Corner windows offer incredibly open views, space, lots of light and a unique interior design. They look equally impressive on the facade of a cottage and in a modern high-rise building. Corner windows increase the illumination of the room, as when using “second light”, but at a normal ceiling height. These windows are unusual, original and will undoubtedly become an exquisite touch to the exterior of the house and its interior design.

A window is called a corner window if it is located on the corner of a building, on two or even three walls at the same time. Such designs have not been uncommon for a long time; just remember the glazing of balconies. But corner windows can look completely different, depending on how the corner itself is made. What are the options?

L-shaped glass unit in which the glass is bent at an angle of 90°

Photo: the latest technology, when the glass itself is bent at an angle of 90°. A glass unit is assembled from bent glass. The result is a corner window with a completely transparent corner. An L-shaped double-glazed window is installed in a frame made of aluminum or wood. It feels like you are sitting in a widescreen cinema.

Photo: corner windows with L-shaped double-glazed windows are the most spectacular Advantages of corner windows with L-shaped double-glazed windows:

- Chic appearance, no bindings;

- No optical distortion;

- Thermal and sound insulation at the level of conventional windows;

- There is no room for ventilation and freezing in the corner, because... there is no junction of structures.

Disadvantages of corner windows with L-shaped glass:

- Such double-glazed windows are not yet produced on an industrial scale, so actually purchasing them is difficult and very expensive; you will have to import them. Cost from 2000 euros.

- Openable sashes only in part of the window structure.

- If the corner window is located above the second floor, it can only be washed using industrial climbing equipment

Photo: bent (curved) double-glazed windows are an affordable alternative to the currently unavailable L-shaped corner windows. And they look unusual Connection of 2 double-glazed windows at an angle of 90° (structural glazing)

This option is common and available and is better known as “structural glazing”. It uses a base of aluminum facade system or spider system (which are almost invisible) and double-glazed windows of a unique format, with elongated outer glass. The joints between the double-glazed windows are sealed with environmentally resistant sealant.

Photo: a corner window in structural glazing does not require a corner support; the double-glazed windows are connected to each other due to the glass protrusion. Advantages of corner windows with structural double-glazed windows:

- Wide-format panoramic glazing without visible frames on the outside;

- Very warm windows. If installed correctly, it can be used in residential areas without the risk of freezing;

- Available for order from companies that deal with aluminum windows;

Disadvantages of corner windows with structural double glazing:

- High requirements for the quality of manufacturing and installation of double-glazed windows; unique materials are used - such glazing cannot be installed independently;

- High price - from 30,000 rubles. m 2 without installation;

- Glazing above the second floor will have to be washed using industrial climbing equipment.

- Openable sashes only in part of the window structure.

Corner windows with connectors

The simplest option for a corner design is to connect two windows together with a special profile.

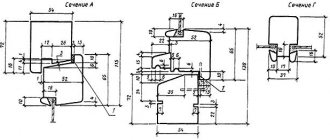

Photo: joining through a connector is widely used in the glazing of balconies and bay windows and is available in any profile - PVC, aluminum, wood. To connect windows at an angle, three types of connecting profile are used:

- Bay window pipe – the ability to connect windows at angles ranging from 90 to 180°

- Angle connector 135°

- Angle connector 90°

Photo: the connection through the connector turns out to be massive, especially if you make windows with casements. In order for a corner window with connectors to be warm and reliable, it is important to follow the installation rules:

- Mandatory reinforcement of connectors inside the window profile. It is necessary to calculate the strength of the connection in order to correctly select the shape and thickness of the reinforcement.

- Mandatory insulation of the connection - there must be seals or insulating materials between the windows and the connector.

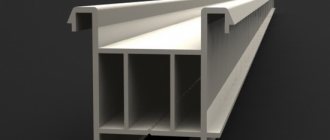

What are bay windows made of?

The main feature of a bay window is the presence of a special pipe that allows you to connect two window blocks together at an angle from 90 to 270 degrees. The pipe has two air chambers, into one of which steel reinforcement is inserted. It is attached to the window block using adapters. There can be several bay windows; this is often found on balconies in modern new buildings. Bay window structures are very difficult to install, so they are much more expensive.

Decor

Window openings in a house are what the eye is drawn to first of all. The decorative design of a bay window plays an important role in the interior. The details used should not only decorate, but be practical.

The bay window sometimes turns into an analogue of a balcony. In this case, the niche is covered with curtains in a straight line from one edge of the wall to the other.

Skillfully selected textiles will help add charm to the interior.

Curtains and curtains

Curtains and curtains for bay windows are purchased taking into account the size of the window openings and their number.

| Types of curtains | Architectural factors | Advantages |

| Roman | dividing windows with partitions | are fixed, create neat folds, do not distract the attention of the interior |

| curtains | large room area | accentuate the bay window |

| tulle | small bay window in a small room | create lightness |

| roller blinds | small room | save space |

| French | panoramic glazing | originality of form, set a romantic style |

| Austrian | large room, panoramic glazing | heavy draperies add sophistication and solemnity |

| muslin | small room | lightness, airiness |

Blinds

When decorating windows, a practical and economical solution would be to install blinds.

Types of blinds:

- horizontal;

- vertical;

In the production of horizontal blinds, plastic, wood, and aluminum are used.

Vertical blinds are made of fabric materials. In most cases, they are installed on separate flat sections of window openings. This is not quite the right solution, since there will be no effect of integrity and symmetry. It would be more correct to fasten them to a solid cornice.

With the help of blinds you can regulate the light flow. Without attracting attention to themselves, they emphasize the elegance of the bay window design. In combination with curtains, they provide protection from ultraviolet rays.

Cornices

Taking into account the design features of the opening, manufacturers produce non-standard cornices for bay windows made of metal, plastic and aluminum.

For smooth movement of curtains, there are flexible curtain rods. Their shape helps to correct bends during installation. They are attached to the ceiling.

Tire curtain rods are easy to use and durable. Special fasteners help connect inflexible elements into one whole. The profile has grooves for runners.

A string cornice is made of string or thick wire. It is characterized by ease of installation, low budget costs, and inconspicuousness. Only light curtains are attached to it. Requires periodic tightening.

In a rod cornice, a round guide is pre-bent in an arc, or assembled, using special connectors, from straight parts into one structure of the required shape. This system is attached to both the wall and the ceiling. The rod cornice is durable and strong.

Glazing options for semicircular balconies

This is primarily determined by the strength of the balcony slab. In new buildings, PVC bay glazing is completely acceptable. Plastic glazing of semicircular balconies of mansions is a common occurrence today. In most cases, such balconies are supported by columns or have a very large slab safety margin. If desired, such a balcony can be made warm without any problems and turned into an extension of the bedroom, living room or kitchen.

If we are talking about a Stalinist building or a renovated house built by the Tsars, then it is better not to tempt fate and the strength of the external slab, but to glaze the bay windows with cold aluminum . Over time, a balcony slab loses its strength and may simply not withstand the weight of plastic glazing, as well as appropriate insulation.

The so-called bay window is a part that is necessarily present in such windows, which makes it possible to combine them at angles of 90 degrees or more. The vertical cylinder is equipped from the inside with a powerful reinforcing profile, so there is no doubt about the strength of the resulting structure.

The need for this element is also explained by the fact that in the area where the adjacent edges of the window converge, a so-called field of cold temperatures is formed, shifted inside the room. This can lead to condensation, and in severe frost - frost freezing.

The design feature of the bay window connector provides for this factor. Models containing 5 or 6 chambers are able to absorb the problem area and prevent these troubles from occurring.

Effective silicone sealant removers

Such compositions are quite widely used in construction.

They serve not only for sealing seams and joints, but also for gluing various materials. During the process of restoration or repair, the old layer of sealant often has to be removed, since otherwise it is impossible to fully assess the true size of the detected defect and effectively eliminate it. Of all the compounds collectively called “sealants,” silicone ones are considered the most “difficult to remove.” This is explained by the fact that at room temperature they harden quite quickly, turning into a solid mass. The process of “dismantling” the old layer is sometimes very labor-intensive and requires patience, accuracy and time. Much depends on the basis with which you have to work.

- Removal methods

- Mechanical

- Combined

- White Spirit

- Acetone

- Table salt

- Useful tips

Removal methods

Firstly, silicone sealant is capable of penetrating deep into the structure of materials (depending on the degree of their porosity), which further complicates the task.

Secondly, the possibility of restoration or partial replacement (planks, slats, etc.) on the surface being treated.

Thirdly, the thickness of the applied sealant layer.

Based on this, the most acceptable and convenient method of removing silicone sealant is selected.

Mechanical

- when there is no risk of scratches on the material. For example, if a tile surface is being processed, then damage to its outer coating cannot be avoided;

- if it is possible to restore its integrity without any particular difficulties;

- when removing sealant from an area that will subsequently be out of the “visibility zone” (lined with appropriate material, blocked by furniture, etc.), or in situations where its appearance does not play a special role (in a hard-to-reach place, in the corner of the basement);

- if the use of chemicals will damage the surface material.

Bay window design

Those who want to give their bay window profile an original and elegant look will be interested in various design ideas and ways to implement them.

The most common among them is the process of applying a film of a certain color or texture to a profile and the result of such an operation. It is used when the standard shade falls out of the overall interior concept or does not suit the customer for any other reason. To give the windows a certain touch of aristocracy, you can use a decorative agent such as. The first ones are more practical because they are installed between the glasses. The latter are applied directly to a light-transmitting surface, which can cause some difficulties during cleaning. However, if you want your windows to have a classic look, then this is the best solution.

Only by meeting all the current requirements during operation can you be sure that the bay window structure will fully cope with the functions assigned to it, among which the highest priority is maintaining the optimal temperature, as well as creating a cozy atmosphere.

It is unlikely that you will be able to find a ready-made model that fits a specific opening. Therefore, the production is preceded by measurements of the relevant location. Based on the identified parameters, they begin to create the product.

The assembly of bay windows is a step-by-step connection of separate window frames along the perimeter of the protruding part of the building. This would not have been possible without the special bay window profile mentioned earlier. It is this that allows the frames to be rotated relative to each other.

Not least in importance is the formation of high-quality waterproofing of bay window joints. This aspect affects how immune the bay window window will be to powerful gusts of wind and how effectively it will resist the penetration of a damp environment into the spaces between the structural fragments.

The finishing touch will be the installation of window sills that match the overall idea of the interior.

Finally, it should be noted that the presence of an architectural protrusion in itself gives the apartment some charm and charm. And with proper design of the bay window using a curved profile, you can emphasize this advantage and give the room a truly fantastic look.

***Click on the photo to enlarge it.

How to remove acrylic sealant?

If during repairs it becomes necessary to seal seams and cracks, sealant comes to the rescue. This is a viscous paste-like substance that, when dried, forms a dense protective layer. You can remove excess acrylic sealant after drying using a solvent.

Today you can find various types of sealants on sale:

- silicone - elastic, moisture-resistant, can withstand high temperatures;

- acrylic - form a reliable connection with any plastics, not moisture resistant;

- polyurethane - are not afraid of water and frost, do not shrink, and have high adhesion;

- bitumen - used for sealing gutters, chimneys and ventilation shafts.

The first three types of compositions are actively used during household work. Acrylic sealants are highly elastic, allowing them to easily withstand loads and vibration. If desired, the sealing layer can be painted with regular paint. The material is ideal for sealing cracks caused by changes in temperature and humidity.

Advantages of acrylic sealant

The basis of acrylic sealant is polymethyl methacrylate, or organic glass. Today, this synthetic polymer is considered one of the most durable types of plastic. In addition to it, the sealant also includes:

- plasticizers;

- defoamers;

- fillers;

- thickeners;

- Surfactants.

The main advantage of acrylic sealant is its cost. If we compare silicone and acrylic compositions, the cost of the first will be 1.5 times higher. In addition, acrylic is a universal material, compatible with most surfaces. For example, Belinka acrylic sealant can be used to join plastic, glass, wood and metal.

Even a person without experience can easily cope with the application of acrylic composition. Belinka Belfix Adhesive BT and Beldom Acryl sealants are equipped with a convenient spout for spot application. Before work, we recommend sticking masking tape onto the surface to be treated. After this, you will not have to think about how to remove the acrylic sealant.

How to remove acrylic sealant if it has dried?

Let's assume that during the process of sealing the seams you did not have time to immediately remove the excess acrylic sealant and it dried out. What to do in this case? There are two ways to remove hardened acrylic:

- mechanical;

- chemical.

In the first case, you will need a sharp razor blade or a stationery knife. Place the tool on the surface and quickly cut off the excess sealant. If the layer of material is large, cut it off gradually. Remains of sealant can be easily removed using a wooden scraper. Do not try to tear off the frozen polymer by hand: this way you can tear off a piece of the base along with it. Try to act as carefully as possible so as not to spoil the appearance of the surface. We do not recommend using hard scourers or abrasive powders to clean the base: they may leave unattractive scratches.

The second method is to use chemical solvents for acrylic. You can find special compounds for removing sealant on sale, but regular white spirit will also work. Test solvent on an inconspicuous area of the coating before removing material. If the test is successful, feel free to apply the composition to the sealant.

Fresh acrylic is easier to remove than dried acrylic. To do this, use vinegar, gasoline or acetone. Wipe the areas with residual sealant with a cotton pad soaked in the composition, and the base will return to its previous appearance. To remove dried materials remaining after mechanical cleaning, white spirit is useful. Since solvents contain toxic components, be sure to wear gloves and a protective mask while working.

Bay windows - glazing and design options

The installation of windows of this type is based on a completely different principle than in the case of traditional window systems. There is a wider range of standards and rules established by GOST.

Only by meeting all the current requirements during operation can you be sure that the bay window structure will fully cope with the functions assigned to it, among which the highest priority is maintaining the optimal temperature, as well as creating a cozy atmosphere.

It is unlikely that you will be able to find a ready-made model that fits a specific opening. Therefore, the production is preceded by measurements of the relevant location. Based on the identified parameters, they begin to create the product.

The assembly of bay windows is a step-by-step connection of separate window frames along the perimeter of the protruding part of the building. This would not have been possible without the special bay window profile mentioned earlier. It is this that allows the frames to be rotated relative to each other.

Not least in importance is the formation of high-quality waterproofing of bay window joints. This aspect affects how immune the bay window window will be to powerful gusts of wind and how effectively it will resist the penetration of a damp environment into the spaces between the structural fragments.

The finishing touch will be the installation of window sills that match the overall idea of the interior.

What are bay windows made of?

Due to the large glazing area, in order to avoid significant heat loss, it is recommended to use energy-efficient double-glazed windows. You will receive more information about these products in a special material on OknaTrade.

Accordingly, all bay windows have the advantages of modern windows made from profile systems and double-glazed windows:

- high level of noise absorption;

- good thermal insulation;

- excellent tightness;

- functionality;

- durability.

Bay pipes

If the window is a continuous structure with a broken shape, difficulties may arise during the installation process. To facilitate installation, special elements were developed - bay windows. Thanks to them, it is possible to join adjacent frames at any arbitrary angle. To impart rigidity to the entire structure, the bay window pipes are additionally reinforced with a reinforcing profile. Two adapters are movably connected to the central element (pipe), due to which the joining, alignment and fixation of individual elements of bay windows occurs. The diameter of such pipes is selected depending on the type of profile used for the manufacture of frames.

Location

The non-standard shape allows you to create an unusual room layout. The choice of style is influenced by factors depending on the architecture of the building.

Options for using additional space.

- Living room. A relaxation area with a fireplace, sofa furniture, and a coffee table directs the eye to the landscape outside the window. It is designed to accommodate all family members and receive guests.

- Bedroom. A space designed for privacy and reading books. Additional sofas, poufs, and comfortable armchairs will provide comfort and coziness.

- Dinner Zone. A bay window will solve the problem of small kitchen footage. A large window will provide a lot of light and visually expand the space. It would be more correct to install a round or oval table, a bench with a soft seat.

- Study. Organizing this option with a library will allow you to work at home. A wide window sill will bring practical benefits. Shelves for documents and office equipment are installed under it.

The bay window can be used as a small gym, or as a children's corner. The winter garden will look great.

The layout of the room and the configuration of bay windows depends on the purposes of use and preferences of the people living in the apartment.

Cost of bay windows

Bay windows can be more expensive than regular ones, especially if you are replacing old ones with new ones made of PVC. The price increases not only due to the larger window area and unusual design, but also due to the reinforced double-glazed window, which ensures the absence of drafts and cold.

The cost of such windows starts from 13,000 rubles . The more sections, the higher the cost. For example, for a three-wall bay window, windows will cost approximately 20,000 rubles, and only three sashes will open (two side and one central), and two more will remain solid.

The opening mechanism also adds some cost to the window. Sliding windows will cost about 3-5 thousand rubles more than swing windows.

Another factor influencing the final cost is window lamination. For a beautiful interior design, it is better to choose windows whose color is different from white.

This will help create a special atmosphere in a room with a bay window, especially if the interior is stylized in one of the authentic styles.

Profile system

If cold glazing is a sufficient measure for apartment owners, then aluminum windows, which are famous for their strength and durability, as well as their magnificent appearance, will be the best for this case.

When the customer has sufficient funds, then nothing prevents him from acquiring wooden windows made of oak or larch. A more budget-friendly alternative is a pine profile.

In the middle of the price ladder there are white plastic windows, which, if the client wishes, can be laminated to a wood texture that quite accurately imitates the real wood.