets.

- Before adjustment, you need to unscrew the linings and remove the handles.

- Then you need to get to the locking mechanism.

- After this, open and close several times. This checks to see if the problem is still there or if everything is working as it should.

If the lock simply jams, lubricate it with grease or machine oil. During lubrication, the lock is turned at certain intervals for the best lubrication of all components of the locking mechanism.

Often the problem occurs due to lack of tongue length. Modern mechanisms have a special insertion position, which just needs to be turned several times with a screwdriver. The tongue extension parameter will be adjusted, and the problem will be solved.

If there is a problem with the lock tongue, it is even easier. It is necessary to measure how much is missing until the tongue is completely inserted, after which it is important to completely pull the lock mechanism out of the door, insert a pre-prepared gasket, and then install the lock mechanism.

The interior door is easy to adjust. To do this, you will need to find out the cause of the problem and prepare the necessary tool. Simple manipulations will allow you to fix the problem yourself.

Standard equipment and additional equipment

The design of a magnetic lock depends on the initial configuration, that is, basic elements and additional devices that can be connected to the mechanism for convenience.

Lock kit upon purchase

The basic set of locking mechanisms for interior doors, entrance doors and gates consists of:

- a powerful magnet operating under the influence of electricity;

- a reciprocal metal strip attracted to the magnetic plane;

- an electrical cable connecting the magnet to the power source;

- fastening connections;

- instructions describing how to install magnetic locks of this type.

A set of elements included in the basic lock package

The magnetic lock can be controlled in two ways:

- a push-button mechanism that closes the electrical circuit when closing and interrupts the power supply when opening;

- an electronic mechanism consisting of two sensors:

- Hall sensor, which constantly monitors the voltage supplied to the lock;

- magnetic contact, giving a signal when the device is operating.

It is impossible to determine by the appearance of the lock exactly how it opens. The Hall sensor is built into the main part of the lock. However, an additional magnetic contact sensor is included with the electronically controlled device.

All sensors, opening buttons and electronic keys are included in the standard equipment.

Additional devices for magnetic lock

Installation of a magnetic lock is possible with additional devices that facilitate its operation and control, these include:

an uninterruptible power supply unit that ensures the operation of the locking mechanism during periods of absence of constant voltage. A battery is built inside the unit, which begins to operate when there is a failure in the central power grid. You can charge the batteries using the mains adapter that is included with the unit;

Equipment that allows the lock to operate in the absence of electricity

controller – a device that is necessary to connect additional equipment. If a control unit is supplied with the lock, then the controller is built into this device. Otherwise, it will need to be purchased additionally;

Equipment designed to connect all parts of the lock

a closer designed for smooth closing of a magnetic lock. If the main locking mechanism is equipped with a closer, then this element will extend the life of the device, since strong shocks that can damage the magnet will be eliminated;

A device that extends the life of a magnetic lock

intercom. This device is mainly installed on the door to the entrance or on the gate leading to the territory of a suburban area. Using an intercom, you can see or hear a person who wants to enter a closed area and open the lock without leaving the apartment or house, respectively.

Devices included in the intercom with video communication function

The complete set of equipment included in the magnetic lock is determined independently by the user.

Misconceptions and Myths

The spread of magnetic locks is limited by various speculations:

- Mortise mechanisms are short-lived or do not work. This is wrong. They produce reliable designs that are difficult to open or break. Well-installed ones will work for many years.

- Magnets are short-lived and quickly lose their magnetic properties. Modern magnets do not demagnetize.

- When the door sags, they jam. If the installation is done professionally, then a slight deviation of the blade will not harm it. Excessive sagging will affect the operation of both the magnetic and mechanical locking devices. They are simply jammed.

- EM systems can be opened without a chip, for which it is enough to enter a universal code. There are no such codes. There are systems that have unique codes, but this is for a small number of systems.

- There is a universal key. Such keys do not exist due to the large number of manufacturers.

Design and principle of operation

The undeniable advantage of an electromagnetic lock is its simplicity of design. The product is based on a core with a winding, hidden in a special housing.

The core deserves special attention. It consists of many sheets of electrical steel, characterized by a slight magnetizing effect. To reduce residual stress, a paint coating is used.

The core, formed from plates, most often has an W-shape. The winding is a coil with a copper wire wound on it. The conductor is coated on top with a special insulating compound.

The product body is made of aluminum or steel. Sometimes plastic is also used, but its disadvantage is a lower resource and less reliable design.

The operating principle is based on the action of electricity and magnet. It is triggered after voltage is applied to the winding and the magnetic elements are activated. As a rule, 5 W of power is enough to securely fix massive doors weighing up to 150 kg.

When the EMC is turned on and off, an electromagnetic circuit is formed, which is affected by alternating current. With the help of a capacitor, charging is carried out through the winding, due to which the polarity of the magnet changes. In this case, the residual current is directed to magnetization reversal.

One of the main elements of an electromagnetic lock is a capacitor. If it breaks, it may be difficult to open the doors.

The solution in this case is only to replace the faulty element and connect it parallel to the terminals.

POWER SUPPLY FOR ELECTROMAGNETIC LOCK

Since electromagnetic locking devices require electricity to operate, the question arises of choosing and purchasing a power supply unit (PSU). First, let's look at what characteristics it should have.

The passport of any electromagnetic lock indicates two values:

- supply voltage;

- rated (operating current).

In principle, everything is simple, you purchase a block that has the appropriate parameters and connect a lock to it.

However, I would like to draw your attention to a few points.

Electromagnetic locks are available in 12 or 24 Volt voltages. There are models that can be powered by any of the specified voltages. The latter, by the way, does not provide anything except dubious versatility and unnecessary movements with switching.

But at 12 Volts, the current, all other things being equal, is greater than with a 24 V supply. The practical conclusion is that longer power lines can be used (again, with the same cross-section and wire material).

The fact is that, according to Ohm's law, the voltage drop (read losses) is directly proportional to the current and resistance of the conductor.

In reality, in most cases this is not important, for example, when connecting an electromagnetic lock to the gate of a private house or cottage. Take a wire with a cross-section of 0.75 mm2 several tens of meters from a twelve-volt unit without any problems.

Such sources are good, first of all, for their prevalence, and as a consequence, the ability to choose a budget model. In addition, now we will talk about power supply redundancy, for this we need a battery, and with 12 V batteries the situation is also simpler.

Critical voltage losses are more common in large access control systems, where the use of a 24-volt lock will be justified. But, since the installation of such access control systems is carried out by professionals, they have the cards in their hands, let them consider everything for a specific configuration and composition of the equipment.

How to choose the right interior door latch

There are several points based on which you can choose the appropriate mechanism:

- the latch must be of high quality and reliable (without chips, scratches, with a durable color);

- if the choice falls on magnetic fittings, then you need to check the magnet itself;

- It’s worth assessing how comfortable it is to hold onto the door handle, since you will have to interact with it every day;

- door fittings must match the interior and decoration; Important! The handle is chosen in the same color as the hinges with the lock.

- the location of the rooms and their functional purpose are taken into account: the same models are often chosen for adjacent rooms, but if the interior doors are located at a distance from each other, then different options can be considered;

- degree of load on the handle - if you install flimsy magnetic fittings on a powerful massive door, it will quickly become unusable;

- When coming up with original solutions, you shouldn’t overdo it; an elaborate model will look ridiculous in an apartment with a regular renovation, but a simple one with a magnetic element will suit any interior.

Handles are made from different materials; the consumer’s choice often stops at the following options:

- Metal. Such products are the most durable and wear-resistant. By applying different coatings, you can get a new solution in terms of color and texture. The most popular models are made of brass; they combine quality and price. The main disadvantages of metal products are that the surface always remains cold, and budget options quickly lose their attractiveness.

- Tree. Best suited for canvases made of similar materials (solid or veneered). For their manufacture, wood of various species is used, including valuable ones. Decorative inserts, inlay or carving can serve as decoration. This solution is not suitable for kitchens and bathrooms due to low resistance to high humidity.

- Glass. These products will be a wonderful decoration for any interior. But they are fragile and expensive.

- Plastic. Such accessories are the cheapest and short-lived. They are installed in rooms such as utility rooms. Disadvantages: low quality, unpresentable appearance.

Tips for use

In order for a magnetic lock installed on an interior door to work long and reliably, it must be used correctly. There is nothing complicated about this, just follow simple rules:

- it is necessary to periodically clean the magnet and the counter plate from debris and metal dust adhering to them;

- In order to ensure the clamping force of the magnetic lock declared by the manufacturer, it must be installed correctly. A deviation from the recommended gap size, even by a few millimeters, changes the strength of its retention, so the installation must be carried out carefully and efficiently ;

- if moisture gets on the lock mechanism, it must be wiped so that the parts do not oxidize;

- Periodically you need to check the fastening of the lock and the mate, and if necessary, tighten the screws.

It is necessary to periodically check and tighten the fastening of the magnetic lock and strike plate

If you purchased and installed correctly a high-quality magnetic lock, then under normal use it will work reliably for many years.