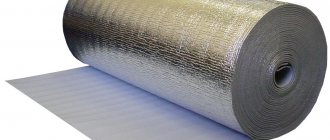

In order to save money on heating the home and to create a comfortable microclimate, the building is insulated with insulating material that has low thermal conductivity. A wide range of insulation materials allows you to choose the most optimal option for a specific design. Among the innovative proposals that deserve attention is Tepofol. The article will discuss the properties and advantages of insulation.

Tepofol is a rolled type of insulation made from polyethylene foam. On one or both sides the canvas is covered with a foil layer (depending on the type of heat insulator). The thickness of the material is available in an assortment (from 2 to 150 mm). Due to its physical properties, Tepofol has the ability to reflect radiation up to 97%, due to which the effectiveness of thermal protection increases.

The new generation heat insulator has a number of advantages, one of which is durability. Tepofol is not subject to shrinkage or abrasion; it retains its properties throughout the operation of the entire building. Therefore, there is no need to plan to replace the heat-protective layer. Real savings on energy resources during the heating season are about 30%.

Characteristics of penofol

This material has the following range of performance characteristics:

- operating temperatures range from -60°C to +100°C;

- thermal reflection on the surface reaches 95 – 97%;

- thermal conductivity indicators depend on the conditions under which the material is used and range between 0.037 and 0.052 W/m°C;

- moisture absorption per volume ranges from 0.35 to 0.7%, this value guarantees high-quality protection of the frame or ceiling from possible moisture ingress;

- if the thickness is 4 mm, then the specific weight will be 44 or up to 74 kg/m3 (this indicator greatly depends on the type of material);

- vapor permeability is no more than 0.001 mg/m h - penofol is an excellent protector against evaporation;

- ultimate compressive strength – up to 0.035 MPa;

- specific heat capacity is 1.95 J/kg°C;

- sound is absorbed - not lower than 32 dB.

More detailed technical characteristics of foil penofol can be found in the table below.

| Characteristics | Types of penofol | Units | ||

| Type A | Type B | Type C | ||

| Optimal temperature | from – 60 °C to +100 °C | °C | ||

| Surface thermal reflectance coefficient | ≥ 95-97 | % | ||

| Thermal conductivity coefficient (I) in dry condition at 20°C | ≤ 0,037-0,049 | ≤ 0,038-0,051 | W/m °C | |

| Water absorption by volume | ≤ 0,7 | ≤ 0,6 | ≤ 0,35 | % |

| Specific gravity (at 4 mm thickness) | 44 + / — 10 | 5 4 + / — 10 | 7 4 + / — 10 | kg/m3 |

| Dynamic modulus of elasticity (Eq) - under load 2 Kpa - under load 5 kPa | 0,26 0,77 | 0,39 0,72 | 0,26 0,77 | MPa |

| Relative compression (Eq) - under load 2 Kpa - under load 5 kPa | 0,09 0,20 | 0,03 0,12 | 0,09 0,20 | units |

| Heat absorption coefficient (S) at a period of 24 hours | 0,51 | 0,45 | 0,51 | W/m² °С |

| Vapor permeability | ≥ 0,001 | mg/m h Pa | ||

| Compressive strength | ≥ 0,035 | MPa | ||

| Reduced impact noise level reduction index | A3003-17 | A3005-19 | A3010-21 | dB(A) |

| Specific heat | 1,95 | J/kg °C |

Application of penofol

This universal type of material is well suited for insulating multi-storey buildings or a summer house in the country. The material is known and popular both in repairs and in fundamental construction.

Penofol is widely used in construction:

- For thermal insulation:

- in hangars or warehouses, heated or cold;

- residential premises;

- for refrigerators, vans or railway carriages, in cars;

- saunas or baths;

- during the construction of children's medical institutions;

- industrial buildings and administrative complexes;

- during the construction of shopping centers, shops, and so on;

- when insulating different types of pipelines;

- for chambers of refrigeration units;

- in water supply, heating or ventilation systems;

- for insulating equipment and machinery (ducts, boilers, etc.).

- To insulate parts of structures:

- when treating ceilings or floors;

- for insulation of window or door systems;

- processing of external and internal walls of buildings;

- for covering in basements and unheated types of premises;

- heat, hydro or vapor barrier of attics or roofs, roofs of various types;

- in the shielding of heating radiators.

It must be remembered that penofol not only helps to keep rooms warm in winter. If you lay it at the bottom of the roof, it will prevent the penetration of summer heat.

Material advantages

The appearance of a new type of insulation on the market did not go unnoticed. The great interest in the material and technology is explained by the following advantages:

• good noise absorption;

• moisture resistance;

• high mechanical strength;

• inertness to the formation of mold and mildew, as well as corrosion;

• the ability to pass air, which allows the walls to breathe;

• light weight of the product, this prevents overloading the load-bearing structures of the house;

• environmentally friendly, during operation the insulation does not emit toxic substances;

Tepofol NPE - Foil-coated (Foil) on one side / Metallized (Lavsan) on one side

Name

| Thickness | Dimensions | Square | Photo | Price per m2. | |

| Tepofol 2mm foiled on one side | 2mm | 1.05mx50m | 52.5m2 | Photo | 18 |

| Tepofol 3mm foil on one side | 3mm | 1.05mx50m | 52.5m2 | Photo | 19,5 |

| Tepofol 4mm foil on one side | 4mm | 1.05mx50m | 52.5m2 | Photo | 22.5 |

| Tepofol 5mm foil on one side | 5mm | 1.05mx50m | 52.5m2 | Photo | 24,5 |

| Tepofol 8mm foiled on one side | 8mm | 1.05mx25m | 26.25m2 | Photo | 35 |

| Tepofol 10mm foiled on one side | 10mm | 1.05mx25m | 26.25m2 | Photo | 38 |

| Tepofol 15mm foil on one side | 15mm | 1.05mx25m | 26.25m2 | Photo | 115 |

| Tepofol 20mm foil on one side | 20mm | 1.05mx25m | 26.25m2 | Photo | 125 |

| Tepofol 30mm foiled on one side | 30mm | 1mx2m | 2m2 | Photo | 185 |

| Tepofol 40mm foiled on one side | 40mm | 1mx2m | 2m2 | Photo | 240 |

| Tepofol 50mm foiled on one side | 50mm | 1mx2m | 2m2 | Photo | 280 |

Characteristics of penofol

This material has the following range of performance characteristics:

- operating temperatures range from -60°C to +100°C;

- thermal reflection on the surface reaches 95 – 97%;

- thermal conductivity indicators depend on the conditions under which the material is used and range between 0.037 and 0.052 W/m°C;

- moisture absorption per volume ranges from 0.35 to 0.7%, this value guarantees high-quality protection of the frame or ceiling from possible moisture ingress;

- if the thickness is 4 mm, then the specific weight will be 44 or up to 74 kg/m3 (this indicator greatly depends on the type of material);

- vapor permeability is no more than 0.001 mg/m h - penofol is an excellent protector against evaporation;

- ultimate compressive strength – up to 0.035 MPa;

- specific heat capacity is 1.95 J/kg°C;

- sound is absorbed - not lower than 32 dB.

More detailed technical characteristics of foil penofol can be found in the table below.

| Characteristics | Types of penofol | Units | ||

| Type A | Type B | Type C | ||

| Optimal temperature | from – 60 °C to +100 °C | °C | ||

| Surface thermal reflectance coefficient | ≥ 95-97 | % | ||

| Thermal conductivity coefficient (I) in dry condition at 20°C | ≤ 0,037-0,049 | ≤ 0,038-0,051 | W/m °C | |

| Water absorption by volume | ≤ 0,7 | ≤ 0,6 | ≤ 0,35 | % |

| Specific gravity (at 4 mm thickness) | 44 + / — 10 | 5 4 + / — 10 | 7 4 + / — 10 | kg/m3 |

| Dynamic modulus of elasticity (Eq) - under load 2 Kpa - under load 5 kPa | 0,26 0,77 | 0,39 0,72 | 0,26 0,77 | MPa |

| Relative compression (Eq) - under load 2 Kpa - under load 5 kPa | 0,09 0,20 | 0,03 0,12 | 0,09 0,20 | units |

| Heat absorption coefficient (S) at a period of 24 hours | 0,51 | 0,45 | 0,51 | W/m² °С |

| Vapor permeability | ≥ 0,001 | mg/m h Pa | ||

| Compressive strength | ≥ 0,035 | MPa | ||

| Reduced impact noise level reduction index | A3003-17 | A3005-19 | A3010-21 | dB(A) |

| Specific heat | 1,95 | J/kg °C |

Features of the use of tepofol types

There are two main categories of this insulator:

- with metallized coating;

- with foil surface.

The first option is good because it has such an important property as the ability to pass steam. This allows the use of this tepofol insulation (or rather heat insulator) in rooms with high humidity, for example, such as shower rooms, baths, saunas

Well, plus you need to think about whether it is worth using a metalized version in case of indoor insulation. The fact is that it is impossible to reflect infrared heat waves here, so mounting this material, for example, on the wall behind heating radiators, is pointless.

But foil material will be very effective in such a situation. The main rule here is that the thicker the foil, the better the ability to reflect heat. By the way, this “Tepofol” is also more resistant to mechanical loads (the level of resistance here also depends on the thickness of the coating).

However, all of the above is not at all a call to use foil insulation. For example, to insulate a concrete floor, it is better not to do this, because the aggressive alkaline effect of the cement-sand mixture will “eat up” the foil completely. At the same time, the metallized layer will last for many years.

It turns out that each option is good in its own way, you just need to understand why exactly the material is being purchased and, depending on this, make a decision about purchasing one or another type of insulator.

Now regarding the scope of application.

Where can I use Tepofol?

Since the structure of the product has not only thermal insulation characteristics, this determines a fairly wide range of tasks where an insulator would not be superfluous.

In particular, the material is purchased for the following purposes:

- to ensure sound and thermal insulation of air ducts and ventilation ducts;

- for insulation and sound insulation of various walls, partitions and ceilings, as well as floors;

- for covering roofs and attic-type premises;

- for installing a reflective plane behind heating radiators;

- for insulation of pipelines and foundations.

If we talk about specific properties, then we can highlight the following:

- absolute environmental safety - the material does not emit any fumes;

- “Tepofol” does not rot and mold and mildew do not form on its surface;

- a light weight;

- the coating is not afraid of rodents and insects.

Well, the insulation characteristics of each product are different - a lot depends on the thickness, type of surface, operating conditions, etc.

Briefly about the main thing

Thermal insulation Tepofol is made of polyethylene foam. The basis of the material is carbon and hydrogen – i.e. Tepofol is completely safe for people and the environment.

Unlike competitors' products, the thickness of finished Tepofol sheets can reach 150 mm.

As a reflector, instead of foil, a lavsan coating is used - on one or both sides. This increases the energy efficiency of the insulator due to its ability to reflect heat.

Although, at first glance, Tepofol is more expensive than its competitors, it must be taken into account that the material is impervious to moisture, and to create a heat-insulating carpet, additional protection from steam, water and wind is not needed. Plus, the material has an almost unlimited service life.

A patented locking connection is used to connect Tepofol sheets to each other. The lock warms up during installation, and the insulation is glued together, forming a continuous heat-insulating layer without cold bridges.

What to choose?

In installation and operating parameters, the differences between Penofol and Tepofol are not significant. Both materials demonstrate:

- the presence of adhesive or locking installation;

- resistance to aggressive destructive influences;

- compliance with environmental safety standards.

Tepofol or Penofol, what to choose?

The criterion may be the availability of modifications for sale with the characteristics specified by the project, the provision of seasonal discounts and other economic business preferences. If you have any questions about whether to choose Penofol or Tepofol, dial the number. Our managers will provide a free consultation and help with calculating the amount of building materials. Don't waste time, make your home warmer and more comfortable!

Penofol

About the manufacturer

Penofol is a brand produced by LIT Plant, which was founded in 1979. The company was the first in Russia to begin applying a reflective layer of foil to the surface of foamed polyethylene. Thanks to this fact, the Penofol trademark is widely known in the Russian market.

Very often, the consumer calls penofol any insulation made of foamed polyethylene with a reflective surface. And this despite the fact that in Russia there are about 30 similar manufacturers with their own brands.

The main activities of the enterprise are:

- production of energy-saving materials based on polished aluminum foil, operating on the principle of reflecting heat flow (reflective thermal insulation), intended for insulation of enclosing structures of residential and industrial buildings;

- production of materials from foamed polyethylene intended for technical thermal insulation of heating and water supply, ventilation and air conditioning systems, for use in “warm floor” systems, as well as for protecting thermal insulation from mechanical damage, atmospheric influences and ultraviolet radiation.

The company is successfully developing and producing products for various purposes under the trademarks: PENOFOL, TILIT, ARMOFOL, TITANFLEKS, used in construction.

About products

A distinctive feature of Penofol is its blue color. In principle, only foil is used as a reflective layer. Excellent quality material with an adhesive layer, one of the best on the market, if not the best.

Since 2015, LIT Plant began producing the updated Penofol material with additional protection against counterfeiting - a hologram, which is printed on both sides on polished aluminum foil.

Self-selection criteria

What is better Penofol or Tepofol? Judging by this review, the performance properties of both insulation materials do not differ significantly, and the price of a 25-meter roll ranges from one and a half thousand to 1,800 rubles. The difference between Penofol and Tepofol is also the possibility of sealing Tepofol installation joints with hot air from a hair dryer.

By choosing one of the insulation materials, the Baustov company guarantees you that you will win in any case, since both insulation materials have equal effective heat saving and a long service life.

Call! We will calculate for FREE

8

Head of Sales Department

Energoizol

- home

- Energoizol

Sort by:

Sort by:

Brand: Energoizol

The Energoizol company produces and sells thermal insulation materials based on foamed polyethylene.

The material is made from high-density polyethylene by foaming with an isobutane mixture using environmentally friendly technology (without the use of freon), which is confirmed by many tests and quality certificates.

Energoizol has excellent sound, vibration, hydro, and of course heat insulating properties. It is used in many areas as a heat-insulating material and is not afraid of temperature fluctuations. It does not change its structure under the influence of high and low temperatures. Durable and has a high melting point. Environmentally friendly, hypoallergenic.

The material can be used as a thermal insulator even in low-temperature freezing units. The structure of the material and its heat-insulating properties will not change in any way due to low temperatures.

Energoizol is duplicated with reflective layers - foil and metallized film (lavsan) to increase its heat-saving properties, which actually gives the “thermos effect”.

A flexible system of discounts and an individual approach to each customer makes working with us mutually beneficial, and the offered price is the most reasonable.

Types of metallized insulation

There are a huge number of insulation materials with a foil layer. Almost every manufacturer of thermal insulation materials has a line with foil coating, and everyone calls their products differently; accordingly, the same material can have a different name. Folgoizol, foil plastic, energoizol, all this is practically the same material.

Let's look at the most popular types of metal-coated insulation.

Foiled polyethylene foam

The most popular foil-coated material is made from polyethylene foam. It can be two or three layers.

It is used everywhere in the construction of houses, baths, saunas. Also used for sound insulation and insulation of cars. Can be used as a backing for laminate and other floor coverings.

The thickness of the foil coating rarely exceeds 15 microns. The foil layer can be applied on both sides of the insulation, due to which the material is able to reflect both internal heat and cold penetrating from the outside of the room.

The base made of foamed polyethylene is environmentally friendly, does not rot and resists moisture well. It has internal pores filled with air, due to which it has good thermal insulation characteristics.

Important! This insulation is most often used for thermal insulation of bath rooms and bathrooms.

Foamed polyethylene with foil coating is produced by the following companies:

- isover;

- isocom;

- TechnoNIKOL;

- isolon.

It is worth noting that there are several technologies for the production of foamed polyethylene:

- The usual, inexpensive one is produced using foaming technology, after which it does not undergo additional processing; as a result, its resistance to dynamic loads is not high enough. Simply put, the material is subject to shrinkage.

- The second method is cross-linked polyethylene, after production it undergoes special processing, due to which it becomes denser and, after removing the load, tends to restore its original shape and size.

Interesting: builders call foamed polyethylene with a metal film applied to the surface “shiny.”

To install such thermal insulation, no specific skills are required:

- It is enough to unroll the roll, cut off the required amount of material and secure it to the insulated surface.

- For fastening, you can use a construction stapler.

The second option for fixing the “shiny” is to press it down with laths for siding or lining. The insulation is laid with an overlap of no more than 10 cm, the joints are glued with metallized tape and pressed with a lath or fixed with staples.

Foiled mineral wool

Another type of insulation with a metal coating is mineral wool.

It is mainly used for external insulation or for thermal insulation of attic rooms. Mineral wool (glass wool), even without a metal layer, has good thermal insulation qualities. The presence of a metal layer on the surface only enhances its effectiveness.

Mineral wool also has its disadvantages. First of all, it is afraid of moisture, so for interior work it is used only for dry rooms, mainly for insulating roofs. The second feature that must be taken into account is almost zero load resistance. This means that even a slight weight of the load can compress the mineral wool, as a result of which the thermal insulation properties are sharply reduced. Using mineral wool for floor insulation is not effective.

Often, mineral wool with a metallized coating is used for insulation of pipelines and chimneys. This is due to the low flammability of the material and the ability to withstand temperatures up to 300 degrees.

Installing such insulation is a little more difficult than the previous one:

- For fastening to concrete, brick and gas-block bases, special dowels for insulating materials are used, the head of which is wide, due to which it does not break the loose structure of the insulation.

When carrying out work on insulating a bath room, it is not recommended to use mineral wool with foil to insulate the ceiling from the inside. Moist steam, penetrating into the structure of the mineral wool, condenses, due to which the material becomes damp and, in contact with wooden parts of the structure, can cause them to rot.

- It is better to lay slabs of foil wool on the back side of the ceiling boards, outside the room. This scheme will prevent the insulation from getting wet, as a result of which the loss of useful heat in the room will be reduced.

Foiled polystyrene foam (with double-sided foil)

The material is used in damp rooms. Thanks to the foil layer, it reflects heat and prevents moisture from entering the material.

Expanded polystyrene is a derivative of polystyrene foam. The structure is dense, finely porous, due to this it resists external loads well. It can easily support the weight of an adult, so you can step on it during installation. The material is recommended by manufacturers as a basis for laying a heated floor system.

Some companies apply special marking lines to the top layer of metallized film, with the help of which it is convenient to control the correct installation of heated floor heating elements.

It is rarely used to insulate the walls of a house, because... It costs a little more than regular polystyrene foam and its use is not economically feasible.

Basalt foil thermal insulator

The material has features that distinguish it from other metal-coated insulation materials.

The fact is that a basalt slab can withstand temperatures up to +700 degrees. This makes it possible to use the material in the construction of buildings that must meet the highest fire safety requirements.

For example, foil-coated basalt slabs are used in the construction of gas stations.

Types of penofol

Manufacturers offer different penofol options for different functionality. The generally accepted classification divides it into three varieties:

- A type – one-sided penofol (aluminum film is applied to one side of the polyethylene after foaming).

This type is used more often as an additional heat insulator with foam; Penofol type A - B type – penofol foil-coated on both sides, has universal use, including for autonomous insulation;

Penofol type B

C type – self-adhesive. On one side there is a layer of reflector on aluminum, on the opposite side there is a moisture-resistant adhesive on polyethylene foam, which is protected by a sticker. This penofol is more convenient for finishing areas that are difficult to reach. No special installation tools are required during installation.

Penofol type C

In addition to these standardized types, the developers have also prepared modifications that occupy a separate niche in the building materials market:

- ALP type - penofol with lamination, on the foil side there is a plastic film. This type of material is used for insulation of agricultural buildings operated in a not too aggressive environment;

- M or R types – one-sided foil with a corrugated “top”;

- AIR – penofol used to prepare air exhaust structures;

- Super NET (from the word “Network”) - the main task of this type of penofol is insulation and steam protection for air vents, pipelines or heating mains.

Explosiveness and toxicity

Temperature limits for use are from +100 to -60 degrees Celsius. At such temperatures, Penofol is an absolutely environmentally friendly material and is completely non-toxic. When using it indoors or outdoors, no precautions are required. The sticky adhesive used in the manufacture of Type C insulation is non-toxic. The adhesive used is based on a water-acrylic dispersion. The emulsion used is non-explosive and non-toxic. Hazard class - 4 (low hazardous substances). The material applied to the adhesive base to protect it is a lavsan siliconized film. Non-toxic.

Penofol parameters

What is Penofol?

Nowadays a lot of materials are produced under the brand name PENOFOL. Perhaps it is worth listing those that are most in demand. Among them we can highlight the classic Penofol, covered with aluminum foil on only one side. This Penofol is type “A”.

Penofol, which is foiled on both sides, is type “B”. Penofol of both these types is quite dense and also resistant to physical stress.

Penofol type C belongs to the category of self-adhesive materials. In it, a polished aluminum coating is applied to a layer of foamed polyethylene on one side, and on the other, a layer of moisture-resistant glue and a film that prevents the adhesion of materials. This type of insulation is used where regular Penofol is not suitable or is too expensive, because no additional devices are needed to attach it.

There is also Penofol, which has perforation. It can also be single-sided or double-sided and was produced not so long ago, and is used for thermal insulation of facades from the outside. Perforation allows moisture to escape from the material. In other words, walls insulated with such material can “breathe”.

About the thickness of Penofol

The thicker the insulation, the more expensive it is. And the price and technical characteristics of foil Penofol are influenced by the number of layers of aluminum foil: there can be one or two. As for thickness, its standard sizes are: 10, 8, 5, 4 and 3 millimeters. You can understand that centimeter-thick material with a double layer of foil will be the most expensive. By the way, it not only stores heat better than anyone else, but also protects well from noise.

In terms of optimal price-quality ratio, Penofol with a thickness of 0.5 centimeters came out on top. If maximum thermal insulation, as well as protection from noise and moisture, is required, then it is better to opt for a centimeter layer of Penofol. As for the other parameters of the insulation, they also depend on the thickness of its layer, as well as on its type.

About Penofol's heat conductivity

Since this insulation is combined, combining heat reflection and absorption, it is difficult to compare it with traditional heat insulators. Penofol insulation helps reduce convection due to the polyethylene foam layer, and the foil layer on the outside can reflect up to 97% of heat rays. The result is comprehensive insulation.

And yet, let’s try to compare, if not the thermal conductivity coefficient, but the heat transfer resistance of Penofol and other insulation materials. If we take this material with a thickness of 4 to 5 millimeters, covered on both sides with aluminum foil, we get a heat transfer resistance of 1.2 to 1.23 square meters-degrees Celsius per watt. To achieve the same result, the layer of mineral wool should be no less than 8 or 8.5 centimeters. Data are calculated according to SNIP II-3-79.

About the material's absorption of water

Penofol almost does not absorb moisture, and it does not matter what humidity the air has indoors and outdoors. This does not depend on the change of season or change in temperature. This distinguishes this insulation from most modern heat insulators.

This distinguishes this insulation from most modern heat insulators.

About the vapor permeability of Penofol

There is no need to lay a vapor barrier film when using Penofol. After all, its vapor permeability coefficient does not even reach 0.001 milligrams per meter-hour-Pascal. We can say that this insulation is an excellent barrier to fumes.

Sound resistance

Speaking about the sound absorption of Penofol, we can name the following number: 32 decibels. This is precisely the sound absorption that class “A” material has. It is mounted not inside the frame of the building structure, but on top of it, with no seams. Therefore, it allows you to protect yourself from various noises: both acoustic and structural. This versatility is a definite plus.

Fire protection

According to the standards, this material is classified as substances that are difficult to burn and do not support combustion. The Research Institute of Construction Physics issued Penofol a certificate of conformity confirming that the material is not a fire hazard. When burned, polyethylene releases water and carbon dioxide. True, if there is not enough oxygen, carbon monoxide may appear.

Service life and safety

One of the cleanest materials in terms of ecology is polyethylene foam. Therefore, it is this that underlies Penofol. By the way, in terms of durability (200 years) this substance can be given the highest score. At the same time, you will be able to protect yourself from the harmful effects of electromagnetic radiation. They can be reduced by two or even ten times.

Reflective thermal insulation technology: 3 installation steps

Reflective thermal insulation is inexpensive, so most people can afford it. Reflective thermal insulation necessarily contains foil.

Among the most popular insulation materials are penoform, penoizol, penophenol, technofol, penofol, tepofol and other analogues.

Using material with a reflector, you can insulate any surface, wall, ceiling of a timber or brick house, create a heated floor system or provide sound insulation.

The insulation for walls can be either regular foil or insulation with foil on one or both sides. The operating principle of such a system is based on the reflection of infrared rays. The foil itself can be insulation, but it is more appropriate to call it "reflective insulation."

The insulation can be:

- Styrofoam;

- Closed cell polyethylene foam;

- Mineral or stone wool.

All insulation materials can be sold both in sheets and in rolls. The safest is considered to be filament insulation made from stone wool. It is mainly used for baths, since the material is non-toxic and does not allow moisture to pass through. Thanks to these properties, reflective thermal insulation can be used for chimneys and any other heated surfaces.

Polymer insulation cannot be used for surfaces with temperatures above 85 degrees.

Reflective thermal insulation may vary in thickness and quality of materials used in its manufacture

Plastic or polyethylene begin to lose their properties at temperatures above 90 degrees. In addition, polymers are used only for internal use. The exception is pipe boxes. When sheathing a house, the effectiveness of polymers as insulation is not observed. But it provides sound insulation and a wind barrier.

Features of penofol: properties and characteristics

Penofol has a wide range of uses. It is used for residential and non-residential buildings, making cladding both inside and outside. This popularity is due to the excellent technical characteristics of the material.

Properties of penofol:

- It has a small thickness. The maximum value for this indicator is 1 cm. This directly affects the cost of the product. For interior work, the optimal thickness is 5-7 mm.

- The thermal conductivity of a foil insulator is difficult to calculate. Typically, heat transfer resistance is used. For double-sided foam foam with a thickness of 5 mm, the resistance is 1.23 m2/S/Watt. When using mineral wool, this indicator can only be achieved with a material thickness of 8 cm.

- Penofol does not allow moisture to pass through.

- The material provides sound insulation. To improve this indicator, all joints will need to be sealed.

- Due to its excellent vapor barrier properties, there is no need to install a corresponding layer.

Penofol is resistant to the negative effects of the external environment. So the material can be used at temperatures up to 100 degrees. It is environmentally friendly, not harmful to health, and resistant to chemicals. Manufacturers talk about the durability of penofol, but this information is not confirmed by research.

Installation of penofol does not require the installation of a vapor barrier layer.

The material is difficult to ignite and does not spread flame. This allows the use of penofol in different buildings. With its help you can reduce heat loss in the room.

Using foiled thermofol: characteristics and advantages

Teplofol is a polyethylene foam. The thickness of the material is small, and the outer covering is made of foil. The scope of application of insulation is varied. When using pipe lining, tepofor prevents the formation of condensation.

Characteristics of thermofol:

- Able to withstand temperatures from 80 to 105 degrees;

- Has 97% radiation reflection;

- Low vapor permeability;

- Weight is 44 kg per 1 m3.

The material has many advantages. They note its small thickness and high efficiency. Thermofol is quite flexible and easy to install. The insulation can be attached directly to the wall using tape or a stapler. It is compatible with most building materials.

Thanks to foil thermal insulation, you can significantly improve the thermal insulation qualities of any room

Teplofol is not the main insulation; it is used in combination with other heating. In addition, you will have to equip ventilation.

Thermofol is used for all surfaces. Moreover, it is not only insulation, but also sound insulation. The material is durable, moisture-resistant, environmentally friendly and inexpensive.

Scope of application of penofol and thermofol

Reflective insulation can be used on a variety of surfaces. The main thing is that they are clean. And so the material can be used on complex structures. For greater efficiency, an air gap should be provided between the foil and the outer trim. The scope of application of penofol concerns any buildings, attic, bathhouse, car.

Insulation is often used for lining pipes and ventilation. For this, a double-sided type of insulation is used. If the pipes are not thick enough, there is no need to create an air gap. If the pipes are large, then this is necessary.

Air gap equipment options:

- You can attach rings made of foil film at a distance of 30-40 cm from each other. And penofol or thermofol is installed on top of the rings.

- Wooden blocks are installed along the pipe, and insulation is wrapped at the top.

The joints are connected using aluminum tape. It is not uncommon for reflective insulation to be used for roofing. It will not only reduce heat loss, but it is an excellent vapor barrier.

Foil insulation is most effective when treating the ceiling of a bathhouse.

External use has 2 manifestation options. You can make a couple of air gaps: between the wall and the materials, between the insulator and the cladding. Here, insulation with double-sided foil material is used. In the second option, it is enough to make one gap between the wall and the material. Here you will need one-sided foiling.

Detailed instructions for using foil penofol

First, attention is paid to the preparatory work. The electrical wiring in the house will need to be checked. The foil should not come into contact with exposed wires, as the material is too conductive.

Instructions for using penofol from inside the building:

- We make a wooden frame. We fasten the wooden blocks using dowels at a distance no wider than 1 m from each other.

- Using a stapler, we secure the penofol. The insulation will have to be cut into strips with a knife in advance. The material must be laid with an overlap. The seams are removed with tape.

- We will equip another frame for ventilation. Any cladding can be done on top.

Before installing foil foam foam, you should familiarize yourself with the recommendations of professionals and watch a training video with a master class

Often the air gap is made only on one side. This reduces the effectiveness of thermal insulation. The foil must be directed inside the room, and not vice versa.

The nuances of insulating a house with penofol from the outside: pros and cons

Decorating the outside of the house is considered more effective. This is especially noticeable in a wooden structure. Perforated penofol is used as insulation. It will not only reduce heat loss, but also protect the house from wind and precipitation.

Insulation from the outside is carried out when there is no desire to lose the area of the room. The material is mounted between the walls and the outer cladding. The best time for work is summer. Then there are minimal temperature changes, and the walls are as dry as possible.

Sequence of external insulation:

- We remove wall coverings. We treat the surface with an antiseptic. Particular attention should be paid to the bottom and corners. They are the ones who get wet and freeze the most.

- In two or three days we will equip the wooden frame.

- We lay penofol overlapping. We secure the joints with tape.

- We install another frame on top. Then we carry out facing work.

Reflective insulation is considered an excellent option to reduce heat loss. In addition, the material also performs a number of other functions. This way the building will become more resistant to the influence of an unfavorable external environment.

Insulation with foil penofol (video)

The technology for using reflective thermal insulation is quite simple. It is necessary to insulate the house with the foil side facing out. To work, you need the material itself, a wooden frame and fastening elements.

Foil penofol is an insulating material with a reflective effect, which has a multilayer structure. The main purpose is to remove drafts or wind currents from building structures, eliminate condensation or moisture, steam that rise up the tiers.

The material also isolates external noise or sounds. It is a universal type of insulator, as it increases sound insulation, vapor barrier, protects against moisture and retains heat. Such features are due to the structural organization of the material and the technology used in production.

The main part of the material is foamed polyethylene . At the same time, the pores formed on it are closed and filled with air. This polyethylene foam is used in the form of skeins with different densities, thicknesses and different internal structures.

Either on one or both sides, based on the purpose of the material, polyethylene is covered with aluminum foil. Before application, it is processed and polished to a shine with a maximum reflectivity coefficient (up to 97% and even more).

More often, foil is applied using heat welding, which provides better adhesion of the material.

The thickness of penofol is from two to ten millimeters, the foil is only from 12 to 30 microns. The thickness of the material can be increased to 40 mm if it is necessary to create particularly powerful thermal insulation, for example, in arctic climate conditions.

The operation of penofol is based on the “Dewar vessel” principle known in physics. At the beginning of the last century, James Dewar established that every substance has a certain resistance to heat transfer.

Whatever this indicator, the material can only stop or make the movement of heat slower, but not stop it altogether.

At the same time, heat waves are collected in the substance and energy accumulates inside the substance; after some time, supersaturation is created, after which any material itself becomes a source of heat.

Experimenting further, Dewar isolated several substances that did not absorb thermal energy, but reflected it.

Among these were all precious metals (platinum, silver and gold), as well as polished aluminum. In this case, heat rays are reflected from surfaces almost 100%.

These reflectors themselves are excellent heat conductors and should be used together with heat absorbers.

A common thermos works in approximately the same way, and Dewar's research became the basis for the creation of space suits and materials for thermal insulation with a reflective effect.

The use of both double-sided and single-sided insulators reduces the cost of heating rooms in winter, and in warm summer weather they prevent the house from heating up too quickly.

Tepofol insulation: scope, characteristics, advantages, installation features

In order to save money on heating the home and to create a comfortable microclimate, the building is insulated with insulating material that has low thermal conductivity.

A wide range of insulation materials allows you to choose the most optimal option for a specific design. Among the innovative proposals that deserve attention is Tepofol.

The article will discuss the properties and advantages of insulation.

Tepofol is a rolled type of insulation made from polyethylene foam.

On one or both sides the canvas is covered with a foil layer (depending on the type of heat insulator). The thickness of the material is available in an assortment (from 2 to 150 mm).

Due to its physical properties, Tepofol has the ability to reflect radiation up to 97%, due to which the effectiveness of thermal protection increases.

The new generation heat insulator has a number of advantages, one of which is durability. Tepofol is not subject to shrinkage or abrasion; it retains its properties throughout the operation of the entire building. Therefore, there is no need to plan to replace the heat-protective layer. Real savings on energy resources during the heating season are about 30%.

Pros and cons of penofol

When using penofol for insulation, the following advantages can be highlighted:

- Penofol has versatility of use - the material can be used during construction and renovation work, externally or in internal insulation of premises. For example, for balcony insulation.

- It has minimal vapor permeability on the insulation side, which makes it possible to use penofol without additional vapor barrier material.

- It provides good insulation from noise; it is often used in homes and workshops against acoustic type noise.

- Compared to other insulators, the material is quite thin. Penofol on both sides 4 mm thick can replace mineral wool laid out 8.5 cm thick, a layer of pine 1.8 cm thick or as much as 3 cm of extruded polystyrene foam.

- Penofol is easy to install . This material is lightweight, it makes it possible to install thermal insulation without outside help. For the work, no extra tools are needed, the material sheet is simply cut with a knife, it can be secured with a furniture stapler, small nails, or tape.

- Penofol is made from environmentally friendly materials that meet all sanitary requirements. The substances from which it is made are used to store food, and some of the manufacturers even warn that penofol will protect against increased radiation.

- This heat-protective material is highly flammable, which significantly increases the level of fire safety in an insulated room.

- It is too thin for rodents that like to make holes in other insulation materials to live in it.

- Penofol is convenient to transport, the canvas is collected in rolls, they can later be hidden in the trunk of a car.

Even taking into account the enormous variety and number of advantages of foil penofol, it also has a number of disadvantages:

- The material is quite soft, which limits its capabilities. It is not suitable for applying wallpaper or plaster.

- To secure it, you may need to purchase specialized glue. True, there are self-adhesive versions of the material.

- Experts recommend not using this material as insulated external insulation for buildings. It can be attached to reflect heat energy or to protect the entire structure from internal moisture with a separate layer.

Which material is better penoplex or penofol? – Website about

The new apartment has two huge loggias, we are planning to insulate them. Which material to choose to minimize costs, penofol or polystyrene foam? We will do the installation ourselves. There are plenty of renovations in a new apartment, so we want to save money wisely.

- At the beginning, I would like to remind you that external thermal insulation is much more effective than internal insulation.

- Penofol is thinner than polystyrene foam, the usable area of the balcony will not decrease.

- Further, if you buy penofol with double-sided foil,

- Penofol is also not bad sound insulation.

- Polystyrene foam is cheaper, but it is flammable, and foam plastic also needs vapor insulation; by the way, polystyrene foam and penofol are often used in pairs.

- Penofol is a non-flammable material; foam releases toxic substances when burned.

- When insulating with penofol, vapor insulation is not needed.

- Self-assembly is possible, although there are no problems with polystyrene foam, which means there are no leaders on this point.

- Penofol is an environmentally friendly material.

- To summarize and summarize, foam plastic is yesterday, and penofol is a modern material, more technologically advanced, more advanced.

- Penofol is most often used in the case of loggias (again, based only on these two materials).

- In the end, I would like to remind you that when insulating a loggia, one should not forget about an integrated approach, that is, the floors, walls and ceiling are insulated.

- For this reason, different insulation materials are often used, for example, if tiles are planned on the floors, then it is necessary to make a screed over the insulation and here it is better to use (if you choose only from these two materials) polystyrene foam, but with waterproofing of the base.

In construction, the use of high-quality insulation is very important; the energy efficiency of the entire building depends on it.

It’s easy to get confused in the names of modern materials, even though similar words hide completely different characteristics and properties. It seems that there is a big difference: penoplex or penofol.

However, these two heat insulators differ even in appearance, although their applications are largely similar. Penofol has some advantages over penoplex in some cases and is inferior in others.

Rolled foil insulation from 2 to 10 mm

There are several trade names under which foil-foamed polyethylene foam (PPE and NPE) of various modifications is hidden (one-sided foil, double-sided, aluminum coating or foil, self-adhesive, reinforced with mesh or film):

- Penofol

- Izolon

- Tepofol

- Teplofol

- Unifol

- Foil plastic

- Alubable (air bubble polyethylene film)

The main purpose of foil insulation is vapor barrier. Quite expensive vapor barrier, compared to other materials of the same purpose, but irreplaceable in baths and saunas. It is in humid, hot rooms that foil-coated polyethylene 100% fulfills its task: reflection of thermal radiation at a high temperature gradient and vapor-waterproofing.

It also makes sense to use foil vapor barrier in attic floors, since a ventilation gap is always provided there, and wind-vapor-waterproofing is needed.

Installation of foil insulation has a number of features:

- It makes sense to use it only in the first inner layer of the insulation cake and with the foil side facing towards the room.

- Reflective insulation performs its functions only with an air gap of at least 2 cm in front, that is, an air gap must be provided between the finishing material and the foil.

- It is pointless to lay foil material under the screed, since without a ventilation gap, aluminum foil loses its reflective ability and even corrodes from the concrete.

- It is necessary to carefully seal the joints with metallized tape.

- Exhaust ventilation is desirable in rooms that are vapor-insulated with foil material, since we have a “thermos”.

Thermal insulation properties of foil insulation from 2 to 10 mm

The manufacturer claims that penofol laid in one layer is equivalent to laying two bricks. According to the latest SNiPs, the masonry should be 6 bricks, therefore a layer of penofol is needed 5-6 cm. This is all lyrics, of course. Comparing reflective insulation and brick is like cold versus wet. You can also insulate with penofol, only a layer of about fifteen centimeters is needed.

Here's how things really are: 150 mm of mineral wool is 200 mm (67 layers) of A03 penofol, this is calculated by the heat transfer resistance (R) of 0.049 W/m°C of polyethylene foam based on foil insulation. Foil does not have such a characteristic at all. Therefore, thin foil thermal insulation for direct insulation is not provided, no matter what the manufacturer writes on its website.

If, when finishing the walls, an air gap is formed in one way or another (we cover it with clapboard, for example), then it makes sense to use foil insulation or penofol instead of traditional vapor barrier films, but not instead of mineral wool or polystyrene foam.

In 2015, GOST R 56734-2015 on reflective thermal insulation in buildings and structures was adopted; you can read the conclusions in more detail. Foamed polyethylene is transparent to IR, and the foil has no resistance to heat transfer. Together, these materials work exactly to their thickness, not being a panacea in thermal insulation.

Advertisements for thin foil insulation claim that the main heat loss in a house is through infrared radiation (up to 90%), this is a lie. But even if this were the case, heat would escape through the windows, which we cannot cover with foil.

Foil, as a way to increase the energy efficiency of buildings, is not mentioned in SNiP on thermal protection.

Video description

See the progress of the experiment in this video.

The results are shown in the table:

Comparison of insulation - test results Source mycdn.me

Damper tape

Another product that builders cannot do without when working with screeds - dry and cement. An edge strip with a thickness of 5 to 10 mm and a width of 5, 8 or 10 mm is laid around the perimeter of the screed. When used on a wet screed, it promotes more uniform drying.

There are varieties of tape with a polyethylene film “apron”. In the classic version, it goes on sale in rolls of 25 linear meters, but it is also possible to order the material according to individual parameters.

Edge tapes Tepofol Source tepofol.ru

Double-sided foiling

- Energofol

- Ventilated space

- Interior decoration

- Rail

Energofol thermal insulation materials are installed between the outer wall and the finishing (both on the outside and on the outside). In this case, it is necessary to leave a space of 7-20 mm in front of the reflective surface of the material from adjacent surfaces. This is done to effectively use the properties of heat-reflecting materials. In the case of using a material with one-sided coating, the material is attached to a wall with a non-laminated surface using small nails, a furniture stapler, Akrol contact adhesives (TU OP 2241-001-32998988-97), Neoprene 2136 aqua spray, 88-NP glue . Or double-sided adhesive tape. After installation, the joints are sealed with aluminized tape (overlapping installation is acceptable). Then, a formwork made of slats 7-20 mm thick is mounted on the heat-insulating material, onto which the finishing material (plasterboard, lining, etc.) is attached. The layers of isolated air created in this way are a good additional heat insulator and steam outlet.

Installation of an insulator with a double-sided reflective coating is carried out on slats (7-20 mm thick) attached to the wall. The joints are glued with aluminized tape (overlapping installation is acceptable). Then, a second row of slats is laid on top of the heat insulator, onto which the finishing material is installed.

When using materials with a double-sided reflective layer, a pleasant microclimate is always maintained in the room. Cool in summer, warm in winter.

Tips for using insulation

- The material must be placed indoors with foil. Thus, thermal energy will be reflected inward, which will significantly reduce heat loss;

- To achieve maximum effect, it is necessary to create a gap of at least 1.5-2 centimeters between the foil and the outer layer of finishing;

- It is best to seal the seams between sheets of material with special foil-based tape. This will achieve an ideal reflective surface. The installation itself must be carried out end-to-end, overlaps are unacceptable;

- Before installing Teplofol on the walls, the walls should be cleaned and treated with an antiseptic. Laying is carried out exclusively on a dried surface;

- In the case of installation on the roof, the process is carried out using a stapler, with which the sheets are attached directly to the frame structure. Installation with a slight sag is allowed, which in turn allows you to create an air gap and further improve the thermal insulation properties. This layer is especially relevant if Teplofol B, which has a double-sided layer of foil, is used. Thus, in the summer months, the roof space will not be hot from the roof heated by the sun.