Platbands are necessary not only for decorating a window, giving the facade a designer look that allows you to bring any ideas to life, but also provide decorative protection for seams from freezing and the negative impact of natural phenomena. Metal trim is a high-quality, reliable material that can protect window seams well, make them airtight and decorate the window itself.

Instructions for finishing window slopes with metal

Korovin Sergey Dmitrievich

Master of Architecture, graduated from Samara State University of Architecture and Civil Engineering. 11 years of experience in design and construction.

Metal-plastic windows are a multifunctional modern product for glazing window openings. The final stage of installing plastic windows is finishing the external slopes. For this, various finishing materials can be used: plaster, paint, PVC panels, plasterboard, but most often metal window trim is produced. Installing a metal slope on windows can be done with your own hands.

Slope function

Finishing windows on the outside with metal slopes performs decorative and protective functions. By installing slopes on windows with your own hands, you can close the installation seam and thereby protect it from exposure to precipitation and direct sunlight .

Metal slopes perform a protective and decorative role

Polyurethane foam, used to seal the joint between the frame and the window opening, is a porous, vapor-permeable substance that allows moisture from the room to pass through it. As a result, moisture and condensation settle on the surface of the window slopes, which leads to the formation of mold and destruction of the integrity of the structure. Moisture from the street can penetrate through the mounting seam and cause fogging and freezing of the window in winter.

By installing metal slopes on windows, you don’t have to worry about these troubles, since metal is a strong, durable and easy-to-maintain material with high performance indicators.

Purpose

Metal external slopes perform several important functions:

- The iron platband for windows gives the appearance of the opening an attractive, neat appearance. The steel slope is often made in the same color as the profile of the window structure - white or brown (for wood-laminated profiles). However, if the customer wishes, the panels can be painted in any color according to the RAL catalog.

The customer can choose any color of the slopes from the RAL catalog

- Protection of the assembly seam from moisture and exposure to natural phenomena in the form of precipitation, wind and temperature changes.

- Protection of the slope surface from dampness, mold formation and destruction. External metal slopes reliably seal the wall surface and increase its heat-insulating qualities.

Metal window trim should be installed immediately after the windows are installed to prevent moisture from being absorbed by the foam . If this cannot be done in the near future due to work on finishing the facade, then the installation seams on the windows can be temporarily covered with polyethylene.

How to prevent moisture from seeping under the trim

During fastening and installation, the main task is to ensure the tightness of the house. The main question that arises. How to prevent moisture from seeping under the trim? During heavy rain, melting snow. Water flows down the walls of the house. It gets into the gap between the wall and the platband. There are several options for solving this problem. Options refer to traditional methods. Only modern technologies and materials are used. These methods will be discussed below. Let's describe each in more detail.

Platbands with wooden canopy

This type of construction has a second name - Finnish. It is mounted under an incline. This way the water drains away. Along the edges on both sides, cuts are also made at an angle.

To ensure that the visor fits snugly, a small cut is made in the log or beam. The edge of the visor is inserted into the cut. From above this place is filled with sealant. The sealant should be frost-resistant. Since it will be exposed to temperature changes from the street side. And the main requirement is compatibility with a wooden surface.

Metal visor

Made from metal 0.5 mm thick. Performs the task of draining rainwater. The metal strip is installed in the letter Z.

Advantages over other materials

There are several types of finishing materials, using which you can give the window opening a complete appearance. These are plaster, drywall, plastic and paint. But in terms of its technical characteristics, none of these materials can compare with metal slopes. When deciding how to make slopes, you need to study the characteristics of finishing materials.

The polymer layer of the steel slope protects the product from rust

When using plaster, you must be prepared for the fact that the plaster layer will crack over time. Moisture getting into the gaps between the window frame and the plaster layer can cause mold to appear.

Drywall as a finishing material for slopes is only suitable for interior work. Even GVLV brand drywall is not able to withstand the direct effects of precipitation. In a short time it will swell, lose its appearance and collapse.

The use of plastic panels for finishing external slopes leads to the fact that in the sun the plastic fades and acquires an unpleasant yellowish tint. And with a sharp drop in air temperature, the plastic becomes brittle and may lose its integrity after minor mechanical stress. Therefore, it is better to use plastic for finishing internal slopes, especially in the kitchen.

Metal slopes are not exposed to weather conditions

The advantages of metal slopes are obvious, since the material for their production is galvanized steel, which is covered with a protective polymer decorative layer at the production stage. This protects products from corrosion and rust.

Manufacturing materials

Modern manufacturers make platbands from a variety of materials: wood and its derivative raw materials, metal, plastic. Naturally, finished products are distinguished by wear resistance, appearance and practicality. Models that are inexpensive and require minimal maintenance include plastic and metal trims. They should only be occasionally cleaned of street dust by wiping with a damp cloth. Wooden frames require periodic painting and impregnation with antiseptics. The frequency of impregnation depends on the stability of the selected composition and the requirements of the manufacturer (many companies recommend re-treatment after 3-5-8 years). But the frequency of changing paint layers directly depends on the wear resistance of the compounds used and their service life. As for cashed MDF, it is intended exclusively for interior work.

Facade stucco is a special type of material. True, in most cases it is used for the restoration of ancient buildings and is quite expensive.

Wood

The quality and durability of wooden platbands directly depends on the wood used and its characteristics. Often for the manufacture of such elements the following are used:

- hardwood species (oak, beech, ash): have maximum resistance to negative influences, but are very difficult to carve;

- soft-leaved species (alder, aspen, linden): easy to process, therefore they are mainly used for the production of carved platbands, but require high-quality protection from moisture;

- conifers (pine, spruce): they are accessible and, with proper protection, retain their pristine state for quite a long time;

- fruit (cherry, apple): they are distinguished by their excellent softness and ease of cutting; elements from them are used as decoration for platbands.

According to the types, wooden platbands are divided into standard (with or without chamfer, with rounding) and carved. The former have a slight thickness and are most often made straight (or with minimal bending). On carved models, figured recesses are cut out in the form of patterns.

Plastic

Plastic platbands are an ideal frame for metal-plastic windows. They can also be installed to frame wooden window structures, painted white or light gray. The advantage of this type of product is its low cost and ease of maintenance. Unlike their wooden counterparts, they do not require constant protection from negative external influences. In addition, they are much cheaper than metal counterparts. The disadvantages of such frames include a small selection of shapes and shades. But with the right color selection, the purchased frame will look appropriate against the background of stone or white brick, and against the background of siding. Installation of plastic platbands can be carried out both inside and outside. Such products are minimally susceptible to temperature changes, and thanks to the high-quality colors used in their manufacture, they will not fade or turn yellow in the sun.

MDF

Modern MDF platbands attract the lowest price. At the same time, their range is quite wide: both straight and rounded elements can be used in the base. The upper part is covered with a special film, which allows you to stylize unusual frames. In addition to the monochromatic design, you can easily find MDF trims with imitation wood, stone and metal surfaces. The only disadvantage of such products is the inability to use them outside. Even with short-term exposure to moisture, the base (MDF) will quickly become unusable and require replacement. Such platbands can only be used for indoor framing of windows or doors. True, it is recommended to install them with extreme caution in bathrooms with insufficient quality (or low-power) ventilation. They do not require special care: simply removing dust or wiping with a slightly damp sponge will be enough.

Metal

Metal casings are a universal and inexpensive solution for any building. In most cases, they are used to stylize administrative buildings and provide additional protection for window openings. But windows in a private house made of brick or stone will also complement well. It is recommended to install such products in addition to metal-plastic windows: they will look out of place with wooden frames. Metal cashing consists of galvanized strips coated with wear-resistant paint. That is why metal frames will last for many years without the need for periodic processing. They look great against the backdrop of non-standard facade decoration: siding, metal and PVC panels, lining. They emphasize the rigor and modernity of the exterior design.

Pros and cons of the material

Despite the fact that external metal slopes are more expensive than other types of finishing, their positive qualities more than make up for this drawback:

they have a high degree of resistance to corrosion and rust;

Metal slopes are covered with a layer of galvanized steel

It is recommended to install noise-absorbing tape along with the slopes

Among the disadvantages, we can note the high cost and the presence of sound effects arising from the fall of drops or hail on their surface . This can be dealt with if you use a special noise-absorbing sealing tape when installing metal slopes.

Another disadvantage of a metal slope is the impossibility of installing it in arched openings.

Preparing for installation

Installing modern metal slopes on windows with your own hands will require the preparation of special materials and tools for this type of work:

- metal sheets;

- level;

- fasteners;

- mounting foam and silicone sealant;

- screwdriver and bits;

- painting knife;

- metal scissors;

- roulette

Excess polyurethane foam must be cut off

Surface preparation involves removing construction dust and contaminants from it. Excess polyurethane foam is cut off with a painting knife, and the seams and joints are treated with silicone sealant. Do-it-yourself installation of a metal slope on windows should be done after the seams have dried .

Sequence of work

Installation of metal slopes on windows involves carrying out measuring work. The width and height of the product will correspond to the internal and external parameters of the opening. The manufacture of the top, bottom and side metal elements is carried out by cutting them from a prepared metal sheet in accordance with the measurements obtained.

Scheme for trimming a metal slope Scheme for trimming the lower metal ebb

Scheme for trimming the upper metal ebb

At the second stage of work, the installation of a low tide takes place, the horizontal position of which is controlled by the building level. The lower junction of the wall and the window frame is equipped with a special heat-insulating material and diffusion tape for noise reduction and moisture protection.

First you need to install the tide

Related article: Mastic for PVC windows

When attaching the ebb, mounting foam is applied to the window opening and to the ebb from the inside. To prevent it from bending due to the expansion of the foam, it is pressed tightly for a while. After the ebb is fixed, the installation of metal slopes begins.

Before installing metal slopes, it is necessary to treat the places where they will come into contact with the window frame with sealant.

Metal slopes are secured with polyurethane foam

First, the side elements are installed, maintaining the required slope from the inside to the outside. The upper and lower parts are adjusted using a knife depending on the level of inclination .

The side elements must be installed in a vertical position and tightened with screws. The upper part is adjusted to the side elements. It is aligned with the outer corners and secured with self-tapping screws.

At the final stage, all contact areas are treated with sealant.

When installing slopes on a façade made of corrugated sheets, use horizontal lintels

If the façade of the house is covered with corrugated sheets, it is necessary to use horizontal lintels when finishing window openings. These are side shelves made of corrugated sheets, which are attached to the wall on one side and to a metal profile on the other. Steel trims give the façade completeness.

Coverings for plastic openings

Plastic processing is characterized by functionality and aesthetics. It can last up to 50 years without changing its properties.

Plastic is a multifunctional raw material, but one of its few disadvantages is the small selection of colors. This issue can be solved if you use textured film. Coloring with stone, metal, wood will harmoniously complement the style of the home. The bases do not require special care or renovation and are weather resistant. Can be installed on log or brick houses.

Installing cash on plastic windows is easy. It does not create a load on supporting structures due to its low weight. Even solid models weigh much less than those made from logs or metal.

Some modifications are designed for hidden installation of communications. They consist of a main profile and a cover. It is convenient to place cables in the internal space.

PVC cashers do not have any significant disadvantages. Some do not use them only because of their artificial origin and low cost, which varies with the status of the building.

Depending on the material of the main frame, the following types of cashing are used:

- For plastic ones, white or dark products made from cast raw materials are usually used. It is necessary that they fit the overall design of the building and cover the joints well.

- For wooden structures, there are special models with a special texture similar to wood.

Installation from the street

PVC decoration for exterior decoration must withstand aggressive climatic conditions, especially negative temperatures.

Decorative qualities should emphasize the external design without destroying the overall style of the building. In addition, they serve as a means of insulation and sound insulation, since they close the gaps between the wall and the window frame. Strong and massive blocks are installed from the street.

Modern foundations perform the following functions:

- creating a finished image of the opening;

- combining mating elements;

- protection of the premises.

Plastic is not susceptible to the formation of fungus and mold, does not lose its decorative effect and can be used for structures made of any materials.

Indoor installation

For interior decoration, you can install less durable casing, since home conditions do not require aggressive influences. It is important to take into account decorative features and select models in accordance with the interior of the room.

The block installed from the room must completely cover the installation seam and correspond to the design of the slopes. Otherwise, the selection of cash depends on the taste of the owner.

It is better to use planks with a width of 3-8 cm. If the wall is uneven, a flat profile with an extension is suitable for a tight fit to the wall.

How to make carved frames for metal windows

Since ancient times, people have been decorating their homes. The buildings from the old era are still preserved. There, the presence of platbands was a mandatory attribute. He pointed to the wealth of the residents who lived in it. This decoration of the house gave it status. Nowadays, platbands are used both for decoration and to perform some useful functions.

Nowadays, the popularity of window frames is gaining momentum. It's becoming fashionable. But not everyone knows that platbands serve as good protection against freezing of the seams between the window opening and the window frame in winter.

Platbands are made from different materials. Consider an option made of iron.

Iron platbands, along with wooden ones, are distinguished by their durable properties. They tolerate moisture and natural factors well. Of course, they are susceptible to corrosion, but if you follow the painting technology, you can achieve the maximum effect of counteracting external natural factors.

Creating metal trim is a real art. For manufacturing we will need a set of tools and consumables:

- Metal sheet, from which we will make our platbands. Iron sheets are produced in factories in rolls. The optimal option for processing and manufacturing platbands will be a sheet thickness from 0.4 to 0.7 mm.

- Large sheets of paper, whatman paper or wallpaper. They will be needed to create a template for our future drawing.

- Jigsaw. For cutting holes in metal.

- Metal drills of different diameters, mainly 8 mm for holes for jigsaws and 4 mm for holes for connections of platbands and its parts.

- Sandpaper. Grinding of flash and irregularities.

- A hammer or riveting machine for joining parts.

Before you start creating platbands, it is worth making slopes. They are also made of metal. Take measurements of the slopes, taking into account the protruding edges. Based on the dimensions obtained, we create a template for future platbands. You should make two parts of the platbands. Side and top with bottom. You should fold a sheet of paper in half and then apply the design. This will simplify the task and you will get two identical drawings. When moving on to working on metal, you need to prepare a place for cutting it so that it is convenient for you. You can use two identical tables. Place them side by side, with a short distance for working with a jigsaw.

Let's start cutting:

- We cut out the blanks of our future platbands from metal to size;

- Glue or attach a template for the future drawing. We mark the drawing;

- We drill holes for cutting out the ornament with a jigsaw;

- We cut out the drawing;

- We clean the edges of the cuts with sandpaper;

- We carry out drilling and subsequent riveting of parts of the platbands;

- If necessary, paint the trim in the color you like.

Now the platbands are ready. All that remains is to mount them to the windows. Installation depends on the materials from which the house is built. You can secure it with nails or self-tapping screws on a wooden house. The dowel should be secured with nails or anchors on brick houses. Metal trims are ready!

Creating metal trims is labor-intensive work. She will be rewarded with a new transformed look for your home. Give positive emotions to you and passersby.

Patterns made from metal sheets. Craft ideas for beginners

Before considering ways to work with metals, it is worth dwelling on ideas and drawings of possible crafts.

Metal crafts are decorations for any interior. Animal and plant subjects, monograms, geometric figures and national ornaments are popular.

A simple product for beginners will be a metal owl. It is made in many ways. Thus, rods bent into round shapes and welded together form a wall-mounted flower stand in the shape of an owl outline.

DIY metal owl

Sheet metal products are made by welding in the following way:

- a sketch of the product and its details are first prepared on paper;

- transfer the pattern to a metal sheet, carefully cut it out with a grinder and clean the edges;

- with a chisel and hammer, notches are applied so as to give the components the appearance of feathers;

- a beak is formed, parts of the paws are cut out of a rod, and bolts are inserted into the holes for the eyes made with a chisel in the head part;

- all parts of the bird are welded together;

- The surface is cleaned of rust using a chemical solvent and varnished.

Protective grilles on windows or fences are decorated with floral ornaments, and a bouquet of iron roses can become an independent decoration for a room. Cold and hot forging are suitable for making branches, flowers and leaves.

Forged roses for windows

Cold forged leaves are created from thin metal 3.5 mm thick, which bends well.

Briefly the stages of the process can be described as follows:

- a sheet pattern of the desired shape is cut out of cardboard;

- transfer the images to a metal sheet and cut them out with special scissors;

- the edges are polished using a machine;

- “Hangnails” are removed with a metal brush;

- clean and polish the surface;

- With a chisel, veins are applied to the leaf plate;

- the edges of leaves and petals are made thinner by beating them with a hammer;

- using pliers, bend the edges and shape the products;

- the finished forms are secured by spot welding to the branches;

- The product is painted or coated with a special varnish.

Floral patterns made by high-temperature forging are stronger due to the compaction of the material. Medium, hard and soft grades of steel are used. The optimal steel grades are those that contain a minimum amount of carbon - 0.25%. And they do not contain harmful additives - sulfur, chromium, phosphorus.

Crafts that you can make yourself from scrap metal can be useful for your dacha.

For example, after cutting a barrel lengthwise, shelves are installed inside and wheels are installed at the bottom. The outside is painted with bright paint. And the cabinet for small items is ready.

Barrel cabinet

Cut crosswise and painted, it turns into an unusual bedside table or coffee table.

Craftsmen decorate the walls of the barrels with openwork carvings, and then build a set for outdoor dining: a table and chairs.

Sculptures of animals or fairy-tale characters are created from unnecessary garden tools and pipes.

Summer residents love furniture made from profile pipes, made with their own hands. This material is practical, inexpensive, and allows you to create many useful things: from furniture to a greenhouse. Combines with other materials: wood and plastic.

To make a bench measuring 2.3 x 0.6 x 0.45 m, a profile pipe with a square section of 0.03 x 0.03 m and a total length of 11 m is used. As well as boards 2.3 m long and 0.06 m wide.

Using the product drawings provided, you can independently make a bench with a back, as well as a greenhouse from a profile pipe with square and rectangular sections of 0.2 x 0.2 m or 0.2 x 0.4 m. Considering that a rectangular pipe is suitable for a durable frame, and a square pipe is suitable for partitions .

Metal parts of old mechanical watches, coins, paper clips, tin cans, cutlery, wire - material for the production of toys or jewelry.

Aluminum and tin are soft metals suitable for making toys. To create a cat, a dog, a hedgehog, a crocodile and a dragonfly, you need to transfer the sketch onto a sheet of tin, cut out the shape and bend it as shown in the dotted lines.

Metal frames for windows - advantages, installation features

Platbands are necessary not only for decorating a window, giving the facade a designer look that allows you to bring any ideas to life, but also provide decorative protection for seams from freezing and the negative impact of natural phenomena. Metal trim is a high-quality, reliable material that can protect window seams well, make them airtight and decorate the window itself.

Platband as decoration

Many have seen ancient wooden buildings decorated with carved platbands on the outside. Such decorations are made by hand and can have a rather complex design that turns a boring house into a work of art. You can create a piece of a fairy tale using metal window frames. Any patterns can also be carved on them, but, unlike wood, metal is a more reliable and practical material that can withstand any load.

If wooden products do not tolerate moisture well, require constant care and are not very durable, then metal analogues do not have these disadvantages. It is enough to use stainless metal or paint the product regularly. Metal window frames can completely replace wooden elements. You can cut out the desired pattern yourself using flat metal sheets, and, unlike working with wood, you do not need to have carving skills or special tools.

It is much easier to work with metal sheets: they will not require drying, special conditions for this, and will not require the use of varnish, which fades in the sun, which is why you have to constantly renew it. After installation, metal platbands will not require additional maintenance and will fit perfectly into the design of the facade. Installation of metal slopes will also not cause any difficulties.

For beauty and aesthetics, plastic corners are installed on the windows. Find out what they are from our material.

Related article: How to foam a plastic window

Production of metal platbands. Platband

Traditional Russian window frames

Platbands are decorative design of a window or doorway in the form of overhead figured profiled strips. Made of wood and richly decorated with carvings - carved platband. Functionally, the platband covers the gap between the wall and the window or door frame.

It is believed that carved platbands spread from the territory of what is now the Nizhny Novgorod region. At that time, wooden shipping disappeared. Carvers who spent their entire lives decorating wooden ships were left without work. Not knowing where to put their labor, they began to decorate their houses, and then the houses of their neighbors.

Based on the type of material from which they are made, platbands are divided into wooden, composite of wood materials, plastic and metal.

- In terms of shape, platbands produced by industry in the form of molded products are:

Telescopic frame

Platband is a molded product. It is installed around the perimeter of the window in a U-shape. It can be external and internal. It is installed after installing the window if there is nothing else to cover the installation seam with. It is extremely rarely needed in standard apartment openings. Since such openings have an outer quarter, that is, a platband is not needed on the outside. And from the inside, the installation seam is closed with slopes.

According to the installation method, platbands can be:

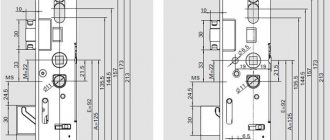

The difference between a telescopic casing and an overhead casing is the presence of so-called “wings” or “beak” - a protrusion located at right angles to the plane of the casing, which fits into the corresponding groove on the frame. By changing the distance by which the platband is pulled out of the groove, complete closure of the junction between the frame and the platband is achieved at different wall thicknesses.

Features of rough material

The thickness of a suitable iron sheet is between 0.40 and 0.70 mm. Such sheets are produced at factories in rolls up to 50 meters long. The width of the product is 1.25 m; the sheets do not always need to be painted, since you can buy an already painted product of the color and shade you need. To ensure that the material does not receive damage during transportation, it is protected from scratches with a special film, which can be removed if necessary. The metal is quite strong and flexible, so it does not cause difficulties when working with it.

Production

In our production we can produce galvanized platbands with steel thickness from 0.3mm to 1.2mm with polymer and powder coating in various colors.

The metal in our production is used by leading domestic manufacturers of galvanized steel coils. We perform precise bending angles and configurations using modern CNC equipment, this allows our customers to be confident in the quality of our products and easily install high-quality products. The edges of the platbands are rolled inward (rolled), making the metal not sharp. The configuration itself can be made of almost any shape and outline; this allows you to reliably hide all joints and crevices, making the unit moisture-proof and aesthetically complete. The production technology consists of processing rolled galvanized steel using sheet bending equipment according to a pre-designed configuration. For additional anti-corrosion resistance, the metal is coated with specialized polymer enamels, which for decoration come in any color according to the RAL Classic color palette. Such coatings do not require any maintenance and are very easy to clean.

What is required to make a slope?

To work you will need:

- The metal sheet from which the platband will be made.

- Wallpaper or whatman paper from which you can make a drawing template.

- Paper clips: These will be needed to secure templates and parts.

- Connecting staples no less than 4 mm.

- Pencil.

- Ruler.

- Eraser.

- Drill 8 mm. You will need it in order to use a jigsaw.

- 4 mm drill for joining parts.

- Metal saw and jigsaw.

- Sandpaper for sanding products.

- A small hammer for straightening and a riveting machine, you can use it manually.

Methods for making platbands

Before proceeding to the manufacture of platbands, you need to install metal slopes on the windows . White metal would be a good option. You will need to measure the slopes to find out their exact size. In addition, you need to take into account the protruding edges: you need to calculate the length and width of the platbands based on these data. Typically the length is 35 cm with the addition of the width of the trim.

Once the size is obtained, you can make templates for the trim. For this you will need whatman paper, you can use wallpaper. You need to make two templates - a long one for the side of the window and a shorter one for the top and bottom if the windows have a size close to the standard one.

The sketch is drawn on a sheet of paper folded in half. The center of the pattern should be on the fold. You don't need to cut out the design twice: using this method, you will get two identical templates without any extra effort, and the templates themselves will be perfectly even.

It is more convenient to make carved metal window frames at a previously prepared workplace. This will require two tables of the same size and height. You need to leave a distance of 8 cm between them so that the jigsaw can maneuver. Most often, metal of two colors is used to make platbands: the top sheet can be white, and the bottom sheet, which will act as a background lining, can be any one.

- To make platbands from a sheet of metal, you first need to cut a sheet of suitable width. Once you have all the lines drawn, you will need to use an electric drill. Using an 8 mm drill, you need to make holes for the jigsaw in the corners of the picture.

- The part that you will cut needs to be placed on the table, so that the cut out pattern is in the center, taking up the free space between the tables.

- After the upper part is ready, you need to move on to making the lower part. You will need to cut a strip of the desired size.

- After this, the metal trims need to be turned over. The finished part should be placed face down. This will free up the outer edge; leave a width of 5 cm and cut out.

- When the workpieces are ready, the protective film will need to be removed and the sheets of metal placed on top of each other. Just in case, secure them with paper clips: to do this, you need to drill several holes with a 4 mm drill. A manual riveting machine is used to connect the parts so that they do not come apart during work.

- After you have secured the sheets, they need to be completely drilled and riveted. The platband can be considered ready.

Arrangement of platbands

There are two options for the cashing device, depending on the features and design of the framed window:

- From 4 sides.

In this option, the platbands are located at the bottom, top and sides of the frame. For some buildings, the lower and upper frames of adjacent windows (located on the same wall at a short distance from each other) may be common. In this case, these elements are installed first, and the side trims are installed after precise adjustment.

- From 3 sides.

This framing method is used when installing an external window sill (low tide). You first need accurate calculations of the size and shape of the installed window sill. Then the side parts are adjusted and installed. The top trim is installed last.

How is installation done?

Once the façade trims for the windows are ready, you can proceed to their installation. It will not take much time and can be completed without the involvement of specialists. The installation method depends on what materials the walls are made of: if they are wooden, you will need the following:

- Hammer and nails 6 cm.

- Mounting gun and silicone: it is better to take a colorless one, it will be needed for sealing cracks.

- Artist's brush and paint to match the color of the trim. With its help, you can paint over the heads of nails and screws and make them invisible.

- Drill with 4 mm drill bit.

- Plugs for screws. You can also use homemade wood products.

- Medical syringe filled with liquid silicone.

- External metal slopes should be ready by this time.

The platband must be fitted tightly to the slope so that it does not protrude beyond its limits, and secured to the wall. If there are uneven places or gaps remain, they need to be coated with silicone sealant. After this, paint all the heads of the screws and nails with a small brush: this will rid the structure of unsightly dark spots.

For more information on how to restore a wooden window and give it a new look, read the article “How to repair and paint a wooden window” on our website.

Decorating windows in a wooden house requires a special approach. Read how to choose a material for covering windows in a wooden house.

What if the wall is brick or block?

Slopes are not always installed on a wooden structure - sometimes the owners want to make a brick house more decorative. You can also use metal slopes for this. The construction of metal slopes in this case is no different, but the use of nails will have to be abandoned.

Before installation, you will need to drill holes for dowels in the walls. It is advisable to use materials at least 6 cm long, otherwise there will be a risk of the structure falling out of the wall. After the holes are ready, you need to insert plastic blanks into them. Holes for screws are also pre-drilled in the mounted slopes: make sure that all holes strictly coincide.

After everything is ready, the structure is put in place and screwed. Working with cracks occurs in a similar way. You can use silicone sealant: a colorless one will be most convenient, since you won’t have to select its shade, but if both the wall and slopes are white, you can use white. It is not recommended to use polyurethane foam. It cannot withstand moisture, requires protection from weather conditions and has an unattractive appearance.

What did the patterns mean?

The variety of designs and patterns is off the charts, but here’s what some of them meant on the trim:

- Wings. They were considered divine, protecting the home and their endless power.

- Bird. It is considered to be the guardian of the past, present and future.

- Sun. It protected the house and created comfort and warmth in it.

- Snake. Associated with nobility and wisdom.

- Cross. This is the harmony of your needs.

- Earrings. It meant that the owners in this house are hospitable.

How to make carved frames for windows from sheet iron

Which of us, seeing before us beautiful, old, log houses, decorated with intricately carved openwork platbands, with rich kokoshniks carved like a royal crown on the roofs, did not admire the fabulous beauty that has come down to us from the depths of centuries. But seeing such beauty and admiring it is one thing. But turning your home into a fairy-tale palace is not an easy task.

Related article: Replacing windows in the entrance, who should pay?

And the point is not even that someone lacks artistic skills or lacks imagination in constructing twisted patterns, the problem is the fragility of external wooden elements and structures. Unfortunately, wooden platbands and carving elements retain their original appearance for many years, only in indoor, dry rooms. In an external humid environment, wood quickly warps, cracks and chips, especially in places with fine carvings. The external environment, sun and rain quickly destroy paintwork, forcing you to spend extra money on paint and repaint everything every two or three years.

Despite some difficulties that may seem at first glance, you should not give up the desire to turn your drab house into a little mansion. The abundance of materials in hardware stores allows you to replace wood with a more durable material. In this master class you will learn how to make carved window frames with your own hands by replacing wood with flat iron.

Flat iron, or flat sheet, as it is correctly called according to the factory classification, is thin tin (0.40-0.70 mm thick), which comes from the factory in rolls of 20, 30 and 50 meters. The standard factory width of sheets in rolls is 1 meter 25 centimeters. Flat iron is painted in different colors, from white to dark chocolate. All iron sheets are covered with a protective film to protect them from scratches during transportation.

Do-it-yourself platbands from corrugated sheets

A great idea is to organize the production of metal window frames from profiled sheets.

Agree, platbands greatly decorate our homes and make them cozy. In the old days, they were also given the meaning of a talisman - they, according to legend, drove away evil spirits from the house. However, with the massive construction of private housing made of bricks, they began to forget about platbands, as if they had no place here. Yes, and wooden trims are a bit expensive, and try to find them again.

And recently, metal platbands have come to replace wooden platbands. They are no less intricate and artistic than their predecessors, but are made using different technologies and from other materials. And if in the old days it took weeks to create one wooden frame, then a metal one can be made in half a day, or even less. You can take training in special courses (some have appeared), they will also provide pattern templates and sketches.

Advantages of metal platbands:

• they are cheaper,

• more durable in comparison with wooden platbands,

• do not require annual painting, like wooden trims,

• come complete with slopes that cover possible side defects and gaps.

The production of platbands uses a smooth painted metal sheet (corrugated sheet), 0.4-0.5 mm thick. Patterns are cut out according to templates and sketches using hand-held metal scissors. If desired or necessary, cutting out patterns can be entrusted to companies that cut metal using a laser.

The following equipment and investments will be required:

• sheet bending machine (for example, LGS-26, price 40 thousand rubles),

• premises for production (own or rented),

• registration of individual entrepreneurs,

• tools (screwdriver, metal scissors, etc.) – from 15 thousand rubles.

If you already have all or part of this, then starting a new business will cost less.

As a result, the total investment will be a little more than 170 thousand rubles. (this includes the cost of the courses).

One platband costs on average 5000-6000 rubles. The cost of corrugated sheeting spent on production does not exceed 15-20% of the cost of the finished casing. One person can make two frames in a day. As the flow of orders increases, workers can be hired. Thus, your production will not only expand, but you will also have the opportunity to create new jobs.

You will spend the first month on registering an individual entrepreneur, purchasing tools, and small trial work. But after a couple of months the costs will pay off. The size of an average order from one client can be 40-50 thousand rubles.

For advertising purposes, first decorate your house, veranda, utility rooms and even fences with beautiful metal trims. Such visual propaganda will not go unnoticed by your potential customers.

As practice shows, this product is popular in rural areas and modern low-rise villages. And so far there is no competition in this market.

Good luck in your new business!

Materials and tools

To make carved window frames we will need:

- a flat sheet of tin iron with a standard width of 1 meter 25 centimeters;

- a roll of wallpaper for making templates for the platband pattern;

- paper clips for fixing templates during translation of drawings and for subsequent fixing of finished parts to each other;

- connecting brackets size 3-4 millimeters;

- a simple pencil;

- eraser;

- ruler;

- an 8 mm drill bit for drilling holes for a jigsaw in the places where the parts of the top cover plate are to be cut;

- a small drill of 3-4 millimeters for drilling holes in places where parts are riveted;

- electric jigsaw;

- metal saw with fine teeth;

- fine and medium sandpaper for grinding burrs on the back of parts;

- manual riveting machine and rubber hammer for straightening workpieces.

Tools for making slotted threads

For the slotting cutting technique, the main tools are a drill and a saw. In this case, the type of sawing tool can be any: from a hand hacksaw to a jigsaw.

How to make carved platbands in a quick, automated way? To do this, you can use power tools:

- Electric drill. Required for drilling preliminary holes in the workpiece for setting the jigsaw blade.

- Jigsaw. It has high productivity and significantly speeds up and simplifies the production of carved products. For a beautiful, neat cut, it is better to use files with fine teeth.

- Manual frezer. The productivity of a hand router is lower than that of a jigsaw and some skill will be required when handling the tool. However, the cuts produced by the router are very neat, and no pre-drilling of holes is required.

The process of making a platband using a manual milling machine

Return to contents

The process of making carved platbands

When starting to manufacture window casings, it is necessary to prepare and install slopes on the windows in advance. One option is white iron slopes.

After we manufacture and install the slopes, we take the exact size from the window, taking into account the edges of the slopes protruding onto the walls. When the size is taken, we calculate the width and length of the platbands. The standard width is 30-35 centimeters, the length of the window plus the width of the casing.

Having taken all the measurements, we make templates for the platbands from any smooth roll of wallpaper. Having chosen a sample drawing, we prepare two templates. One long side and one short for the bottom and top of the window. Fold the cut strip of paper in half and draw a sketch so that the center of the pattern is at the fold. When the design is cut out, its second half will automatically be ready, so you will get the correct, even template.

We prepare the workplace, for this we place two tables of the same height, next to each other in length, leaving a gap of 7-8 cm between the tables, this is the place to work with an electric jigsaw. Platbands are made of two colors of metal (the simplest option). The top overlay color will be white, and patterns are cut out on it. The second color of your choice is the background lining under the top carved sheet.

We take a sheet of flat iron and cut strips for the trim of the required width.

We turn the blanks of the upper overlay part of the platband face down, and securing the template with paper clips to the reverse side, we transfer the openwork pattern of the platband.

When the drawing is ready, take an electric drill, insert an 8 mm drill and drill through holes along the edges of the drawing for a jigsaw file and begin cutting out the casing.

We cut out the frames for the iron windows.

We place the strip of iron on the table so that the part to be cut out is in the center of the table, and begin to cut out the design along the contour. Having cut out the upper part, we proceed to making the lower, background part of the casing. To do this, we also cut the sheet of iron into strips of the size we need, taking into account the edging. The width of this sheet should be 4-5 centimeters wider.

Turn the sheet face up. We place the finished top blank of the casing on it face down. We trace the outer edge along the edge of the design 4-5 cm wide and begin cutting.

Having prepared both pieces, remove the protective film from them and place them on top of each other.

We fix them with paper clips and make 1-2 holes with a 3-4 millimeter drill. Using a manual riveting machine, we make a control coupling so that the parts do not come apart. After that, we drill and rivet the entire structure. The window casing is ready.

DIY metal trims. Platbands made of sheet material

Cut strips of a certain width from prepared thin metal for metal trims. Turn the blanks intended for the upper section of the product face down, and fasten the template prepared in advance with paper clips on the reverse side. Transfer the openwork pattern from the sample directly to the platband.

Patterns for metal trim

After the entire pattern has been transferred, use a drill to drill holes along the edge of the pattern. Then cut out the ornament using these marks. Place the strip on the table so that the part that needs to be cut lies in the middle. Cut out the design along the marked border. This way the top part is prepared. To prepare the lower section, thin sheets of iron should be cut into strips, taking into account the edging.

Turn the blank strip face up and place the previously prepared top part face down on it. Draw an outer border along the edge of the pattern 4 centimeters wide and you can cut it out. When both pieces are ready, remove the protective film from them and place them on top of each other.

Cut out pattern for metal trim

Secure with paper clips and make several holes with a thin drill. Using a manual machine that can rivet, make a preliminary coupling so that the parts do not move apart. After this, drill and rivet the entire workpiece. The platband is ready for installation.