It's no secret that wooden and plastic windows of modern designs are at the peak of popularity. But there are also many people who refuse to replace old wooden windows with new ones. But what’s interesting is that financial capabilities are not the most important argument when you don’t want to replace windows.

Some people are so used to using sash windows that a sash design is not suitable for them. In order to diversify the sales market and satisfy all customer needs in the window business, manufacturing companies have developed the design of wooden windows with a window.

In our article we will try to analyze not only the advantages of wooden windows with vents, but also their disadvantages.

Glazing options for wooden windows for a summer residence

A window structure made of wood is in many ways similar in structure to a plastic one. There is a main profile in which glass, seals and fittings are placed. Even if you are not often outside the city, rarely spend the night or hardly visit the site in winter, installation of double-glazed windows is very important.

Our company installs three profile options - Econom, Standard and Elite. For areas where you visit during the warm season, the first type is good. Models differ in profile thickness, type of seal, fittings and materials.

Advantages of window units with a window

On the Russian market you can find not only plastic windows with vents, but also their relatives made of high-quality wood. Compared to Soviet-era windows, they have a lot of advantages:

- No drafts. This ventilation mode can be called comfortable, since even with the window completely open there will be no draft.

- The wooden windows with a window are equipped with a child lock, which is locked for security purposes. Therefore, there is no longer any need to worry about the child opening the window on his own.

- Effective ventilation in the kitchen. It's no secret that a flap in the kitchen that is wide open can cause a draft. The flap in the tilted position may not cope with the task, which will lead to poor ventilation of the room during cooking. Therefore, a window provided in a wooden window will be an ideal option for ventilation. It completely eliminates the formation of drafts and effectively removes unpleasant odors.

- Extra space on the windowsill. Modern designs with double-glazed windows and a window allow you to use the window sill at your discretion very effectively. Old windows do not have this option, since the window sills are very narrow. In a modern design, you can not only store fruit here, but also place indoor flowers.

Comparison of wooden profiles

| Economy | Standard | Elite | |

| Three-layer laminated timber | Spliced pine | Pine, larch, oak, mahogany | Pine, larch, oak, mahogany |

| Profile thickness | 78 mm | 78 mm or 90 mm | 78 mm or 90 mm |

| Color | White | Any color from the standard set of colors and RAL color chart, double-sided painting possible | Any color from the standard set of colors and RAL color chart |

| Double-glazed window | 42 mm (4×14×4x16×4) | 42 mm (4x14x4x16x4) or 52 mm (4x20x4x20x4) | 42 mm (4x14x4x16x4) or 52 mm (4x20x4x20x4) |

| Seal contours | Two sealing circuits from Deventer | Two sealing circuits from Deventer. It is possible to install a third sealing circuit on windows with a thickness of 90 mm | Two sealing circuits from Deventer. It is possible to install a third sealing circuit on windows with a thickness of 90 mm |

| Accessories | Siegenia-Aubi | Siegenia-Aubi, Roto, Maco | Siegenia-Aubi, Roto, Maco |

| Paints and varnishes | White paint: ADLER (Austria) or MAV (Belarus) | ADLER (Austria), REMMERS, SIKKENS (Germany) | ADLER (Austria), REMMERS, SIKKENS (Germany) |

| Drainage profile | Unpainted aluminum | Painted, framed, sash | — |

| Production drainage and ventilation system | — | — | GUTMANN (Germany) |

| Possible configuration complexity | — | Arch, circle, triangle, trapezoid, curved glass installation | Arch, circle, triangle, trapezoid |

Disadvantages of wooden windows with vents

- The first drawback is the high price. Naturally, an ordinary wooden window with double-glazed windows, but without a window, will cost less. This is explained by the fact that more materials and labor hours will be spent to produce a window with a vent. It turns out that a small detail can affect the price increase.

- Additional partitions in the window block reduce the flow of natural light into the room. This difference can be noticed if a window unit without a window is installed in one room, and in another with a window, then the difference in the degree of illumination will be noticeable to the naked eye.

It’s easy to see that the advantages of a wooden window block with a window are much greater than the disadvantages. How critical they will be in your situation is up to you to decide. Therefore, before choosing a design, analyze the pros and cons again.

Wooden windows made of pine, larch and oak

In 2014, we began producing wooden windows in St. Petersburg. New equipment, qualified specialists and automated production processes give us the opportunity to produce wooden windows with double-glazed windows quickly and efficiently.

We produce windows only from proven quality materials. Our models are assembled from timber with a thickness of 74 to 110 mm at the request of customers and are equipped with 2- or 3-chamber double-glazed windows with a seal from the German company Schlegel.

Wooden windows made of pine

In terms of their heat-saving and performance characteristics, pine windows are not inferior to windows made from more expensive types of wood. Moreover, such windows are as affordable as possible.

Wooden larch windows

Larch is the most reliable material for our climate. The pores of this tree contain a lot of resin, due to which larch windows have increased moisture resistance and durability.

Related article: Purchase and sale agreement for PVC windows

Wooden oak windows

Oak windows are the most reliable, durable and beautiful. By installing oak windows in your cottage or apartment, you will emphasize your level of connoisseur of beauty and strength.

For metal-plastic windows

Manufacturing Features

All the time that I worked with metal-plastic windows, I met people who wanted to order a design with a window. At the same time, the force of habit was so great that I was not able to dissuade everyone from this idea in favor of a more effective mechanism for ventilating the room.

The main difficulty when inserting vents into a plastic window is related to the limitations imposed by technological production processes. Without going into details that are only interesting to professionals, these restrictions may be related to:

When welding a profile (pictured), the machine can only work with workpieces of a certain length

- with the size of the sash itself. The design of most machines for cutting and welding PVC profiles allows you to form products with linear dimensions no less than a certain value. This means that it will not always be possible to make a sash with a width of about 30 - 35 cm - and some operations will have to be performed manually. This not only increases the cost of the process, but also reduces the level of reliability;

Handicraft production of miniature sashes

- with glass size. The situation is the same as with the sash profile: it is possible to make a double-glazed window smaller than a certain size, but this must be done manually, and therefore it is time-consuming and expensive;

- with special fittings. As a rule, turn-and-turn kits are installed on sashes of at least 350x400 mm (+/- 20 mm in both directions depending on the manufacturer), and tilt-and-turn kits are installed on even larger products. Consequently, some vents will have to be fitted with standard hinges and locking bolts, which significantly limits functionality, but most importantly, it breaks the tightness by reducing the quality of the clamp.

If the sash is smaller than a certain size, then the fittings simply won’t fit on it.

There is one more nuance why a PVC window with a window seems to me not the best solution. The thing is that the plastic profile used to make the sash is quite high. So it turns out that the already small window opening will be limited on all sides by a frame at least 50 mm wide, so in a 30x40 mm window the light opening will be only 20x30 mm.

In general, the difficulties are surmountable - but they exist, and due to them the price of the window structure increases by about 30-40%.

Advantages and disadvantages

Despite the fact that installing vents in metal-plastic windows is associated with certain difficulties and is not widely practiced, this solution also has objective advantages:

- Ventilation is carried out through a relatively small open opening, which allows you to retain heat when ventilating the room in winter . This applies to both fully opening the sash and setting it to micro-ventilation mode: in winter, even a standard micro-gap 2 mm wide ensures a fairly quick cooling of the room.

A window is most often installed at the top of the opening, because cold air from the street mixes with warm air under the ceiling. This allows you to avoid the discomfort that is inevitable when a person is blown with a cold stream from a window.

- The open window turns into an improvised hood. This advantage will be appreciated by smokers, as well as those who like to cook: as my experience shows, smoke from the stove is much better removed through the sash open at the top of the window.

Not the worst option in terms of functionality and design

- Not having a large opening makes your window safer. On the one hand, the risk of unauthorized entry from the outside is reduced, on the other hand, the likelihood that children or pets, standing on the windowsill, will fall out of the window open for ventilation is minimized.

As for the disadvantages, they are also quite significant:

- Adding a small opening flap significantly complicates and increases the cost of the design. In this case, the width of the sash is usually greater than its height, which increases the load on the hinges.

- The small size of the window rarely allows you to install a full-fledged fittings complex on it. This means that we have to be content with only a rotary opening, without the possibility of micro-ventilation, stepped ventilation, tilt-up installation, etc.

Solving the problem with step-by-step ventilation using the “crutch” option

If these functions are important to you, and you definitely want to see them in your window, then instead of a classic window, you should install a transom - a wide and low sash in the upper part of the window, with hinges on the lower side, providing only folding opening. To install a transom, the fitting systems of most manufacturers have special transom scissors, so the functionality of such structures is quite wide.

- As I noted above, the significant width of the profile panels leads to a reduction in the light opening. So the location where the window is installed will significantly shade the room.

- Finally, the handle of the window is usually located slightly above the eye level of a person of average height. Taking into account that in order to rotate it and properly press the sash to the frame, you need to apply force, I would call this solution not the most optimal. Well, making the sash lower means losing the advantages that it has.

A solution that I frankly don't understand. Well, it's probably convenient...

In general, you probably already understand: I think installing a window in a metal-plastic window is not the best choice. For ventilation, a flap, a transom or even a supply valve would be better suited, but if you want a classic design, then that can also be implemented.

By the way, you can use all of the above to choose a reliable contractor. Please note that the window manufacturing company will tell you when you ask to embed the window into the structure.

If they refuse right away - it’s bad, if they immediately agree - it’s also not very good, but if they present arguments that roughly coincide with those you read above, you can think about cooperation. If specialists know the strengths and weaknesses of the solutions offered to the client, then there is a high probability that they will do the job well and not just take money.

The suspended version of the transom is an excellent alternative

Making a window with a vent

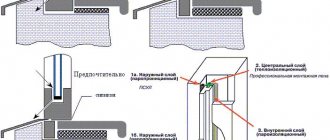

Scheme of half-preparing the sash for installing the window.

Before sawing the bars, it is necessary to make a drawing of the window. At the same time, it must contain the dimensions of the sashes and windows. This will make it possible to buy only the required amount of wood materials, and will also help in the future to make the correct marking and cutting of the bars.

The window frame consists of such structural elements as:

- box;

- vertical strapping bars (right and left);

- 2 doors: 1 with a window and 1 without it;

- slab for the window;

- transom;

- imposts (horizontal, vertical);

- fastening elements (hinges).

Next, you should prepare the parts of the wooden window. They begin to do this by sawing off parts from the prepared block, the length of which corresponds to the horizontal and vertical bars of the trim, slabs, and transom. Their number and dimensions must strictly correspond to the window drawing. According to these drawings, you can saw off the parts of the window. Next, folds are made on the strapping bars, slab, and transom. The presence of such a recess on parts of the window will allow the glass to be secured in the future.

It is necessary to ensure that the depth of all folds is the same for all elements of the window, otherwise the glass will not fit tightly and it will be impossible to insulate it. Moreover, on the transom, such folds are made on both sides of the bar. These indentations must be made with an electric plane. You can also cope with this task using a saw, having first clamped the block in a vice for rigidity.

Window position diagrams.

However, the saw for such work must have fine teeth, otherwise when cutting, the edges may turn out to be uneven and chipped. If, when making folds, minor defects (small depressions) are formed, then they can be leveled using a special putty for wood.

On the slab, in addition to the fold, it is necessary to cut a quarter into which the window will later lie. The size of the selected quarter for the slab depends on which way the window will open, outward or inward. If you plan to open the window inward, then on the rebate side an additional limiting strip is nailed or screwed onto self-tapping screws. When opening the window inward, there is no need for such a bar. Additional deepening can be made using a chisel, and this can be done neatly and evenly.

After this, they begin to make spikes and eyes. It is with the help of them that the frame will be fastened. The tenon is a protrusion specially cut to size, and the slot (groove) is called an eye. The execution of lugs and spikes must be done strictly according to size and very carefully, not allowing deviations of even a millimeter. The reliability of fastening and the durability of the frame depend on their correct execution. When creating a tenon, it is necessary to take into account that its front shoulder will be the size of the already sawn seam. After marking, the cuts are made using an electric jigsaw or a metal file. To make an eyelet, you need to make cuts according to the markings.

We offer wooden windows manufactured using European technology EURO IV-78!

Why? Such windows have excellent energy-saving characteristics, are simple and reliable to use and, most importantly, have become very affordable! Examples of prices can be viewed in a specially created section.

Related article: Is it possible to install a plastic window in a steam room?

Production technology

Our production was established in St. Petersburg in 2001 and over the years we have accumulated enormous experience. We must understand that the use of modern technologies is impossible without the use of modern equipment and high-quality European components.

- The production facility is equipped with German woodworking equipment from Weinig. Read our story with illustrations and videos.

- Wooden windows are made from three-layer laminated timber with a cross-section of 78*80mm - this is an ideal material for windows that is not subject to warping. A wooden beam will never lead. Why? You can read more about the construction of timber here!

- The windows have a “thick” 2-chamber double-glazed window (3 glasses). Read more.

- The lower part of the frame (as standard) must have a drainage tire to protect it from the effects of precipitation. Closer picture.

- For reliable operation of all window functions (turning, tilting, micro-ventilation), German fittings Siegenia Aubi are used. Read more about accessories.

- It is mandatory to comply with the necessary environmental and green standards: harmless German water-based Adler paints are used. You can find out more about painting here and here read about the processing of wood and joints.

- The most modern German Q-Lon Shlegel seal is used as the sealing contour. Read more here.

What types of wood do we offer?

We offer pine, larch and oak.

Pine

Thanks to the excellent ratio of cost, consumer properties and appearance of products, pine windows have recently become very popular! Increasingly, consumers are abandoning plastic in favor of inexpensive wood. Depending on the configuration, pine windows will be approximately twice as expensive as the simplest plastic windows (for example, Veka Euroline). And if you compare it with more expensive systems such as Veka 70 or Veka 82 mm, the difference will tend to zero.

Larch

Larch windows are only 20-30% more expensive than pine windows, but the hardness and strength of larch is comparable to the strength of oak windows

! According to research conducted by the Moscow State Forestry University, the fire resistance of larch wood is approximately twice as high as that of pine wood. It is believed that the strength of larch becomes higher over the years due to the polymerization of resins (larch is a rather resinous tree).

In addition, larch is an amazing material for its resistance to water and moisture! Larch windows do not swell or rot. As evidence, we can recall the thousand-year-old wooden piles of Venice, the walls of Siberian forts, the ships of the Pomors, the windows in the Hermitage, and finally! We can safely say that larch windows are recognized as the safest and most reliable wooden windows for St. Petersburg in the lower price range (among hardwood windows).

Oak windows are approximately twice as expensive as standard pine windows. However, oak has a remarkable property: after being in water for decades or in moist, airtight soil or climate, it becomes unusually strong, hard, and at the same time acquiring a dark brown color. Believe it or not, oak has its own special energy that brings peace and prosperity to the home! We can proudly say that oak windows are the strongest wooden windows, perfect not only for St. Petersburg but also for the entire North-Western region.

What might be required for the job?

Making a wooden window yourself begins with purchasing wood and preparing tools. You will need:

To work with wood you will need: a hammer, a saw, a level, a chisel, a tape measure, a pencil.

- frame bars with a cross section of 50x60 mm;

- bars for windows with a section of 50x50 mm;

- carpenter's chisel;

- hammer;

- caliper for precise marking;

- tape measure (ruler), square;

- pencil (marker);

- an electric jigsaw with a set of spare files or a hacksaw;

- medium and fine sandpaper;

- construction knife with spare blades;

- electric plane.

In order for the manufactured window to serve for a long time without replacement or major repairs, the bars for its manufacture must be of excellent quality and dry.

They should not have chips, cracks or other defects that could cause damage to the wood during processing or sawing. Knots should be in a minimum quantity and be small in size, or better yet absent. Such source material will not only last a long time, but will also be easy to process.

Wooden windows for an apartment

Wooden windows for apartments are back in fashion. For Russia, where a third of the country’s area is covered with forests, natural wood is an affordable material and a good alternative to plastic:

- environmentally friendly, non-toxic material;

- renewable resource;

- completely recyclable;

- is not a pollutant and does not harm the environment.

St. Petersburg Trade and Production offers a large selection of wooden double-glazed windows for an apartment, house, or cottage: folding, sliding, as well as classic ones with a window.