Not every room needs to install opening plastic windows; sometimes a simple blind window will suffice.

This option allows you to save money, since you do not need to use a large amount of fittings to install and produce such a structure.

Blind products for window openings are in demand in rarely visited rooms where ventilation is not required. To understand where it is better to install such windows, it is recommended to learn more about their types, pros and cons.

What it is?

The term “fixed plastic windows” refers to a structure made of a frame and double-glazed glass without sashes and window fittings. Such products cannot be opened at all .

These structures are purchased in order to save money, as well as to improve thermal insulation and prevent high noise levels in the room. Such products have long taken root in the Russian market due to their availability and durability. Of course, caring for such a window product will be problematic, since it does not open.

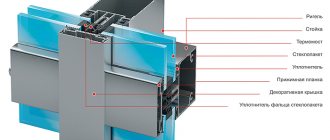

Note! When installing such a product, a glass unit is inserted into the frame and pressed from the inside with a wide bead. In PVC windows, the width of the glazing bead is 33 mm.

When and where is installation possible?

Installation is advisable in the following cases:

- private sector;

- premises located on the first floors;

- when the room is already glazed with several windows with opening sashes and there is no need to make another window product the same;

- if the room has many openings with a small area;

- with panoramic glazing.

The last point deserves special attention.

It is recommended to use blind sashes for panoramic glazing due to the large dimensions of the design of such a product.

If you hang window fittings on a window of such an area, this will make it heavier, and over time the sashes will sag. This will not happen in the case of a solid double-glazed window.

It is not recommended to install blind structures in rooms where there are no other opening windows, where there is no ventilation valve for air supply, and also where there are no other ventilation systems.

Flaws

When choosing plexiglass glazing, you must remember about the flammability and high coefficient of thermal expansion of the material. It does not withstand exposure to open fire, so to avoid damage, all products made from it should be kept away from the fireplace, gas stove, heating boiler and other sources of fire.

Acrylic sheets are very durable, but their surface is not as hard as that of silicate glass, so scratches, abrasions and other minor mechanical damage can appear on it quite quickly if the product is not properly cared for.

In general, the numerous advantages of plexiglass more than cover its disadvantages, so in everyday life, general civil construction and other areas, this material is gradually becoming a full-fledged replacement for silicate glass.

Subtypes of closed PVC structures

All these window products can be divided into subtypes according to:

- designs;

- glass unit;

- window profile;

- shape and color.

By design, such windows are single, double, or triple-hung. The most common option is a single-leaf blind window. Also, one of the sashes in a three-leaf window may be blind - in this case, it can be easily washed by opening the adjacent sashes.

According to the type of double-glazed window, blind products are one, two, three, four and five-chamber. The most common ones are one, two and three-chamber, since a blind window product is itself airtight and installing more double-glazed windows does not make sense.

According to the window profile, such products are made from class A and B profiles. Class A has an outer wall thickness of 2.8 mm, and class B has a thickness of 2.5 mm. There is also class C, but it is mainly used when creating windows for non-residential premises.

The shape and color of the products are rectangular, triangular and arched . Creating a window of any shape will be the main advantage of a blind design, since fittings are not used here and it does not matter how the window will open.

Types of plexiglass

Many people, when choosing acrylic or a material such as plexiglass, ask the question - what is the difference, which is better? In fact, the difference is not significant. There are commonly used terms that mean the same material, namely this:

- Polymethyl methacrylate.

- Organic glass, or as it is often called, plexiglass The material is very similar to silicate glass, but has characteristics many times better.

- Acrylic glass or acrylic. The material is made using organic components.

- Plexiglas is one of the varieties of plexiglass. When choosing plexiglass or acrylic, you are making a choice, essentially, between the same materials, but you should focus on the purpose and conditions of use of the finished product, since there are varieties of plexiglass with different parameters.

Acrylic glass is produced using two main technologies, namely:

- Extrusion method;

- Casting method.

When manufactured using the first technology, the material turns out to be less durable than when using the second method.

In this case, fewer color options are available, but the finished sheet size can be much larger. Also, due to certain manipulations, the master has the opportunity to make a finished sheet of plexiglass of the required thickness, ranging from 1.5 to 24 mm, but cast plexiglass can be of greater thickness. Cast acrylic is less easy to process, especially when it comes to gluing; this should definitely be taken into account when working with this material at home.

There are many varieties of acrylic on the market, which opens up wide opportunities for designers who are increasingly using this material in their projects. The following varieties can be distinguished:

- Grandsilk. This material is made with a surface that imitates metallic. You can find about 40 varieties of color solutions. Most often used in furniture production.

- Kamellit and Shine Glass. This type of plexiglass has a glossy surface. Among the features, it is worth highlighting the high degree of resistance to water. The material can be easily polished. It does not lose its color saturation over many years. Most often used in the manufacture of kitchen furniture.

- Satin Glass. A type of acrylic with a matte surface. When used, no touch marks or scratches remain on the surface. It is most often used in furniture production, in the manufacture of chairs and interior partitions. Decorative elements made from this material are very popular.

- Element Glass. This is one of the most unusual types of acrylic. The difference is that various materials are “fused” into the base; they can be of either natural or artificial origin. These are shells, dried twigs, pebbles or even fabric. The scope of application of this plexiglass is quite diverse, because the material is unusual and simply looks gorgeous.

- Plexiglas SDP. A type of cellular plexiglass. Consists of two layers. Among the characteristics, it is worth noting increased impact resistance, as well as resistance to atmospheric influences, therefore, this is an excellent choice for outdoor use.

- Frizzz. This is a very interesting and beautiful type of acrylic. The material is matte and has a velvety structure. Among the characteristics is increased resistance to scratches and dirt. Area of use: window dressing, office furniture production, light cubes.

- Plexiglas with fluorescent effect. This material is made transparent, but in various colors. Its ends emit a “glow” when exposed to ultraviolet rays. As a rule, this material is used in the manufacture of shop windows, as well as art installations.

Plexiglas processing

This material belongs to high-quality types of plastic. It is good for both indoor and outdoor use. The modern market offers a wide selection of plexiglass with various operational features. It is worth noting that it is easy to process, which means that, if desired, you can independently make various products from it. You can learn more about acrylic processing by going to the appropriate section on our website.

Insert options

In the production of blind plastic window products, not only double-glazed windows are used, but also plastic inserts. It is recommended to take a closer look at the different insert options.

Plastic

A plastic insert into a blind window is called a sandwich panel. It is often used on balcony doors at the bottom to visually divide the structure. Often such a panel is used for a blind window without a double-glazed window.

There are such design features:

- Protecting the room from views from the outside, especially if the room is on the ground floor.

- Relevant for bathrooms whose windows border other rooms.

- Can be used for further ventilation outlet.

- This panel has good thermal insulation - 0.8 m2/kW.

But there is also a minus - the sandwich panel does not have sufficient sound insulation , which is why it is not recommended to insert it into the structure in places where there is a high noise level. Sometimes, as an alternative, a combination of double-glazed glass on one side and a panel on the other is used.

Double-glazed window

Double-glazed glass insert is the most common option. These are not only high energy-saving indicators, but also an attractive appearance.

Several advantages:

- tightness;

- good noise absorption;

- different glass thicknesses ensure good thermal conductivity;

- ease of care.

This design will cost a little more than a sandwich panel and this will be its only disadvantage.

Polycarbonate

Of the two types of polycarbonate (monolithic and cellular), it is the first that is considered the most durable transparent material currently on the market. It is not afraid of heating up to +100 degrees, frost up to -50 degrees, exposure to precipitation and other adverse factors, and is not broken even with a hammer or crowbar.

On a note! The material is ideal as an anti-vandal protective coating - it can only be destroyed by a pistol shot.

The advantage of monolithic polycarbonate is the possibility of use in fire-hazardous facilities and in hot workshops in production. It has low toxicity, low smoke generation and belongs to the category of self-extinguishing materials.

Cellular polycarbonate is perfect for making greenhouses and conservatories, glazing bus stops, and creating canopies. It is thin, light, but durable, as it has a special honeycomb structure. There is air inside the honeycomb, located between two thin sheets, so the material has low thermal conductivity. Cellular polycarbonate can also be bent, which only expands its scope of application.

Cellular polycarbonate partition

Important Features

The characteristics of closed PVC windows include::

- Intended only for the first floors.

- Made from polyvinyl chloride.

- Can be single or separate.

- They do not have an opening mechanism.

- Single-chamber or double-glazed windows.

- Use of plastic beads.

- The profile width is on average 70 mm.

- The width of the outer wall is 2.7-3 mm.

- Type of plastic – frost and ultraviolet resistant.

- Factory service life is at least 40 years.

It is worth mentioning separately about the dimensions of blind structures. Often these dimensions are 500x500mm, 600x1300mm, 1300x1300mm, as well as 2100x1300mm and 1600x2100mm. The latter option is used in a high opening and has a T-shaped division.

Thermoplastic

Extruded plastic (PET) is similar in properties and composition to plexiglass, only it is more durable - it can withstand loads 10 times higher. The material retains all its properties over a wide temperature range (-40...+70 degrees), is non-toxic, resistant to aggressive liquids and chemicals. It is perfect not only for household purposes, but also for use in medicine and the food industry.

Monolithic sheet plastic PET-A

It is made from:

- advertising banners, billboards;

- interior elements;

- designer products;

- lighting devices;

- glazing of doors.

Requirements for a window unit

The main requirement for installing such a window product is that it cannot be used above the first floor . This is due to a violation of fire safety rules. A few more requirements for such structures:

- There should be no cracks, chips, scratches or other defects on the double-glazed windows.

- The window seal must not be compromised.

The sashes must have the correct shape, distortions are not allowed.- Each design must have a passport.

- During installation, waterproofing and vapor barrier tapes must be used.

- There should be no cold bridges in the fastening points.

- The profile specified in the order must be used.

- Installation must take place at a temperature not lower than -18 degrees.

Attention! According to the requirements, all components for a solid structure must be tested for durability.

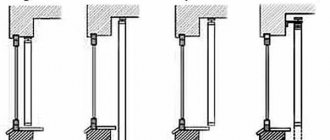

DIY installation features

There are several features when installing a closed PVC structure:

- First, prepare the opening: to do this, dismantle the glazing beads and carefully remove the old glass.

- Remove the external flashings, remove the frame and remove the entire seal.

- Remove window sills and remove plaster from slopes.

- The opening is prepared and the slopes are leveled.

- The frames are then assembled into one block.

- Insert the block into the opening, fix it with wedges on the sides, using a building level.

- Holes are drilled in the walls and the block is secured with bolts.

- Glue the outer joint with a diffusion strip.

- The seam is sealed with polyurethane foam 70%, after 20 minutes - the remaining 30%.

At the final stage, double-glazed windows are inserted and a window sill is installed.

Terms of use

The main feature of using such a design is the problem of caring for it.

You can wash such a window product only from the outside , and this is most feasible if the structure is installed on the ground floor.

To do this, just use a stepladder. The question also arises: how to ventilate a room with such a window?

- Firstly, you should not install such products where there are no other opening windows in the room.

- Secondly, if a window is installed, then forced ventilation will have to be installed to ventilate the room.

Replace glass in a door - how to replace glass in an interior door

Doors with glass inserts of various configurations and sizes are not an invention of today or even yesterday. Previously, this was called stained glass doors and they were installed not only for beauty and grace. In some houses and other residential and non-residential premises, such doors also carried a certain semantic load. They depicted coats of arms, some landscapes and religious symbols. Nowadays, this point is rarely observed, but other functions have appeared.

Visually increasing space, better lighting, maintaining the overall style of the room, and so on. But the inserts have changed little in their physical properties, and sometimes it becomes necessary to replace the glass in the door. It is, of course, easier to call a glazier specialist, but doing it yourself is not so difficult.

How to replace glass in a door?

Replacing glass in a door

The answer to this question suggests itself, and it is quite natural. Another similar glass. Logical, isn't it? But sometimes it happens that glass that is suitable in size, design or color cannot be obtained within a short period of time, and replacing broken glass in an interior door is simply necessary. Leaving it in place, firstly, is unsightly, and, secondly, dangerous. Especially if there are small children in the house, who constantly forget the most important instructions of their parents and can get hurt. And therefore, you will have to look for a replacement, and neither pride nor aesthetic education allows you to leave a hole in the door.

The simplest option is to insert a neatly cut piece of plywood or fiberboard. They can even be somewhat refined by pasting them with some exquisite pattern. Or attract the same children to paint it in the style of the early impressionists. Just remember that this is a temporary option and you still need to look for and then insert suitable glass.

Getting ready for work

Tools for work

Any household work related to the repair of some mechanism, household appliance or interior door begins with the fact that the person who is going to carry out this repair selects the optimal set of tools. To fix an iron, you will probably need a soldering iron. To hang wallpaper, you need a roller, scissors and an assistant. To hang a shelf in the bathroom, you need a drill, dowels and precise instructions from your wife on exactly where to hang the shelf.

To replace broken glass in a door you will need:

- Gloves.

- Wide screwdriver.

- Hammer.

- Chisel.

- Sharp knife.

- Tape measure or centimeter.

- Sealant, rubberized gasket or glazing bead.

And the last step before replacing the glass in an interior door is to remove the door itself from its hinges and place it in a comfortable position. Of course, you can carry out this operation right on the spot, but it will be more convenient, and removing modern doors is a matter of a few seconds, you don’t even need an assistant. Just open the door, lift it and that's it.

Just make sure that the fragments from the damaged insert do not fall out and injure you.

Step-by-step instructions for replacing glass

Features of working with glass for doors

So, all the preparatory work has been done. The right tool is within arm's reach. No one is running around or standing over your shoulder. Let's get started:

- We remove the damaged glass and all fragments. This is where gloves are needed. The chips are probably sharp and it is quite possible to injure yourself on them when pulling them out with your bare hands.

- Remove the bead or gasket.

- Remove any putty or sealant.

- It would be a good idea to go around the entire perimeter with sandpaper.

- We take measurements. It must be taken into account that the glass insert itself must be installed without the slightest effort. Therefore, both the length and width are calculated so that they are several millimeters smaller.

- Based on the dimensions obtained, we order glass from a glazier or cut it out ourselves.

At this point, the process of removing the glass insert, which for some reason has broken or become unusable, can be considered complete. The time has come to restore the door to its original condition.

- Along the entire perimeter, closer to one edge, it is necessary to apply a layer of silicone sealant.

- The new glass insert is secured with a gasket.

- On the other side of the glass, a layer of silicone sealant is again applied.

- We secure the insert with glazing beads and leave it for some time necessary for the sealant to harden.

- We shake the doors lightly, checking that the glass insert does not rattle. Otherwise, seal the joint with another layer of sealant.

- If everything is done efficiently and there are no side effects, you can safely hang the door in its rightful place.

All that remains is to check that the door, updated with a new glass insert, rotates on its hinges as freely as before and to carefully tidy up the workplace, where there could be glass shards invisible to the eye. Sometimes even working with a powerful vacuum cleaner for a long time cannot collect them all. In this case, it’s worth using a little trick that everyone used in childhood when sculpting figures from plasticine. Knead a medium-sized piece of this elastic substance in your hands and walk it over the entire work area. Even the tiniest fragments will not hide from plasticine, and the heels of all your family will be safe.

Paneled door

With paneled doors, everything is both more complicated and easier at the same time. It’s more difficult because you’ll have to disassemble almost the entire door piece by piece. Easier, because there is nothing difficult about it.

We also remove the door from its hinges. We lay it horizontally. We find special plugs that cover the fasteners. Carefully remove them and unscrew the fasteners until access to the damaged element opens. Let's delete it. We insert the same one in its place and do everything in reverse order.

Door with grooves

There is another configuration of interior doors in which you can replace damaged glass yourself. This is a door with special grooves at the end, through which, without any difficulty, you can remove a broken insert or its fragments and through the same groove insert new glass, selected in size and color.

There is also a little secret here on how to do this operation faster and easier. If the new glass, which was selected with special care, and should simply fly into place with a whistle, does not want to be inserted there, you just need to slightly lubricate its edges with a soap solution. After this, the sliding of glass in the groove will become much smoother and easier.

Apartment renovations can be of different types. Planned capital. Temporary, necessary only until better materials are purchased. And urgent, delaying which even for a few days means exposing your loved ones to danger. Broken or cracked glass in an interior door refers to the latter option. There is no need to hesitate to replace it. And why? To gain the necessary knowledge? They are not required. This work is no more difficult than others you do around the house. But even if there are any doubts, it doesn’t cost anything to just sit down and think for a few minutes about how to do it quickly, simply and efficiently.

prodverivdome.ru

Pros and cons of use

The main advantages include:

- Favorable cost of glazing: since fewer profiles are used, the price of the structure will be lower.

- Excellent tightness.

- Minimal heat loss.

- High light transmittance due to the minimum number of constituent elements.

- Maximum usable space on the windowsill.

- Possibility of glazing large window openings.

- Long service life due to the lack of fittings.

Important! The disadvantages include difficulties with cleaning double-glazed windows, difficulties with ventilating the room, as well as the inability to easily exit through the window product in the event of a fire.

Average prices in the Russian Federation

The cost of a fixed plastic window is affected by its size, the presence of double-glazed windows or PVC inserts (sandwich panels).

For example, a structure measuring 500x500 mm will cost an average of 900 rubles, and with installation - 1200 rubles.

At the same time, a product measuring 2100x1300 mm, three-leaf, will cost from 7,080 rubles without installation, and from 10,300 rubles with it. If instead of glass a sandwich panel is used in the design, then a product measuring 840x1560 mm will cost 3,500 rubles.

Is it possible to make it openable and how?

This procedure can be done, but do not forget about the accuracy of measurements and the accuracy of the installation itself . A master must come to the work site and take measurements and send a request for production. When the structure is ready, the installer will come.

The blind glass unit is dismantled, holes are made on the frame for the hinges. Install the frame and all necessary fittings. On average, such a service will cost 10,000 rubles including the sash.

Video on how to make fixed windows openable: