We have already written about what Penoplex 30 mm lightweight insulation can do in an article on the website, now let’s talk about other types of products from the popular brand.

Are you planning to use Penoplex extruded polystyrene foam for thermal insulation of an object, but can’t figure out the brands and density of insulation? Especially for you, we have systematized useful information in this article so that you can easily understand the densities of Penoplex and give even an experienced builder a head start.

Penoplex density 35 kg/m3

It makes no sense to talk about the relevance of the problem of reducing the level of heat loss from buildings and structures. Given the increased demand for products in the “insulation” category, the market is literally flooded with various samples. This article is devoted to one of the most popular modern heat insulators Penoplex 35 - its characteristics, properties, specific application.

This insulation is a type of expanded polystyrene, which is produced by extrusion under conditions of high pressure and temperature. This technology provides increased density of samples with low weight, which makes them universal in use.

Main characteristics of slabs

It makes no sense to list everything for the reason that many of them will tell a reader who does not have a specialized education little about anything. But knowing some will help you make a choice, given the large assortment of Penoplex heat insulators (the article What is better to choose - Technoplex or Penoplex insulation can help with this?).

1. Density (kg/m3) - it is indicated in the name of the sheets of the series (35). Although this value is average. Depending on the manufacturer of Penoplex 35, the indicator of this characteristic varies between 29.5 - 36.5.

2. Daily water absorption (in% of the total volume of the sheet) – no more than 0.1.

3. Strength (flexural, in MPa) – 0.4.

4. Standard sheet sizes (cm) – 120 x 60, thickness from 2 to 10.

5. Thermal conductivity (W/m) – 0.030.

6. Pack weight (kg) – from 10 to 15 (depending on the thickness of the samples).

Features of thermal insulation material

1. Several types of insulation are sold under the Penoplex brand. Samples with a density of 35 differ from analogues in that they have a minimal thermal conductivity coefficient in numerical terms.

2. The low level of water absorption of Penoplex in most cases allows you to avoid additional waterproofing of surfaces.

3. Increased resistance to ignition. This is ensured by the introduction of “fire retardant” class substances into the feedstock before molding Penoplex sheets, which sharply reduce the likelihood of flame propagation. In fact, the material is not flammable. With increased thermal exposure, it basically melts, and the release of toxins is minimal.

4. Correct and relatively small sample sizes allow:

- accurately determine the volume of purchase of Penoplex (by number of sheets or by m3);

- significantly simplify the thermal insulation process;

- dramatically reduce the amount of waste during cutting, which to a certain extent affects the final price of insulation;

- organize the transportation of sheets in any convenient way. If we are not talking about m3, then you can deliver the material from the store to your home manually.

5. Sufficient density of Penoplex series 35 slabs allows for external finishing of surfaces without installing a supporting structure. Mainly - with plaster compositions, with additional reinforcement of the layer with reinforcing (plastic) mesh. Another option is wallpapering any type.

6. Since this insulation has a polymer base, Penoplex does not rot or be destroyed by biological pests. The result is a long, maintenance-free service life.

7. The low weight of the samples allows them to insulate any base; moreover, they do not weigh down the structure.

The disadvantage of Penoplex with a density of 35 is perhaps the only one, but it should be taken into account. The density of the structure is reflected in such characteristics as thermal conductivity, sound insulation and vapor permeability. The latter is especially relevant if installation is carried out by gluing sheets to the base. Carrying out additional measures to ensure natural circulation of air flows under the cladding leads to an increase in the cost of work.

Before purchasing Penoplex, it is advisable to determine not only the linear dimensions, but also the optimal thickness of the sheets.

The high technical characteristics of Penoplex of this series, taking into account zero flammability and a large selection of sizes, allow it to be used for insulation of a wide variety of structural parts:

You can buy a variety of products that are used to insulate pipelines. Due to good sound insulation, the noise level during hydraulic shocks in the systems is reduced.

| Thickness, mm (number of sheets per package) | Cost, rubles |

| 20 (18) | 1 290 |

| 50 (8) | 1 470 |

| 100 (4) | 1 360 |

*Approximate prices for the Moscow region.

** Prices for Penoplex with a density of 35 standard sizes, in rubles per package, depending on the thickness. The number of sheets is indicated in parentheses.

Cost per m3 – 4,490 rubles.

When purchasing Penoplex, you should take into account the inevitability of cutting and adjusting individual segments, so the batch volume must be increased by approximately 10% of the calculated one.

Types, characteristics, properties

Penoplex is available in several categories:

- Comfort. For insulation of walls, balconies, loggias.

- Foundation.

- Pitched roof.

- Wall.

Types and purpose of Penoplex insulation

As you can see, the manufacturer clearly delineates the areas of application of the material. With the general technology, they differ in density. The densest ones are for the foundation and floor, since they must withstand considerable loads for a long time. The manufacturer claims that the service life of Penoplex Foundation is up to 50 years.

Design differences

Some of the types of Penoplex have structural differences:

- Penoplex Wall slabs have a rough surface; stripes are applied to the surface of the slab using a router. All this improves adhesion to the wall and/or finishing materials.

- Penoplex Comfort is distinguished by an L-shaped edge, which during installation guarantees the absence of through seams.

- Penoplex Roofing has a U-shaped edge, which increases the reliability of the connection.

You can distinguish by external signs

. This is what concerns external differences. Next, let's look at the technical specifications. First, let's pay attention to what is common to all types, then to what distinguishes them.

General characteristics

Since the production technology of all types of Penoplex is similar, they have many of the same characteristics:

- Water absorption is very low: when immersed in water for a day, no more than 0.4% of the volume;

- when immersed for 28 days, 0.5% of the volume.

Flammability is not the best characteristic

Penoplex insulation boards are available in different thicknesses and densities

As you can see, according to temperature indicators, any type of Penoplex can be used in any part of the country - from the south to the north. Moreover, if you leave it to “winter” unprotected, nothing will happen to the material. This is not the merit of Penoplex, but a general property of extruded polystyrene foam.

What distinguishes different types

The manufacturer divided the types of Penoplex into areas of use. Their properties are optimal for a specific application. For example, the increased density of EPS required for a screed will not be needed when installing it on a plinth. Taking into account the fact that the price differs significantly, it makes no sense to use the “Foundation” brand for other purposes. But the difference in locks, with other characteristics being equal, can be neglected. Here we are talking about ease of installation. Although, this is also important.

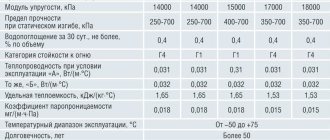

| Parameter | Comfort | Foundation | Roof | Wall |

| Density | from 20 kg/m3 | 27-35 kg/m3 | 26-34 kg/m3 | from 20 kg/m3 |

| Elastic modulus | 15 MPa | 17 MPa | 17 MPa | 15 MPa |

| Thickness | 20, 30, 40, 50, 100 mm | 50, 100 mm | 100 mm | 50 mm |

| Static bending strength | 0.25 MPa | 0.4 MPa | 0.4 MPa | 0.25 MPa |

As can be seen from the table, Penoplex for foundations and roofs is denser, stronger, and better able to withstand bending loads. Designed for walls and the “Comfort” brand are less durable, since their area of application does not require resistance to mechanical stress.

Penoplex 35

Wholesale price from Price from 4300 rub.

Penoplex 35 is a type of thermal insulation material that belongs to the so-called new generation. The slabs are actively used during repair and construction work where builders are faced with the task of maximizing heat conservation.

! The difference between this material and similar options is that it contains a fire retardant - a substance that can increase the resistance of slabs to combustion.

Since the product is not at all afraid of moisture, it can be used in a variety of conditions, and installation will not take much time or effort.

Among the distinctive advantages it is worth noting:

- environmental friendliness;

- low flammability;

- low water absorption coefficient;

- strength;

- high sound insulation performance;

- excellent heat saving performance.

The material has a fairly low chemical resistance to polyester resins and coal tar, benzene, xylene and toluene, diethyl ether and methyl acetate-based solvents, oil paints and formaldehyde. But, at the same time, it perfectly resists the effects of organic and inorganic acids, bleach and salt solutions, cement and ammonia, alcohol dyes and even caustic alkalis.

During the manufacturing process of Penoplex insulation, an effective fire retardant with a high-tech patented additive is added to the feedstock, which significantly increases the resistance of the final product to combustion, due to which it is classified as fire-resistant. In the event of a fire, the material does not emit poisonous or toxic gases, and its combustion products are equivalent to those gases (CO and CO2 - carbon dioxide and carbon monoxide) that ordinary wood emits during combustion.

Important points when working

We have already found out that the Penoplex 35 material has excellent characteristics and is quite easy to install. But it is still worth knowing about some issues that arise during the thermal insulation of walls. So, first you need to secure the sheets, blow out the formed joints with foam, then cover it all with a special heat-reflecting material (preferably foil-coated PET film). It sits on polyurethane-based glue, the joints are taped with metal tape. As a result, you can achieve the notorious “thermos effect”.

Remember that the most important thing when thermal insulation is the correct choice of material to be used. For a long time, ordinary polystyrene foam was considered ideal in this case - it was inexpensive and installed quickly enough.

But penoplex 35 gradually replaced polystyrene foam due to its parameters, which significantly exceed the parameters of ordinary foam plastic thermal insulation. All its characteristics - thickness, dimensions and density - ensure maximum heat saving efficiency.

Video - Penoplex insulation

To sum it up. Should I buy or not?

In view of all of the above, we can safely say: Penoplex 35 is one of the best thermal insulation materials of our time. Its thermal conductivity parameters are almost the same as those of air, and it weighs little, thanks to which it can even be installed with glue. No other material will provide such high-quality insulation of a building with such a thin layer.

In short, if your plans include insulating your home, then be sure to pay attention to Penoplex 35 - its characteristics are truly excellent. And even now, when utility bills are constantly rising, you simply have to think about saving energy.

Application area

So, you can buy material for repair and construction work that involves insulation:

- pitched roofs;

- foundation (vertical, horizontal insulation and under the sole);

- walls;

- cold bridges;

- roofs on corrugated sheets or reinforced concrete base;

- exploited and unexploited roofing;

- paths in parks and gardens;

- engineering networks;

- floors in warehouses, refrigerators, shopping malls and residential buildings.

! The use of such insulation during the construction of buildings makes it possible not only to speed up the entire work, but also to simplify it and reduce possible costs.

Penoplex 35 will help solve a variety of heat conservation problems. This is what led to the fact that the material soon became indispensable not only in civil engineering, but also in industrial construction for thermal insulation of basement floors and foundations, interfloor ceilings and roofs, sandwich panels and comfortable floors, etc.

What is Penoplex and its scope of use

Penoplex (sometimes written “Penoplex”) is a thermal insulation material produced by the company of the same name.

is a large Russian manufacturer of construction and decorative finishing materials based on polymers. The company began its activities in 1998 with the launch of the first production line in Russia for the production of thermal insulation materials from extruded polystyrene foam under the PENOPLEX® brand.

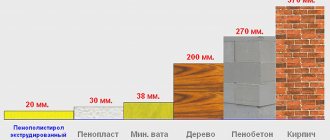

produces extruded polystyrene foam (EPS or XPS). This material is used as insulation. It differs from its cheaper analogue - foamed polystyrene (foam plastic, EPS or PPS) in its greater density, due to which it better withstands mechanical loads. Another distinctive feature is lower vapor permeability. Or rather, it produces almost no steam. And the main trump card is the best thermal characteristics. Penoplex 20 mm thick in terms of heat retention is equivalent to almost double the thickness of mineral wool and 37 cm of brickwork.

Penoplex is one of the most effective thermal insulation materials

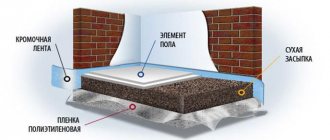

These characteristics determine the area of use of Penoplex. It is recommended for insulating areas where resistance to stress is important, and low vapor permeability is one of the requirements. More specifically, it is recommended to use Penoplex:

- For floor insulation: under the screed, on it, as an intermediate layer;

- when installing a floor on joists (with some reservations);

- thermal insulation layer under a heated floor (water or electric).

Another area of use is thermal insulation of facades or interior walls. But here you need to understand that due to the fact that Penoplex practically does not conduct moisture, additional measures will be needed to ensure that vapors do not get inside the wall. In addition, a well-thought-out ventilation system is needed to normalize the humidity in the house. And, in addition, you need to select the thickness of the insulation so that the dew point is inside the insulation, but not in the wall.

Optimally - insulation of a recessed base

If you prefer “breathable” walls and natural humidity regulation, Penoplex is not suitable for wall insulation in this case. It does not fit under ventilated facades either. The exact task there is to remove moisture from the insulation due to the movement of air in the ventilation gap. This material is not able to provide this, since moisture simply does not get inside Penoplex.

Basic installation rules

Of course, in this case it all depends on what exactly you are going to insulate. Although there are generally accepted provisions. Let's look at them first:

- there should be no gaps between the plates of material, the size of which would be more than 2-3 mm;

- all individual elements must be securely fastened; dowels can be used as such good fasteners;

- the use of waterproofing layers is optional: expanded polystyrene does not absorb moisture due to its special structure;

- there is also no need to protect the material from stress, because it already has high compressive strength.

As you can see, using such slabs you get a lot of advantages. At the same time, the price of Penoplex 35 is very low.

- Exterior walls

To insulate external walls, the slabs of the insulation you are using are attached to the load-bearing walls using disc dowels. For ventilation, it is necessary to leave a small gap, and then make the masonry from the facing material. The advantage of Penoplex in this case is that its installation does not require waterproofing, since there are grooves along the edges of the slabs that promote the formation of cold bridges.

Lay the slabs into the partition frame and cover it with the selected finishing material (lining or plasterboard). Such a partition will be reliably insulated. At the same time, its performance characteristics will also be quite high.

But in this case, you will already need to take care of waterproofing the foundation. In this case, the rough base should also dry very well.

Penoplex is glued on top of the waterproofing layers you have applied. How does this happen? So, for the whole process you need to use a special bitumen-cement adhesive. Just apply it to the surface of the slab and stick it. After the work is completed, the foundation can be covered with earth.

! Such slabs can also be used to reliably insulate the part of the base that protrudes above the ground. To secure all individual elements, use disc dowels.

Installation technology

When laying on horizontal surfaces - floors, flat roofs - the slabs are simply laid on a flat surface. The surface should be without sharp changes, the maximum deviation is 2-3%. This requirement must be met so that voids do not form. When laying, we monitor the joints; it is advisable to glue them (you can use tape) or fill them with the same foam/glue on which the slabs are attached.

When using Foam plastic for insulation of balconies

If two layers of thermal insulation are laid, it is positioned so that the EPS slabs of the second row overlap the seams of the lower one. They also say that the slabs are laid with alternating seams or “staggered”.

When mounting on vertical surfaces, double fastening is used:

- Glue or adhesive foam is applied to the plane.

- Additionally fixed with umbrella dowels.

According to the technology for installing slab insulation on facades, umbrella dowels are installed at the junction of two sheets (any two sheets) and two additional fasteners in the plane of the sheet. That is, there are at least 8 fasteners per sheet (indicated in red in the figure). More is possible. Less - no. Unless, of course, you want the insulation and finishing to come off. If the winds in the region are strong, it is better to put more. To insulate the inside, you can install less (see diagrams below).

Schemes for installing umbrella dowels when installing Penoplex on vertical surfaces

During installation, on the outer slabs and around openings, we install fasteners more often: three to four elements per slab. To keep the insulation rigid in the corners of the openings, a mesh is attached to it before plastering. It is attached at an angle of about 45°, securing the joint. Under such conditions, there will be no problems with finishing inside or outside.

If plaster, facade tiles, finishing stone and other heavy materials are subsequently applied to Penoplex, before installation, care must be taken to improve the adhesion of the material to the wall and to the finish. Even if you are installing a Penoplex Wall with stripes, it is better to add roughness to the slab using a metal brush. And from both sides. If the wall is smooth, it also doesn’t hurt to add roughness - for better adhesion.

If the wall is smooth, it also needs to be processed by putting a metal attachment on the drill

To work with Penoplex, a special adhesive mixture is recommended: Ceresit ST 84, illbruck PU 010, Titan 753, Ceresit CT-85, Kreisel 210 and 220, Baumit ProContact, STO Baukleber, Soudal Soudabond, Penosil Fix and Go, Den Braven, Krass.

Price for Penoplex 35

The price is affordable, which makes it possible to use these polystyrene foam boards both for insulating large buildings and large areas, and for renovating private apartments and houses.

| Dimensions | packaging volume, m3 | quantity pcs/pack | average package weight, kg | Cost per pack. |

| (1200*600*20) | 0,2880 | 20 | 10 | 1252 |

| (1200*600*30) | 0,3024 | 14 | 10 | 1315 |

| (1200*600*40) | 0,2880 | 10 | 10 | 1252 |

| (1200*600*50) | 0,2880 | 8 | 20 | 1252 |

| (1200*600*100) | 0,2880 | 4 | 20 | 1252 |

- These thermal insulation boards have a width of 600 mm and a thickness of 20 to 100, depending on the brand. The standard length of the slabs is 35-1200 mm with 1/4 (quarter) perimeter processing.

- For the needs of railways, slabs are produced with a total length of 4000 and 4500 mm each. The perimeter edge remains straight, but there is a special profile (oblique quarter) along the long side.

- Penoplex 35 slabs are supplied to customers packaged in polyethylene film, which can protect the material from the penetration of UV rays. The height of each package is from 40 to 42 cm with a different number of plates. More precisely, 4 to 17 pieces. The volume of an average package of slabs is 0.288 cubic meters.

Cost of penoplex 35

- Sheet thickness - 20, number of sheets per package - 18, price - 1290 rubles;

- Sheet thickness - 50, number of sheets per package - 8, price - 1470 rubles;

- Sheet thickness - 100, number of sheets per package - 4, price -1360 rubles.

But depending on the region, the price may vary significantly. Per m3 the average price is 4490 rubles. You need to buy penoplex 10% more than necessary. Since when adjusting some segments or cutting, more material will be needed.

Content

Penoplex, being literally a bright representative of a new generation of materials for thermal insulation, has already received worthy recognition among construction experts and ordinary users. Actually, strictly speaking, penoplex is not something super-revolutionary; it is polystyrene foam in its essence. But with certain characteristic features that distinguish this material from the foam plastic we are all familiar with.

The material solves the problem of heat conservation almost perfectly; according to the conclusion of construction organizations, it is optimal for solving many similar problems. Many today have begun to consider penoplex an almost irreplaceable material in civil and industrial construction. And although we all know that there are no ideal materials, they all have their pros and cons, we recognize the fact of the existence of such an opinion and dwell deeper on its undeniable advantages:

- Low thermal conductivity - the most important indicator for insulation purposes;

- Minimum water absorption, which is typical for this material;

- High strength index.

As market statistics show, one of the most popular among Russian consumers from the entire product line today is one of the types of expanded polystyrene, produced under the Penoplex brand. And it is especially popular for practical construction purposes, judging by the actual requests of Internet users, its specific standard size is penoplex-35 . According to our research, it is its technical characteristics that people are especially often interested in and, accordingly, ask all sorts of questions to our specialists. We’ll talk about penoplex-35 today.

Domestic analogues of the material

Russian manufacturers have also launched the production of extruded polystyrene foam.

There are two analogues on the market: Technoplex and Polyspen. Each brand has its own characteristics.

Technoplex

Strength and thermal conductivity indicators are the distinctive features of Technoplex slabs. The manufacturer managed to achieve outstanding technical performance through the use of nanotechnology in the manufacture of insulation. The method involves adding graphite particles to help increase the density of the material. The heat insulator is used in private construction, as well as when installing a heated floor system. Unlike penoplex, technoplex is not orange, but light silver. The insulation produced varies in thickness. The plates are equipped with a special edge that simplifies installation. After fastening, finishing should be done as quickly as possible to protect the heat insulator from atmospheric influences.

Polyspen

Extruded polystyrene foam from Polyspen LLC is manufactured in three types, which differ in technical characteristics and scope of application:

- Polyspan Standard. They are used for foundation insulation, as well as for floor insulation.

- Polyspen 35 is indispensable for insulating building envelopes.

- Polyfoam 45 with the greatest strength is used in road construction, since it can even withstand the weight of an airplane. It is recommended to use it for thermal insulation of structures subject to heavy loads.

Polyfoam slabs of different sizes and thicknesses are available on the market; therefore, the density of the material also differs.

About the exact name ↑

A small but important digression. You can often hear reproaches that the not entirely correct name of the material is often used - “penoplex” and not “penoplex” (as it would be correct, the latter spelling is correct, see photo).

PenoplEx is exactly the brand name of the material, reflected in the name of the brand of the same name. But in everyday life, as it turned out from our rather in-depth statistical study, this material is much more often called penoplex . Moreover, the difference in the use of terms is neither more nor less, but a whole order of magnitude! That is, it is with the letter “e” that the material that consumers love is called exactly 10 (!) times more often than with the letter “e”. What do you order us to do if such a spelling has become so firmly established in our everyday life? We are sure that all this is not accidental and is strongly connected with the peculiarities of the Russian language. Well, such a deliberate “E”, which is not characteristic of our morphology, does not (and will not) take root in our country, so it is involuntarily pushed out, replaced by a more natural one for pronunciation. It seems that manufacturers should not be offended by consumers for this, but it is better to take this spelling as a basis as well, as it is completely natural and more acceptable to the population.

Penoplex installation

As for the installation process, this material, as noted above, is quite easy to handle. The work consists of several simple stages.

Stage 1. The surface is thoroughly leveled and cleaned of dirt.

Stage 2. Plates of material are laid, dowels or glue are used for fixation.

Stage 3. A protective layer is laid on top of the slabs. That's all.

Note! If the material will be laid on the floor, then first you should prepare a layer, thanks to which point-type loads will be distributed.

It is also advisable to seal the joints between the slabs with mounting tape so that the concrete solution does not get inside during pouring (it is recommended not to use glue for this). You also need to leave small deformation gaps around the perimeter (they will subsequently be filled with foam). And if everything is done correctly, according to the instructions, then the created layer will efficiently retain thermal energy.

What is the material ↑

These are extruded slabs of a recognizable “brand” orange color with a density of 35 kg/cub.m.

Thermal conductivity

Vapor permeability

Mechanical properties

Compressive strength at ten percent strain 0.25 N/mm2 (according to EN 826).

Dimensions

1200*600* 20,30,40,50,60,80,100 mm

The price of penoplex may vary somewhat depending on seasonality and region, the average figures are as follows: 1200-600, 30-100 mm - 3700 rubles / cubic meter.

Scope ↑

- For insulation under the sole during the construction of foundations;

- Horizontal and vertical insulation when constructing foundations;

- Insulation of roofs (on a reinforced concrete base), incl. exploited;

- Insulation of roofs carried out using corrugated sheets;

- Insulation of pitched roofs;

- Thermal insulation of walls;

- Thermal insulation of floors not only in residential premises, but also in warehouses and retail buildings, refrigeration complexes, ice arenas, etc.

- Arrangement of garden and park areas;

- Thermal insulation work with utility networks;

- Insulation of cold bridges;

Fire hazard and flammability group ↑

Extruded polystyrene foam of the Penoplex 35 brand is produced in sheets with a width of 600 mm and a thickness of 23 to 100 mm.

Penoplex, as we have already mentioned, is generally resistant to high and low temperatures. In addition, it is also considered resistant to open fire. The declared flammability group for penoplex 35 is G1.

So far no one has officially refuted this, although there are other private opinions on this matter. Some experts question this figure, believing that extruded polystyrene foam, which is what penoplex actually is, is a priori unlikely to have such a flammability group, believing that the maximum that should be assigned to it is G3, G4. The logic in this message is as follows: “All materials based on polystyrene foam are classified in groups G3 or G4 in terms of flammability. So if for some reason we saw in the certificate the flammability class G1, G2, then this is most likely an erroneous indicator. These materials are classified as flammable (in the best case, moderately flammable). At the same time, they should also be considered as representing a high danger in terms of the toxicity of combustion products that have high smoke-forming properties.” This point of view is fully reasoned and has a right to exist. At the same time, as we see in practice, Penoplex-35 slabs, according to their characteristics, are optimally suited for thermal insulation of various types of enclosing structures and structures, incl. exploited and ordinary roofs, foundations (including shallow ones), walls, floors, etc. When producing penoplex-35, to increase resistance to combustion, the manufacturer added an effective fire retardant to the raw materials with a special additive patented by the manufacturer. As for the results of test tests that were carried out by some fire safety centers, they showed that Penoplex 35 slabs in their fire-technical qualities correspond to low-flammable materials (according to GOST 30244-94). They are also classified as hard-to-burn materials (according to ST SEV 2437-80). Penoplex is characterized as a material that does not spread flame over the surface. Also, based on the results of experiments, Penoplex-35 is determined to be a moderately flammable material, although with a fairly high ability to generate smoke.

During the combustion process, extruded polystyrene foam emits, as tests show, two types of gases (carbon monoxide CO and carbon dioxide CO2). Actually, just like wood. This is what distinguishes it from many organic heat insulators, which release into the atmosphere a whole range of substances hazardous to health. I think it will be useful for someone to watch a video about how a floor is insulated using sheets of Penoplex-35:

remember the fire in the lame horse and the death of 150 people who inhaled smoke from smoldering polystyrene and everything will become clear. Even in its normal state, it emits a dangerous gas due to which children die in the womb. IN THE USSR IT WAS FORBIDDEN TO USE IN RESIDENTIAL PREMISES. watch the video on YouTube with the academician.

Well, in a neutral state, he does not represent anything dangerous, this is not true. BUT when burning, yes, polystyrene foam releases phosgene, and it is really dangerous, you are more likely to be poisoned than to burn.

There’s no need to make a fuss about dangerous polystyrene foam if you haven’t really figured it out. Penoplex 35 slabs differ from other penoplex items in that an effective fire retardant (fire-retardant composition) is introduced into the feedstock. This is some kind of additive patented by the manufacturer. I won’t say for sure, but they say it greatly increases fire resistance. That is why people have increased interest in Penoplex 35.

Special independent tests were carried out on penoplex 35 in St. Petersburg, I read. And according to fire-technical characteristics, it was classified as a low-flammable material (GOST 30244-94) and a difficult-to-burn material (ST SEV 2437-80). In the specification they indicate that Penoplex 35 does not spread flame over the surface, it is a moderately flammable type. The only thing that confuses us is the “high smoke-generating ability” - after all, toxic smoke is dangerous in the first place. I don’t know if it’s true or not, but they claim that Penoplex 35 emits only 2 gases when burned: carbon monoxide and carbon dioxide. But wood also produces exactly such compounds. So it is no more harmful than wood? if I understand correctly.

Penoplex 35 has increased combustion resistance due to the fire retardant in the raw material. Penoplex 35 burns poorly and does not spread fire over the surface. It can be used for foundations, walls, roofs and floors.

Technical characteristics of penoplex 35

Let's consider the most basic characteristics of penoplex, which will be understandable to any reader, since some characteristics cannot be understood by a person who does not have a specialized education. Therefore, we will highlight the main factors that will help you make the choice of thermal insulation material:

- Water absorption per day. It is indicated as a percentage of the total volume of the sheet. Water absorption should be up to 0.1.

- Sheet sizes. The thickness of the penoplex sheet can be 2-10.5, and the width and length are 60x120.

- 35 is the density of the material. It is measured in kg/m3. This value is average, since different manufacturers produce penoplex with different densities. Typically, the density value ranges from 29.5 to 36.5.

- The thermal conductivity of the material is 0.030 W/m.

- The bending strength is 0.4 MPa.

- The weight of one pack can be 10-15 kg. Weight depends on the thickness of the sheets.

Advantages and disadvantages

Penoplek is a brand of insulation. There are several types of thermal insulation materials. Penoplex, which has a density of 35, differs from other types in that it has a minimal thermal conductivity coefficient. This is a significant advantage.

Let's consider other advantages of Penoplex with a density of 35:

- There is no need to install additional waterproofing, since penoplex has a low level of water absorption.

- Penoplex does not rot or be destroyed by biological pests, as it has a polymer base.

- Long service life.

- Little weight. Therefore, any structure can be insulated.

- High resistance to fire. A substance is added to the feedstock that reduces the likelihood of ignition. When exposed to flame, the insulation will not burn, but may only melt. This will release a minimal amount of toxins.

- Penoplex has convenient and small sheet sizes. Therefore, it is possible to accurately determine the required amount of insulation, as well as the installation process is simpler, the amount of waste during cutting is reduced, and foam sheets can be transported in any way. If the penoplex is not in m3, then you can deliver it manually yourself.

- Due to the high density of the slabs, they can be used as external decoration without constructing a supporting structure. Finishing can be done using plaster compounds with reinforcement of the layer with plastic mesh or wallpapering.

If there are many advantages of penoplex, then only one disadvantage can be identified: the density of the structure. It affects sound insulation, thermal conductivity and vapor permeability. If installation is carried out by gluing sheets, then vapor permeability is important. Therefore, it is necessary to carry out additional work on the installation of natural circulation, which requires additional costs.

Before purchasing penoplex, you should decide on the thickness and linear dimensions of the material. This thermal insulation material has only one drawback, which indicates its quality, so penoplex can be safely used for thermal insulation.

Area of application of penoplex

The scope of application of penoplex 35 is quite wide. This is due to the fact that this thermal insulation material has high technical characteristics. Penoplex 35 has zero flammability and also has a large selection of sheet sizes. Therefore, the insulation can be used to insulate structures of different sizes.

Penoplex 35 can be used to insulate the following structures:

Penoplex is produced, intended for insulation of pipelines. The noise level during hydraulic shocks in the systems is significantly reduced, since this insulation has good sound insulation.

Description of material – penoplex

Innovative insulation to create a comfortable atmosphere in the home.

The insulation consists of slabs consisting of sealed small cells, due to which the water absorption rate is almost zero. The material obtains its density and thermal conductivity thanks to a special production method. Expanded polystyrene is used to make boards. The granules are placed in an extruder, where the material foams under the influence of temperature and pressure. It is then passed through dies, which give the heat insulator the shape of slabs. The result is insulation with high technical performance.