There are a lot of methods and technologies for glazing a balcony; they can be classified according to the following parameters:

- The degree of thermal insulation. There are two types of structures: warm - designed for arranging balconies used as additional living space; cold – protect primarily from direct exposure to precipitation, wind and dust.

- Material of frames and sashes. Nowadays, structures made of metal-plastic, wood and aluminum are common. Combined solutions are also possible, for example, aluminum-wooden ones, in which a weather-sensitive wooden frame on the street side is covered with an aluminum profile.

- Construction type. Conventional frames (profile, double-glazed window), frameless glazing, panoramic, stained glass, French balconies, non-standard projects (bay window, corner balconies of complex shape, including glazing of the internal corners of the building, balconies with extension).

- Method of opening the doors. Swivel, tilt or a combination of these methods, sliding, hanging.

Cold and warm glazing

When installing cold-type , a lightweight profile (usually aluminum) with a small number of insulated chambers and without any additional insulation is used. As a translucent filling, either a single-chamber double-glazed window consisting of two sheets of 4 mm each, or single glass is used.

Cold glazing has the following advantages:

- Relatively low weight of the structure. A lightweight aluminum profile in combination with single glass minimally loads the load-bearing balcony slabs, which is especially important when glazing in old buildings.

- Good transparency. The structure is assembled from a narrow profile, which takes up noticeably less space on the total area of the balcony. Thin glass, especially one-strand glass, better transmits natural daylight from the street.

- They're cheap. Fewer expensive materials are used for production, assembly and installation of frames is simpler. Cold balconies themselves are cheaper, since there is no need to insulate the floor and perimeter.

The main disadvantage is low thermal insulation. In the cold season, the temperature inside the balcony will be 3-5°C higher than outside. Some types of cold structures are not designed to install a mosquito net or protective screen for pets (anti-cat system).

Warm glazing

If the balcony is intended to be used as an additional living space, you will have to use a massive warm profile and an appropriate double-glazed window to glaze it. Warm profile systems have up to 7 insulated chambers; the energy efficiency of some models is further increased by special polymer inserts with low thermal conductivity.

Warm 7 chamber PVC profile 85 mm

Advantages of warm glazing:

- The microclimate of the balcony is practically no different from the general climate in the apartment.

- The wide frame profile and double-glazed windows allow you to achieve a high level of sound insulation, which is impossible with cold glazing;

- The massive and durable design of a warm balcony provides better protection against burglary than its cold counterparts.

Flaws:

- The weight of the profile system and the glass unit makes the structure massive, which is why such glazing cannot be installed on every building. Balcony slabs of Khrushchev's houses built in the last century simply cannot withstand the weight load. Actually, they are designed for the weight of the glazing, but it is unlikely that it will be possible to place any furniture on the balcony.

- Multilayer double-glazed windows and a bulky frame profile allow much less light to pass through, compared to cold options.

The features of the components and the complexity of installation make warm balconies quite expensive.

Possible difficulties during installation

Glazing work at height is a very important construction work, the implementation of which is associated with both hazardous work factors during the installation process and during operation of the window structure.

Errors associated with glazing are often made by contractors already in the process of preparing construction and installation work , if a thorough examination of the technical condition of external structures, especially for balconies, was not carried out, design calculations for strengthening structures and the selection of economically sound glazing options were not carried out.

Such errors are very difficult to correct and lead to the creation of an emergency situation in the house due to the possible collapse of PVC systems.

In addition, you can make many mistakes during installation work, especially if they are performed by non-professional performers :

The frame is not installed level, the sash is jammed, and the fittings do not work. Since the frame is already fixed, it is impossible to fix the problem without dismantling it.- Weak fastening of the PVC frame in the central part; the sash touches the frame when opening/closing.

- A low-quality PVC block for glazing was purchased without a quality certificate, with poor heat-insulating characteristics, and poorly functioning fittings.

- The work was carried out without agreement with the operating organization in violation of the space-planning design of the house, fire safety rules, SES, environmental and energy efficiency standards. Such glazing must be dismantled at the request of executive authorities.

- The balcony glazing is installed on a weak parapet and balcony slab, which may cause destruction and collapse of the structure, especially with gusts of wind.

- Assembly seams are not sealed.

- The canopy or roof over the balcony is not completed.

- The ebb and window sills are not completed.

Classification of glazing of balconies and loggias depending on the material

Both warm and cold structures can be made of PVC profile, aluminum, wood or a combination of some of these materials.

Metal-plastic glazing

Now this is the most common and affordable option. Features of PVC windows:

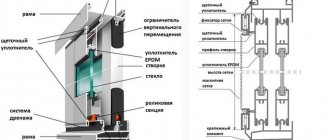

- The supporting frame and opening elements (sashes) are made of a multi-chamber plastic profile, reinforced with a reinforcing insert. Warm products have up to 7 chambers and are partially filled with thermal insulating polymer. The outer walls of the profile are made up to 3 mm thick, the internal partitions are 1 mm thick.

- The structure includes either double-glazed windows or opaque filling (sandwich panels). Depending on the brand of the profile system, a double-glazed window with a depth of more than 40 mm can be installed in it. Warm products are equipped with two-chamber (3 sheets, 2 chambers) double-glazed windows. To increase the sound-absorbing effect, glass of different thicknesses is used, and the size of the chambers is also different.

Energy efficiency is improved by filling the chambers with inert gas and using special glasses or coatings for them. - The junction of the frame to the glass unit and the sash to the frame is sealed with elastic bands, thanks to which it is possible to achieve high tightness of the structure. This point should be taken into account during installation, since the flow of air into the room will only be possible when the windows are open. Typically, additional ventilation (supply valves) is installed to ensure the necessary circulation.

- The most popular color is white. This profile is usually cheaper, looks good and is easy to maintain. Other colors are also available: the profile plastic is either painted by adding pigment to the polymer or laminated with a textured film. Both options are characterized by excellent performance and appearance. The film most often imitates valuable types of wood (a common option is oak), and does not fade or peel for the entire service life of the structure.

What is better to use for insulation?

We have already discussed this issue in detail in the article: “Do-it-yourself insulation of a balcony”

Plates based on basalt fiber. This is an environmentally friendly material that is suitable for insulating residential premises. The only condition is the mandatory use of hydro- and vapor barrier.

Another good option is regular foam. The optimal solution for small balconies. Due to its small width, it does not require the installation of a frame, so it is suitable for insulating narrow loggias.

Ways to open the doors

Now the most common options are:

- Tilt and turn opening. The fitting mechanism is reliable, resistant to burglary, ensures a tight connection of the sashes to the frame, there is the possibility of micro-ventilation, installation of additional protection against child access, a microlift and other useful functions.

- Rotary. The sash opens by rotating in a horizontal plane around its left or right axis.

- Folding. The sash opens by turning in a vertical plane around the lower axis.

- Hanging. Similar to folding ones, but the hinges are at the bottom.

- Sliding vertical sashes. They are equipped with English-type wooden windows and aluminum structures. Just like the horizontal version, they are mainly used for cold balconies.

- Sliding horizontal sashes. More often observed in aluminum structures. The only advantage is saving space on the balcony; the window sill can be used for flowers and other household needs. Does not provide a tight connection sufficient for the normal implementation of warm glazing. In winter, ice may form in the guides, which makes opening difficult.

The Slidors sliding system has been developed for plastic balconies. If installation standards are observed, plastic does not freeze like an aluminum profile and retains its functionality. The cost of such glazing is comparable to cold aluminum, but, according to the manufacturer, it is 2 times warmer and much stronger.

Necessary tools for glazing

A set of tools and consumables should provide the entire technological installation process from measuring the structure, dismantling the old PVC frame structure, installing a new one, adjusting the operation of fittings and pressing the sashes.

Basic set of tools for glazing balconies and loggias:

- Measuring kit: tape measure, level, angle and plumb lines.

- Metal and rubber hammer.

- Mallet.

- Assembly knife.

- Hacksaw and wood saw.

- Scrap.

- Electric drill and screwdriver.

- Victory drills.

- Self-tapping screws, anchors and dowels.

- Wooden beams for a loggia or metal fastenings for a balcony parapet.

- Polyurethane foam.

- Slings.

- Waterproof and heat-protective materials for warm glazing options.

Classification by type of construction

The most common and accessible traditional glazing method is an opaque bottom finish around the perimeter and frames with double-glazed windows at the top. There are also frameless options, French balconies (panoramic), stained glass and custom designs.

Frameless glazing

The doors are not framed by a profile visible to others. Visually, the structure looks like it is assembled from separate sheets of glass. Each section at the top and bottom is attached through guides to the load-bearing elements of the balcony; on the sides, the blind sections are connected to each other using sealant. Appropriate mechanisms and seals are provided for opening elements.

Advantages of frameless solutions:

- The maximum possible translucency since there are no racks or partitions.

- Balconies glazed in this way look original, light and airy.

- The safety of the structure is ensured through the use of durable impact-resistant glass and reliable fasteners.

Flaws:

- Low thermal insulation. Energy-efficient solutions are expensive and weigh a lot, which significantly limits the possibility of their installation.

- Relatively low absorption of external noise. Sound louder than 10 dB, especially in the low frequency range, will be heard indoors.

- Qualified specialists are required for installation.

- The most even surface around the installation perimeter is required.

See how it looks in our video:

French glazing type

Installation of French balconies is carried out directly on the lower concrete slab. If there was a solid fence before, it will be completely dismantled. Depending on the customer’s wishes, the structure can be assembled from solid blocks or from groups of elements. The filling is made transparent, tinted, matte, or double-glazed windows with an adjustable level of light transmission are installed.

Advantages of French type balconies:

- High degree of natural light during the day, which helps save energy.

- The absence of a bulky fence increases the usable area, in addition, such structures themselves look more spacious.

- High level of energy saving and noise absorption, which allows you to equip warm balconies.

Flaws:

- Relatively high price, especially when using special double-glazed windows as filling (energy-saving films, adjustment of light transmission).

- In summer, excessive heating of the room is possible, in particular on balconies installed on the sun side.

- The sealed design requires the installation of additional ventilation.

- Warm balconies are usually made of PVC profiles glazed with massive energy-saving double-glazed windows. This places a significant load on the load-bearing slab, which must be taken into account in the design.

When might PVC frames need to be replaced?

There are several cases when owners decide to install PVC glazing. These include :

- urgent work to eliminate an emergency situation, which is carried out immediately upon detection;

- planned - for the creation of primary glazing, carried out throughout the year;

- promising - related to modernization, for example, replacing cold glazing with warm glazing with the installation of energy-efficient double-glazed windows, can be performed during a major home renovation.

Emergency replacement of PVC glazing on loggias and balconies is usually caused by mechanical damage to the structure or from hurricane winds, or as a result of improper installation of the system. It is necessary to begin eliminating it immediately, inviting specialists - high-altitude workers - for this work, so that the collapse of the structure does not cause an accident for surrounding people.

How is technology changing?

Due to the introduction of new technologies and materials in construction, in most cases, the installation of glazing on loggias and balconies is associated with modernization and major repairs, both in a separate apartment and in an apartment building.

These directions of modernization are different, for loggias mainly energy-efficient warm glazing is installed , with the goal of creating an auxiliary warm room, and for balconies, due to their small area, greater emphasis is placed on new design forms, for example, installing French or panoramic frameless structures.

significant benefits to the owners for several decades :

- Obtaining additional living space.

- Insulation of the façade part of the wall, which will have a positive effect on saving energy resources.

- High resistance to heat loss in the room.

- Increased noise protection of the apartment.

Non-standard projects

This category includes semicircular, round, polygonal structures and balconies with extensions. The arrangement of excessively long or narrow rooms can also be called non-standard, but their glazing is not much different from the usual.

Round and semicircular balconies are glazed in one of three ways: chord, bay or radius.

- Chordata. The perimeter semicircle is filled in sectors with straight frames, resulting in a somewhat angular structure. This option is the easiest to implement and the cheapest, but it does not look the best and is characterized by low energy-saving qualities.

- Bay window. The glass in this case is also flat, but a special semicircular profile is used, thanks to which the angles between the sectors are smoothed and the structure is more rigid. Bay balconies are more expensive than chord balconies, but they are warmer and more reliable.

- Radial. The most expensive and high-quality option. The profile goes around the contour of the fence, completely repeating its shape. The designs use special glass with good sound and heat insulation; panoramic implementation is possible without vertical profiles.

Glazing of polygonal individual projects or balconies in buildings of the p-44 series technically differs little from the arrangement of conventional straight or U-shaped structures.

Plastic window installation technology

Installing plastic windows on a loggia or balcony is not an easy task, but it is quite doable. When deciding to save on installation and perform this process yourself, you should carefully familiarize yourself with the technology for performing the work. To learn how to install plastic windows according to GOST, watch this video:

Window measurements

They begin replacing windows by taking their measurements. This process must be carried out very responsibly. Ordering windows from the company of your choice is possible only after accurate measurements of the future window have been taken.

So, the correct process for measuring windows is based on measuring distances in three places. These are the two extreme points of the fence and in its middle. Since the opening is never ideal, several measurement options are needed to determine the dimensions of the future window. The smallest value is taken as a basis.

Window measurement scheme

So, the basic rules for taking measurements:

- The width of the window structure is determined by the length of the fence on which the window will be installed. From the obtained value, subtract 60–70 mm on each side. This provides space for the installation of connecting profiles.

- The height of the window is determined by the distance from the fence to the upper ceiling. At the same time, do not forget to reduce the values by 25–30 mm.

Preparing the opening

Before starting the installation of new windows, remove the old sashes and dismantle the window frames.

After the measurements have been taken and the windows have been ordered, we begin preparing the opening for the installation process. First, the old device is dismantled. The work must be carried out very carefully and avoid breaking the fence.

- Glass is first removed from old frames. This is done using a chisel. First, remove the vertical beads, then the top and bottom, after which the glass is removed;

- then the window sashes are removed from the hinges;

- then in some places they saw the frame and carefully break out its parts.

All disassembled parts must be removed from the balcony room and the opening must be cleared of debris and dust.

Installing the visor

Before installing the structure, it is necessary to determine the suitability of the old visor. If its further use is possible, then it remains to check its stability and, if necessary, strengthen it. If there is a need to install a new canopy, then this process can be performed according to the following scheme:

- First, the rear frame is installed. It is welded from metal corners. Then we make holes in it for the anchor bolts. In the upper part of the frame, holes are made in increments of 40–60 cm, and in the lower part it can be increased.

- Next, the frame is pre-installed in its place, the level is checked and the places where the holes fall are marked. We also mark the line for placing the upper part of the frame.

- At the next stage, we make holes for fasteners in the concrete floor along the marked points, and make a groove along the line. The depth of the groove must be at least 20 mm.

- Next, the back frame is attached to the wall, and the slopes and crossbars are attached to it.

- We prepare the roofing material for the canopy. In most cases, galvanized stainless steel is used for this. The visor is installed with the edge in the groove, and then attached to the frame by welding. The groove is sealed with cement mortar. For more information about installing the visor, watch this video:

The installation of the canopy must be done before installing the window structures, since after installation it is quite difficult to insert it into the opening between the profile and the ceiling and almost impossible to securely fasten it.

Elimination of condensation

When installing PVC windows on the balcony, you need to be prepared for the formation of condensation. Moisture accumulation occurs due to temperature differences. The following tips will help you avoid condensation:

- the balcony railing must be insulated using membrane waterproofing;

- the presence of two chambers in a double-glazed window and double insulation in the frame also helps;

- installation of special ventilation holes on the frame;

- It’s a good idea to equip hoods on the balcony space.

All these recommendations are associated with design features and certain financial costs. There are a couple of universal and simple solutions available to everyone:

- lit candles are a beautiful and practical way to remove excess moisture;

- natural ventilation, or regular ventilation.

Accessories

The quality of the fittings determines the tightness of the closure, tightness, security against burglary, the functionality of the sash and, in many respects, the service life of the double-glazed window. Therefore, it is better to give preference to reputable brands. The traditional leaders in the window fittings market are German and Italian manufacturers: Rehau, Siegenia, Maco, Roto, GU, Aubi, Winkhaus , etc.

For balconies on low floors, it is recommended to provide anti-burglary fittings that will prevent entry into the apartment from the street. If there are children in the house, it is necessary to install removable handles, locks and blockers. For a balcony door, it is better to provide a double handle that can be opened from the inside and outside - this will significantly increase ease of use.

General information

Sliding balcony glazing has become popular due to its low weight, low price and convenient operation. The system is called this because it opens not in a hinged way (as is done in most windows, when you turn the handle and pull it towards you), but in a sliding way (that is, the glass slides apart, thereby freeing up space). The design of sliding and casement windows is completely different, so do not confuse them.

Such a product (sliding windows) can be made of plastic, but the most popular option is aluminum sliding windows for the balcony. This material has a large number of advantages compared to plastic (this will be discussed in the article below). In addition, the aluminum sliding system has several varieties, which is why people often do not know what is best to choose.

Types of double-glazed windows

Balcony double-glazed windows are structures consisting of several layers of glass. The chamber is the space between the layers. The number of chambers is the determining factor in the classification of double-glazed windows into types. Manufacturers offer three main types:

- single-chamber;

- two-chamber;

- three-chamber.

Each of these types has its own characteristics, advantages and disadvantages.

Single chamber

The design of a single-chamber balcony double-glazed window implies the presence of two glasses with a thickness of at least 6 mm. The width of the chamber enclosed between them reaches 14-18 mm. The total width of the glass unit is approximately 30 mm.

Simple at first glance, the device also has its advantages:

- light weight;

- arrangement of large areas;

- accessibility to a wide range of consumers.

One camera also has disadvantages:

- the small thickness of the glass unit will not allow for complete insulation;

- poor sound insulation.

Double chamber

Two chambers in a double-glazed window on the loggia will provide more tangible comfort than one. This type of construction is thoroughly durable, as it has 3 glasses and 2 chambers. Chambers may also differ in volume. In this case, the total thickness should be no more than 30 mm.

A double-chamber double-glazed window differs from a single-chamber double-glazed window in the following ways:

- using materials with a higher level of thermal insulation;

- cost, which is usually a quarter higher.

When choosing high-quality and reliable fittings, double-glazed windows will justify the credit of trust with their durability and strength.

How to care for sliding windows?

Sliding windows, unlike casement windows, require more careful maintenance. Therefore, let's take a closer look at the features of caring for sliding windows on the balcony. Mandatory maintenance elements include adjusting locks, adjusting limiters (they can get lost), lubricating fittings, and cleaning the surface from dust and dirt. It is worth noting that it is necessary to clean not only the surface of the glass unit and profile, but also the insides of the gutters, seals and other elements of sliding windows.

If cracks have formed on the surface, they urgently need to be sanded and covered with a special product. It is enough to lubricate the fittings once a year, but if it wears out quickly, you can lubricate it once every six months. Regular machine oil is suitable for this purpose, or you can purchase a specialized product from the manufacturer. The surface of the profile itself must be wiped from dust at least once a week; this is not only the care of interior elements, but also the prevention of allergic diseases. It is enough to wash the glass itself once every 2-3 weeks with specialized products and a soft cloth.