Icer

6627 0 0

Icer September 14, 2016Specialization: master in the construction of plasterboard structures, finishing work and laying floor coverings. Installation of door and window units, finishing of facades, installation of electrical, plumbing and heating - I can give detailed advice on all types of work.

Very often I am asked the question of how to insulate the floor on a balcony with my own hands - they say that the process is complex and cannot be overcome without construction experience. But in fact, any person can do the work, especially if we consider the Knaufsuperpol technology. This option is characterized by simplicity and very high speed of work; you can insulate the structure in just a couple of hours and get a smooth and durable surface. Another plus is the cleanliness of the work; you don’t have to mix the solution or drill into the concrete.

This is what the insulation structure looks like - everything is very simple and reliable

Insulation with expanded clay

A balcony slab made of reinforced concrete is characterized by significant strength with extremely low thermal insulation ability. This is inherent in all products with high density and specific gravity used as strength elements of a building. The inclusion of structures with such properties in the interior will lead to rapid heat loss and increased heating costs.

The use of expanded clay gravel and sand as a thermal material has a long history, its properties have been tested by experience and practice. With a relatively low volumetric weight and sufficient strength, its thermal conductivity approaches that of modern thermal insulation products. Ease of installation, immunity to moisture, and low cost are among the positive properties of expanded clay.

Small granules have lower thermal insulation properties than large ones

Expanded clay gravel, used as insulation, is distinguished by fractions:

- expanded clay 5–10 mm;

- expanded clay 10–20 mm;

- expanded clay 20–40 mm.

The material with the largest granule size has the lowest thermal conductivity. But sometimes even expanded clay sand with a fractional composition of up to 5 mm is used. This depends on the laying technology, layer thickness, and the chosen finishing design, which represents the flooring above the laid insulation.

The structural feature of the balcony slab is that its upper cut is higher than the surface of the floor panels in the apartment. Therefore, to maintain a single floor level, you will have to reduce the thermal insulation layer.

For small thicknesses, expanded clay sand or gravel of the finest fraction is used. The effect of such insulation will be far from ideal. Therefore, consider the climate zone in which your building is located .

If winter is characterized by low temperatures, typical, for example, of central Russia, then it is better to use more effective products as a starting material: polystyrene foam, polyurethane foam, hard mineral wool and the like, and expanded clay for additional insulation and creating layers.

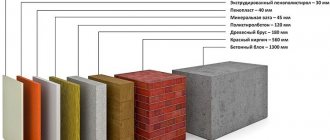

No. 4. Penofol

Penofol is one of the most modern insulation materials, which combines the advantages of polystyrene foam and mineral wool, but the material is very thin, so it is optimally suited in cases where every centimeter of space counts. Penofol consists of polyethylene foam and aluminum foil, and its action resembles a regular thermos. The material does not retain the warmth of the room, but reflects it. Penofol is produced in rolls 3-10 mm thick. Main advantages of the material:

- the minimum thickness at which the thermal insulation properties are not inferior to other materials. Thus, a 4 mm thick layer of penofol can replace 8.5 cm thick mineral wool or 3 cm thick polystyrene foam. Space savings are obvious;

- the material does not absorb moisture at all, so there is no need to worry about waterproofing;

- additional sound insulation. Penofol will reduce the load from acoustic and structural noise, which is more than relevant for balconies and loggias facing directly onto the street;

- maximum ease of transportation and installation. The material can be cut without fear of crumbs, secured with glue or tape;

- difficult to reach for rodents;

- fire safety. Penofol is a low-flammable and low-combustible material;

- environmental friendliness.

Reviews from experts say that penofol is one of the best and most reliable insulation materials at the moment . But it also has some disadvantages. Thus, the material is quite soft, and when installing it it is better not to use nails so as not to disrupt the integrity and basic properties of the material. Despite the excellent properties of penofol, today it is usually used not as an independent insulation, but in combination with other materials.

Work technology

Expanded clay is a lightweight bulk material, working with which is not difficult. It is enough to pour the required volume into a limited space and level it with a trowel, a rule, or just a piece of a flat board, focusing on the upper level mark, previously applied to the wall or obtained using a laser plane builder.

In large spaces, expanded clay is laid along laid guides, but for a small balcony area this is not necessary. After creating a layer of the required size, a cement screed 3-5 cm thick is applied on top of it. It fixes the insulation, giving strength to the composition, and serves as the basis for constructing a “clean floor”. For information on floor insulation with expanded clay and installation of dry screed, watch this video:

The screed is made from a cement-sand mortar, in which the ratio of the volume of sand and the weight of grade 500 cement is 1 to 4, that is, 250-300 kg of binder component is mixed per cubic meter of aggregate. The sand used is of good quality, medium size, without clay inclusions. The mixture is diluted with water to a plastic state and mixed manually or using a power tool with a special attachment. To increase density and reduce the amount of water, it is recommended to add a concrete plasticizer.

The finished solution is applied to the expanded clay in a layer of equal thickness, the surface of which is leveled with a trowel or rule. Pre-hardening of the screed will take two to three days, depending on humidity and air temperature. Brand strength is considered achieved after 28 days of setting under favorable conditions. For more information about expanded clay insulation, watch this video:

The advantage of insulating the floor on a balcony using expanded clay is its immunity to moisture. The granules have a closed pore structure, obtained by swelling of the raw material under intense heating.

Even if there are deficiencies in the external finishing of the balcony slab, which allows moisture or fumes to penetrate, the material under study will reliably perform its functions.

No. 6. Warm floors as an alternative

The underfloor heating system allows you to solve a lot of problems of creating an optimal microclimate on a balcony or loggia. Firstly, you won’t have to think about other heating systems, and secondly, it will be pleasant to walk on the floor even barefoot. However, in order not to heat the street, thermal insulation materials should be used in this case as well. Heated floors can be water, electric or infrared. It is problematic to use a water system on loggias and balconies, so they settle on the last two options. Electric heated floors can be of two main types:

- cable system . Its use requires the organization of a screed with a layer of insulation and waterproofing. The thickness of the screed should be at least 4.5 cm, and the heating cable should be located at a depth of 3 cm from the top edge. The finishing coating must have good thermal conductivity, so ceramic tiles are often used as it. It will be possible to turn on the heated floor system only after the screed has completely dried, which is 2-3 weeks;

- heating mats are used when it is impossible to organize a cement-sand screed. The mats are laid simply and quickly using tile adhesive, and installation can be carried out directly on the old coating. The finishing can be absolutely anything, the main thing is that the finishing material tolerates such heating well. You can use heated floors immediately after the glue has dried. The disadvantages of this solution are the high cost and the need in some cases to use an additional heating source.

An alternative to them is infrared film floors , which are as easy as possible to install. Such a floor will heat the surrounding objects, and from them the air will warm up. The Sun heats our planet using the same principle. With such floors, the microclimate on the balcony will be as healthy as possible. You can use anything as a finishing coating: linoleum, carpet, tile, laminate. It would probably be too much to list the advantages of using heated floors. Of course, electricity bills will be higher, but if you compare them with the fee for the constant use of electric heaters, then heated floors are still more profitable, and many times more. The difficulty of installation is often cited as a disadvantage. This statement is partially true for the cable system, but the remaining options for organizing heated floors are as simple as possible and can be implemented on your own.

Why expanded clay?

I would like to immediately note that this material is most importantly environmentally friendly. In addition, it is extremely durable, has enhanced heat retention properties, is frost and fire resistant, and is easy to use. And also, what is important for those who always save, expanded clay is quite cheap.

Comparing all the components of this material, we can say that insulating a loggia with expanded clay is the most profitable construction solution.

In addition, using expanded clay, due to its lightness, you can avoid additional loads.

Related article: How to install light on a balcony from an outlet

Proper floor insulation

But if you decide to insulate the balcony floor with expanded clay, then it is worth remembering that the temperature conditions here are much lower than on the loggia, so the backfill layer will have to be made thicker, which means the volume of the room will decrease.

For installation you will need to prepare special metal profiles, cement and sand.

There are several methods of laying technology, but no matter which one you use, each one includes compaction, which is done after every fifteen-centimeter layer, which increases the consumption of expanded clay by 15%.

However, if the bottom layer is filled with cement mixture, and only after it has dried, the next layer is poured, then raw materials will be saved and compaction will be easier.

Let's assume that the floor screed has already been done

Alas, we cannot offer any magical solutions. At a distance of 60 mm from the threshold you can place: facing tiles + a layer of adhesive and an additional 30 mm screed. The remaining 10 mm will not save you. The total insulation thickness of 50 mm is nothing if you are going to install a heated cable floor. The lion's share of the heat will go outside, it will be cold on the balcony, and the electric meter will spin like Volochkova in his heyday. You have four options:

Option to insulate the floor, walls and ceiling of a balcony/loggia from the inside

- Disassemble what has already been done and start again, consciously approaching the issue of insulation.

- Place another 100 mm of insulation above the already made screed + 50 mm on the screed and tiles. The floor level will rise by 9 cm relative to the threshold.

- Leave it as is, accepting the cold and excessive consumption of electricity.

- Make a compromise decision: abandon the second layer of screed, put 50 mm high bars on the screed, and a board or plywood on them. The excess above the threshold is only 15 mm.

We cover a significant layer of insulation on top with a window sill

Expanded clay insulation procedure

- In order to be able to insulate the floor with expanded clay in an apartment or on a balcony, you will need sand, cement and metal profiles, as mentioned above. First, you need to align the profiles as horizontally as possible to the surface, using cement beacons.

- It is worth remembering that the expanded clay layer is laid on top of the waterproofing layer. This can be a polyethylene film that is laid on the floor before the beacons are installed. The edges of the film can be glued with tape, which will allow you to get a solid canvas. The film should extend onto the walls by at least ten cm.

- After the insulation and beacons are installed, you can begin filling with expanded clay. When filling the gaps between the beacons, it is important to remember that you need to leave at least 3 cm in order to make a cement screed afterwards. After laying out the expanded clay, you need to check the upper level again by pulling the fishing line along the beacons.

- The final point is the cement binder (the solution is placed on the expanded clay as carefully as possible, and in portions, so as not to disturb the structure). This is the only way to avoid structural damage and the formation of potholes. Once everything has dried, the floor can be covered with the floor covering you like.

Insulation using expanded clay concrete

Expanded clay is produced by firing clay, so this material is very light and its surface has many air pores.

For this reason, a solution of cement with expanded clay creates a layer with an air cushion, which plays the role of a good heat insulator.

The process of insulating the floor on a loggia with expanded clay is very simple: after mixing a solution of cement and sand, the entire surface of the concrete floor is covered with expanded clay in an even layer with a thickness of 3-5 cm, after which beacons are installed, and a layer of prepared cement mortar is poured over them.

It must be borne in mind that the cement mortar must be as thick as possible, otherwise the light clay material will float to the surface and the thermal insulation layer will be damaged, and it will also be impossible to perfectly level the screed.

If you replace expanded clay with sawdust, you can simply add them to the solution and, after thorough mixing, make a screed.

Is it possible to insulate walls with expanded clay?

So, insulating coatings with expanded clay is possible, but is it possible to insulate balcony walls with it? In principle, there is nothing that cannot be brought to life.

However, experts say that such insulation will significantly reduce the area, which is already small. In addition, the expanded clay inside the wall can be rubbed, which threatens the loss of its characteristic features.

Therefore, expanded clay insulation of balcony walls can be found not so often.

Is insulating a balcony with expanded clay profitable? There are a huge variety of thermal insulation materials, but no matter how good they are, they have a main drawback - the release of harmful substances when heated, some of them are even fire hazardous.

But expanded clay is an ecological raw material that does not emit dangerous odors, is extremely reliable, does not burn or sink, and, importantly, is quite cheap. Based on these criteria, expanded clay has become incredibly popular, and it can also be used to insulate floors in all rooms.

Each fraction of this material is divided into three categories: 0.5-1.0 cm; 1.0-2.0 cm and 2.0-4.0 cm and has a porous structure.

Expanded clay is obtained by firing clay rocks, which actually affects its low cost. By the way, if we compare expanded clay in terms of thermal insulation properties, we can note that 10 cm of expanded clay is equal to a meter high brickwork or ¼ meter of solid wood.

Thus, if you weigh all the pros and cons, the conclusion suggests itself: insulating a balcony with expanded clay is a winning solution: it saves the budget and is as safe as possible for health. In addition, this material serves as an excellent sound insulator, which is incredibly important in conditions of city noise coming in around the clock both from the street and from restless neighbors.

More on this topic on our website:

- How to make a wooden floor on the ground with expanded clay insulation

- Owners of wooden houses know firsthand how important it is to timely and well insulate their home. Cold floors are the main problem in most private homes.

Insulation of expanded clay ceilings

To keep your home warm, you should insulate the ceiling. Also, insulating the ceiling will help save on gas and electricity, which are used for heating.

How to insulate an attic and roof with expanded clay

- Insulating the roof and attic is not only a means of increasing the overall comfort and efficiency of the house. When building new houses, the roof and attic are already insulated.

How I insulated a bathhouse with expanded clay

- Expanded clay, as an insulating material, was chosen long before the completion of work on the log house. Pine timber, wooden floors in the dressing room and lounge, upcoming wall finishing.

Related article: How to make a window sill on a balcony with your own hands

Add a comment Cancel reply

You can subscribe to new publications by email.

No. 1. Styrofoam

Polystyrene foam, or expanded polystyrene, has been used as insulation for a very long time and today, despite the emergence of many other materials, it does not lose its position. Each of us knows what the material looks like: it consists of numerous balls, which in turn are built by their cells. Thermal insulation properties are explained by the porous structure and the presence of air in these pores. In fact, foam is 98% air.

According to the production method, polystyrene foam is divided into two large groups: extruded and expanded. Extruded polystyrene foam is commonly called penoplex . It consists of small granules, is difficult to cut, lacks many of the disadvantages of the foam plastic we are used to, and is ideal for insulating loggias. The sheets can have a thickness of 2 to 10 cm; they fill the holes between the floor joists, the cracks are foamed, after which the finishing coating is laid.

The popularity of polystyrene foam is associated with a huge number of its advantages:

- light weight, making transportation and installation easier;

- affordable price;

- excellent thermal insulation properties;

- soundproofing properties;

- does not absorb moisture, will not be a place for mold and rodents to grow.

Main disadvantages:

- flammability, so it is better to give preference to material impregnated with an antiprene composition;

- rodents can live in the foam;

- instability to mechanical damage, so insulation work must be carried out with some caution. Penoplex is almost free of this drawback, since due to its smaller granules it can withstand heavy loads.

Problems that arise when insulating the floor on a loggia with expanded clay

The loggia area can be used in different ways. Some owners decide to adapt this part of the apartment for living. But in order to be comfortable on the loggia at any time of the year, it will need to be properly insulated. Including, the floor needs insulation. Expanded clay can be used to protect floors from the cold. It remains to be seen how to handle it.

Preparing the floor for work

Work begins with the removal of the old floor covering, as well as the elimination of defects found underneath it. After all, it is possible that cracks will appear on the floor. Because of them, the heat and sound insulation capabilities of the floor are noticeably reduced. The cracks must be covered with at least concrete. Ideally, lay a polyethylene foam tape around the perimeter. It protects well from heat loss.

No. 5. Foam glass

For loggias and balconies, the number of possible insulation materials is greatly reduced due to specific conditions. We have to refuse, for example, ecowool, but foam glass can be used. In terms of its composition, the material is ordinary silicate glass, but the production method allows it to add unique properties. Glass waste is crushed into powder, melted, and due to the action of a gas-forming agent in the form of coke or coal, the mass increases tens of times and acquires a porous structure. Not only is this material much lighter than glass, but it also has many other advantages :

- good heat and sound insulation properties. A 10 cm thick slab reduces noise levels by 56 dB;

- durability. The material can retain all its basic properties for 100 years;

- tolerates cold and heat, temperature changes well, does not change geometric dimensions;

- does not burn, because it is based on glass, which melts at a temperature of 10000C and does not ignite;

- strength;

- the material is not afraid of water, but allows air to pass through.

Due to its high cost, foam glass is not so often used for insulating residential buildings and, especially, loggias and balconies. In terms of its overall performance qualities, it is an ideal insulation material.

remstroiblog.ru

Laying expanded clay on the loggia floor

For good thermal insulation, the expanded clay layer should reach a thickness of about 7 cm or even more. Expanded clay of the middle fraction is best suited for such work. It is easy to handle, but it has good thermal insulation properties.

Expanded clay is laid on the floor in a continuous layer, without the formation of cavities. If water periodically appears on the loggia due to poor-quality glazing, it is advisable to further protect it. A plastic film is placed under the expanded clay and on top of it. Although expanded clay itself does not deteriorate from moisture, when wet, its insulating characteristics may decrease.

No. 2. Mineral wool

Mineral wool is a whole class of materials, the production of which is carried out from mineral raw materials by heating it until it melts, drawing it into separate threads and forming fibers. If blast furnace waste was used as a raw material, then the result is slag wool , if the basis was glass waste or silicon-containing rocks, then glass wool . Often, mineral wool is understood as stone wool , which is produced from basalt rocks. It has the best performance properties, and that is what we will talk about.

Stone wool is produced in slabs and rolls, but can also be in granular form and directed with a special installation onto the insulated surface to fill all the cracks. Whatever the form of mineral wool, its main advantages are:

- good thermal insulation properties. The thermal conductivity coefficient is approximately on the same level as polystyrene foam, so the material will provide excellent protection and will not release valuable heat;

- ability to pass air - the microclimate of the balcony will be in perfect order;

- non-flammability;

- noise insulation properties;

- resistance to mechanical damage;

- rock wool is not touched by rodents;

- durability;

- affordable price.

The combination of all these advantages explains the wide distribution of the material. It is worth noting that glass wool and slag wool will be cheaper, but they are more fragile, and all work will need to be carried out in protective equipment.

Installation of dry screed on the loggia

Now you need to prepare the base on which the flooring will lie. Use GSP, MDF or OSB boards. It is advisable to take panels of the maximum size. If the loggia is not too large, sometimes one solid piece is enough to cover the entire floor area at once. When using several panels, you will have to additionally fasten them with mounting tape.

Flooring installation

Now the owner just has to lay the flooring. These can be a variety of materials, but it is best to choose products with maximum moisture resistance. For example, dense linoleum or vinyl tiles are suitable. Although the most ordinary laminate will also perform well.

There is nothing incredibly complicated about insulating floors on a loggia. Using suitable material and following the recommendations of professionals, each owner will achieve excellent results and receive a loggia with comfortable conditions.

conclusions

If the floor on the balcony is without insulation, and glazing with subsequent installation of thermal insulation is planned in the near future, it is recommended to consider different methods. The simplest, fastest and most affordable option is the installation of materials characterized by appropriate properties. Each of them has its pros and cons.

If you are screeding over heat-insulating slabs, it should be taken into account that in this case an additional significant load is placed on the concrete base of the balcony. Wooden construction is more lightweight, so it is used more often. However, wood is susceptible to moisture and is undermined by insects. This option is only suitable for linoleum. Tiles cannot be laid on top of a wooden structure, since the base of this type will be constantly deformed.

Step-by-step video on floor insulation on a balcony:

Why insulate?

If the balcony is closed, then it is better to insulate it. Otherwise, when the temperature fluctuates, condensation of excess moisture will occur on the walls and glass. Excessive dampness can lead to mold or mildew that is not easy to remove. Furniture and household items placed on the balcony will also deteriorate from increased dampness. An insulated balcony will become a cozy place to relax and safely store household items. Raising the floor using a layer of expanded clay and cement screed is a reliable way to increase the living area and create a thermal buffer that improves the microclimate in the room.

Material characteristics

Expanded clay is ceramic granules with a diameter of 1-4 cm. It is obtained by firing clay balls. With a sharp increase in temperature, the moisture contained in the balls evaporates and comes out, creating numerous pores. The surface of the granules is baked and forms a durable layer. It is these pores that determine the decent thermal insulation qualities of the material. Expanded clay belongs to the group of inexpensive backfill materials; it is used for thermal insulation of floors. The density of the material is 250-600 kg/m3, thermal conductivity is 0.09-0.1 W/m*K. Three fractions of expanded clay are produced, differing in the diameter of the granules.

How to insulate a balcony with expanded clay

Pros and cons of using

The material has a number of significant advantages:

- low cost: this is the most affordable of the materials used for insulating balcony floors;

- ease of use: laying expanded clay does not require highly qualified performers, nor does it require expensive equipment;

- fire safety: ceramics do not burn and do not contribute to the spread of fire; when heated, they do not emit toxic fractions;

- environmental friendliness: no substances harmful to health are released during production, installation and operation;

- resists rotting, mold and mildew, the spread of bacteria and insects;

- frost resistance;

- low specific gravity: creates a small additional load on the supporting structures.

Related article: How to properly insulate a balcony from the inside with your own hands

The material also has a number of disadvantages:

- the thermal insulation coefficient is the lowest of the insulation materials used for balconies, this leads to the need to use a thicker layer;

- a cement screed is required to fix the expanded clay;

- high hygroscopicity requires serious waterproofing measures.

To create an equal insulating effect, a layer of expanded clay must be used three times thicker than, for example, expanded polystyrene.

Thermal protection made of polystyrene foam

Expanded polystyrene is the most common type of foam in construction, inferior in strength to penoplex. However, with a lag floor construction, this insulation is used even more often than XPS. The popularity of expanded polystyrene is due to the fact that, with sufficiently high thermal insulation properties, it is much cheaper than penoplex, and the lower strength of foam when laid between joists is not relevant.

Expanded polystyrene is available in several grades, differing in density and thermal conductivity. When choosing this insulation, you should give preference to a material of a higher grade, since with increasing density, its thermal insulation characteristics also increase.

| Polystyrene (foam) | Density kg/cub.m | Thermal conductivity (W/Mx0°C) |

| Brand PSB-S15 | 11-15 | 0,037 |

| Brand PSB-S25 | 16-25 | 0,035 |

| Brand PSB-S35 | 25-35 | 0,033 |

| Brand PSB-S50 | 35-50 | 0,031 |

To insulate the balcony floor, polystyrene foam no thinner than 5 cm is used. The preparation of the base is carried out in the same volume as for the installation of polystyrene foam.

- Cheap material;

- Low thermal conductivity;

- Low specific gravity;

- Low moisture absorption - up to 3%;

- Frost resistance;

- Sufficient heat resistance (does not deform when periodically heated to 60°C);

- Durability – more than 30 years.

- Even species with fire retardants in their composition burn and release toxins;

- Over time, styrene begins to be released into the air;

- Unresistant to ultraviolet radiation and many solvents.

Technology of thermal insulation of balconies with expanded clay

How to insulate the floor on the balcony? The method of using expanded clay is not particularly complicated. It is quite within the capabilities of a home handyman with general construction skills. You just need to be careful and sequence the operations.

Required materials and tools

To lay an expanded clay insulating layer you will need:

- expanded clay in bags;

- waterproofing film: polyethylene 150-200 microns or roofing felt;

- cement;

- water;

- sand;

- reinforcing mesh, plastic or metal;

- container for mixing the solution;

- Master OK;

- construction mixer or drill attachment;

- level;

- rule;

- beacons for setting the floor level.

To insulate a balcony with expanded clay you will need a waterproofing film

When working, you should use thick clothing and shoes, protect your hands with gloves, and protect your eyes with safety goggles.

Surface preparation

Before insulating the floor on the balcony with expanded clay, it is necessary to remove all the furniture from it and remove the existing floor covering down to the concrete. The concrete needs to be vacuumed and dried. Now you can begin the main part of the work.

Laying the waterproofing layer

Due to the high hygroscopicity of the material, it is necessary to provide high-quality waterproofing. To do this, use dense polyethylene with a thickness of 150-200 microns or ordinary roofing felt, laid with an overlap. The waterproofing should extend onto the walls by 5-10 cm.

Expanded clay backfill

On the walls you will need to mark the level of the expanded clay layer. It is necessary to take into account the fact that balcony floors are always arranged with a slight slope towards the street. This is necessary for complete drainage of rain and melt water. After glazing and insulating the balcony, there is no such need, and it is better to make the raised floor level relative to the horizon. When calculating the layer thickness, it is necessary to ensure sufficient thermal insulation. At the same time, you need to ensure that after installing the screed and laying the finishing floor covering, you do not raise the final floor level above the frame of the balcony door.

Backfilling expanded clay on the balcony

Expanded clay is poured over the waterproofing from bags and leveled with a rule so that it moves at the level of the markings applied to the walls.

Let's assume that the floor screed has not yet been done

Judging by the description, the total height of the floor on the balcony is 40+30+60=130 mm. We don’t know what result you want to achieve: to ensure that the room is simply maintained at a positive temperature, or, judging by the mention of the heating cable, to ensure that it is warm on the balcony, almost like in the room. Let's say you want it warmer. In this case, only 80 mm remains for insulation, since 50 mm will be taken up by tiles and screed. If you don’t have a warm room downstairs, in a climate similar to Moscow, in order to get 15 ºС in winter (assuming heating), the layer of effective insulation on the floor must be at least 150 mm. On the walls and ceiling, by the way, too. If you save on insulation, you will have to turn on the electric heating at full power, which will hurt your pocket.

When installing a floor screed, in addition to effective insulation from below, it is necessary to take into account that the screed must be separated from the walls by a strip of heat-insulating material (damper tape in the illustration)

Effective insulation is light extruded polystyrene foam, polystyrene foam, soft mineral or glass wool, ecowool. When using fluffy materials, do not allow them to become moist. If the balcony fencing is concrete and it is problematic to make a ventilated layer, it is better to lay cotton wool, having previously packed it in sealed bags. The thermal insulation properties of expanded clay are 2.5-3 times worse; there is no point in considering it at all.

Two slabs of mineral wool, each 50 mm thick, were laid on the floor of this balcony, for a total of 100 mm. A floor board will be placed on top. The frame of the walls, judging by the photo, will allow 80 mm to be laid there. This is twice as effective as what you are planning to do.

We would recommend placing the heating cable in the screed only if you can properly insulate the floor. With a polystyrene foam thickness of 150 mm, the total height will be 200 mm, which is 70 mm above the threshold. If you are not satisfied with this, do without a screed at all, put joists, with insulation between them. On top you can lay a 25 mm floorboard or a 15 mm layer of plywood and insulated linoleum, carpet or laminate. And you can heat it with a convector or an infrared film floor, rolling it out under the covering. Then the total height will be smaller: 175 mm. And if you do not exceed the threshold level, 100 mm will remain for insulation.

It would be useful to “wrap” the balcony from the inside with a layer of foil foam insulation, reflecting infrared rays with a film inside the room