Plastic doors are installed in residential premises, shops, and warehouses. Such popularity lies in the benefits they offer. This design allows for tightness, which eliminates heat leakage, as well as good sound insulation. Fittings for plastic doors vary. Each part has its own purpose and characteristics. Incorrect installation of fittings will negatively affect the quality of the structure.

Accessories for plastic doors

Main types of accessories

High-quality fittings for PVC doors do not have to be expensive. These details can be:

- buy ready-made

- order individually.

Fittings for plastic doors can be different.

Often the fittings are a standard part, which is designed for classic operating and installation conditions. When purchasing such products, you need to familiarize yourself with the main manufacturers of accessories that produce high-quality products. The functionality and durability of a part is influenced by the quality of production. If it fails, you can purchase a domestic analogue or an original product from the manufacturer.

Thanks to a wide range of accessories, you can easily find a replacement for an old or broken part

Latches

The latch is a kind of lock. It ensures tight fixation of doors in closed and ajar positions. Latches are different, it all depends on the method of their fastening.

The latch is a mandatory part of a plastic door

Table 1. Main types of latches

| View | Description |

| Roller | It is considered the simplest part in structure and operation. When the doors are closed, tension is created on the spring, which pushes the ball and ensures a tight fit. It takes more effort to open doors than to close them. |

| Magnetic | It consists of two magnetic plates. If the door is slightly open, they are attracted to each other, and in the closed position they provide a tight fit. One of the most important elements of a balcony door. Magnets allow you to fix the door in one position, thanks to which:

|

| Hale retainer | Its structure is similar to a roller latch, but instead of a ball, it uses a cut cylinder. To open the door you need to press the handle, and to close it you just need to push. |

Main types of latches

Instruction No. 1 – self-installation of the magnetic latch

You can install the latch yourself, without the help of a specialist. First you need to purchase the mechanism itself and determine the place where it will be located.

Step No. 1 - installing the first plate on the door

When you have chosen a location for the latch, you need to drill a hole in the door leaf using a drill. Then screw a self-tapping screw into it, onto which the magnetic latch will be attached.

The location for the latch is selected individually, usually in the middle of the door

Step No. 2 - attaching the plate to the frame

Now you need to attach a metal case with a magnet to the frame. It will also require making holes for screws at the same level as the latch.

It is important that the magnetic latches are installed at the same level

Step No. 3 - checking the functionality of the latch

After installing the second magnetic plate, you need to check the functioning of the entire latch. This is quite easy to do. You need to try closing and opening the door. If the latch is not installed correctly, closing the door will be problematic. If any problems arise, but you cannot fix them yourself, it is better to call a specialist.

Video - Installing a balcony latch and hook

Pens

The handles are designed for opening and fixing the doors in different positions. They relate to:

- the most mobile;

- frequently used.

Therefore, they are more subject to stress, which is why more often than other parts they become unusable. Handles are installed at a certain height of the door and often when they fail they need to be replaced rather than repaired.

Handles are single-sided and double-sided

Table 2. Main types of handles

| View | Description |

| Stationary | They are the simplest part, without specific mechanisms. Such a handle only helps to open and close the door, without locking it. |

| Push | They feature a simple locking mechanism. When pressed, the “tongue” of the handle falls into the hole located in the doors. Typically this type of handle is equipped with a halyard, roller latch. |

| Rotary | The most popular model. Allows you to open doors by turning the handle. It is also possible to set the “ventilation” mode. |

Main types of handles for PVC doors

A variety of materials can be used to make handles. The most popular are:

- metal;

- plastic.

Loops

They refer to movable elements for securing doors to the door frame, on which the strength of the entire structure directly depends. The hinges must be of high quality, since they bear the main load. The standard model can withstand a weight of about 150 kilograms. Please note that hinges require regular maintenance. They should be constantly lubricated, each element should be adjusted - this directly affects the durability of the part.

Since each door model may vary in weight, the hinges must be installed and adjusted correctly. Only after precise adjustment will they ensure good pressing density of the sashes, without leaving a gap between them. Therefore, it is quite difficult to set up the loops yourself; it is better to use the services of a specialist.

The hinges must support the weight of the door

Seals

The structure will not be airtight without the use of seals, regardless of its quality. They are attached along the entire perimeter of the frame to ensure tight closure of the sashes. The seals are made of rubber, and their surface is covered with special grooves. Quite often such parts have a manufacturer’s label. When caring for seals, it is important not to use aggressive chemical compounds.

It is necessary to take into account that rubber is not resistant to long-term exposure to external negative factors, and therefore often becomes unusable. If defects appear on the seals, they must be replaced, otherwise the tightness of the plastic doors will be compromised.

The tightness of doors is affected by the quality of the seals and the correctness of their installation.

Combs

The combs are made in the form of a lock and are designed to fix the doors in the open or closed position. Made from:

- plastic;

- metal

This type of fittings is not large in size and is a supporting part that prevents the doors from slamming when a draft occurs. The comb allows you to keep the doors open to ensure ventilation of the room. However, pets or small children cannot exit through them.

Combs are a great way to protect doors from damage due to drafts

Closers

The purpose of the door closer is to smoothly close the doors, prevent them from slamming and ensure a tight fit to the base. Such fittings happen:

- bottom;

- hidden;

- external.

Thanks to closers, doors are protected from mechanical damage (due to strong impacts on the frame) and drafts.

Such fittings ensure smooth and silent closing of doors. Despite its external complexity, the door closer is a simple design consisting of:

- housings;

- spring system.

The speed of movement of the closer can be changed independently

Choosing a closer

When choosing such fittings, the following criteria must be taken into account.

- Each type of door closer is designed for different loads. It is better to choose a design that can withstand the heaviest weight.

- You need to make sure that the location of the plastic door provides space for the closer.

- Do not purchase a door closer that is too large - it must match the size of the doors.

- If you need fittings for a plastic entrance door, it is better to choose a door closer that can withstand temperature changes.

A correctly selected door closer will last a long period and will not deviate from the overall style of the room.

Instruction No. 2 - self-installation of the door closer

Installing the closer is not difficult at all. Therefore, you can install such a part yourself, without resorting to the services of a specialist.

Step No. 1 - determine the direction in which the door will open

Since the closer consists of two parts, you need to determine which of them will be attached to the frame.

- If the doors open towards themselves, then you need to attach the device to them, and the lever to the frame.

- If the doors open outward, the lever must be attached to the doors, and the system to the frame.

It is important to install the door closer on the correct side

Step No. 2 - installation of all parts

The kit includes parts for attaching the closer. You can tighten the screws using a screwdriver or screwdriver.

Example of door closer installation

Step No. 3 – checking the functionality of the structure

After installation, you need to double-check the functionality of the structure, if necessary, adjust it.

If you can’t install the fittings yourself, it’s better to use the services of a specialist

Video – Installation instructions for door closer DC120 ASSA ABLOY

Stoppers

Stoppers are designed to fix doors in any required position. They are made of plastic. They are a simple design. They are installed between the frame and the canvas, fixation is provided by springs.

Stoppers are ideal for plastic balcony doors

Fasteners

They come in the form:

- latch;

- element located inside the handle;

- special pen.

Espagnols can be installed on the inside of the door, ensuring its secure fixation in the required position. This is a fairly simple and reliable design that provides good sealing. Despite its simplicity, the latch has a long service life. The latches can be equipped with an additional lock for turnkey closure.

Espagnols have one significant drawback - if the structure is skewed, they cannot perform their functions correctly

A handle with a built-in lock will be relevant for a plastic entrance door. This design is appropriate in a private house; for an apartment it is better to choose a different type of door. When choosing such a handle, you need to take into account that it is not a full-fledged latch, it is rather an additional element for pressing the sash, which helps other latches to operate. The main advantage is the ability to install child protection, which does not allow the child to open the doors without the help of parents.

Locks

This part should be designed specifically for PVC doors. Locks that are installed on other models are not suitable - their installation will damage the plastic sheet.

A lock is a mandatory type of hardware for entrance doors.

Table 3. Classification of locks for PVC doors

| View | Classification | Description |

| Depending on constipation points | Single lock | Not intended for entrance doors. A tight fit of the doors is ensured exclusively at the location of the lock. |

| Multi-point | Handle driven - the movement of the key provokes the movement of the bolt, which locks the lock, pressing the door to the frame. | |

| With a cylinder drive - simultaneous entry of the trunnions into the slats occurs along with the movements of the crossbar. | ||

| Depending on the material | Metal | They are distinguished by increased strength indicators. |

| Partially plastic | More practical and easy to use than metal models. | |

| Depending on the locking mechanism | Falevoy | Such models come in both single- and multi-locking types. |

| Roller | ||

| Rigel |

There are also locks:

- levelers;

- cylinder.

A lever lock is more difficult to pick than a cylinder lock

Types of handles

The question of how to install a handle on a plastic door is certainly important and we will analyze it thoroughly, but you need to install a specific model, so first we will study what the modern market offers in this niche.

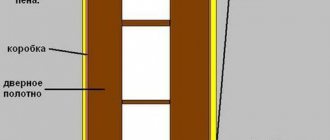

There are several types of plastic doors, the gradation depends on the installation location, purpose and size of the product, respectively, before attaching the handle to the door being installed or replacing it on old doors, you need to pay attention to the type of doors. We will not go into details; we will list only 3 main areas.

- Entrance doors - in apartments and private houses are extremely rare; they are mainly installed on shops, offices and public buildings, which means the handle must have high mechanical strength and be easily replaceable;

- Balcony blocks and doors for terraces - the massiveness and resistance to burglary of such blocks is lower; attention is mainly paid to the level of tightness and the decorative component. Handles with locking mechanisms predominate here;

- Interior doors are lightweight structures with the same lightweight latches and locks. High-strength massive handles are inappropriate on interior doors; the emphasis is on matching the interior and ease of everyday use.

Before replacing or installing a handle, you should pay attention to the type of plastic door.

Now let's figure out what kind of handles exist for plastic doors :

- Stationary model - a stationary handle for a plastic door is in no way connected with the locking mechanism; such a handle is rigidly mounted on the door leaf and is intended solely for pulling or pushing;

- One-way push model - as the name suggests, this handle is installed on a plastic door only on one side. It differs from stationary models in that it is structurally connected to a locking mechanism; in order to open the doors, you need to press the handle. These models predominate in balcony blocks;

- Double-sided push model - a double-sided handle for a plastic door differs from the above-mentioned single-sided model only in that 2 identical push handles are installed on both sides of the door leaf, but both push handles are part of the same locking mechanism, they work synchronously and their fastening

There are several hundred models of handles for plastic doors, but they all belong to one of 3 types

Design differences

Within each type of handle there are often separate subtypes, so in the stationary direction there are 2 types of designs:

- Durable and powerful handles on plastic entrance doors have the shape of a bracket and are made of metal. The configuration and layout of such handles may be different, but they always come in pairs and are installed on both sides;

- The stationary shell handle is usually attached only on one side and in balcony blocks acts as an auxiliary element paired with a one-sided push handle. The point of such a tandem is that the push handle is connected to the lock, and on open balconies this is not always convenient.

The shell handle has a couple more names - it is a petal and a smoker's handle. The first option is a related model and, unlike the shell, has a smooth hook shape, and the shell is called a smoker’s handle because it is installed on balconies and allows you to close the door when going out for a smoke break.

The smoker handle comes in several forms.

Push handles also come in several varieties. In this case, it all depends on the type of locking mechanism. If a standard lock with a cylinder cylinder and a traditional latch is installed, then it comes with classic push handles.

But in balcony blocks where a ventilation mode is provided, window-type handles are usually installed, which move around the central axis and are installed in accordance with the selected mode.

A window push handle is placed on a plastic door when the door system has several operating modes

Rules for choosing accessories

The fittings differ in terms of quality, but when choosing, it is better not to save money, as this will negatively affect the functionality and reliability of the entire plastic structure. It is also not recommended to purchase products from unknown manufacturers, since such parts do not always have:

- high operating period;

- good quality.

You need to purchase fittings from trusted and most popular companies.

Since fittings are not just a functional part, but also a decorative part of the structure, it is necessary to take into account its appearance. The modern market offers a wide range of products that differ:

- high comfort;

- attractive appearance.

A plastic door must meet certain requirements.

- Provide protection against burglary.

- Withstand heavy load.

- Has high levels of comfort and stability during operation.

The fittings must match the style of the room.

Based on these requirements, when choosing fittings you need to consider:

- door weight (the higher this indicator, the more reliable the fittings are required);

- opening method;

- the ability to adjust each element to improve the functionality of the entire structure.

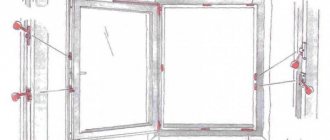

An example of how a plastic door can open.

All fittings are interconnected. This is not to say that one detail is more important than another. If one element fails, the functioning of the entire structure is disrupted. Taking into account all the recommendations presented, the plastic door and its fittings:

- will last as long as possible;

- will fail less often.

What materials are the fittings made from?

Door hardware is made from a variety of materials. Metal is used for the basis of each part. Since handles are regularly exposed to mechanical stress during use, special attention is paid to their coating. It provides protection from negative external factors.

Fittings are made from a variety of materials

Door locks are made from mechanically resistant materials. The lock body is necessarily made of high-strength steel, which must be coated with a protective coating with anti-corrosion properties.

The eye can include several materials at once.

- Housing made of plastic or metal.

- Optical element made of glass or transparent plastic.

Repair of possible hardware breakdowns

Various types of problems may arise with accessories during operation. Among all the possible difficulties, two are the most common.

- If the latch does not fix the position of the door, then a pair of metal washers can be added under its cylinder. If the locking is correct, but even the slightest wind tears the doors off, you should add another latch.

- A common problem is a tight latch, which complicates the process of opening and closing doors. To get rid of this problem, it is recommended to lubricate the mechanism with oil.

Proper installation reduces the likelihood of latch problems

Sagging doors

To deal with this problem, you need to adhere to the following algorithm.

- Place a mark where the door leaf meets the frame.

- Move the door in the opposite direction.

- Using a hex key, turn the screw located on the top hinge clockwise - continue until it is pressed tightly.

- Carry out similar actions with the bottom loop.

The hinges can be adjusted horizontally and vertically

Loss of tightness due to wear and tear of the insulation

Fixing this problem is quite simple.

- First you need to buy a new seal. It should be the same as spoiled.

- The old seal should be removed from the groove using any available tool, such as a screwdriver, and a new one should be put in its place.

- For better fixation, you can add rubberized glue to the groove.

The seal is a short-lived accessory that needs to be changed periodically

Problems with opening and closing doors

This problem often occurs when the function of the pen is disrupted, because it:

- tightened too tightly;

- does not turn completely.

To fix the problem, make horizontal adjustments to the hinges. If there is a malfunction of the handle with a core, you should:

- dismantle every part of it;

- check how the pin is secured (it connects the handle and the core).

If the connecting pin has any defects, it must be replaced. In some cases, the entire handle may need to be replaced.

If you can’t solve the problem yourself, it’s better to call a specialist

Universal multi-point locks

Based on the general principle of operation, multi-point locks come in two types:

- typical;

- universal.

Typical multi-point locks are designed for door leaves of a certain height - the manufacturer’s range usually includes several of the most popular standard sizes. The configuration of universal multi-point locks allows you to “customize” them to fit different door sizes in a wide range.

Artem MedvedevTechnical Specialist

One lock can be used on doors of various lengths - both standard (1871-2170 mm), low (1628-1870 mm) or high (2171-3000 mm). Versatility is achieved through additional elements: to increase the height of the lock, an extension and connector are used. And to shorten it, it is enough to cut the tire in a certain zone (according to the markings) and connect it using the comb available in these zones.

Universal multi-point locks are characterized by an increased class of burglary resistance.

Artem MedvedevTechnical Specialist

The previous generation of locks, with pins 20 mm long, corresponded to the first class of burglary resistance (against vandalism). The new series of universal locks with hook locks has received a certificate for compliance with the third class (RC 3) of burglary resistance - they provide a confirmed high level of security. The locks comply with the German certificate DIN EN 18251-3 and are designed for 200,000 opening-closing cycles - this ensures a high level of reliability and durability. Corrosion resistance complies with DIN EN 1670 standard (class 4 test for 240 hours in salt spray). The locks are suitable for use on entrance doors in particularly harsh operating conditions.

Multi-point locks in this class can be enhanced with double hooks, double hooks and double trunnions, or four hooks. Also, if necessary, additional elements are installed:

- corner switches with roller pins (150×150 mm);

- latch with roller pins;

- upper and lower bolts (for double doors);

- duplicate bolt locks;

- blocking brackets;

- movable latches;

- shortened latches;

- latch plates.