began the history of Russian extruded polystyrene foam by launching in 1998 a production line for PENOPLEX boards at a plant in Kirishi, Leningrad Region.

Penoplex production method: Polystyrene granules enter an extruder, where they are heated and mixed under high pressure. At the same time, a gaseous blowing agent is supplied to the extruder. Thanks to high pressure and heat, the blowing agent enters the granules and increases their volume. The resulting mass is pressed through a die, the material is cooled and cut into slabs. As a result, small closed cells are formed in XPS, which give penoplex excellent thermal insulation properties and negligible water absorption.

Penoplex brands

- Penoplex COMFORT

- Penoplex BASE

- Penoplex FOUNDATION

- Penoplex GEO

- Penoplex ROOFING

- Penoplex FACADE

- Penoplex 45

Penoplex COMFORT

Overall dimensions: Length-1185 mm, width-585 mm, thickness 20; thirty; 40; 50; 100 mm.

TU 5767-006-54349294-2014

Orange color.

Surface: smooth.

PENOPLEX boards are packaged in heat-shrinkable UV-stabilized film.

Application of Penoplex COMFORT

It is used for thermal insulation of canopies, plinths, and pitched roofs. Strictly not applicable:

- in loaded structures.

Areas of application of Penoplex COMFORT:

- Roofs, walls, balconies, loggias.

- Thermal insulation of utilities.

- Insulation of livestock farms, cowsheds.

- For insulation of greenhouses.

Advantages of Penoplex COMFORT:

- Thermal conductivity coefficient is 0.032, hence high thermal insulation.

- Inertness to rotting, that is, resistance to fungi, mold, microorganisms.

- Resistant to temperature changes.

- Environmentally friendly, that is, it does not release harmful substances into the environment.

- Durable, up to 50 years of operation.

- Easy installation, convenient dimensions.

- Poor steam conductivity.

- Selected quarter (L-shaped edge). Allows you to join slabs like a construction set.

Penoplex COMFORT technical characteristics

| Name | Test method | Slab indicator |

| Compressive strength at 10% linear deformation, not less | GOST EN 826-2011 | 0.15 (1.5; 15) MPa |

| Water absorption in 24 hours, no more | GOST 15588-86 | 0.4% by volume |

| Water absorption in 28 days | 0.5% by volume | |

| Fire resistance category, flammability group | F3-123 | group G4 |

| Calculated thermal conductivity coefficient under operating conditions “B” | SP 50.13330.2012 | 0.032 W/(m×°K) |

| Sound insulation of partition (GKL-PENOPLEX® 50 mm-GKL), Rw | GOST 27296-87 | 41 dB |

| Improvement index for structural noise insulation in floor construction | GOST 16297-80 | 23 dB |

| Vapor permeability coefficient | 0.005 mg/(m.h.Pa) | |

| Density | from 20 kg/m3 | |

| Elastic modulus | 15 MPa | |

| Specific heat | 1.45 kJ/(kg.°C) | |

| Static bending strength | 0.25 MPa | |

| Standard sizes | Width | 585 mm |

| Length | 1185 mm | |

| Thickness | 20, 30, 40, 50, 100 mm | |

| Operating temperature range | THAT | -70 … +75 °С |

Let's consider the pros and cons

Are you considering using eco-friendly insulation when building or renovating a private home? If yes, that's great! There are several types of insulation. Extruded polystyrene , or penoplex, is one of the most popular.

Advantages

This material has many advantages . Here are some of them:

- Extremely low thermal conductivity coefficient . Only 0.032 W/(m×°K) - 22 times less than that of sand-lime brick.

- Moisture resistance . The granules of Osnova products do not absorb water, so the performance characteristics remain normal.

- Decent durability . The material holds its shape well and is difficult to damage or tear, which cannot be said about foam plastic.

- High sound insulation . A nice bonus when there is a noisy highway outside the window, or the house is located in a densely populated area.

- Ease of installation . tongue-and-groove locks on the edges of the sheets , so during installation you can do without adhesives.

- Biostability . It is not destroyed by putrefactive bacteria and mold fungi.

- Environmental friendliness . The thermal insulation contains no harmful substances. After installing it indoors, you won’t have to keep the windows wide open for a month.

- Long life span . The manufacturer assures customers that the product will serve faithfully for at least 50 years.

Flaws

Penoplex Osnova thermal insulation also has disadvantages :

- High flammability . The insulation belongs to class G4 , which means that its flue gases heat up to temperatures above 450 °C. Even if the polymer just starts to smolder, you will have to stay away from it.

- Low vapor permeability . The walls will hardly “breathe”, and the windows will fog up, so you need to equip the room with a high-quality ventilation system.

- Susceptibility to UV rays . The insulator is “afraid” of ultraviolet radiation. Under the influence of the sun, the structure of the granules quickly collapses . The solution is to coat the polystyrene with a finish.

The material is lightweight, making it easier to work with. You can cut the sheets using a regular painting knife .

Penoplex BASE

Overall dimensions: Length-1185 mm, width-585 mm, thickness 20; thirty; 40; 50; 100 mm.

TU 5767-006-54349294-2014 amended. 1-6

Orange color.

Surface: smooth.

PENOPLEX boards are packaged in heat-shrinkable UV-stabilized film.

Application of Penoplex BASIS

This brand of penoplex is intended for insulation in civil and industrial construction, in walls, roofs, anywhere where there are no special loads on the structure being insulated.

Advantages of Penoplex BASIS:

- Low thermal conductivity.

- Almost no water absorption.

- Great compressive strength.

- Great bending strength.

- Environmentally friendly, that is, it does not release harmful substances into the environment.

- Durable, up to 50 years of operation.

- Inertness to rotting, that is, resistance to fungi, mold, microorganisms.

Penoplex OSNOVA technical characteristics

| Name | Test method | Slab indicator |

| Compressive strength at 10% linear deformation, not less | GOST EN 826-2011 | 0.17 (1.7; 17) MPa |

| Water absorption in 24 hours, no more | GOST 15588-86 | 0.4% by volume |

| Water absorption in 28 days | 0.5% by volume | |

| Fire resistance category, flammability group | F3-123 | group G4 |

| Calculated thermal conductivity coefficient under operating conditions “B” | SP 50.13330.2012 | 0.032 W/(m×°K) |

| Sound insulation of partition (GKL-PENOPLEX® 50 mm-GKL), Rw | GOST 27296-87 | 41 dB |

| Improvement index for structural noise insulation in floor construction | GOST 16297-80 | 23 dB |

| Vapor permeability coefficient | 0.005 mg/(m.h.Pa) | |

| Density | from 20 kg/m3 | |

| Elastic modulus | 15 MPa | |

| Specific heat | 1.45 kJ/(kg.°C) | |

| Static bending strength | 0.20 MPa | |

| Standard sizes | Width | 585 mm |

| Length | 1185 mm | |

| Thickness | 20; 30, 40, 50, 100, 120, 150 mm | |

| Operating temperature range | THAT | -70 … +75 °С |

How not to lose money

If designers and builders do not take into account the physical and chemical characteristics of penoplex, its strength and thermal characteristics deteriorate long before the end of its service life, which leads to a decrease in the thermal efficiency of the house. Some of the most common errors include the following solutions:

- Use of material with a density lower than technologically justified . Penoplex, like any polymer, is oxidized by atmospheric oxygen. The rate of oxidation (change in chemical structure and deterioration in performance properties) depends on the density of the material. The use of slabs with a lower density (an understandable desire to save money) deteriorates the thermal protection of the structure 2-3 times faster, and this is noticeable already in the first 7-10 years of operation.

- Use of incompatible materials . Plates made of extruded polystyrene foam will deteriorate at an accelerated rate if substances that are dangerous to the structure of the penoplex (for example, oil-based paints containing volatile hydrocarbons) are used during construction.

- Ignorance of labeling features . An inexperienced person, seeing the words “Mark 25” on the packaging, makes a logical, in his opinion, conclusion that inside there are slabs with a density of 25 kg/m 3. But in technical specifications this is the designation for material with a density from 15.1 to 25.0 kg/m 3 . Some manufacturers, caring for maximum profits, supply penoplex of the lowest density under this brand (15.1 kg/m 3 , the density of packaging plastic). The result of the substitution soon appears on the “insulated” façade – with damp spots and mold.

- Incorrectly carried out insulation . Improper insulation leaves an air gap between the wall and the slab material. The structure becomes inhomogeneous, the dew point shifts into the gap. Condensation is inevitably absorbed into a denser material (wall), and thermal efficiency drops, sometimes significantly.

Penoplex FOUNDATION

Overall dimensions: Length-1185 mm, width-585 mm, thickness 50; 100 mm.

TU 5767-006-54349294-2014

Orange color.

Surface: smooth.

PENOPLEX boards are packaged in heat-shrinkable UV-stabilized film.

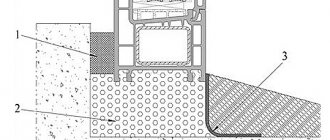

Application of Penoplex FOUNDATION

Thermal insulation of deeply low (buried) places. Namely deep and shallow foundations, garden paths, septic tanks.

Swedish stove technology.

Engineering Communication.

Advantages of Penoplex FOUNDATION:

- Low thermal conductivity.

- Almost no water absorption.

- Great compressive strength.

- Great bending strength.

- Environmentally friendly, that is, it does not release harmful substances into the environment.

- Durable, up to 50 years of operation.

- Inertness to rotting, that is, resistance to fungi, mold, microorganisms.

Penoplex FOUNDATION technical characteristics

| Name | Test method | Slab indicator |

| Compressive strength at 10% linear deformation, not less | GOST EN 826-2011 | 0.3 (3.0; 30) MPa |

| Water absorption in 24 hours, no more | GOST 15588-86 | 0.4% by volume |

| Water absorption in 28 days | 0.5% by volume | |

| Fire resistance category, flammability group | F3-123 | group G4 |

| Calculated thermal conductivity coefficient under operating conditions “B” | SP 50.13330.2012 | 0.032 W/(m×°K) |

| Sound insulation of partition (GKL-PENOPLEX® 50 mm-GKL), Rw | GOST 27296-87 | 41 dB |

| Improvement index for structural noise insulation in floor construction | GOST 16297-80 | 23 dB |

| Vapor permeability coefficient | 0.005 mg/(m.h.Pa) | |

| Density | 27-35 kg/m3 | |

| Elastic modulus | 17 MPa | |

| Specific heat | 1.45 kJ/(kg.°C) | |

| Static bending strength | 0.4 MPa | |

| Standard sizes | Width | 585 mm |

| Length | 1185 mm | |

| Thickness | 50, 80 mm | |

| Operating temperature range | THAT | -70 … +75 °С |

Application area

There are two areas of using penoplex: thermal protection and sound insulation. In many cases these functions are combined. In a residential apartment or individual building, penoplex can be used for:

- thermal insulation of the ceiling above a cold basement or technical underground;

- material for wall insulation;

- sound insulation of walls, interfloor ceilings;

- thermal insulation of the attic floor in the presence of a cold attic;

- insulation of the attic roof.

Each surface uses its own type of extruded polystyrene foam. If you do not want to understand in detail the different types of penoplex (“Foundation”, “Roof”, “Wall”), you can opt for the universal one - “Penoplex Comfort”.

You can also insulate the bathhouse with penoplex. Read about how to insulate a ceiling with penoplex here.

Penoplex GEO

Overall dimensions: Length - 1185 mm, width - 585 mm, thickness 40, 50, 60, 80, 100 mm.

TU 5767-006-54349294-2014 amended. 1-6

Orange color.

Surface: smooth.

PENOPLEX boards are packaged in heat-shrinkable UV-stabilized film.

Application of Penoplex GEO

This brand of penoplex is used for thermal insulation of loaded floors, foundations, roofs, stylobates, as well as in places where high fire resistance is not required. All these are areas of civil and industrial construction.

Advantages of Penoplex GEO:

- Low thermal conductivity.

- Almost no water absorption.

- Great compressive strength.

- Great bending strength.

- Environmentally friendly, that is, it does not release harmful substances into the environment.

- Durable, up to 50 years of operation.

- Inertness to rotting, that is, resistance to fungi, mold, microorganisms.

Penoplex GEO technical characteristics

| Name | Test method | Slab indicator |

| Compressive strength at 10% linear deformation, not less | GOST EN 826-2011 | 0.3 (3.0; 30) MPa |

| Water absorption in 24 hours, no more | GOST 15588-86 | 0.4% by volume |

| Water absorption in 28 days | 0.5% by volume | |

| Fire resistance category, flammability group | F3-123 | group G4 |

| Calculated thermal conductivity coefficient under operating conditions “B” | SP 50.13330.2012 | 0.032 W/(m×°K) |

| Sound insulation of partition (GKL-PENOPLEX® 50 mm-GKL), Rw | GOST 27296-87 | 41 dB |

| Improvement index for structural noise insulation in floor construction | GOST 16297-80 | 23 dB |

| Vapor permeability coefficient | 0.005 mg/(m.h.Pa) | |

| Density | 28-36 kg/m3 | |

| Elastic modulus | 17 MPa | |

| Specific heat | 1.45 kJ/(kg.°C) | |

| Static bending strength | 0.4-0.7 MPa | |

| Standard sizes | Width | 585 mm |

| Length | 1185 mm | |

| Thickness | 20, 30, 40, 50, 60, 80, 100, 120, 150 mm | |

| Operating temperature range | THAT | -70 … +75 °С |

A little history

A brief history of the emergence of extruded polystyrene foam (the official name of penoplex) is as follows:

- 1941 _ Like many other useful things, the material was originally developed for the needs of the army (in this case, the US Navy). This year, The Dow Chemical company received a patent for a new development, and already in 1942 it established large-scale supplies. The moisture-resistant material with excellent heat-insulating properties was used in the production of boats and life rafts.

- 1952 _ After the war, the Americans continued to use penoplex, its use expanded significantly, first in the refrigeration industry, and then in construction.

- 1963 _ Extruded polystyrene foam has spread throughout Europe and has since occupied a stable niche in the insulation market.

- 1998 _ Extruded polystyrene foam began to be produced in Russia (in the Leningrad region) under the Penoplex trademark and was adequately appreciated by builders.

Penoplex ROOFING

Overall dimensions: Length - 1185 mm, width - 585 mm, thickness 30, 40, 50, 60, 80, 100 mm.

TU 5767-006-54349294-2014 amended. 1-6

Orange color.

Surface: smooth.

PENOPLEX boards are packaged in heat-shrinkable UV-stabilized film.

Application of Penoplex ROOFING

Penoplex ROOF is used for insulation of load-bearing roof structures of any type. Including for thermal insulation of stylobates and parking lots.

Advantages of Penoplex ROOFING:

- Low thermal conductivity.

- Almost no water absorption.

- Great compressive strength.

- Great bending strength.

- Environmentally friendly, that is, it does not release harmful substances into the environment.

- Durable, up to 50 years of operation.

- Inertness to rotting, that is, resistance to fungi, mold, microorganisms.

Penoplex ROOF technical specifications

| Name | Test method | Slab indicator |

| Compressive strength at 10% linear deformation, not less | GOST EN 826-2011 | 0.25 (2.5; 25) MPa |

| Water absorption in 24 hours, no more | GOST 15588-86 | 0.4% by volume |

| Water absorption in 28 days | 0.4% by volume | |

| Fire resistance category, flammability group | F3-123 | group G4 |

| Calculated thermal conductivity coefficient under operating conditions “B” | SP 50.13330.2012 | 0.032 W/(m×°K) |

| Sound insulation of partition (GKL-PENOPLEX® 50 mm-GKL), Rw | GOST 27296-87 | 41 dB |

| Improvement index for structural noise insulation in floor construction | GOST 16297-80 | 23 dB |

| Vapor permeability coefficient | 0.005 mg/(m.h.Pa) | |

| Density | 26-34 kg/m3 | |

| Elastic modulus | 17 MPa | |

| Specific heat | 1.45 kJ/(kg.°C) | |

| Static bending strength | 0.4 MPa | |

| Standard sizes | Width | 585 mm |

| Length | 1185 mm | |

| Thickness | 20, 30, 40, 50, 60, 80, 100, 120, 150 mm | |

| Operating temperature range | THAT | -70 … +75 °С |

Vertical surfaces

"Penoplex Osnova" is used to insulate walls, facades and basements of buildings.

Work can be carried out both outside and inside. Insulation from the outside is more competent from the point of view of thermal engineering, since the material protects not only the room, but also the supporting structure from exposure to cold air, thereby extending its service life.

Please note: it is rational to insulate rooms in apartment buildings above the second floor from the inside, since external insulation will require the services of industrial climbers, which will increase the cost of insulation measures.

Penoplex FACADE

Overall dimensions: Length - 1185 mm, width - 585 mm, thickness 20, 30, 40, 50, 60, 80, 100, 120, 150 mm.

TU 5767-006-54349294-2014 amended. 1-6

Orange color.

Surface: smooth.

PENOPLEX boards are packaged in heat-shrinkable UV-stabilized film.

Application of Penoplex FACADE

It is used as thermal insulation for insulation of internal and external surfaces, that is, facade systems, walls, wall partitions). Penoplex FACADE is designed with a milled surface, which facilitates the adhesion of plaster and glue to the surface and reduces the time required for plastering the building facade.

Advantages of Penoplex FACADE:

- Low thermal conductivity.

- Almost no water absorption.

- Great compressive strength.

- Great bending strength.

- Environmentally friendly, that is, it does not release harmful substances into the environment.

- Durable, up to 50 years of operation.

- Inertness to rotting, that is, resistance to fungi, mold, microorganisms.

Penoplex FACADE technical characteristics

| Name | Test method | Slab indicator |

| Compressive strength at 10% linear deformation, not less | GOST EN 826-2011 | 0.2 (2.0; 20) MPa |

| Water absorption in 24 hours, no more | GOST 15588-86 | 0.4% by volume |

| Water absorption in 28 days | 0.5% by volume | |

| Fire resistance category, flammability group | F3-123 | group G3 |

| Calculated thermal conductivity coefficient under operating conditions “B” | SP 50.13330.2012 | 0.032 W/(m×°K) |

| Sound insulation of partition (GKL-PENOPLEX® 50 mm-GKL), Rw | GOST 27296-87 | 41 dB |

| Improvement index for structural noise insulation in floor construction | GOST 16297-80 | 23 dB |

| Vapor permeability coefficient | 0.005 mg/(m.h.Pa) | |

| Density | 25-33 kg/m3 | |

| Elastic modulus | 15 MPa | |

| Specific heat | 1.45 kJ/(kg.°C) | |

| Static bending strength | 0.25 MPa | |

| Standard sizes | Width | 585 mm |

| Length | 1185 mm | |

| Thickness | 20, 30, 40, 50, 60, 80, 100, 120, 150 mm | |

| Operating temperature range | THAT | -70 … +75 °С |

Installation technology

When laying on horizontal surfaces - floors, flat roofs - the slabs are simply laid on a flat surface. The surface should be without sharp changes, the maximum deviation is 2-3%. This requirement must be met so that voids do not form. When laying, we monitor the joints; it is advisable to glue them (you can use tape) or fill them with the same foam/glue on which the slabs are attached.

When using Foam plastic for insulation of balconies

If two layers of thermal insulation are laid, it is positioned so that the EPS slabs of the second row overlap the seams of the lower one. They also say that the slabs are laid with alternating seams or “staggered”.

When mounting on vertical surfaces, double fastening is used:

- Glue or adhesive foam is applied to the plane.

- Additionally fixed with umbrella dowels.

According to the technology for installing slab insulation on facades, umbrella dowels are installed at the junction of two sheets (any two sheets) and two additional fasteners in the plane of the sheet. That is, there are at least 8 fasteners per sheet (indicated in red in the figure). More is possible. Less - no. Unless, of course, you want the insulation and finishing to come off. If the winds in the region are strong, it is better to put more. To insulate the inside, you can install less (see diagrams below).

Schemes for installing umbrella dowels when installing Penoplex on vertical surfaces

During installation, on the outer slabs and around openings, we install fasteners more often: three to four elements per slab. To keep the insulation rigid in the corners of the openings, a mesh is attached to it before plastering. It is attached at an angle of about 45°, securing the joint. Under such conditions, there will be no problems with finishing inside or outside.

If plaster, facade tiles, finishing stone and other heavy materials are subsequently applied to Penoplex, before installation, care must be taken to improve the adhesion of the material to the wall and to the finish. Even if you are installing a Penoplex Wall with stripes, it is better to add roughness to the slab using a metal brush. And from both sides. If the wall is smooth, it also doesn’t hurt to add roughness - for better adhesion.

If the wall is smooth, it also needs to be processed by putting a metal attachment on the drill

To work with Penoplex, a special adhesive mixture is recommended: Ceresit ST 84, illbruck PU 010, Titan 753, Ceresit CT-85, Kreisel 210 and 220, Baumit ProContact, STO Baukleber, Soudal Soudabond, Penosil Fix and Go, Den Braven, Krass.

Penoplex 45

Overall dimensions: Length - 1185 mm, width - 585 mm, thickness 40, 50, 60, 80, 100 mm.

TU 5767-006-56925804-2007 amended. No. 1-6

Orange color.

Surface: smooth.

Plates 45 are packaged in heat-shrinkable UV-stabilized film.

Application of Penoplex 45

Wherever there are special requirements for the heaviest loads. This, for example, is the construction of airfield runways and roads.

Advantages of Penoplex 45:

- Low thermal conductivity.

- Almost no water absorption.

- Great compressive strength.

- Great bending strength.

- Environmentally friendly, that is, it does not release harmful substances into the environment.

- Durable, up to 50 years of operation.

- Inertness to rotting, that is, resistance to fungi, mold, microorganisms.

Penoplex 45 technical characteristics

| Name | Test method | Slab indicator |

| Compressive strength at 10% linear deformation, not less | GOST EN 826-2011 | 0.5 (5.0; 50) MPa |

| Compressive strength at 2% linear deformation, not less | GOST R EN 1606 | 0.19 (1.9; 19) MPa |

| Water absorption in 24 hours, no more | GOST 15588-86 | 0.2% by volume |

| Water absorption in 28 days | 0.5% by volume | |

| Fire resistance category, flammability group | F3-123 | group G3 |

| Calculated thermal conductivity coefficient under operating conditions “B” | SP 50.13330.2012 | 0.032 W/(m×°K) |

| Vapor permeability coefficient | 0.005 mg/(m.h.Pa) | |

| Density | 38-47 kg/m3 | |

| Elastic modulus | 20 MPa | |

| Specific heat | 1.45 kJ/(kg.°C) | |

| Static bending strength | 0.35-0.7 MPa | |

| Standard sizes | Width | 600 mm |

| Length | 1200/2400 mm | |

| Thickness | 40, 50, 60, 80, 100, 120, 150 mm | |

| Operating temperature range | THAT | -70 … +75 °С |

Price of PENOPLEX BASE per m3 and packaging depending on thickness

| Length | Width | Thickness | Things | m2 | m3 | Price RUR/m3 | Price RUR/pack. |

| 1185 | 585 | 50 | 8 | 5,55 | 0,2776 | 7250 | 2 013 |

| 1185 | 585 | 100 | 4 | 2,77 | 0,2772 | 7560 | 2 096 |

| 1185 | 585 | 20 | 20 | 13,86 | 0,278 | 8250 | 2 294 |

| 1185 | 585 | 30 | 13 | 9,01 | 0,2704 | 7800 | 2 109 |

| 1185 | 585 | 40 | 10 | 6,93 | 0,277 | 7450 | 2 064 |

| 1185 | 585 | 60 | 5 | 3,47 | 0,208 | 7250 | 1 508 |

| 1185 | 585 | 80 | 5 | 3,47 | 0,2775 | 7560 | 2 098 |

Prices are approximate, excluding delivery from the factory in multiples of the truck. You can find out the price for your property by sending a request by email [email protected] or by phone.