In any room, windows and doors are most susceptible to external influences. From the outside, wind, temperature changes, and precipitation negatively influence, but indoor conditions are different, and the double impact of these factors leads to the destruction of structures. Since houses built from sandwich panels have become popular relatively recently, questions arise about the integration of doors and windows into these structures.

So, what are the features of installing doors in sandwich panels? In houses made of sandwich panels, it is recommended to cut out door openings in advance that are convenient for fastening. It is also necessary to determine the direction of opening the doors to ensure ease of movement. In order to ensure free passage and carry-through of furniture, it is recommended to choose the width of the doorway from 70 to 80 cm. First, the door frame is installed. If the opening is built vertically into the wall, the door is leveled using a level and wedge spacers. After that, the plastic door is secured with special fasteners, and the wooden door is nailed down. When the door frame is installed, the door is attached to the hinges, but it must be remembered that the distance between the door frame and the door itself is about 4-5 mm. Now all that remains is to insert the handle and lock.

Installation principles

The principle of installing windows in a sandwich panel is the same as installing a door, but an additional advantage is the ability, if desired, to embed a window into the solid wall of a house made of sandwich panels. The size and shape of windows must be carefully designed to enhance the appearance of the home's exterior and comply with building codes. In accordance with standards, the glazing area in a house should be 12-18% of the area. You should not make very large windows, since the main heat transfer will go through them. In structures made of sandwich panels for mounting windows, one should not forget about 2-centimeter gaps for ease of installation. It should be noted that the symmetrical arrangement of windows gives the building architectural aesthetics. When installing windows, you need to pay special attention to the lower part, since drains and window sills that are too large will spoil the appearance of the house and cause discomfort to residents.

After installation, the structure is sealed with a wide range of sealants, depending on the characteristics of the windows and doors. After complete assembly and filling of the openings, foaming is carried out to ensure heat and sound insulation.

Based on the above, it is much easier to install doors and windows in houses made of sandwich panels than in brick ones, and if installed correctly, they will ensure coziness and comfort in the house for many years.

Hello, friends, in the article installation of sandwich panels you will learn how and how to install sandwich panels, what tools are used, installation rules, my story of how we installed the panels for the first time at a construction site. I will provide a technological album for downloading on the installation of sandwich panels with assemblies of windows, doors, roof ridge and much more.

installation of sandwich panels

In the article on installation of metal structures, I promised that I would write an article on this topic and provide an album for downloading on panel installation units.

Main features and advantages of doors

Metal-plastic doors are easy to use and do not require maintenance. Painting is not at all necessary; the products are washed in the usual way with a soapy solution. They close and open without effort. The models are characterized by an excellent level of moisture and heat insulation. The sound insulation achieved with their help does not leave much to be desired; PVC structures will protect the owner perfectly from street sounds. Therefore, such doors are popular in medical and educational institutions, and the same applies to office buildings.

Metal-plastic doors are adapted to difficult operating conditions. They are not afraid of high humidity, significant temperature fluctuations, including in a relatively short period of time and sharp winds. The dimensions of the product remain stable, it does not crack or swell, this applies to the entire period of operation of PVC structures.

Variety of decorative sandwich panels used for PVC doors

Start of installation of sandwich panels.

When everything is ready and equipped, the installation order will be determined. Depending on the size of the building, the panels can be mounted in a horizontal or vertical position.

Sandwich panel tape

Before installing the panel on the columns and crossbars, special self-adhesive tapes are glued at the points of contact. The tapes reduce vibration and ensure a tight fit of the panels to the building structures.

The panels are secured with special self-tapping screws made of carbon or stainless steel with a seal, with a metal drill if they are attached to metal structures.

If the building frame is made of wood, then the panel is pre-drilled and secured with wood screws. They are attached to the concrete with special dowels after pre-drilling the panels and concrete structures. The length of the self-tapping screws is selected based on the thickness of the panels.

If the panel is 50 mm thick, then use a 75 mm screw or a 200 mm panel then use a 240 mm screw.

Installation of sandwich panels begins from the corners of the building. The panels are mounted using special gripping clamps. Clamp is a special screw grip with rubber-coated jaws, with loops for lifting by crane.

Traverses with a vacuum grip are also used to lift the panels. If the panel is not large or heavy, it can be lifted and secured manually. The panels are mounted taking into account all the technological holes specified in the project.

Installation of roofing sandwich panels

Openings for windows, doors, utility networks are marked and cut out on the ground. In this case, the proverb “measure seven times and cut once” is very useful; panels cost from 1,500 rubles per 1 m2 and if they are not cut correctly, then in most cases you will not be able to install it anywhere.

Mark the holes on the sandwich on both sides and cut it with an electric jigsaw with metal files. When cutting with a grinder and a metal cutting wheel, the edges on the panel turn out torn. Screwdrivers are also used to fasten panels with screws to the building structure. The equipment used is a crane and a telescopic tower, which work in pairs.

Balcony door for my friend

Friends and acquaintances often turn to me for advice on glazing apartments and houses. This time I was selecting glazing options for my friend’s apartment. And if everything with the windows was clear and simple, then we didn’t manage to choose a balcony door right away.

The stereotype of “transparent top, white bottom” turned out to be so tenacious that I had to spend a lot of effort to convince her to consider different options. In the end, a completely glass door without lintels was chosen. Her friend now admires her, and her guests are surprised, “Was it really possible?” There is much more light, and the small kitchen looks more spacious!

Photo: © depositphotos

But I would like to start not with door options, but with the legal side of the issue, which apartment owners forget about. When replacing balcony doors, there is often a temptation to change their shape and/or size. Make the opening wider, remove the window sill block and combine the balcony with the room. So, this is all considered a redevelopment and it is far from a fact that it will be allowed.

So, what not to do:

- Remove the balcony block and combine the balcony or loggia with the room, since this is a violation of the thermal circuit. You are connecting an additional room for which the heating system is not designed. And insulating the balcony does not help at all. For such amateur activities, fines are provided, and in exceptional cases even the sale of the apartment at auction.

- Expand the doorway using side walls, a wall above the door and a threshold.

You can, if you can get permission:

- Remove the window sill block (the part of the wall under the window) and install a warm swing, sliding or folding door. The key word is warm. Simply installing a glass partition (frameless glazing or cold aluminum sliding) to divert eyes will not work; such alterations will not be approved.

You can without permission:

- Change the design of the window facing the glazed balcony, for example, install a window without a lintel, instead of a double-hung one. Or instead of an opening one, put a blind one.

- And, of course, you can install a window + door balcony block in strict accordance with the existing opening. Remember that the color of the profile on the outside should be the same as on the entire facade of the house. Through the glazed balcony the color of the balcony block is visible.

The friend did not want to deal with permission for redevelopment and immediately refused the sliding door. But, for the sake of completeness, I will tell you about all possible configurations of balcony doors.

Completion of the installation of sandwich panels

After installing the panels, preparatory work begins for the installation of windows and doors. Windows and doors are not attached to the panels themselves, but to metal plates welded to the columns or crossbars of the building. After this, windows and doors are installed and the final stage is the installation of shaped elements.

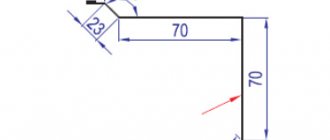

Window fastening unit to sandwich panels

Before installing the shaped parts, all empty cracks are filled with polyurethane foam. Shaped elements consist of strips, window sills, ebbs, external corners, cornices.

Installation of vertical flashings will be inserted from the bottom up, so that the whips are located along the flow of water to prevent it from getting inside. The shaped elements are fastened with self-tapping screws and the joints are sealed with sealants. How to properly seal and the consequences of poor quality work can be found in this article.

Features of the appearance of door structures

If you look at the design, then doors of this type look at least no worse than similar products made from other materials. The buyer receives a door of any color specified in the catalogue. The PVC structure can be filled with either a sandwich panel or a high-quality double-glazed window, as well as various combinations of both. At the same time, at the request of the customer, the filling glass can be corrugated or tinted. There are also options on the market that imitate the appearance of a wooden surface. Doors made of metal-plastic are available as sliding and swing doors.

When ordering a metal-plastic structure, decide on all the nuances, including the type of double-glazed window, PVC profile and fittings, as well as the color and finishing options of the product and the filler required by the customer - glass or sandwich panel.

To save money, I cover the door with plastic panels myself. This is also useful in cases where the door has lost its appearance after prolonged use. After covering the structure with your own hands with PVC panels, it regains its attractive appearance.

Appearance of traditional sandwich panels designed for use with plastic doors

My experience in installing sandwich panels

Everyone has ever had to do something for the first time. This was the case with my editing work. It seems like you read all the instructions, study the drawings, and still, while working, you wonder if you’re doing it right. This is because you don’t know what result to expect.

The article “My Construction Site 3” describes the beginning of my next shift at a construction site and my first acquaintance with the installation of sandwich panels and their dismantling. At this checkpoint facility, sandwich panels were installed and dismantled 5 times.

The panels are installed once, as they break easily and the insulation peels off. The appearance of these panels has deteriorated greatly after repeated installations.

The first mistakes did not check the geometry of the metal structures. During the installation of the panels, the corners turned out to be uneven; I had to cut some panels lengthwise and large gaps.

Due to non-compliance with the diagonals of the building frame, the roofing panels had to be cut, since the joints and exits along the edges of the building panels did not match.

We couldn’t find grips or clamps for installation. They made holes along the edges of the sandwich panel, threaded a wire for lifting with a crane, and installed it this way. In several cases, the wire cut through the thin metal of panels, resulting in them falling and breaking.

They installed the panels, but did not paint the welding joints of the metal frame, did not apply the tape, the customer forced it to be dismantled. After numerous mistakes, the work on installing the sandwich panels got better and everything went fine.

True, there were similar mistakes at other sites; workers cut the opening out of size, and a new panel had to be ordered.

The panels arrive at the construction site in a film, which serves to protect the coating during transportation. The film on the outside is removed immediately during installation, and the film on the inside can be removed after completion of work. At some sites, I saw such a picture, workers were tearing off the film on the sandwich panels in small pieces, since they didn’t tear it off right away, it stood for a long time and the glue dried out.

Video from the construction site showing how the frame of the columns is installed (children under 16 are not allowed to watch; there is profanity) and at the end of the video the installation of sandwich panels is shown

You can find out what types of sandwich panels there are in the article “PVC Sandwich Panels”. After you have installed the sandwich panels, the next step is installation of the strips; read about the pitfalls in this matter here.

Where can I buy a PVC door at a profit?

The price of plastic door structures from the Okna-Star company is one of the lowest in the Moscow region, since we have our own production, a full staff of employees from engineers to installers, and our own fleet of vehicles.

The cost of the company's products does not contain trade or intermediary markups, since all materials and components come directly from manufacturers at wholesale prices.

The company often carries out large-scale orders, after which there is a surplus that is sold at discounts. Sale at the enterprise - an opportunity to buy ready-made PVC entrance doors at a significant discount - up to 50% of the cost. At the sale you can also inexpensively buy interior and balcony door structures with glass or sheet PVC profiles, and windows of standard sizes.

If you need a high-quality entrance, interior or balcony plastic door with or without glass, send a request through the website or place an order by calling the specified phone number.

| Delivery | |

| Delivery within the Moscow Ring Road | 2 500 ₽ |

| Delivery in Podolsk region | From 1600 ₽ |

| Delivery more than 10 km outside the Moscow Ring Road | From 2900 ₽ |

| Delivery over 20 km beyond the Moscow Ring Road | From 3300 ₽ |

| Delivery over 30 km outside the Moscow Ring Road | From 3700 ₽ |

| Delivery over 40 km outside the Moscow Ring Road | Calculated individually |

Tips for choosing balcony doors

A few more recommendations to help make a comfortable and safe balcony door:

- There is not a single person in my circle who has not been locked out on the balcony at least once.

Photo: for your balcony door, choose a double-sided handle with a key-locking hardware, for example, Roto NT. Double-sided handles, unlike external opening handles, are available in different colors, © Roto Often, small children, while playing, cover their mother, who is hanging up the laundry. It will be very difficult to break into a closed door to get into the apartment. A simple balcony handle, which is recommended by managers of window companies, in this situation is not a helper, but a pest.

If you feel sorry for 2000 rubles when buying a door, imagine that you are locked on the balcony, and your one-year-old baby is alone in the apartment. Believe me, if you ever find yourself in such a situation, you won’t mind 10,000, but you won’t be able to make a beautiful handle on both sides, so order it right away. Please note that this option is not provided in economy accessories.

- If you choose an all-glass door, I strongly recommend installing an anti-vandal film on the inner glass or using triplex. Especially if there are small children in the house. Broken glass is a scary thing, and the film will prevent fragments from flying away and injuring a person.

- Triplex is installed not only for safety, but also for sound insulation. And if you have a work office planned on your balcony, then don’t save money, but get yourself a triplex. You will ensure silence, even when the whole family is gathered at home, and the children are “walking on their heads.”

- When deciding to widen the opening or demolish a window sill block, remember to obtain permission. Don't expect that no one will find out. Today you are not planning to sell your apartment, but what will happen in a few years? With such unauthorized alterations this will be impossible.

- If the balcony is glazed and insulated, then you can choose a single-chamber double-glazed window for the balcony door. And if not, then it is better to choose a warm profile from 70mm wide, and a 2-chamber double-glazed window with energy-saving I-glass.

- You can save on glazing if you install a blind window in the balcony block. It will increase the natural light in the room and expand it visually.

- In any case, you shouldn’t skimp on accessories. A door, especially an all-glass door with a 2-chamber double-glazed unit, weighs much more than a window sash, and the fittings are subject to greater loads. Therefore, it is better to opt for well-known brands that can withstand the weight of heavy structures and give preference to tilt-and-turn fittings. You don’t want problems with the door such as sagging and distortions after a few years, do you?

Balcony door with Roto* fittings |

Average prices

Average prices for sandwich panels depend on the material from which the plates and internal filler are made, as well as the external finish:

Bauset TPL (3000×1500x9) – 2200 RUR/piece;- Thermoplastic ST matte 10 mm – 750-1000 r/piece;

- Rosstar ST glossy 10 mm – 1100 RUR/piece;

- Thermoplastic ST 10 mm laminated – 7000-11000 r/piece;

- Bauset RSFoam 5х2030х3050 – 9200 r/pcs;

- HPL Fundermax facade panels 2800x1300x4 mm – 24,000 RUR/piece.

Material requirements

Sandwich panels that are used for slopes of residential premises must consist of materials that, when heated from the sun's rays, will not release harmful chemical fumes into the air. The water absorption of the panel should not exceed 0.55%, and the flammability of the product should correspond to class G1.

The panel itself must adequately protect the window opening and mounting seam from the external environment, and also have sufficient strength so as not to be damaged by mechanical influences. Sandwich panels must have a warranty period of at least 5 years.

The panel must be resistant to wear and temperature changes, and also not lose its shape during the entire designated period of operation, as this will affect the insulating properties and appearance of the slopes.