Plastic doors are practical, inexpensive and therefore very popular products. They are used as balcony partitions, as well as entrance and interior structures. They can be of different sizes and purposes, but they will not be able to work without fittings. Therefore, hinges for plastic doors must be selected carefully and adjusted in a timely manner. It is these elements that bear the main load. Next, let's look at the differences between hinges for plastic doors and how to choose them correctly.

How to lubricate the hinges of plastic windows?

Like any other hinges, hinges for plastic windows require lubrication. As you know, parts that rub against each other quickly wear down, which can affect the functioning of the window. In addition, during the operation of plastic windows, dust and dirt adhere to the hinges. As a result, problems may arise, for example, with windows closing with a script and the pressure being insufficient. The best solution to these and other problems is to periodically lubricate the hinges.

It is important to note right away that standard household lubricants, such as vegetable oil or petroleum jelly, are not suitable for lubricating hinges. Technical, synthetic or mineral motor oils are best suited for this task.

All parts of the plastic window that are subject to friction should be lubricated, i.e. those that move when the window opens/closes. It should be noted that before lubrication, all metal surfaces that are planned to be lubricated must be cleaned with a brush or rag. The recommended interval for lubricating hinges is 1 year. A couple of drops will be enough for each surface; when using a sprayer, the distance to the loops should be about 5 cm.

Varieties and device

Choose hinges for doors from high-quality alloy.

When purchasing plastic structures, you should remember that hinges can have different types and characteristics:

- When choosing door hinges, you need to familiarize yourself with the requirements of the entire structure as a whole. Only after this will it be clear what elements are required.

- Theoretically, plastic windows and canvas perform the same function, the only difference is in size. Due to this, fasteners for a plastic door must be of a more durable type.

- For doors, a hinge made of aluminum alloy is better suited. Due to the strength of the material, the reliability of fastening will increase significantly.

- When purchasing balcony doors, it is best to choose fastening elements that have an adjustable function. Thanks to this, it will be possible, if necessary, to adjust the structure vertically or horizontally;

It is important to remember that during operation, the fastening mechanisms that are responsible for opening and closing doors must be lubricated occasionally. The quality of service of the structure will depend on this.

When to adjust or change hinges

Adjustment of the hinges is required in cases where either partial depressurization of the window structure occurs, or there is sagging of the sashes, which cling to the frame profile when opening/closing. These fittings are replaced in the following cases:

- if the adjustment did not give a positive result;

- after lubrication, the doors lock when moving;

- the integrity of one of the elements of the loop group is violated.

Although quite a lot of instructions on replacing and adjusting these components of window fittings are publicly available, it is better to invite specialized specialists to carry out such activities. Otherwise, you may not only not achieve the desired result and ruin the hinges, but also break the transmission mechanism, which is fully responsible for the tightness of the window and the opening of the sash.

Replacing a door hinge

In most cases, balconies do not have hinges from branded manufacturers, so breakdowns are not excluded.

It is important! Most often, adjustable hinges on plastic doors made of aluminum or zinc alloys are damaged, so you cannot do without replacing the entire part.

To do this job, you need to prepare several tools:

- hammer,

- pliers,

- punch.

Now you need to remove the door leaf, for which you need to adhere to the following action plan:

- remove decorative parts of the structure,

- knock out the axle,

- remove the door from the lower element,

- dismantle the broken part,

- install a new part.

It is important! Remember that all manipulations with the door are performed when it is slightly open.

With gentle blows of a hammer, the axle is recessed on the upper hinge until its lower part appears. Then, using pliers, grab the visible part of the axle and pull it down.

If the door block is installed on three hinges, then such manipulations must be carried out with the middle element of the fittings. The lower part is significantly different from the upper and middle loop; the axis on which the canvas is held is tightly fixed, so it should not be knocked out.

Door hinge options

When the door leaf tilts towards itself, it needs to be lifted up about 6 cm so that the axle completely comes out of the cylinder. Remember that a model with triple glazing, a wide strip and insulation will weigh a lot, so it is recommended to carry out the removal work with an assistant.

After removing the door and removing the broken hinge, you need to install new ones, which should be selected as similar in type and design as possible, then you will save yourself from the additional work of drilling new holes for fastening.

If the cause of the breakdown is a manufacturing defect, then it is more advisable to look for another model of door hardware, which will be an order of magnitude more expensive, but much higher quality and more durable. This will help you avoid additional costs for purchasing new products from Chinese manufacturers and will allow you to forget about this problem for a long time.

Fittings for plastic doors are available in a wide variety, so it is very difficult to figure out which product is right for you. Experts advise coming to stores with broken hinges removed so that the consultant can choose the right hardware part correctly.

If you have to order door hardware online, then you need to carefully rewrite the markings on the broken part and order an identical one.

Voted over 263 times, average rating 4.2

Comments

Unfortunately, there are no comments or reviews yet, but you can leave your...

Add a comment Cancel reply

We recommend reading

Hinges, Fittings Selection and installation of hidden hinges for metal entrance doors Metal entrance doors must ensure the safety of housing and ...

Hinges, Fittings Drop-shaped hinges with bearings To ensure that the door holds firmly and opens easily, ...

Hinges, Accessories How to cut hinges with a router and what devices are used? When installing new interior doors, many are faced with...

Hinges, Fittings Making homemade hinges for doors: why a responsible approach is needed High-quality fittings are an important condition for long-term and stable ...

Breakdowns and problems during their operation

If plastic hinges were purchased from an unreliable seller separately or as part of a door structure, they may break. Problems can also arise if they are installed, adjusted and operated incorrectly.

The main malfunction is the displacement of the clamp flap, which leads to drafts or the inability to open/close the door. In this case, the loop needs to be adjusted.

Complete failure of the hinge requires its replacement. All door fittings require lubrication of constantly rubbing parts. To do this, it is necessary to use technical oils. If this is not done once every six months, the doors will begin to creak and close poorly, and over time they will not be able to perform their functions at all.

Characteristics of door hinges

The main parts of such fittings are hinges for plastic doors. They bear the main load during operation. Therefore, when choosing, you need to pay attention to the material, manufacturer and workmanship.

If you decide to install fittings from a branded manufacturer, then you are guaranteed quality and reliable operation. Typically, each hinge is designed for 200,000 openings and closings.

As for accessories at affordable prices, it is impossible to guarantee such a result.

It is important! If a door hinge breaks, you need to assess the extent of the damage and decide on further tactics; perhaps you can get by with simple adjustments.

Door hinges

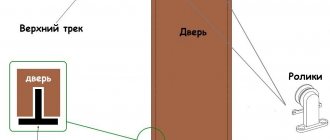

Types of canopies for plastic door structures

For installation of plastic doors, the following types of fittings are most often used:

- Applied hinges (photo). This subtype of fastener is usually installed on pendulum-type products and in rooms where the load on the structure will be strong and constant. The product is capable of acting as a door closer, providing autonomous closing of the door without any extra effort;

- Overhead fastener (photo). When installing this type of fittings, special attention should be paid to ensuring that the location of the element’s fastening perfectly matches the location of the reinforcing metal parts located on the body.

Craftsmen recommend using overhead hinges on balcony structures, as they are less resistant to loads.

Design Features

The hinges are subject to significant loads, which necessitates their manufacture from metal and stainless steel. Some parts may be made of Teflon. All these materials are strong enough to provide the mechanism with a long service life.

The purpose of installing hinges is to secure the canvas to the frame so that it can be opened. Hinges should not only serve as an element necessary for opening the door, but also ensure smooth and easy opening, as well as a tight fit of the door leaf to the frame.

The correct choice of hinges, timely and qualified adjustment will ensure excellent operation of the mechanism throughout its operational period.

The hinge for plastic doors consists of:

- Metal tab attached to the canvas;

- Pins providing fasteners;

- Bushings, usually made of Teflon material, which are located between the door and the leaf.

People who understand the design of hinges for ordinary wooden interior doors will notice that they have a similar design. However, a feature of the hinges under consideration is that they require adjustment of both their position and the position of the fabric attached to them.

The adjustment makes it possible to move the leaf in any direction relative to the doorway by a few millimeters. With proper adjustment, you can achieve a tight, gap-free fit of the door to the frame, as well as trouble-free operation of the locks.

The hinge for a plastic door is in most cases installed through a special tab, which is also called a template. The template is fixed on the door in the place where the hinge will be installed in the future. It is the template that allows you to adjust the door horizontally.

Vertical adjustment is carried out thanks to special adjustment screws hidden in the hinge itself. The screws are closed under special caps that protect the mechanism from dust and are also installed for decorative purposes.

Long service life of doors is achieved through the use of durable materials. The design of the hinges uses Teflon - a very durable and lightweight material that ensures the durability of the mechanism. In addition, special ball-type bearings are built into the hinges, ensuring easy opening of the blade and reducing wear on the mechanism.

Don’t forget that the design allows you to take care of it at any time, carry out lubrication procedures, and adjustments. It is thanks to the design features of the mechanism and the possibility of maintenance that good reliability and durability of the product is achieved.

There are also situations when the hinge for a plastic door cannot withstand the load and requires replacement. Basically, such problems can arise due to defects in the production of structural elements of the mechanism; as a rule, the product body (most often aluminum) or the axial cylinder fails.

This is not a common occurrence and when using high-quality fittings, breakdowns practically do not occur. If a breakdown does occur, the loop can be replaced with a new one that is suitable in size. Structurally, the procedure for replacing the hinge is quite simple and does not cause problems even for beginners.

Classification

Products of this class have different types, which are classified according to several criteria. As a result, hinges on plastic doors differ in the following parameters:

According to the width of the sash, they are distinguished:

- products for narrow profiles, up to 90 mm;

- products for wide profiles, up to 110 mm.

Depending on the loads withstand:

- for narrow profiles, products that can withstand up to 80 kg are used;

- for a wide profile, products that can withstand up to 160 kg are used.

Overlap width:

- products with linings;

- products whose design is intended for use with a wide overlap.

By installation method:

- Any manufacturer of products for PVC profiles uses its own fastening system. As a result, the fastenings on plastic doors are fixed using a special template, which is designed to facilitate the fastening process.

Based on the material of manufacture:

- product body made of zinc alloy or aluminum;

- pins and liners made of stainless steel or ferrous alloy;

- spacer sleeve made of super-strong plastic or Teflon;

- fasteners are made of galvanized or stainless steel.

By the number of regulation methods:

- PVC door fastenings have three ways of regulation: height, horizontality and quality of clamping.

In addition, door products differ in design and color, which is explained by different manufacturing technologies and the capabilities of the manufacturer.

Door hinge device